Understanding the Parts Diagram of Stihl HSA 56

Maintaining and optimizing garden equipment can greatly enhance its performance and longevity. A comprehensive understanding of the various elements that make up your tool is essential for effective usage and repair. This section delves into the intricate parts of your equipment, shedding light on how each component functions and contributes to overall efficiency.

For users seeking to troubleshoot issues or simply to familiarize themselves with their device, a detailed exploration of the individual segments is invaluable. Recognizing how these components interconnect and their specific roles can lead to better maintenance practices, ensuring your equipment remains in peak condition.

Whether you are a seasoned gardener or a novice, having access to a thorough breakdown of your device’s makeup will empower you to tackle repairs confidently. This knowledge not only enhances your skills but also allows for a more informed approach to the care and handling of your essential gardening tool.

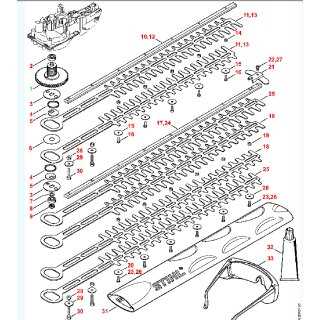

Understanding Stihl HSA 56 Components

Familiarity with the various elements of a power tool can greatly enhance its effective use and maintenance. Each component plays a critical role in the overall functionality, ensuring optimal performance and longevity. This section explores the essential pieces that make up this specific model, shedding light on their functions and importance.

Power Source: The energy unit is fundamental for operation, providing the necessary force to power the machine. Understanding its capacity and maintenance needs can prevent unexpected failures.

Cutting Mechanism: The blade assembly is crucial for achieving precise and clean cuts. Knowledge of its construction and the materials used can inform users about appropriate care and replacement options.

Handle and Controls: Ergonomically designed grips and control features enhance user experience. Familiarizing oneself with the placement and function of these elements is vital for safe and efficient operation.

Safety Features: Integrated safety systems are essential for protecting the user. Awareness of these mechanisms helps in understanding their purpose and ensuring compliance during use.

Housing and Frame: The outer casing provides structural integrity and protection for internal components. Recognizing the materials and design can assist in troubleshooting and maintenance tasks.

By gaining insight into these individual elements, users can enhance their operational knowledge, ensure proper upkeep, and extend the lifespan of the equipment.

Overview of Stihl HSA 56 Parts

This section provides a comprehensive examination of the essential components that make up the featured gardening tool. Understanding these elements is crucial for effective maintenance and optimal performance.

| Component | Description |

|---|---|

| Blade | Precision-engineered for clean cuts, essential for shaping hedges. |

| Motor | Powers the device, providing necessary strength for various tasks. |

| Battery | Supplies energy, enabling cordless operation for increased mobility. |

| Handle | Designed for comfort and control, ensuring user-friendly operation. |

| Casing | Protects internal components while contributing to the tool’s overall durability. |

Importance of Regular Maintenance

Benefits of Routine Care

- Enhanced Performance: Regular checks and servicing ensure that equipment operates at peak efficiency, leading to better results in less time.

- Increased Lifespan: Routine maintenance can significantly extend the life of tools, saving money on replacements in the long run.

- Safety: Well-maintained equipment is less likely to malfunction, reducing the risk of accidents and injuries during use.

- Cost Efficiency: Identifying and addressing minor issues early can prevent more significant, costly repairs down the line.

Key Maintenance Tasks

- Regularly clean and inspect equipment after each use to remove debris and prevent rust.

- Check and replace air filters to ensure proper airflow and engine function.

- Sharpen blades and cutting tools regularly for efficient cutting performance.

- Lubricate moving parts to minimize wear and tear.

- Store tools in a dry, protected area to avoid damage from weather conditions.

How to Identify Faulty Parts

Determining the condition of components in your equipment is crucial for maintaining optimal performance and longevity. Recognizing signs of wear and malfunction can save you time and money in the long run. Here, we outline effective methods to assess whether individual elements require replacement or repair.

