Understanding the Stihl HS82R Parts Diagram for Effective Maintenance

Maintaining outdoor tools is crucial for ensuring optimal performance and longevity. An intricate understanding of the components that make up your trimming device can significantly enhance its functionality. By familiarizing yourself with these elements, you can effectively troubleshoot issues and undertake necessary repairs.

In this guide, we delve into the essential aspects of your cutting apparatus, highlighting various parts and their roles. Each component is designed with precision, and recognizing their arrangement can simplify maintenance tasks and help prevent common malfunctions.

Whether you are an experienced user or new to trimming equipment, having access to a detailed visual representation of the machinery will serve as an invaluable resource. It empowers you to identify parts accurately and understand their interactions, leading to better care and usage of your tools.

Understanding Stihl HS82R Components

A thorough comprehension of the various elements that make up this particular tool is essential for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance, contributing to the overall efficiency and longevity of the equipment. By familiarizing oneself with these integral parts, users can enhance their experience and troubleshoot issues more effectively.

The mechanism consists of several key elements, including the cutting blade, motor assembly, and housing. Each piece is designed to work in harmony, allowing for precision cutting and ease of use. Regular maintenance and an understanding of how these parts interact can prevent common problems and ensure that the tool functions at its best.

Familiarity with the assembly layout aids in identifying specific components when repairs or replacements are necessary. Whether it’s understanding the role of the fuel system or the importance of the ignition components, having this knowledge empowers users to take charge of their equipment’s upkeep.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricacies of machinery. They provide a clear overview of the various elements and their relationships, facilitating easier assembly, maintenance, and repair. By breaking down complex structures into manageable visuals, users can enhance their comprehension and efficiency.

These illustrations serve as invaluable references, helping technicians identify specific pieces quickly and accurately. This leads to reduced errors during repairs and ensures that replacements are made correctly. Ultimately, having access to such detailed visuals not only saves time but also promotes the longevity and functionality of equipment.

Furthermore, these guides foster a deeper appreciation of the mechanical design, allowing users to delve into the mechanics and functionality of their tools. Understanding how each part interacts contributes to more informed decision-making regarding repairs and upgrades, ensuring optimal performance.

Overview of HS82R Trimmer Features

This section highlights the essential characteristics of a well-regarded cutting tool, designed for precision and efficiency in maintaining landscapes. Users will appreciate the balance between power and ease of use, making it suitable for both professional landscapers and homeowners alike.

Equipped with a robust engine, this device ensures reliable performance while minimizing vibration. Its ergonomic design enhances user comfort during prolonged operation, allowing for better control and reduced fatigue. The lightweight construction facilitates easy maneuverability, making it ideal for intricate trimming tasks.

Blade Efficiency: The cutting mechanism features dual blades, providing a clean and precise cut. The spacing of the teeth is optimized for handling various types of vegetation, from thick branches to delicate shrubs.

Durability: Built with high-quality materials, this tool is designed to withstand the rigors of regular use. The corrosion-resistant components ensure longevity, even in challenging environments.

Maintenance: Easy access to key parts simplifies routine maintenance, ensuring that users can keep their equipment in top shape without excessive effort.

Overall, this tool combines innovative technology with practical features, making it an excellent choice for anyone looking to achieve professional-quality results in their gardening and landscaping projects.

Common Replacement Parts Explained

In any gardening tool, certain components are prone to wear and tear over time, necessitating regular maintenance and occasional replacements. Understanding these essential elements can significantly enhance the longevity and efficiency of the equipment, ensuring optimal performance during use.

