Key Components Overview for Stihl FS56C

Maintaining outdoor tools can often require a clear understanding of how various elements fit together. Proper knowledge of the internal setup and connections ensures that repairs or replacements can be done efficiently, without unnecessary trial and error. By gaining insight into the organization of different sections, users can keep their machines in top working condition for longer periods.

A detailed look at the mechanical structure helps in identifying key areas that may require attention. This approach simplifies the troubleshooting process, allowing users to locate the specific areas of concern. Whether dealing with routine maintenance or complex repairs, having a reliable reference on hand provides clarity and saves time.

Knowing the correct configuration is essential for anyone looking to handle repairs themselves. With a well-organized visual representation of the components, users are

Stihl FS56C Parts Overview

Understanding the essential components of this trimmer model is key to ensuring its optimal performance and longevity. Each element works together, contributing to smooth operation and effective results during use. By familiarizing yourself with these components, you can identify potential issues early and perform necessary maintenance or replacements.

The cutting system is a primary feature, designed to tackle various types of vegetation. This mechanism, combined with the drive shaft and engine, powers the tool to deliver efficient cutting power. Ensuring these areas are in good condition will help maintain peak performance.

The controls, including the throttle and stop switch, allow for easy operation and quick adjustments during use. Keeping these elements well-maintained ensures safe handling and responsive control. Periodic checks of the handle and supporting frame are also important for ergonomic use and comfort.

Lastly, the protective housing and guard shield are critical for safe operation, preventing debris from causing

Engine Components Breakdown

The internal structure of a power tool’s engine involves various interconnected elements that work in harmony to ensure efficient performance. Understanding how these components interact can help in maintaining and troubleshooting the device, ensuring longer service life and reliable operation.

- Cylinder: The core of the engine where combustion occurs, converting fuel into mechanical energy.

- Piston: A moving part within the cylinder that is propelled by expanding gases, driving the crankshaft.

- Crankshaft: Transforms the linear motion of the piston into rotational energy, powering the tool.

- Carburetor: Ensures the correct mixture of air and fuel, essential for the engine’s combustion process.

- Spark Plug: Ignites the air-fuel mixture in the cylinder to create combustion.

- Exhaust System: Channels the spent gases out of the engine, allowing fresh fuel to enter.

Each of

Fuel System and Related Parts

The fuel system is a crucial component that ensures the smooth operation of any engine. By efficiently delivering the necessary mixture of fuel and air, it helps maintain performance and reliability. This system is made up of several interconnected elements that work together to ensure the engine runs efficiently and consistently, avoiding issues such as stalling or poor combustion.

Key elements within this system include the tank, lines, and filters, all of which contribute to regulating fuel flow. These components require regular maintenance and inspection to prevent blockages or leaks, which could hinder the engine’s functionality. Ensuring the integrity of this system is essential for optimal performance and long-term durability.

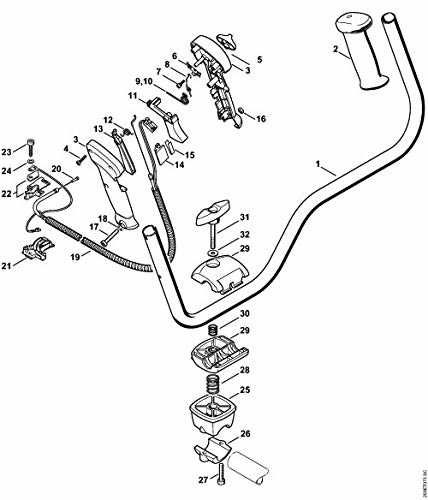

Handlebar and Control Setup

The proper configuration of the handlebar and controls is crucial for both comfort and safety during operation. Adjusting these components correctly ensures a better user experience and reduces strain during extended use. In this section, we’ll focus on how to achieve an optimal setup for better handling and control.

- Begin by positioning the handlebar to match your height and stance. It should be at a level where your arms remain relaxed but stable during use.

- Ensure that all controls are within easy reach. You should be able to access them without straining or shifting your grip.

- Lock the handlebar securely after adjustment to prevent any movement during operation.

