Comprehensive Guide to Stihl HL 135 Parts Diagram

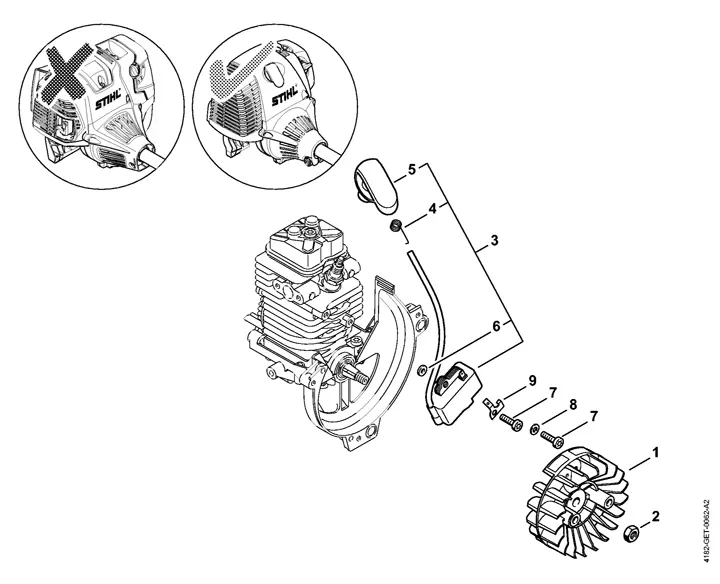

In the realm of outdoor equipment maintenance, having a clear visual reference can significantly enhance the efficiency of repairs and replacements. A comprehensive illustration that outlines the components of a specific model allows users to navigate the intricacies of their machinery with ease. This resource serves as an essential tool for both seasoned technicians and novice users, facilitating a deeper understanding of how each piece functions within the whole.