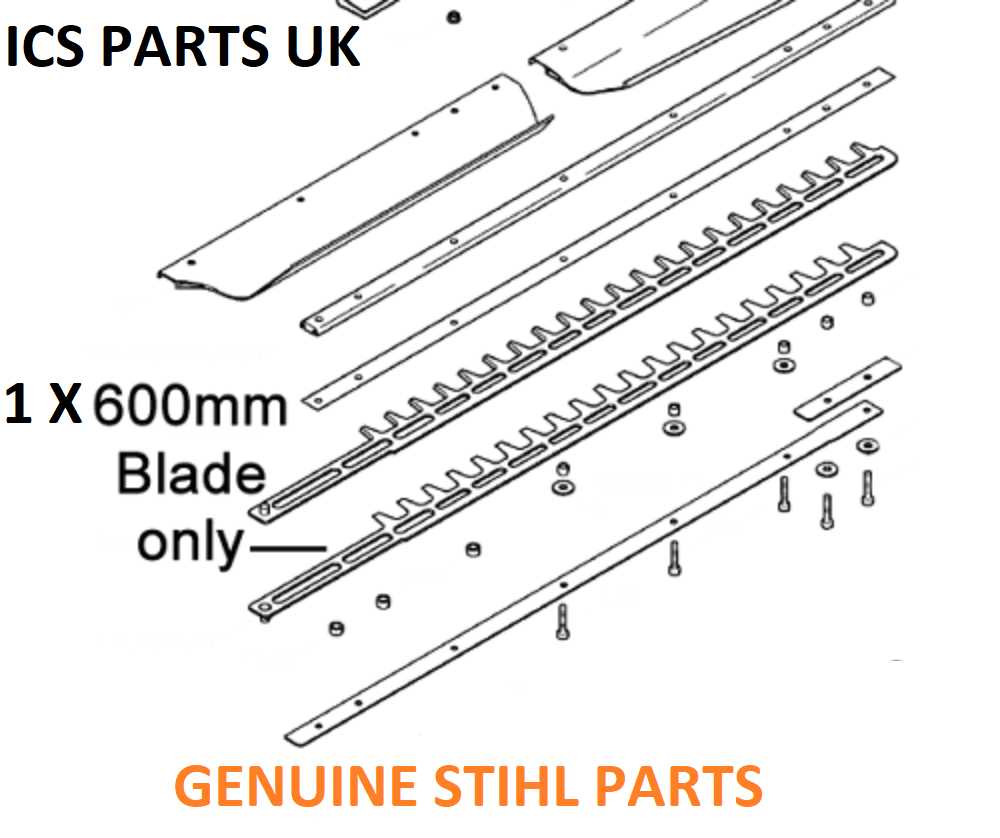

Blades

The cutting edges are among the most crucial elements, as they directly affect the quality of the cut. Over time, blades can become dull or damaged, requiring sharpening or replacement. Ensuring that the blades are in top condition is vital for achieving clean and precise cuts, which ultimately contributes to the health of the plants being trimmed.

Filters

Air and fuel filtration systems play a critical role in maintaining the efficiency of the machinery. Clogged or worn filters can lead to reduced performance and increased emissions. Regularly checking and replacing these filters ensures optimal airflow and fuel efficiency, promoting smoother operation and extending the life of the engine.

How to Interpret the Diagram

Understanding the visual representation of components can greatly enhance your ability to assemble and maintain your equipment. It provides a clear layout of each element, showing how they interconnect and function together.

First, start by identifying the key sections of the visual guide. Each part is typically numbered or labeled, which allows for easy reference when searching for specific pieces or instructions.

Next, pay attention to any accompanying notes or legends that explain symbols or abbreviations. These details are crucial for grasping the full context of the representation.

Finally, use the layout as a roadmap for repairs or maintenance. Familiarity with the arrangement will enable you to delve into any tasks with confidence, ensuring that you handle each component correctly for optimal performance.

Tools Required for Repairs

Proper maintenance and repair of equipment demand specific tools to ensure efficiency and effectiveness. Utilizing the right instruments not only facilitates the repair process but also enhances safety and durability of the equipment. Below are essential tools that can aid in achieving successful repairs.

Basic Hand Tools

Essential hand tools include wrenches, screwdrivers, and pliers. These instruments are fundamental for loosening and tightening components, allowing for straightforward adjustments and replacements.

Specialized Equipment

For more intricate repairs, specialized tools such as torque wrenches and multimeters may be necessary. These tools help ensure that components are tightened to the correct specifications and assist in diagnosing electrical issues.

Step-by-Step Repair Process

Repairing your cutting tool can seem daunting, but with a clear plan, the process becomes manageable. By following a systematic approach, you can identify issues, gather necessary components, and restore functionality efficiently. This guide outlines the essential steps to ensure a successful repair.

