Comprehensive Guide to Stihl FS91R Parts Diagram PDF

When it comes to maintaining outdoor machinery, having a clear understanding of its individual elements is crucial for optimal performance and longevity. Whether you are a professional landscaper or a weekend warrior, knowing the specific components that make up your device can save time and prevent potential issues.

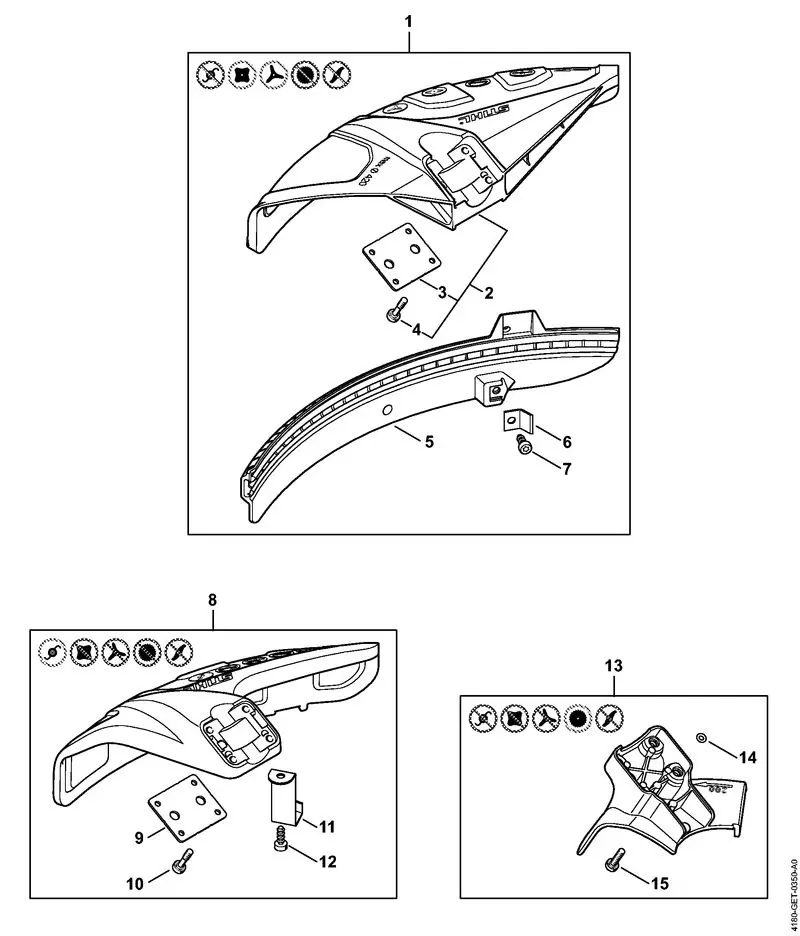

The intricate assembly of tools requires detailed information to assist users in identifying parts and ensuring proper functionality. A visual representation of these elements can significantly enhance one’s ability to troubleshoot problems and carry out effective repairs.

Accessing a comprehensive resource that outlines the various components and their interconnections empowers users to take control of their maintenance routines. By familiarizing oneself with the structure and organization of these elements, one can ensure that every task is performed with precision and care.

