Understanding the Stihl HL 91 K Parts Diagram for Efficient Maintenance

Maintaining the efficiency of your gardening equipment is essential for optimal performance. A comprehensive understanding of its individual elements can significantly enhance your ability to troubleshoot issues and carry out necessary repairs. This knowledge empowers users to extend the lifespan of their machines while ensuring they operate smoothly.

Each piece of machinery comprises a variety of essential elements that work together seamlessly. Recognizing how these components interact allows for better maintenance practices and informed decision-making when it comes to repairs. By exploring the intricate relationships between these parts, you can achieve a deeper appreciation for the functionality of your device.

Whether you are a seasoned professional or a casual gardener, familiarizing yourself with the layout and roles of these various elements can be incredibly beneficial. This exploration not only aids in effective upkeep but also enriches your overall experience with your gardening equipment.

Overview of Stihl HL 91 K

The HL 91 K is a versatile tool designed for various gardening and landscaping tasks, combining efficiency with user-friendly features. It excels in trimming and maintaining hard-to-reach areas, ensuring a clean and polished look for any outdoor space.

Key Features

This equipment boasts a lightweight design, making it easy to handle for extended periods. Additionally, its adjustable head allows for precise angles, enhancing versatility in different applications. Engine performance is optimized for power and fuel efficiency, catering to both professional landscapers and home gardening enthusiasts.

Applications

Ideal for trimming hedges, bushes, and other foliage, the HL 91 K is a reliable choice for maintaining the aesthetics of gardens and public spaces. With its durable construction, it can withstand rigorous use, making it an ultimate companion for any gardening project.

Key Features of the Model

This model stands out for its innovative design and robust functionality, catering to the diverse needs of users. Its construction reflects a blend of durability and efficiency, making it a reliable choice for various outdoor tasks.

Ergonomic Design: The user-centric design ensures comfort during extended use. The lightweight frame minimizes fatigue, allowing for more extended periods of operation without compromising performance.

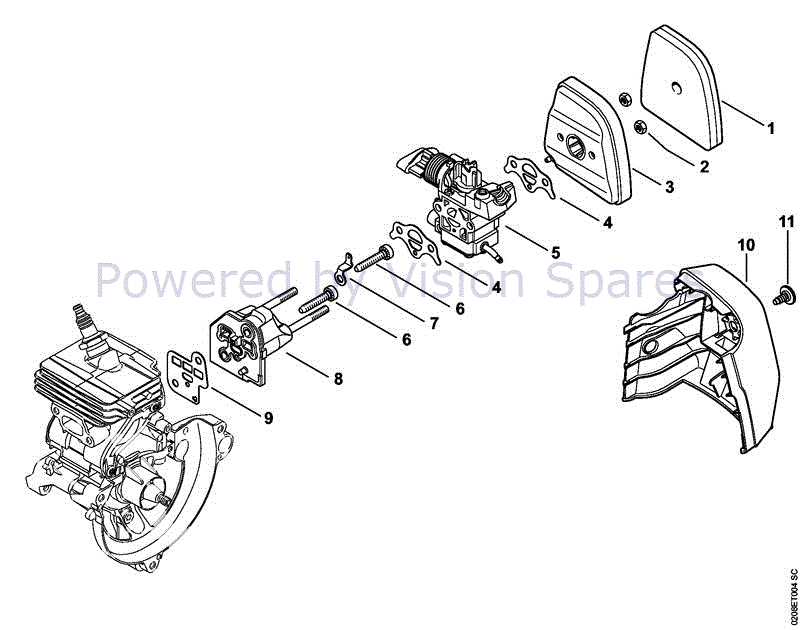

Powerful Engine: Equipped with a high-performance engine, this device delivers exceptional power while maintaining fuel efficiency. This balance makes it suitable for both professional and residential applications.

Versatility: This model is designed to accommodate a range of attachments, enabling users to switch between tasks seamlessly. Whether trimming hedges or clearing overgrown areas, its adaptability enhances productivity.

Safety Features: Built-in safety mechanisms provide peace of mind during operation. These features minimize the risk of accidents, making it suitable for both experienced users and novices.

Easy Maintenance: Simplified maintenance procedures ensure that the device remains in top working condition with minimal effort. This convenience allows users to focus on their tasks rather than spending time on upkeep.