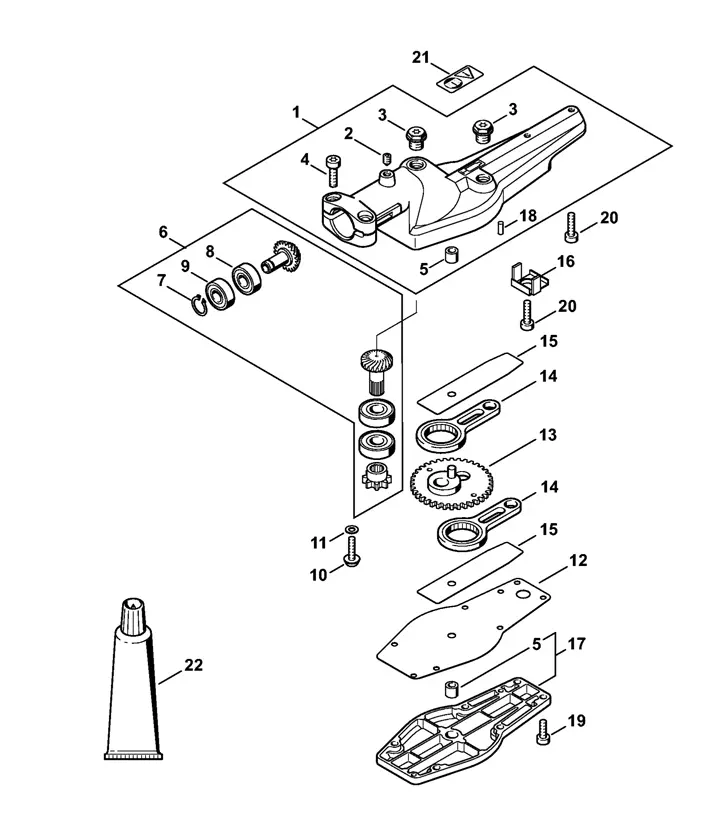

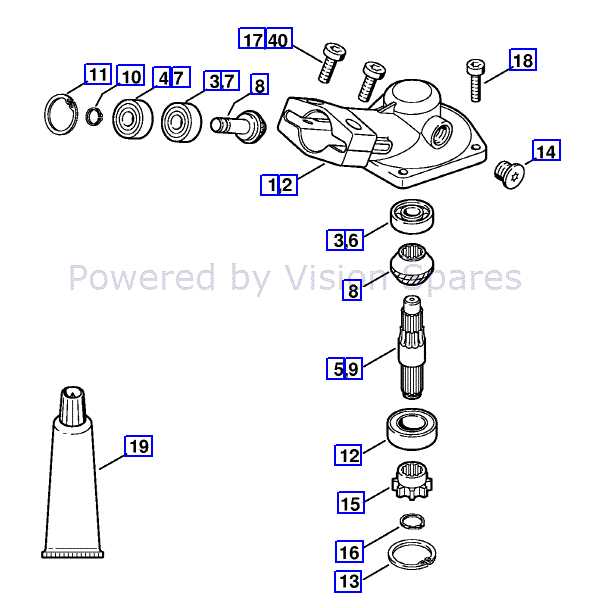

Identifying individual elements within a complex system is crucial for effective troubleshooting. With a detailed breakdown, users can pinpoint potential issues and determine the necessary replacements. Such resources empower individuals to take control of their equipment’s upkeep, promoting longevity and optimal performance.

Furthermore, having access to an accurate visual guide fosters confidence in tackling maintenance tasks. Whether it’s assembling, disassembling, or simply understanding the arrangement of parts, this knowledge equips users to approach their equipment with assurance. Ultimately, a well-organized reference can lead to more informed decisions and better care for valuable outdoor machinery.

Understanding Stihl HL 135 Components

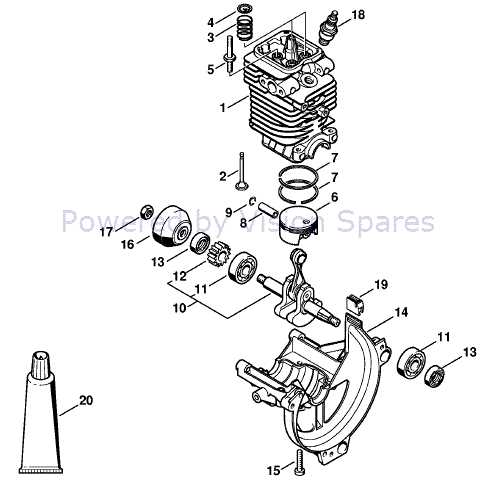

Exploring the various elements of a gardening tool reveals the intricate design and engineering that contribute to its overall functionality. Each segment plays a pivotal role in ensuring efficient operation, making it essential for users to familiarize themselves with these components. This knowledge not only aids in maintenance but also enhances performance during use.

Key Elements and Their Functions

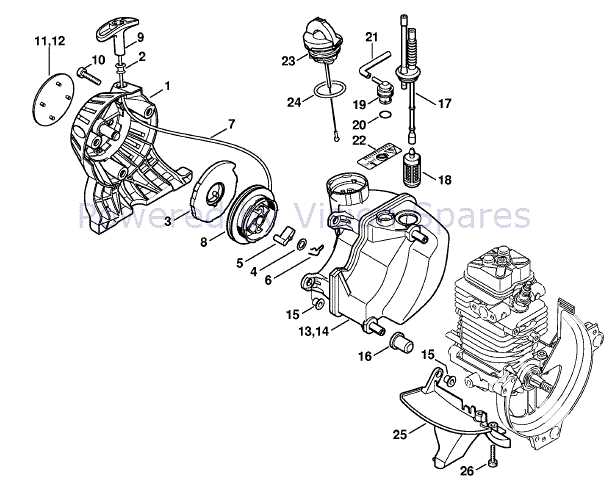

- Engine: The powerhouse of the tool, responsible for generating the necessary energy to operate effectively.