Properly setting up the handlebar and controls can significantly improve maneuverability, offering precise co

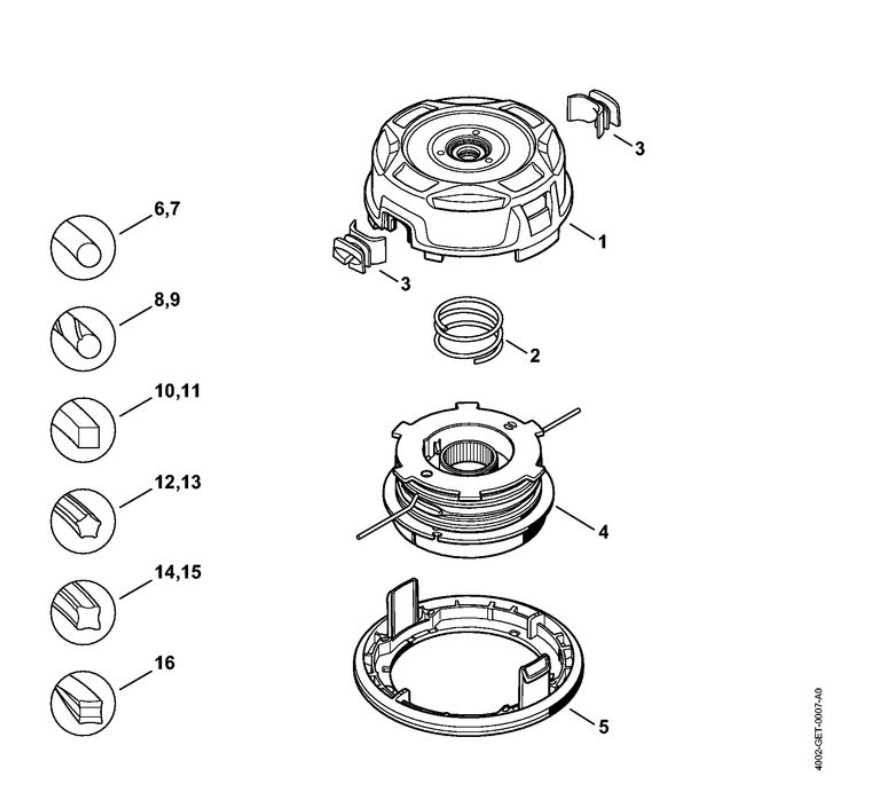

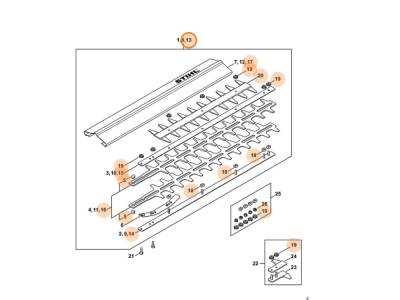

Cutting Blade Mechanism

The cutting blade mechanism is a crucial component for efficient trimming and cutting in various environments. It ensures precise and effective operation, enabling the tool to handle different types of vegetation. Understanding how the blade interacts with other elements of the system helps in maintaining optimal performance.

The design of the cutting mechanism focuses on durability and functionality, allowing for a range of applications. Below is an overview of the main aspects involved in the operation of this system:

- Blade Type: Various blades are available to suit different tasks, whether it’s trimming grass or cutting through thicker vegetation.

- Attachment Process: The blade connects securely to the tool, ensuring stability during operation while minimizing vibration.

- Safety Features: Protective elements are incorporated to safeguard the user and prevent damage to the blade during use.

- Air Filter and Maintenance Tips

Ensuring the longevity and efficiency of your equipment requires regular attention to its filtration system. The air filter plays a crucial role in maintaining optimal performance by preventing dust and debris from entering the engine. Proper care and maintenance of this component can significantly enhance the lifespan and functionality of your machine.

To keep your filtration system in top condition, follow these essential maintenance tips:

Tip Description Regular Inspection Check the air filter frequently for any signs of dirt or clogging. A clean filter allows for better airflow and engine performance. Cleaning If the filter is reusable, clean it with soap and water, then let it dry completely before reinstalling. Replacement For disposable filters, replace them according to the manufacturer’s recommendations or when you notice a decrease in performance. Proper Installation Ensure the air filter is correctly seated in its housing to prevent unfiltered air from entering the engine. Seasonal Maintenance Conduct a thorough check before the start of each season to ensure the air filter is in good condition, especially after prolonged use. By adhering to these maintenance practices, you can ensure that your equipment operates efficiently and remains reliable for years to come.