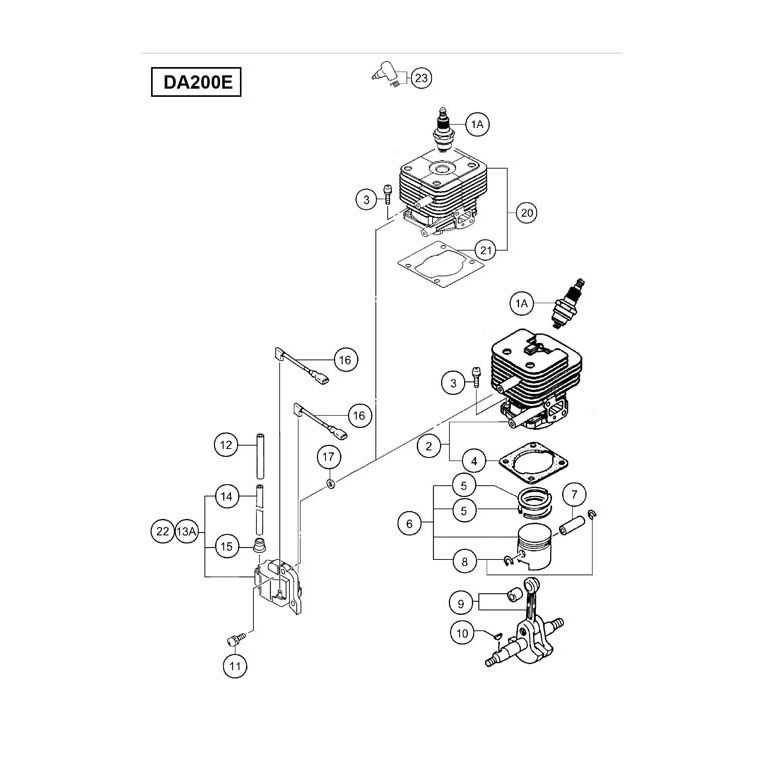

Understanding the Stihl FS91R Components

Gaining insight into the various elements of a brush cutter is essential for both maintenance and effective usage. Each component plays a crucial role in ensuring optimal performance, and understanding these parts can help users troubleshoot issues, perform repairs, and enhance overall efficiency.

Main Elements

The key components of a brush cutter include:

- Engine

- Drive Shaft

- Cutting Head

- Handlebar

- Fuel Tank

Importance of Each Part

Each part serves a specific function:

- Engine: Powers the tool and determines its cutting capabilities.

- Drive Shaft: Transmits power from the engine to the cutting head.

- Cutting Head: The main working area that houses blades or line for cutting.

- Handlebar: Provides control and stability during operation.

- Fuel Tank: Holds the fuel necessary for the engine’s operation.

Understanding these components will not only aid in the effective operation of the equipment but also extend its lifespan through proper care and maintenance.