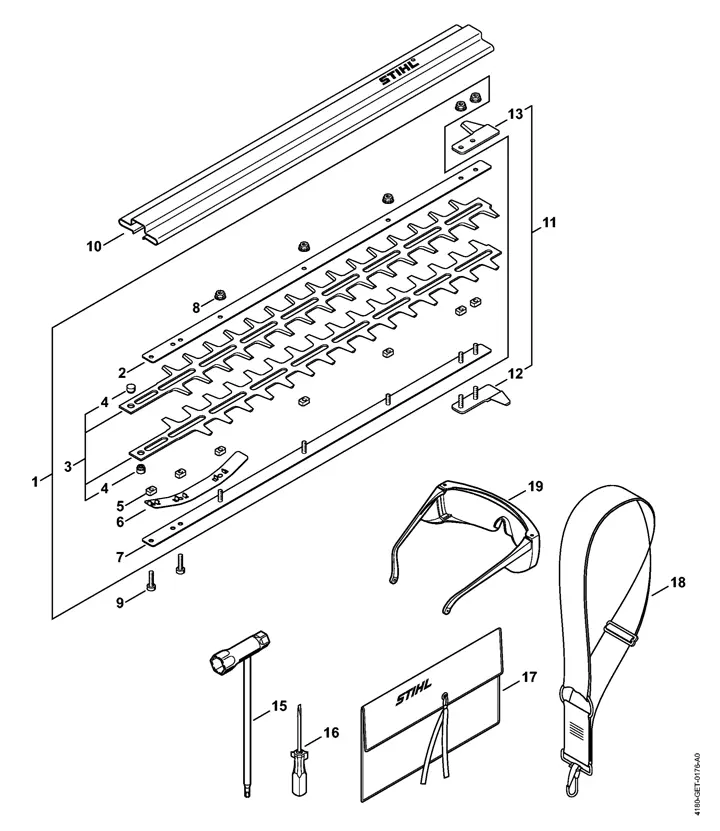

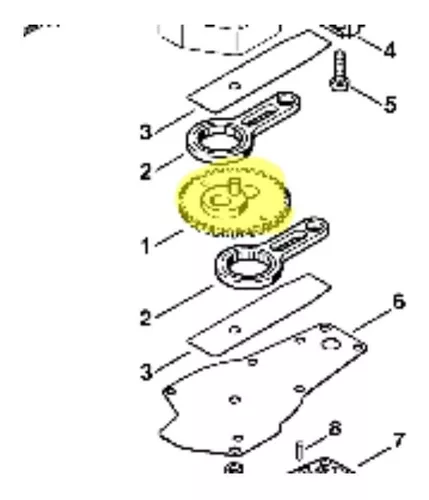

- Blade: Designed for cutting and trimming, its sharpness and shape determine the efficiency of the task.