Visual Inspection

Start with a thorough visual examination. Look for any noticeable signs of damage, such as cracks, corrosion, or excessive wear. Pay close attention to moving parts, as they are more susceptible to deterioration. A strong indication of trouble can be the presence of unusual discoloration or debris buildup, which may hinder functionality.

Performance Evaluation

Next, conduct a performance evaluation. If you notice a decline in efficiency or unusual noises during operation, it could signal a deeper issue. Inconsistent output, vibrations, or overheating are also critical indicators that should not be overlooked. If any irregularities are detected, further investigation is warranted.

By employing these techniques, you can effectively pinpoint problematic components and ensure your equipment operates smoothly.

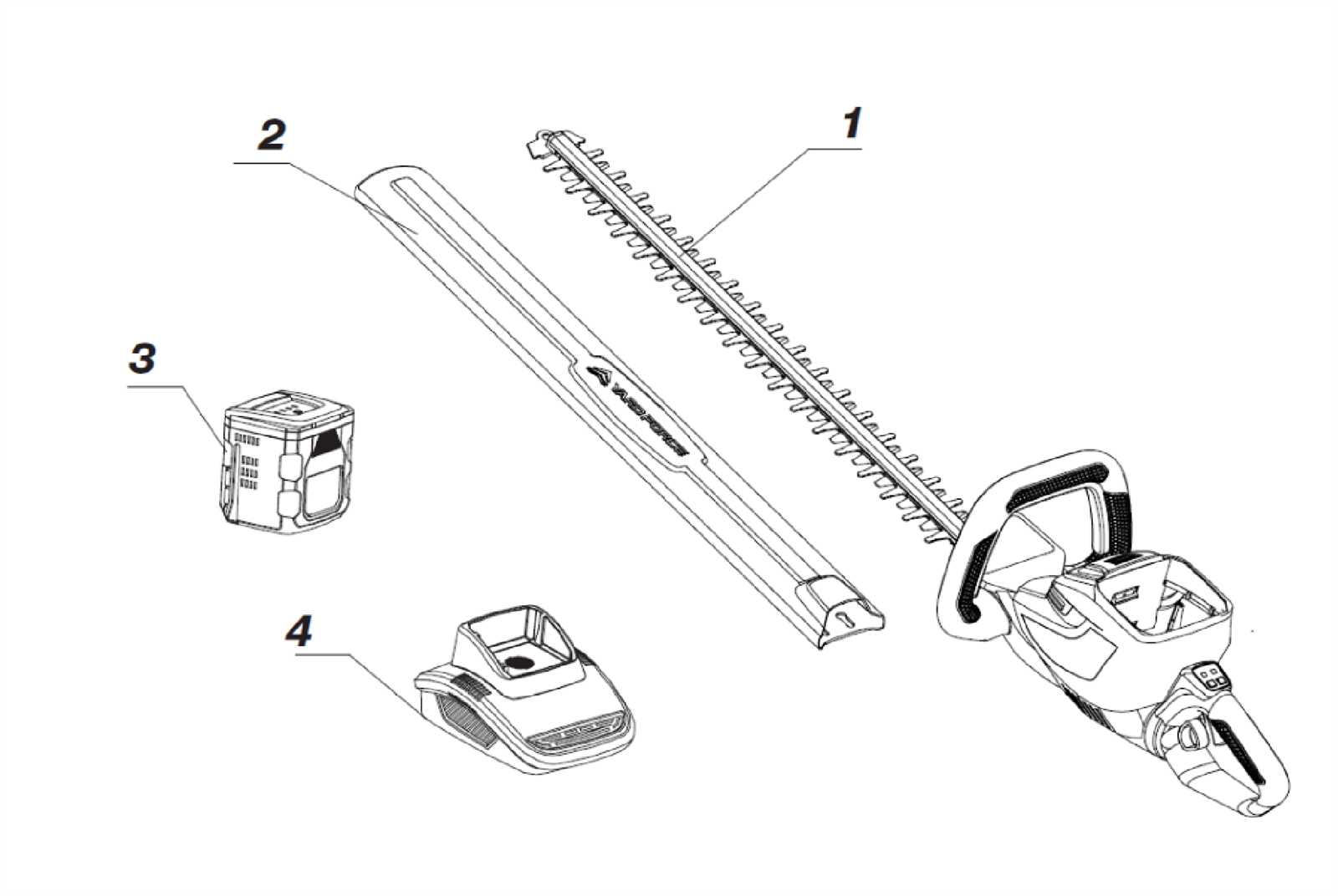

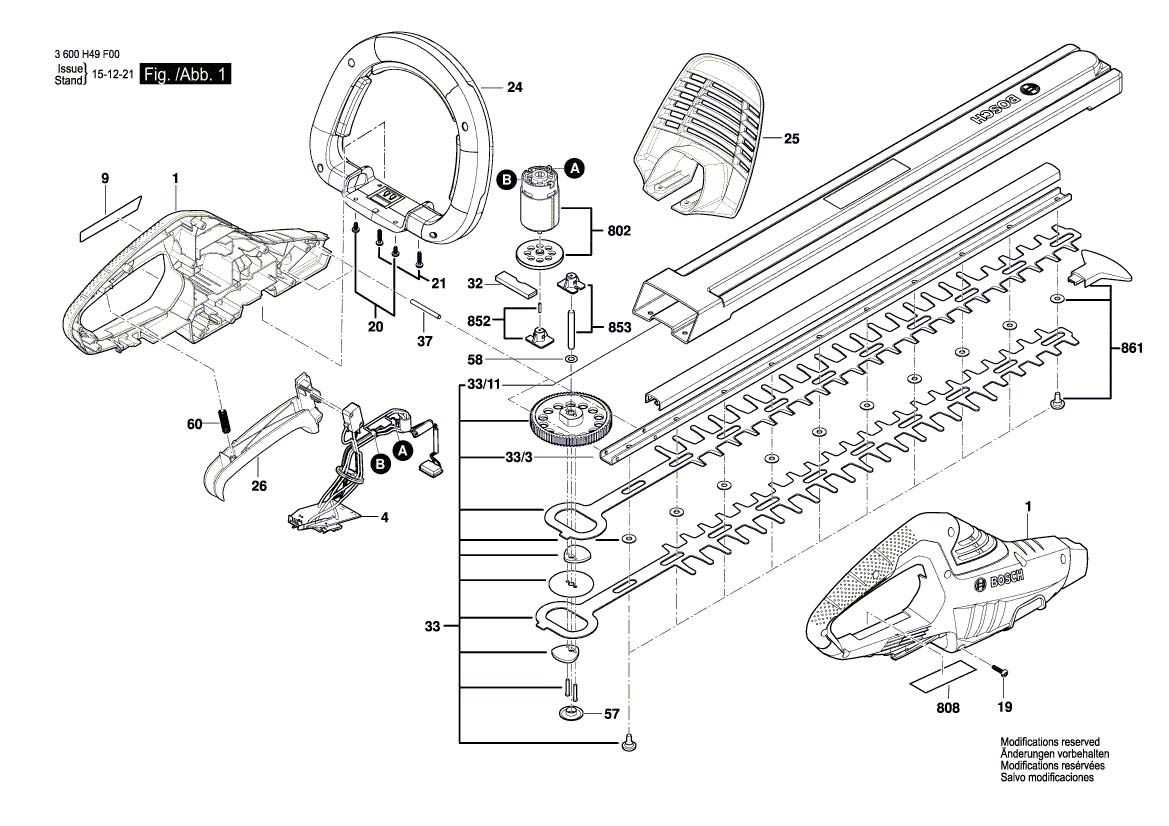

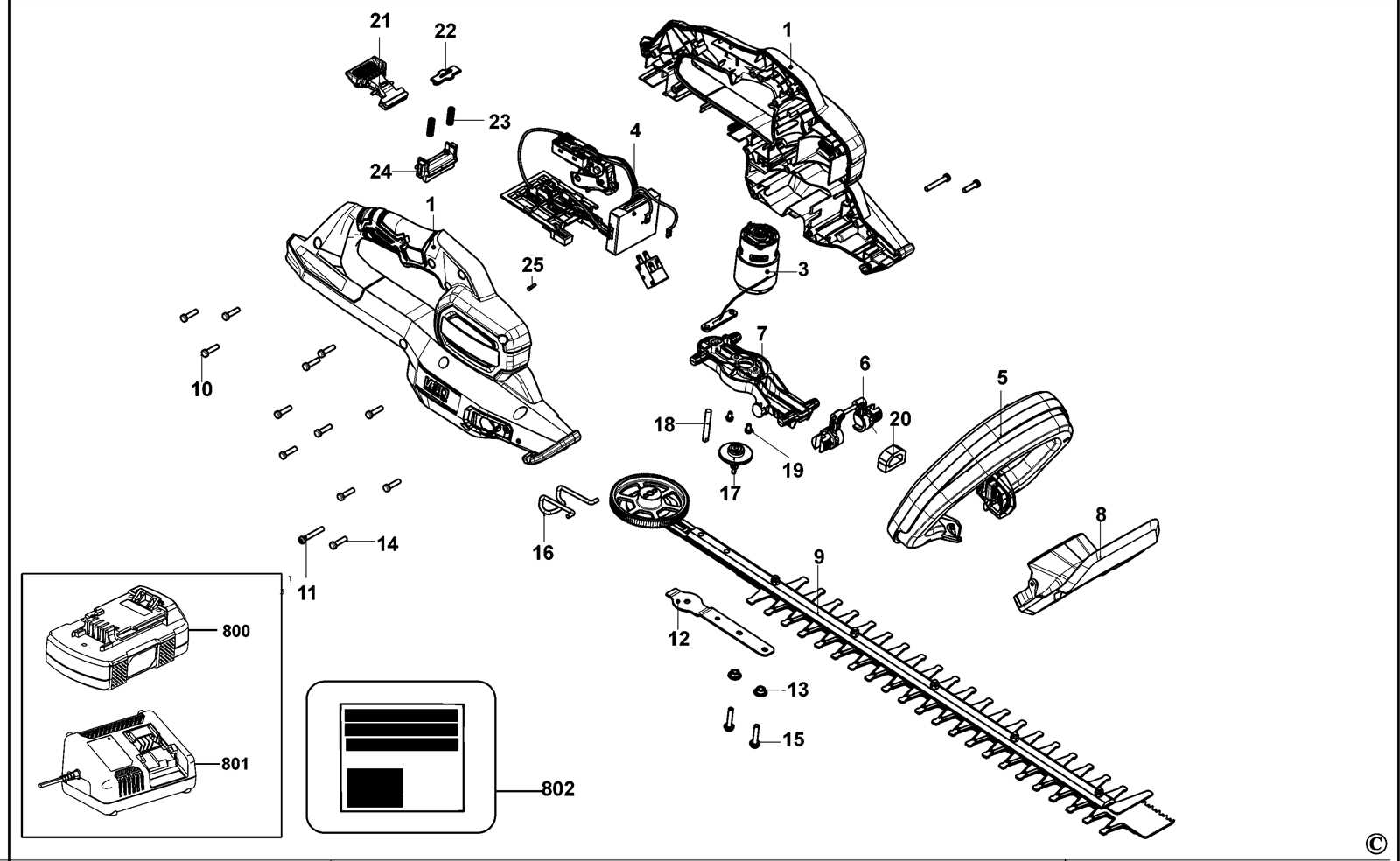

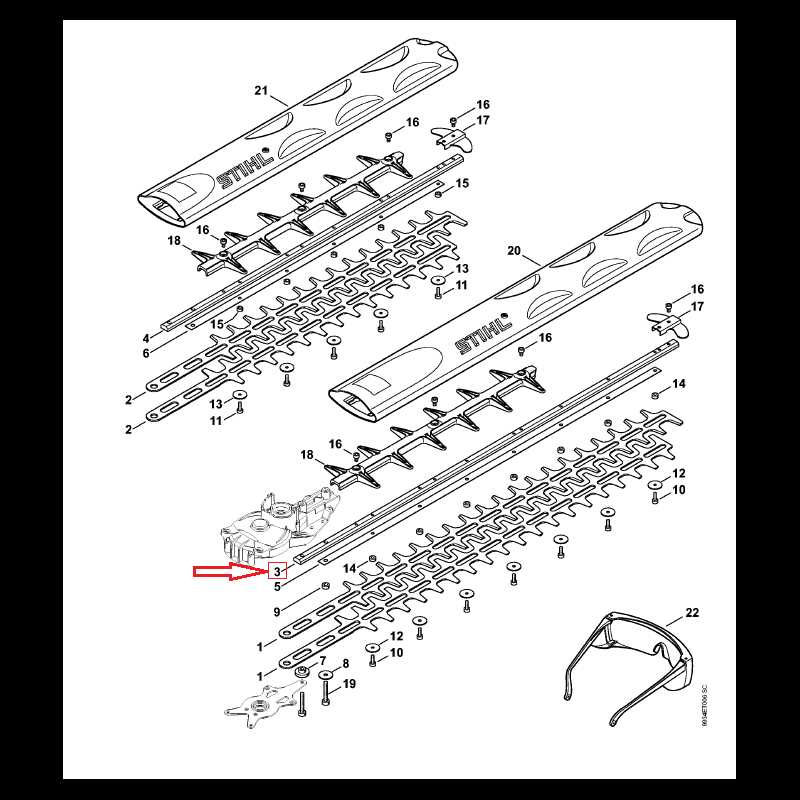