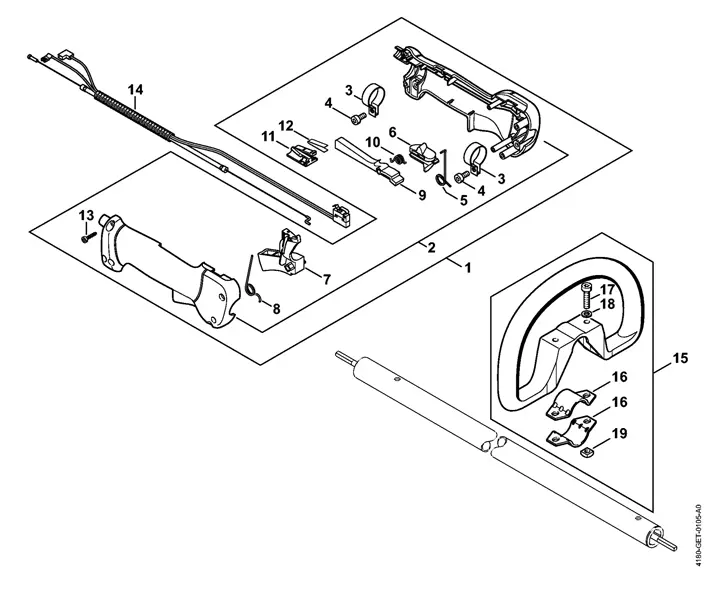

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations that detail the components of equipment provide invaluable guidance, enabling users to identify and replace specific elements with confidence. These illustrations serve as a roadmap, simplifying complex processes and reducing the risk of errors during assembly or disassembly.

Enhancing Efficiency

Utilizing visual guides significantly boosts efficiency in repair tasks. When individuals can easily locate and understand each component’s role, they can work more swiftly and accurately. This leads to reduced downtime, ensuring that machinery remains operational and effective.

Facilitating Troubleshooting

Visual resources are crucial for diagnosing issues. By referencing these guides, users can pinpoint faulty elements quickly, allowing for targeted solutions. This not only streamlines the repair process but also enhances the overall reliability and longevity of the equipment.