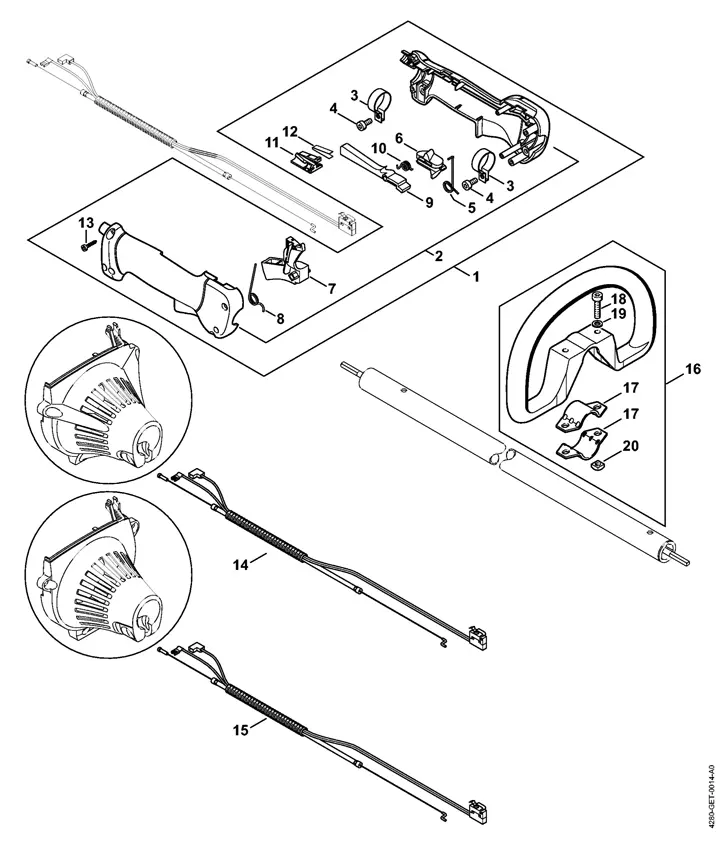

- Shaft: Connects the engine to the cutting head, transmitting power and providing stability during operation.

- Handle: Offers grip and control, allowing users to maneuver the equipment with ease.

- Fuel System: Ensures the engine receives the right mixture for optimal performance.

Maintenance and Care

- Regularly inspect the cutting tool for any signs of wear or damage.

- Keep the engine clean and ensure proper fuel levels to maintain efficiency.

- Sharpen the blade as needed to achieve clean cuts.

- Check the shaft for any looseness or misalignment to prevent operational issues.

Understanding these components and their functions helps users maximize the effectiveness and longevity of their gardening tool, ensuring a rewarding experience with every use.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations of each element not only simplify the identification process but also enhance the overall comprehension of how different parts interact. By using these illustrations, users can ensure that they are making informed decisions regarding repairs, replacements, and upgrades.

Enhanced Maintenance and Repair

Utilizing visual guides allows users to pinpoint specific areas of concern quickly. This leads to more efficient troubleshooting and reduces the risk of overlooking essential components during service. Moreover, having a clear visual reference fosters confidence in undertaking repairs, as individuals can systematically address issues with a better understanding of the assembly.

Improved Communication

Diagrams serve as a universal language among technicians and users alike. When discussing repairs or modifications, these visuals facilitate clearer communication, ensuring that all parties are on the same page. This clarity is particularly beneficial in collaborative settings, where multiple individuals may be involved in the maintenance process.

Key Features of Stihl HL 135

This versatile tool is designed for efficiency and comfort, making it an essential addition to any gardening arsenal. Its thoughtful engineering enhances user experience while ensuring optimal performance for various tasks.

- Powerful Engine: Equipped with a robust engine that delivers reliable performance, enabling the user to tackle even the most challenging jobs with ease.

- Adjustable Length: Features an extendable shaft that allows for customization, providing access to hard-to-reach areas without straining.

- Lightweight Design: The construction is designed for minimal weight, ensuring ease of use over extended periods without fatigue.

- Ergonomic Handle: The tool boasts a comfortable grip that reduces vibrations, enhancing control and overall comfort during operation.

- Multi-Functional Attachments: Compatible with various attachments, making it suitable for trimming, pruning, and other landscaping tasks.

These features combine to create a powerful and user-friendly tool that meets the demands of both professionals and home users alike.

Common Issues and Solutions

When using outdoor power equipment, users may encounter various challenges that can hinder performance. Understanding these common problems and their potential solutions can significantly enhance the overall experience and prolong the lifespan of the equipment.

Engine Performance Issues

One prevalent concern is engine performance. Symptoms such as rough idling, stalling, or difficulty starting may arise. Often, these issues are linked to fuel quality or the air filter’s condition. Solution: Ensure you are using fresh, high-quality fuel and replace the air filter regularly to maintain optimal airflow.

Blade and Cutting Performance

Another frequent issue is inadequate cutting efficiency, which can result from dull blades or improper tension. This can lead to unsatisfactory results and increased wear on the equipment. Solution: Regularly sharpen the blades and check the tension to ensure they operate effectively.