Ignition System Components

The ignition system is a critical element of small engine functionality, ensuring the proper initiation of combustion within the engine cylinder. It comprises various components that work in harmony to generate and deliver the spark needed for fuel ignition.

Ignition Coil: This device converts the low voltage from the battery into a high-voltage spark. It plays a vital role in producing the necessary electrical energy to ignite the fuel-air mixture.

Spark Plug: The spark plug is essential for transferring the electrical charge from the ignition coil to the combustion chamber. It creates a spark at precisely the right moment, igniting the compressed fuel mixture and allowing the engine to operate efficiently.

Flywheel: This component houses the magnet that generates a magnetic field, which is crucial for the ignition coil’s operation. The flywheel’s rotation is synchronized with the engine’s cycle, ensuring that the spark occurs at the optimal time.

Contact Breaker: Often found in older models, this device interrupts the current flow to the ignition coil, enabling the generation of a spark. Its proper functioning is essential for the overall performance of the ignition system.

Wiring Harness: This assembly connects all the components of the ignition system, allowing for the efficient transmission of electrical signals. A well-maintained wiring harness ensures reliable performance and minimizes the risk of electrical failures.

Throttle Assembly and Cable

The throttle assembly and its associated cable play a crucial role in the operation of outdoor power equipment. This component regulates the engine’s power output by controlling the air and fuel mixture that enters the combustion chamber. A well-functioning throttle mechanism ensures optimal performance and efficiency, making it essential for effective operation.

Functionality of the Throttle Assembly

The throttle assembly is designed to respond to the operator’s input, allowing for precise control of engine speed. When the throttle lever is engaged, it adjusts the position of the throttle plate, which directly influences the amount of air entering the engine. This adjustment is vital for achieving the desired power levels during various tasks.

Maintenance Tips for the Cable

Regular maintenance of the throttle cable is necessary to prevent wear and ensure smooth operation. Inspect the cable for fraying or damage, and lubricate it periodically to reduce friction. Keeping the cable properly adjusted is also essential; any slack can lead to delayed throttle response, affecting performance. Proper care will extend the lifespan of both the assembly and cable, contributing to the overall efficiency of the equipment.

Recoil Starter and Spring

The recoil mechanism is essential for initiating the operation of a handheld engine tool. This component enables the user to restart the engine effortlessly after it has been turned off. The recoil starter comprises a pull handle, a flexible cord, and a coiled spring, all of which work together to facilitate easy engine ignition.

Functionality of the Recoil System

The recoil starter operates through a simple yet effective mechanism. When the handle is pulled, the cord unwinds from the spool, engaging the engine’s flywheel and initiating combustion. Once the engine starts, the spring retracts the cord back into its original position, ready for the next pull.

Components Overview

Understanding the individual components of the recoil starter can help in maintenance and troubleshooting. Below is a summary of the main parts involved:

Component Description Pull Handle The grip used by the operator to pull the starting cord. Starting Cord A durable line that connects the pull handle to the spool, allowing for the engagement of the engine. Coiled Spring Stores energy when the cord is pulled and retracts the cord when released, ensuring a quick return to position. Spool Holds the starting cord and allows it to wind and unwind during operation. Drive Shaft and Transmission