Understanding Component Functions

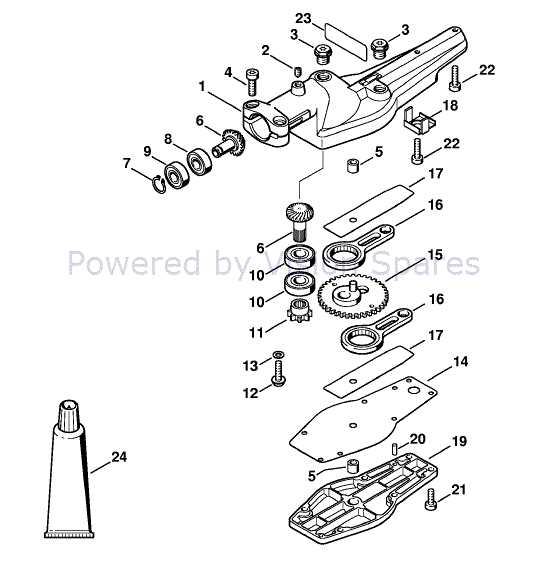

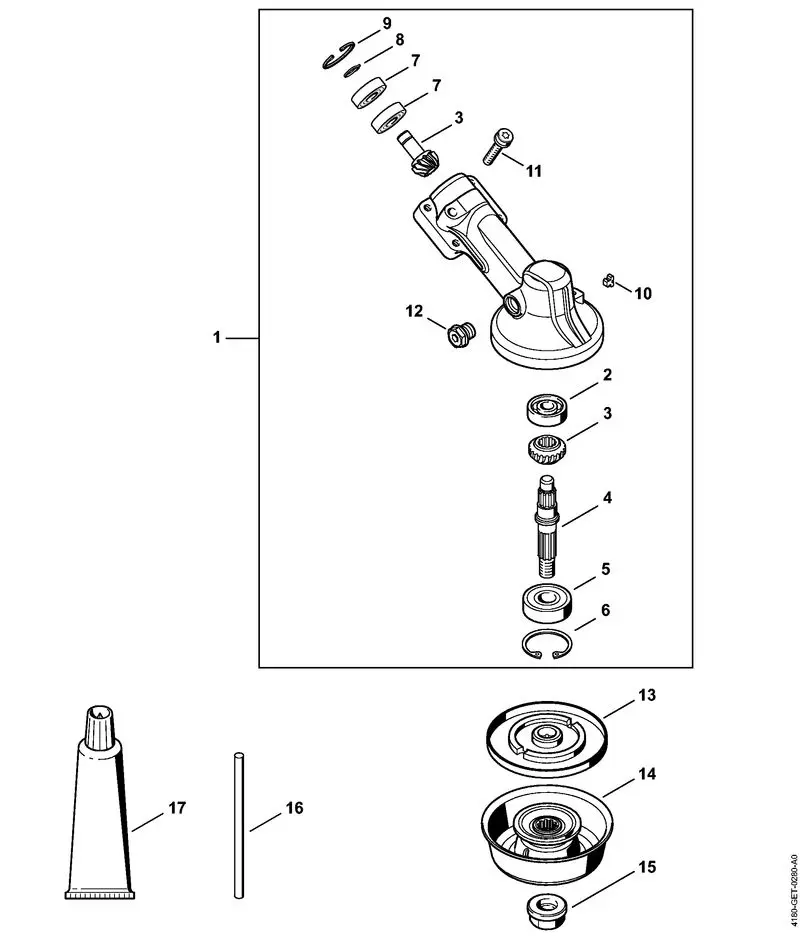

Every piece of equipment consists of various elements, each serving a specific purpose that contributes to the overall efficiency and effectiveness of the tool. Understanding these functions not only aids in proper usage but also enhances maintenance practices, ensuring longevity and optimal performance.

Key Elements and Their Roles

The primary components often include the engine, cutting mechanism, and control systems. The engine is responsible for generating power, which drives the cutting mechanism. This part is crucial for the tool’s ability to perform its intended tasks. Control systems, such as handles and switches, enable the operator to manage the equipment safely and effectively, allowing for precise operation.

Maintenance and Functionality

Regular maintenance of each component ensures they function harmoniously. For instance, keeping the engine clean and well-lubricated prevents overheating and wear. Similarly, inspecting the cutting elements for sharpness and damage is essential for achieving optimal cutting performance. Understanding these interrelationships helps users appreciate the importance of each component in the equipment’s operation.

Common Issues with HL 91 K

Understanding the typical problems associated with this particular gardening tool can greatly enhance its performance and longevity. Users often encounter a range of challenges that, if addressed promptly, can prevent further complications.

Frequent Mechanical Failures

Mechanical breakdowns are a common concern, often resulting from wear and tear over time. Regular maintenance can mitigate these issues.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Engine Starting Problems | Difficulty in ignition or stalling | Check the spark plug and fuel mixture |

| Overheating | Excessive heat during operation | Inspect cooling fins and air filter |

| Blade Malfunctions | Uneven cuts or vibrations | Sharpen or replace the blade |

Fuel System Issues

Problems within the fuel system can significantly affect functionality. Ensuring a clean fuel pathway is crucial for optimal operation.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Clogged Fuel Filter | Reduced power and performance | Replace the fuel filter |

| Old Fuel | Starting issues and poor combustion | Use fresh fuel and clean the tank |

| Fuel Line Leaks | Fuel odor and loss of power | Inspect and replace damaged lines |

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. Regular maintenance not only extends the lifespan of your tool but also enhances its efficiency, allowing you to achieve the best results.

1. Regular Cleaning: After each use, clean the exterior to remove dirt and debris. This prevents buildup that can affect performance.

2. Inspect Components: Periodically check all moving parts for wear and tear. Identifying issues early can save you from costly repairs.

3. Lubrication: Keep all mechanical parts well-lubricated to reduce friction and wear. Use the recommended lubricants for best results.

4. Store Properly: When not in use, store your equipment in a dry, protected area to prevent rust and damage from environmental factors.

5. Follow Manufacturer Guidelines: Adhere to the maintenance schedule and recommendations provided by the manufacturer for optimal performance.

By integrating these practices into your routine, you can ensure the ultimate reliability and efficiency of your equipment for years to come.

How to Locate Parts

Finding the necessary components for your equipment can seem daunting, but with the right approach, it becomes manageable. Understanding where to search and how to identify the specific items you need is crucial for effective maintenance and repair.

Start by consulting the manufacturer’s documentation, which typically includes detailed references to each element. This resource can provide valuable insights into model-specific requirements, ensuring you have the correct information at hand.

Additionally, online resources, including forums and dedicated websites, can be invaluable. Engaging with communities that share similar interests often yields quick responses and recommendations for reliable suppliers.

Consider visiting local retailers that specialize in outdoor tools. Many of these establishments have knowledgeable staff who can assist in locating the required components and may even offer advice on installation.

Lastly, don’t overlook the potential of contacting the manufacturer directly. Their customer service representatives are equipped to guide you in finding the right pieces, ensuring compatibility with your model.

In summary, utilizing a combination of documentation, online communities, local stores, and direct manufacturer contact will streamline your search and enhance your repair efforts.