Identifying Replacement Parts

Understanding how to locate suitable components for maintenance and repair is crucial for ensuring optimal performance of your equipment. Knowing the essential features and specifications will help you select the right items for replacement, prolonging the lifespan and functionality of your machine.

Here are some steps to effectively identify the components you need:

- Consult the Manual: Always start by referring to the user manual. It provides detailed information about the components, including their specifications and compatibility.

- Model and Serial Numbers: Check the model and serial numbers on your equipment. These numbers are vital for finding exact replacements.

- Visual Inspection: Perform a thorough examination of the equipment. Identify any worn or damaged items that require attention.

When searching for replacements, consider the following options:

- Authorized Dealers: Purchase from certified retailers to ensure you receive genuine components.

- Online Resources: Utilize reputable websites that specialize in equipment parts. They often provide detailed listings and diagrams.

- Forums and Communities: Engage with online communities where users share experiences and advice on sourcing specific components.

By following these guidelines, you can efficiently identify and procure the necessary items to maintain your equipment in peak condition.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your equipment. Regular maintenance not only enhances functionality but also minimizes the likelihood of costly repairs. By following a structured routine, you can keep your tools in optimal condition and extend their lifespan significantly.

Routine Inspections

Conduct regular checks on your machinery to identify any signs of wear or damage. Look for loose bolts, frayed cables, or any unusual sounds during operation. Addressing minor issues promptly can prevent them from escalating into major problems.

Cleaning and Storage

After each use, ensure that your device is cleaned thoroughly to remove debris and residue. Store it in a dry, protected environment to prevent rust and deterioration. Using a protective cover can also shield it from dust and moisture, further enhancing its durability.

Where to Find Diagrams Online

Locating visual schematics and illustrations for various equipment can greatly enhance understanding and maintenance. Numerous online resources provide detailed drawings and breakdowns, facilitating easier repairs and part identification. These resources can save time and ensure accurate assembly, making them invaluable for both enthusiasts and professionals.

One of the most reliable sources is the official website of the manufacturer, where you can often find technical resources, including comprehensive visuals. Additionally, various online forums and communities dedicated to gardening and outdoor tools frequently share useful links and user-generated content, making them a great place to seek assistance and tips.

Another option is specialized retail websites that offer parts and accessories for outdoor equipment. Many of these sites include breakdowns alongside their product listings, providing a straightforward way to view components and understand their arrangements. Finally, consider online marketplaces that may feature user manuals and service guides, often uploaded by previous owners or repair enthusiasts.

Ordering Genuine Stihl Parts

When it comes to maintaining outdoor equipment, ensuring you have authentic components is essential for optimal performance and longevity. Using original elements not only enhances the functionality of your machine but also preserves its warranty and resale value. This section will guide you through the process of acquiring these vital items efficiently and reliably.

Why Choose Authentic Components?

Opting for genuine items guarantees compatibility and reliability, reducing the risk of malfunctions that can arise from using substandard alternatives. These elements are specifically designed to meet the exact specifications of your equipment, ensuring smooth operation and enhanced safety. Furthermore, purchasing original components supports the manufacturer, allowing them to continue producing high-quality tools.

Where to Purchase

Acquiring authentic items can be done through various channels. Authorized dealers provide a trustworthy option, ensuring that you receive legitimate products with appropriate warranties. Additionally, official online platforms often have a comprehensive selection, making it easy to find what you need. Always verify the source to avoid counterfeit items that may compromise your equipment’s performance.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor power equipment, having the right tools is essential. Proper tools not only make the job easier but also ensure that repairs are performed safely and effectively. Below is a list of necessary items that will help you tackle any maintenance task with confidence.

Essential Hand Tools

- Wrenches: A set of adjustable and fixed wrenches will help you tackle various nuts and bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers in different sizes are crucial for loosening and tightening screws.

- Pliers: Needle-nose and slip-joint pliers will assist in gripping and manipulating components.

- Socket Set: A socket set allows for easy access to hard-to-reach fasteners.