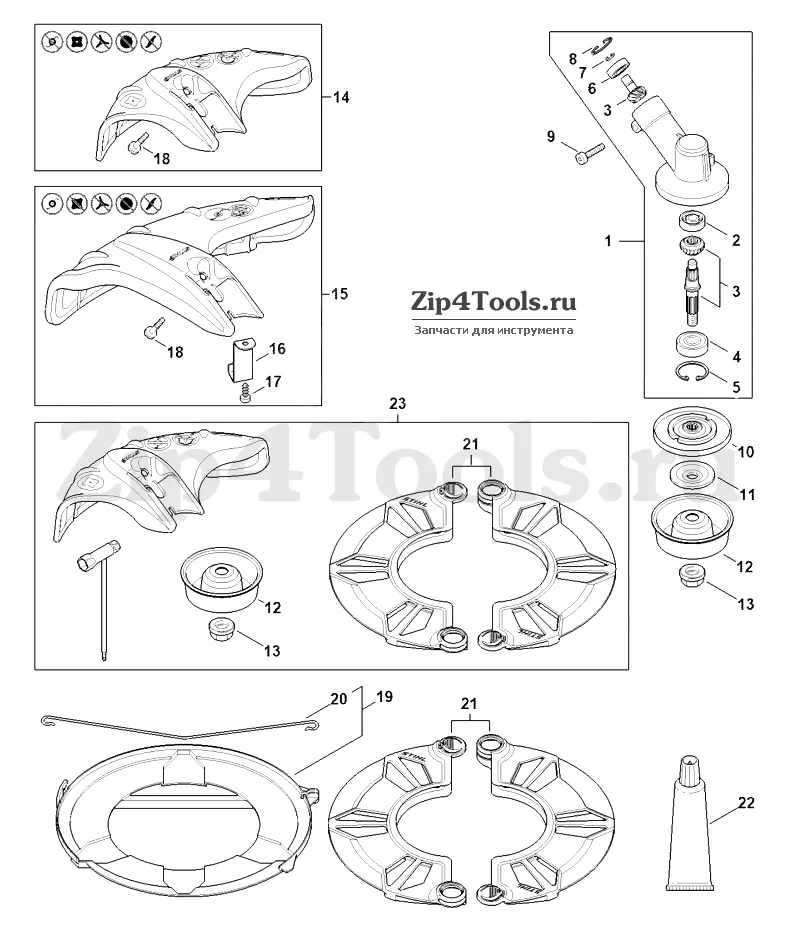

The drive shaft and transmission are integral components in the functionality of outdoor power equipment, playing a crucial role in transferring mechanical energy from the engine to the cutting tools. This system ensures efficient operation and optimal performance, allowing users to achieve their desired results in various tasks.

Functionality of the Drive Shaft

The drive shaft acts as a connector between the engine and the cutting mechanism, transmitting rotational force while maintaining stability. Its design enables it to withstand considerable torque and minimize vibrations, ensuring a smooth operation during use. Regular inspection and maintenance of this component are essential to avoid potential disruptions in performance.

Transmission Mechanics

The transmission is responsible for regulating the power output to the cutting attachments, allowing for adjustments in speed and torque as needed. This adaptability is vital for tackling different terrains and vegetation types. Proper care of the transmission system, including lubrication and checking for wear, will enhance the longevity and reliability of the equipment.

Muffler and Exhaust System

The exhaust system plays a crucial role in the efficient operation of small engines, ensuring that gases produced during combustion are effectively routed away from the engine. A well-designed muffler minimizes noise while maintaining optimal engine performance, contributing to both functionality and user comfort.

Components of the Exhaust Assembly

The exhaust assembly typically consists of several key components. The muffler, which is responsible for reducing engine noise, works in conjunction with exhaust pipes and gaskets to form a sealed system that directs exhaust gases safely away. Proper maintenance of these components is essential for preventing blockages that could hinder engine performance.

Importance of Regular Inspection

Regular inspection of the exhaust system is vital for identifying any signs of wear or damage. Over time, components may corrode or become clogged, leading to decreased efficiency and increased emissions. By ensuring that the exhaust system is in good condition, users can enhance engine longevity and maintain compliance with environmental regulations.

Protective Guard and Safety Features

Effective safety measures are essential for ensuring the user’s well-being during operation. Implementing protective barriers and features greatly reduces the risk of accidents and injuries. These components are designed to provide a shield between the user and potential hazards, promoting a secure working environment.

The following key safety features enhance protection during use:

- Blade Guard: A sturdy cover that protects the user from debris and sharp edges while the tool is in operation.

- Safety Switch: A mechanism that prevents accidental activation, ensuring the device only operates when intended.

- Handle Grip: Ergonomically designed to provide a firm hold, reducing the chance of slips during use.

- Vibration Dampening: Features that minimize the impact of vibrations on the user’s hands, improving comfort and control.

- Emergency Stop: A quick-release system that allows the user to halt operation immediately if needed.

By incorporating these safety elements, users can work with confidence, knowing that their equipment is designed to prioritize their protection and efficiency.