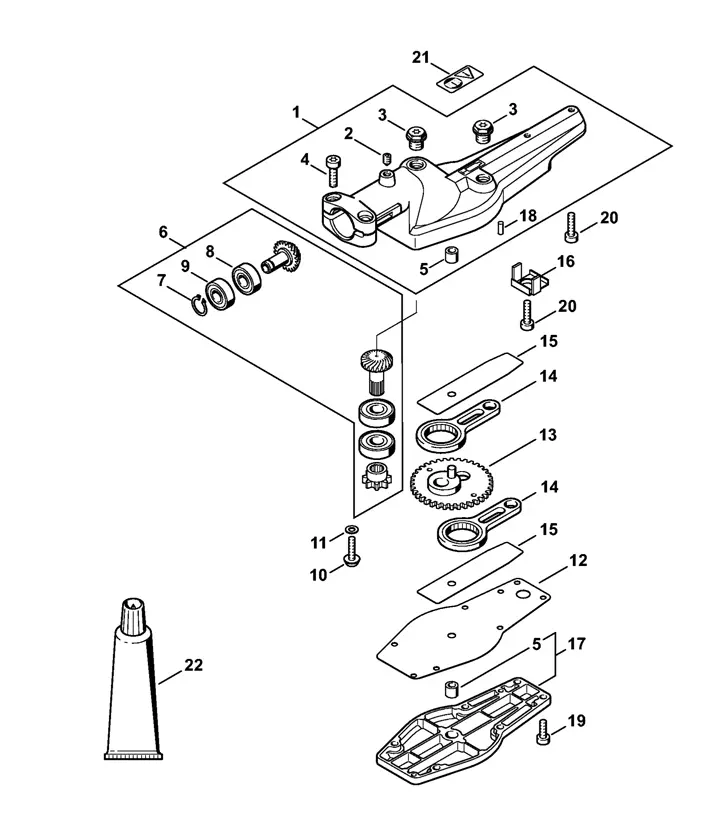

Visual Guide to Parts Diagram

This section offers an insightful overview of the components found within a particular garden tool, highlighting their arrangement and functionality. Understanding the configuration of these elements can significantly enhance maintenance and repair efforts.