- Cutting Tools: A utility knife or wire cutters are useful for cutting through cables or ties.

Power Tools and Safety Gear

- Drill: A power drill can expedite tasks such as removing screws and bolts.

- Impact Wrench: This tool is helpful for loosening stubborn fasteners.

- Safety Glasses: Protect your eyes from debris and other hazards while working.

- Gloves: Durable gloves will safeguard your hands from sharp edges and rough materials.

- First Aid Kit: Always have a basic first aid kit on hand for any minor injuries that may occur.

Equipping yourself with these tools will not only streamline your repair tasks but also enhance your overall experience in maintaining your equipment. Proper preparation is key to successful repairs.

Step-by-Step Repair Guide

Repairing your outdoor equipment can seem daunting, but with the right approach, it becomes manageable. This guide provides a structured process to help you efficiently address common issues, ensuring your machine operates smoothly once more.

-

Gather Necessary Tools and Materials

- Screwdrivers (flathead and Phillips)

- Wrenches

- Replacement components

- Lubricants and cleaning agents

-

Consult the User Manual

Refer to the manufacturer’s guide to familiarize yourself with specific instructions and safety precautions relevant to your model.

-

Prepare Your Workspace

Ensure your work area is clean, well-lit, and organized. Lay out all tools and parts to avoid confusion during the repair process.

-

Identify the Issue

Carefully assess the equipment to determine the problem. Listen for unusual sounds and look for visible damage or wear.

-

Disassemble the Equipment

Use the appropriate tools to carefully remove components, noting their arrangement for easier reassembly.

-

Replace Damaged Parts

Install new components as needed, ensuring they match the specifications outlined in the manual.

-

Reassemble the Equipment

Follow your notes to put everything back together, ensuring all screws and fasteners are securely tightened.

-

Test the Equipment

After reassembly, conduct a thorough test to confirm the repair was successful and the unit operates correctly.

By following these steps, you can effectively troubleshoot and fix common problems, extending the life of your outdoor tools and maintaining their performance.

Upgrading Your Equipment

Enhancing your tools is essential for improving performance and efficiency in any outdoor task. Upgrading not only extends the lifespan of your equipment but also provides access to the latest technology, making your work easier and more effective. Whether you are a professional or a hobbyist, investing in quality components can lead to significant improvements in productivity.

Benefits of Modern Components

Utilizing advanced parts can drastically enhance functionality. Newer models often feature improved power, reduced emissions, and better fuel efficiency. Additionally, many upgraded elements are designed for easier maintenance, which can save you time and effort in the long run. With the right enhancements, you can achieve more with less strain on your tools.

Choosing the Right Upgrades

When considering upgrades, it is crucial to select components that are compatible with your existing tools. Researching specific options and reading reviews can help you make informed decisions. Focus on reputable brands known for durability and performance. Remember, the right upgrades not only improve functionality but also ensure safety during operation.

Customer Reviews and Experiences

Feedback from users provides valuable insights into the performance and reliability of equipment. Many individuals share their journeys, highlighting both positive aspects and challenges encountered during usage. These personal accounts often serve as a guiding light for potential buyers, offering real-world perspectives that go beyond technical specifications.

Customers frequently praise the efficiency and durability of their machines, noting how well they handle various tasks. One user mentioned that their model significantly reduced the time required for maintenance work, while another emphasized its lightweight design, making it easy to maneuver in tight spaces. Such testimonials underscore the practical benefits of choosing quality tools that enhance productivity.

However, some users also report challenges, particularly concerning maintenance and replacement components. Several reviews highlighted the need for occasional servicing to keep the equipment in top condition. These experiences remind potential buyers to consider not only the initial investment but also the long-term upkeep of their tools.

Overall, the shared experiences of customers reveal a balanced view, combining both the strengths and weaknesses of the equipment. This wealth of information can help prospective owners make informed decisions, ensuring they choose a model that aligns with their specific needs.