Ordering Replacement Components

When it comes to maintaining your equipment, securing the right replacement items is crucial for optimal performance. Whether you’re looking to restore functionality or enhance durability, understanding the ordering process can save you time and effort.

Identifying the Right Components

Before placing an order, it’s essential to identify the specific components needed. Consider the following steps:

- Consult the user manual for your equipment to find the exact specifications.

- Examine the damaged or worn-out parts to determine the correct replacements.

- Use online resources or contact customer support for assistance in identifying the required items.

Where to Order

Once you have identified the components, you can explore various avenues for placing your order:

- Official Retailers: Start with authorized dealers to ensure authenticity and quality.

- Online Marketplaces: Websites often provide a wider selection and competitive pricing.

- Local Repair Shops: These can be convenient for immediate needs and expert advice.

By following these steps and choosing the right sources, you can effectively procure the necessary components to keep your equipment running smoothly.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right instruments is essential for a smooth and efficient process. Proper tools not only enhance your ability to perform tasks effectively but also ensure safety during repairs. Whether you’re a seasoned technician or a DIY enthusiast, being well-equipped will make all the difference in achieving successful outcomes.

Essential tools may include wrenches, screwdrivers, and pliers, which serve as the foundation for many repair jobs. Additionally, specialized instruments such as torque wrenches and multimeters can help address specific issues with precision. It’s important to invest in high-quality equipment that can withstand regular use and deliver reliable performance.

Don’t overlook safety gear as well; gloves, goggles, and masks are vital for protecting yourself from debris and harmful substances during repairs. Having an organized workspace with all necessary tools at hand not only improves efficiency but also minimizes frustration during the repair process.

Assembly and Disassembly Guide

This section provides a comprehensive approach to the assembly and disassembly of your gardening tool. Understanding the steps involved is crucial for maintenance and ensuring optimal performance. Proper handling will not only prolong the lifespan of the equipment but also enhance its efficiency during use.

When assembling or disassembling, it’s important to follow a systematic method. Begin by gathering all necessary tools and components, ensuring you have a clean and organized workspace. Familiarizing yourself with the key elements will facilitate a smoother process and help avoid any potential mishaps.

| Step | Action | Tips |

|---|---|---|

| 1 | Prepare your workspace | Ensure good lighting and ample space. |

| 2 | Gather tools and components | Check that all items are in good condition. |

| 3 | Remove fasteners | Use the correct tool to avoid stripping. |

| 4 | Carefully detach components | Keep parts organized for easier reassembly. |

| 5 | Inspect parts for wear | Replace any damaged components. |

| 6 | Reassemble in reverse order | Ensure all fasteners are tightened securely. |

Following these steps will lead to a successful assembly or disassembly process. Always consult your equipment’s manual for specific instructions and safety precautions. Proper care and handling will ensure that your tool remains reliable and effective for years to come.

Upgrades for Enhanced Performance

Enhancing the efficiency of your gardening tool can significantly improve its functionality and longevity. By integrating specific modifications, users can experience increased power, reduced wear, and improved handling. These enhancements often focus on optimizing various components to achieve the ultimate performance.

Engine Modifications: Upgrading the engine can lead to improved power output and fuel efficiency. Consider tuning the carburetor for better air-fuel mixture or opting for a high-performance spark plug.

Cutting Tools: Switching to superior cutting attachments can enhance precision and reduce the time spent on tasks. Look for blades that are designed for durability and efficiency.

Weight Distribution: Adding or adjusting components to balance the tool can make it easier to handle, reducing fatigue during prolonged use. Accessories like harnesses can also distribute weight more evenly.

Maintenance Enhancements: Incorporating high-quality lubricants and filters can extend the lifespan of crucial components. Regular upkeep with premium products ensures optimal functionality.

Investing in these upgrades not only maximizes performance but also elevates the overall experience, allowing for more enjoyable and efficient gardening tasks.

Comparing Parts with Other Models

This section explores the similarities and differences found in components across various equipment models, highlighting how these variations can affect performance and usability. Understanding these distinctions is crucial for users aiming to optimize their tools for specific tasks.

For instance, when examining components from different series, one might notice that certain features are designed for enhanced efficiency or durability. This comparison not only aids in selecting the right tool but also assists in maintenance decisions, ensuring optimal functionality over time.

Moreover, compatibility between models can offer valuable insights for those seeking to upgrade or replace specific elements. Identifying commonalities allows users to make informed choices, potentially saving time and resources while enhancing overall equipment performance.