Preparation

- Gather your tools: Ensure you have all required tools handy, such as screwdrivers, wrenches, and pliers.

- Review the user manual: Familiarize yourself with the device’s specifications and components.

- Establish a clean workspace: Clear a designated area to keep everything organized during the repair.

Repair Steps

- Identify the issue: Determine the malfunction by checking for visible damage or listening for unusual sounds during operation.

- Disassemble the unit: Carefully remove the outer casing and any other components necessary to access the faulty part.

- Inspect the parts: Look for wear, cracks, or other signs of damage that may require replacement.

- Replace damaged components: If you find any faulty elements, replace them with new, compatible parts.

- Reassemble the tool: Once all repairs are completed, carefully put the unit back together, ensuring all screws and fasteners are tightened properly.

- Test the equipment: After reassembly, run a brief test to ensure everything functions correctly and safely.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan of your gardening equipment. Regular attention not only ensures optimal performance but also reduces the likelihood of unexpected breakdowns.

- Regular Cleaning: Remove debris and dirt after each use to prevent buildup.

- Sharpen Blades: Keep cutting edges sharp to enhance efficiency and reduce strain.

- Lubrication: Apply appropriate oils to moving parts to minimize friction and wear.

- Check Fasteners: Periodically inspect and tighten screws and bolts to maintain structural integrity.

- Storage Conditions: Store equipment in a dry, sheltered area to protect against weather damage.

By following these guidelines, you can significantly extend the life of your tools and ensure they operate at peak performance.

Identifying Worn Parts Quickly

Recognizing when components have deteriorated is crucial for maintaining optimal performance and safety. Regular inspection allows for early detection of wear, preventing further damage and ensuring smooth operation.

Visual Inspection Techniques

Begin with a thorough visual examination. Look for any signs of cracking, fraying, or unusual wear patterns. Pay attention to areas that experience frequent movement or stress, as these are more prone to deterioration.

Performance Indicators

Monitor the equipment’s performance closely. If you notice a decline in efficiency or unusual noises, it may indicate that certain elements are compromised. Timely intervention can save time and costs in the long run.

Where to Find Genuine Parts

Locating authentic components for your tools is essential for maintaining their performance and longevity. Ensuring that you use original replacements can significantly enhance the efficiency and durability of your equipment.

Authorized Dealers

One of the most reliable sources for original components is through authorized retailers. These dealers provide:

- Verified quality

- Expert assistance

- Warranty options

Online Marketplaces

Reputable online platforms can also be a great option. When shopping online, consider:

- Reading customer reviews

- Checking for seller ratings

- Ensuring return policies are clear

Common Troubleshooting Scenarios

When operating power tools, encountering issues is not uncommon. Understanding typical problems and their solutions can enhance performance and prolong the lifespan of the equipment. This section will explore frequent challenges users may face and provide effective strategies to address them.

One prevalent issue is the tool not starting. This could stem from a drained battery or fuel problems. Checking the power source and ensuring proper fuel levels can often resolve this scenario. If the equipment starts but runs poorly, clogged filters or dull blades might be the culprits, necessitating cleaning or replacement.

Additionally, excessive vibrations during use can indicate loose components or imbalanced parts. Tightening any loose screws and inspecting the blade alignment are essential steps to mitigate this issue. Lastly, if unusual noises are heard, it is crucial to stop using the tool immediately and inspect for any visible damage or wear.

Expert Advice on Upgrades

Enhancing the performance of your equipment can significantly improve efficiency and longevity. Here are some tips to consider when looking to elevate your tools:

- Research Components: Investigate various enhancements available for your specific model to ensure compatibility.

- Prioritize Quality: Opt for high-quality materials and components to avoid premature wear and failure.

- Consider User Needs: Evaluate how upgrades can cater to your specific tasks, such as increasing power or reducing weight.

- Maintenance Matters: Regular upkeep is crucial; sometimes, a simple tune-up can yield better performance than a full upgrade.

By taking these factors into account, you can make informed decisions that ultimately lead to enhanced functionality and satisfaction with your tools.