Key Components Overview

- Power Source

- Cutting Mechanism

- Handle Assembly

- Guarding Systems

- Control Features

Exploring Each Element

- Power Source: Vital for operation, ensuring efficiency and longevity.

- Cutting Mechanism: The heart of the tool, responsible for achieving desired results.

- Handle Assembly: Provides user comfort and control during use.

- Guarding Systems: Essential for safety, preventing accidents during operation.

- Control Features: Allow for easy adjustments and settings while in use.

Common Issues and Solutions

When operating a handheld cutting tool, users may encounter various challenges that can affect performance. Understanding these common problems and their solutions can enhance the longevity and efficiency of the equipment.

- Tool Won’t Start

- Check the battery charge; replace or recharge if necessary.

- Inspect the power switch for any damage or malfunction.

- Ensure all connections are secure and free from debris.

- Inconsistent Cutting Performance

- Verify the sharpness of the cutting blades; sharpen or replace if dull.

- Examine the cutting height and adjust according to the task.

- Clear any obstructions that may hinder smooth operation.

- Excessive Vibration

- Check for loose screws or components and tighten as needed.

- Inspect the handle and grips for wear and replace if damaged.

- Ensure proper maintenance of the internal mechanism.

- Battery Issues

- Monitor the battery health regularly and replace when necessary.

- Store batteries at recommended temperatures to prevent damage.

- Keep battery contacts clean to ensure good connectivity.

By addressing these common concerns proactively, users can maintain optimal functionality and enjoy a smoother cutting experience.

Replacement Parts Availability

Access to quality components is essential for maintaining the performance and longevity of outdoor equipment. Ensuring that users can easily find suitable replacements contributes to the overall efficiency and reliability of their tools. This section explores the avenues available for sourcing these crucial elements.

Where to Find Components

Replacement items can often be acquired from a variety of sources, including authorized retailers, online marketplaces, and specialized shops. It’s important to verify the credibility of the source to ensure the quality of the products.

Compatibility and Specifications

Before purchasing, users should confirm the compatibility of the items with their specific model. Detailed specifications help in selecting the right components, preventing any potential issues during installation.

| Source | Availability | Notes |

|---|---|---|

| Authorized Dealers | High | Quality assured; warranty options available. |

| Online Retailers | Medium | Variety of options; check reviews. |

| Local Shops | Variable | Support local businesses; limited selection. |

Tools Needed for Repairs

When it comes to performing maintenance or fixes on outdoor equipment, having the right instruments is crucial for achieving optimal results. Whether you’re tackling minor adjustments or comprehensive repairs, being equipped with essential tools not only streamlines the process but also ensures safety and precision.

Essential Hand Tools

Basic hand tools are foundational for any repair job. Items such as screwdrivers, wrenches, and pliers play a pivotal role in disassembly and reassembly tasks. A good-quality socket set can also be invaluable for accessing hard-to-reach bolts.

Power Tools for Efficiency

In addition to hand tools, certain power tools can enhance efficiency. A drill with various bits can expedite the process, while an impact wrench is particularly useful for loosening stubborn fasteners. Ensuring you have these tools readily available will significantly reduce downtime and improve the overall repair experience.

Step-by-Step Repair Process

Understanding the procedure for fixing your equipment can greatly enhance its performance and lifespan. By following a systematic approach, you can identify issues and implement effective solutions. This guide outlines the essential steps for a thorough restoration process.

- Gather Tools and Materials

Before starting, ensure you have all necessary tools and replacement components. Common items include:

- Screwdrivers

- Wrenches

- Replacement parts

- Lubricants

- Cleaning supplies

- Disconnect Power Source

Safety should be your top priority. Make sure to disconnect the power source to prevent accidental activation during repairs.