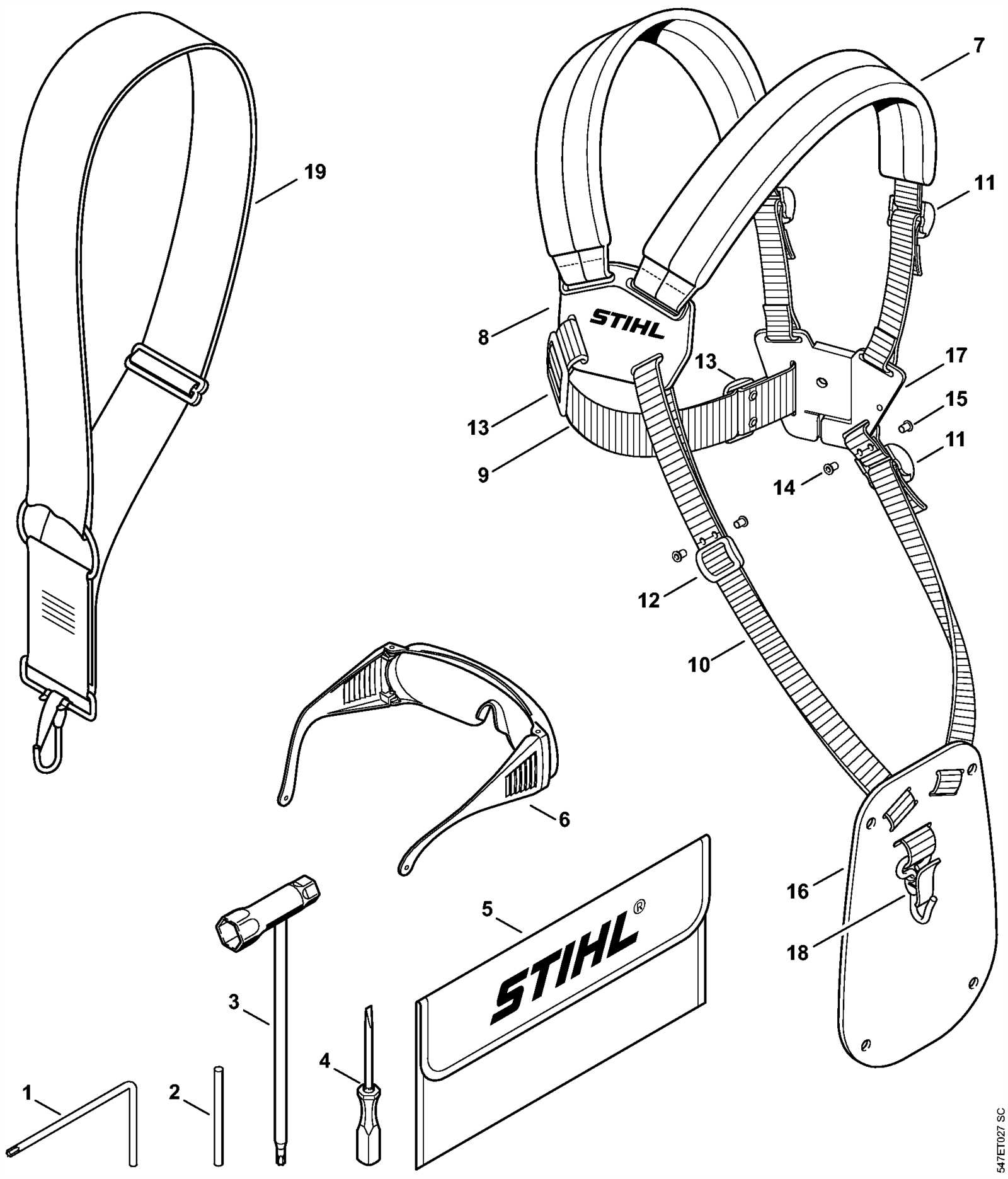

Replacement Parts for Common Repairs

When maintaining outdoor power equipment, understanding the essential components that may require replacement is crucial for efficient operation. Regular use can lead to wear and tear on various elements, making it necessary to identify which parts are most commonly needed for repairs. This knowledge can help ensure optimal performance and prolong the lifespan of the equipment.

Here are some key components to consider for frequent repairs:

- Trimmer Line: Essential for cutting grass and weeds, this line may need regular replacement due to wear from use.

- Air Filters: These components keep the engine clean and functioning smoothly. Clogged filters should be replaced to maintain efficiency.

- Spark Plugs: Vital for ignition, worn or fouled spark plugs can lead to starting issues and should be checked periodically.

- Fuel Filters: Keeping fuel systems clean is important. Replace these filters to prevent clogs and ensure proper fuel flow.

- Cables and Wires: Over time, cables can fray or break. Inspecting and replacing them can prevent operational failures.

By being proactive and replacing these common components as needed, users can avoid more significant issues and keep their equipment running smoothly.