Importance of Parts Diagrams

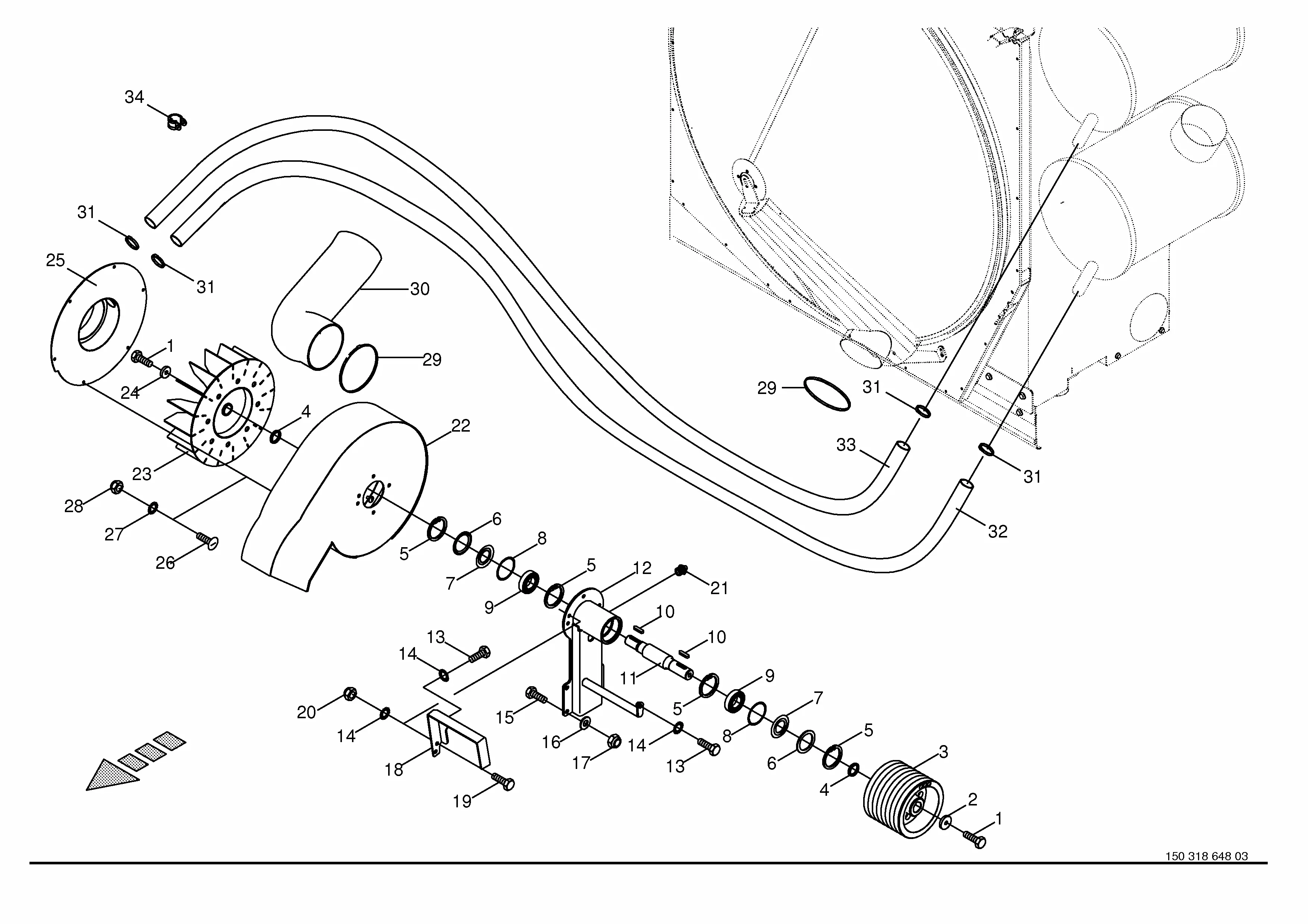

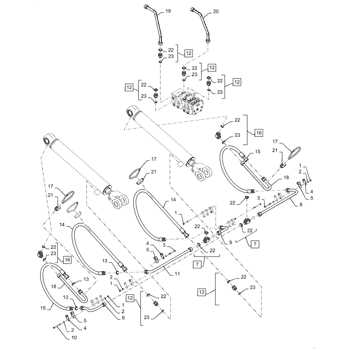

Visual representations of components play a crucial role in the maintenance and repair of equipment. These illustrations provide clarity, ensuring that users can easily identify individual elements and understand their relationships within the whole system. By having a clear overview, technicians can perform repairs more efficiently, reducing the risk of errors and enhancing overall functionality.

Benefits of Visual Guides

- Enhanced Understanding: Users can grasp complex assemblies quickly, leading to better troubleshooting and repair processes.

- Time Efficiency: Clear visuals minimize the time spent searching for specific parts or understanding their placement.

- Accurate Reassembly: With detailed illustrations, reassembly becomes more straightforward, reducing the likelihood of mistakes.

Applications in Maintenance

- Routine Maintenance: Regular checks become easier, as users can reference visuals to ensure all components are in good condition.

- Emergency Repairs: In critical situations, having a visual guide allows for quick identification of damaged or missing elements.

- Training Tools: New users can learn the layout and function of equipment more effectively, speeding up their learning curve.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of machinery. These visual representations offer a clear view of components and their relationships, enabling users to identify and source specific items efficiently. Mastering the art of interpreting these visuals can save time and enhance your repair experience.

Key Elements of Visual Representations

When examining a technical illustration, it’s important to familiarize yourself with its main components. Here are the typical elements you will encounter:

| Element | Description |

|---|---|

| Symbols | Each component is represented by a unique symbol, often accompanied by a reference number. |

| Legends | A guide explaining what each symbol and number represents, usually found on the side of the illustration. |

| Groupings | Components may be clustered together to show how they interact or assemble within the larger structure. |

Steps for Effective Interpretation

To make the most of these illustrations, follow these steps:

- Start by reviewing the legend to understand the symbols.