- Inspect the Equipment

Conduct a visual inspection to identify any visible damage or wear. Look for:

- Cracks or breaks

- Worn-out components

- Loose connections

- Disassemble the Unit

Carefully remove the outer casing to access internal parts. Keep track of screws and small pieces to ensure reassembly is straightforward.

- Replace or Repair Components

Address the identified issues by either repairing damaged parts or replacing them. Ensure that all new components are compatible.

- Clean the Interior

Before reassembling, clean any dust and debris from the interior. This helps improve efficiency and prolongs the life of the equipment.

- Reassemble the Equipment

Carefully put all parts back together in reverse order of disassembly. Double-check that all screws and connections are secure.

- Test the Equipment

Reconnect the power source and conduct a test run. Observe for any unusual noises or behaviors that may indicate further issues.

Following these steps methodically will help ensure that your equipment operates smoothly and effectively for years to come.

Safety Precautions During Maintenance

Ensuring safety while performing upkeep on equipment is essential for both personal protection and the longevity of the device. Adhering to specific guidelines can prevent accidents and enhance operational efficiency.

- Always wear appropriate protective gear, including gloves, goggles, and ear protection.

- Disconnect power sources before starting any maintenance tasks to avoid accidental activation.

- Work in a well-ventilated area to minimize exposure to harmful fumes.

- Keep your workspace organized to reduce the risk of slips and falls.

By following these precautions, you can help ensure a safe and effective maintenance process, ultimately prolonging the life of your equipment.

Specifications Overview

This section provides a comprehensive look at the key features and technical details of a popular battery-powered cutting tool designed for efficient trimming and maintenance. Understanding these specifications is essential for users seeking optimal performance and reliability in their gardening tasks.

Key Features

The device is engineered with several important characteristics that enhance its usability and effectiveness:

| Feature | Description |

|---|---|

| Weight | Approximately 2.5 kg (5.5 lbs) |

| Cutting Length | 24 cm (9.5 inches) |

| Battery Type | Lithium-ion |

| Runtime | Up to 50 minutes on a full charge |

| Noise Level | Quiet operation at 85 dB(A) |

Performance Metrics

Analyzing the performance metrics allows potential users to gauge the tool’s efficiency in various conditions:

| Metric | Value |

|---|---|

| Cutting Speed | 2500 strokes per minute |

| Max Cutting Diameter | 10 mm (0.4 inches) |

| Vibration Level | Low vibration for user comfort |

| Warranty | 2 years limited warranty |

Comparing with Other Stihl Models

This section explores how one specific model stacks up against its counterparts in the same lineup. By examining features, performance, and user experiences, we can uncover the nuances that differentiate them.

When assessing performance, key factors such as battery life, cutting efficiency, and weight come into play. For instance, while some variants may offer enhanced power, others excel in maneuverability, making them suitable for different tasks.

Another critical aspect is the ease of maintenance. Certain models are designed for user-friendly upkeep, reducing downtime and ensuring that users can quickly get back to work, while others may require more attention and specialized tools.

Ultimately, the choice between these models often hinges on specific needs and preferences, emphasizing the importance of understanding the unique attributes of each option available.

Where to Find Expert Help

When dealing with maintenance and repair needs for your equipment, seeking professional assistance can ensure optimal performance and longevity. Various resources are available to connect you with knowledgeable individuals who can provide guidance and support.

- Authorized Service Centers: Look for local centers that specialize in your equipment brand, as they often employ certified technicians.

- Online Forums: Join communities where enthusiasts and experts share insights and troubleshooting tips related to your specific model.

- Manufacturer’s Customer Support: Reach out directly to the manufacturer for recommendations on skilled professionals.

- Local Hardware Stores: Many stores offer repair services or can refer you to qualified mechanics in your area.

Exploring these avenues can help you connect with experienced individuals who can assist in resolving any issues efficiently.