- Identify the components you need based on their reference numbers.

- Cross-reference with your equipment manual for additional context.

By honing your ability to read and analyze these technical visuals, you can streamline your repair process and ensure a more efficient maintenance routine.

Common Issues with FS91R Parts

When dealing with outdoor power equipment, understanding potential problems is crucial for maintaining optimal performance. Various components can exhibit wear and tear over time, leading to inefficiencies and operational challenges. Here are some common issues users may encounter with these essential tools.

- Fuel System Problems:

- Clogged filters can restrict fuel flow.

- Incorrect fuel mixture may cause starting issues.

- Starting Difficulties:

- Worn spark plugs can lead to misfiring.

- Issues with the ignition system can prevent starting altogether.

- Wear on Cutting Attachments:

- Blades may become dull, affecting cutting efficiency.

- Housing damage can lead to operational instability.

- Vibration and Noise:

- Loose components can increase vibrations during use.

- Worn bearings may contribute to excessive noise levels.

Regular maintenance and timely replacements are key to preventing these common issues. By staying proactive, users can ensure longevity and reliability from their equipment.

Where to Find Replacement Parts

Locating components for outdoor equipment can be a straightforward task if you know where to look. Understanding your options will help you source the right pieces quickly and efficiently. Below are some reliable avenues for acquiring the necessary items.

Online Retailers

The internet offers a vast selection of suppliers, making it easy to find the exact components you need. Here are some popular options:

- Manufacturer’s Website: The official site often has an extensive catalog of available items.

- Third-Party Vendors: Websites like Amazon and eBay may provide competitive pricing and a wide range of choices.

- Specialized Stores: Many online shops focus specifically on outdoor equipment, offering both genuine and aftermarket options.

Local Dealers and Shops

In addition to online sources, checking local establishments can be beneficial. Consider these venues:

- Authorized Dealers: These retailers typically carry original components and can offer expert advice.

- Repair Shops: Local service centers may stock common items and can assist with finding less common ones.

- Hardware Stores: Some larger hardware outlets may have a selection of parts suitable for various models.

Maintenance Tips for FS91R

Proper upkeep of your equipment is essential for optimal performance and longevity. Regular attention to maintenance tasks can prevent issues and ensure that your machine operates smoothly, providing reliable service for years to come.

Routine Checks

- Inspect the air filter regularly to ensure it is clean and free from debris.

- Check the spark plug for wear and replace it as needed to maintain efficient ignition.

- Examine fuel lines for any signs of damage or leaks.

- Keep the exterior clean to prevent dirt accumulation, which can affect performance.

Lubrication and Storage

- Apply appropriate lubricant to moving parts to minimize friction and wear.

- Store the equipment in a dry, sheltered location to protect it from the elements.

- Ensure fuel is fresh and store it in a sealed container to avoid contamination.

Upgrading FS91R Components

Enhancing the performance and efficiency of your outdoor power equipment can significantly improve its capabilities and longevity. By focusing on key elements, users can tailor their machines to meet specific needs, ensuring they operate at optimal levels. Upgrades can range from enhancing power delivery to improving user comfort and ease of operation.

One of the most impactful modifications involves the cutting mechanism. Upgrading to a higher quality or more specialized blade can lead to improved cutting efficiency and precision. Additionally, considering options that reduce vibration can enhance overall handling, making prolonged use more comfortable.

Another crucial area for enhancement is the power system. Investing in a more robust engine component can lead to increased reliability and performance. This change not only boosts power output but also ensures that the equipment can handle tougher tasks without compromising functionality.

Furthermore, upgrading the fuel system can optimize fuel efficiency and minimize emissions, contributing to a more eco-friendly operation. Components designed for better fuel delivery and combustion can lead to noticeable performance improvements.

Finally, don’t overlook the importance of ergonomic features. Replacing grips or handles with more comfortable options can make a significant difference in user experience, particularly during extended use. Enhancements in this area can lead to reduced fatigue and improved control.

Comparing FS91R with Other Models

When evaluating various models of outdoor power equipment, it’s essential to understand how different options stack up against each other. This comparison focuses on features, performance, and user experience, providing insights to help potential buyers make informed decisions.

Key Features to Consider

- Engine Power: Assess the engine specifications for efficiency and reliability.

- Weight: Lighter models may offer better maneuverability, while heavier ones might provide more stability.

- Fuel Efficiency: Consider how much fuel each model consumes during operation.

- Attachment Compatibility: Some units allow for various attachments, enhancing versatility.

Performance Insights

- Cutting Speed: Evaluate the cutting capabilities and speed of operation for different models.

- Durability: Look at user reviews to determine how well each option holds up under regular use.

- Noise Levels: Quieter models can be beneficial for residential areas.

- Maintenance Requirements: Some units may demand more frequent upkeep than others.

By examining these aspects, users can better understand how various machines perform and which might be the best fit for their specific needs.

Tools Needed for Repairs

When undertaking maintenance or repair tasks on outdoor equipment, having the right tools is essential for efficiency and safety. Proper preparation can make the difference between a straightforward job and a frustrating experience. Below is a list of tools that are commonly required for these types of repairs.

Essential Hand Tools

- Wrenches: Adjustable and socket wrenches for loosening and tightening bolts.

- Screwdrivers: A set of both flat-head and Phillips-head screwdrivers for various screws.

- Pliers: Needle-nose and standard pliers for gripping and twisting.

- Utility Knife: For cutting tasks and removing old components.

Specialized Equipment

- Torque Wrench: To ensure that fasteners are tightened to the correct specifications.

- Fuel Mixing Bottle: For accurately measuring and mixing fuel and oil.

- Cleaning Brushes: For removing dirt and debris from parts.

- Safety Gear: Gloves and goggles to protect against debris and chemicals.

Having these tools at hand will streamline your repair process and help maintain the longevity of your equipment.

Customer Reviews of FS91R Parts

This section delves into the experiences and feedback from users regarding components related to a specific outdoor power equipment model. Insights from various customers can help potential buyers make informed decisions and understand the reliability and effectiveness of these items.

Positive Experiences

- Many users have praised the durability of the components, noting they withstand regular use in demanding conditions.

- Customers often highlight the ease of installation, making repairs and upgrades accessible even for those with minimal mechanical experience.

- Several reviews commend the performance improvements observed after replacing worn-out items, leading to better efficiency and productivity.

Areas for Improvement

- Some customers have reported issues with specific components not fitting as expected, suggesting a need for better compatibility information.

- A few users noted that certain parts wear out quicker than anticipated, prompting suggestions for enhanced material quality.

- Concerns have been raised regarding customer service response times, with users desiring quicker support for inquiries and issues.

Overall, feedback indicates a mix of satisfaction and areas for enhancement, guiding future customers in their purchasing journey.

Resources for Stihl Enthusiasts

For those who are passionate about outdoor power tools, a wealth of information and support is available. These resources help enthusiasts enhance their knowledge, improve maintenance skills, and connect with like-minded individuals. Whether you’re a novice or a seasoned user, having access to reliable materials is essential for optimal performance and longevity of your equipment.

Online Forums and Communities

Engaging with online platforms allows users to share experiences, ask questions, and receive valuable advice. Participating in discussions can uncover tips on troubleshooting, upgrades, and best practices. These communities often have members who are knowledgeable about specific models and can provide insights that are not readily available in manuals.

Educational Videos and Tutorials

Visual learning can be incredibly effective when it comes to understanding tool operation and maintenance. Numerous video tutorials showcase step-by-step procedures for repairs and enhancements. These resources can simplify complex tasks and help users feel more confident in their abilities.

Utilizing these resources can significantly enrich your experience and expertise, making every project more enjoyable and efficient.