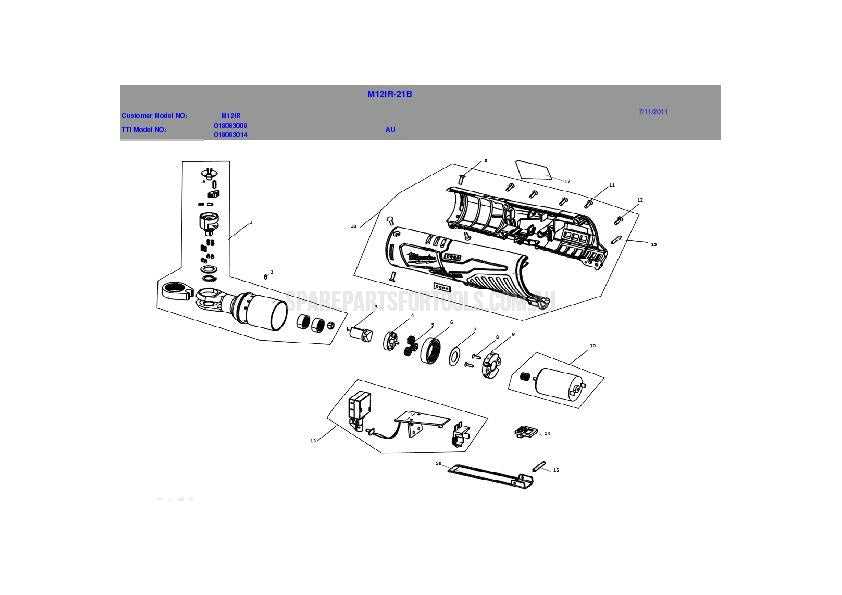

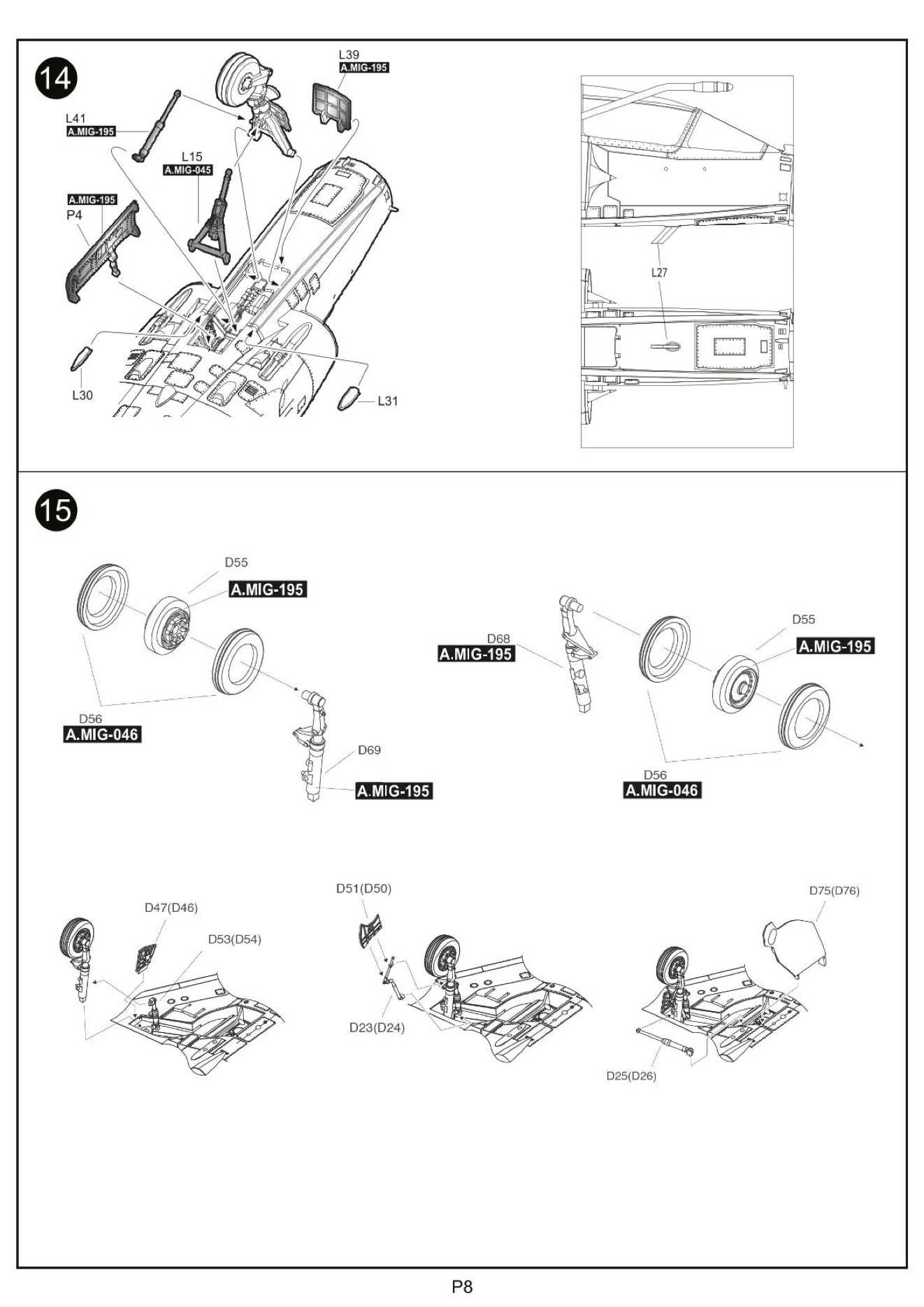

Understanding the Parts Diagram of Stihl HTA 85

Every effective tool relies on a harmonious interplay of its various elements. Grasping how these individual components work together is essential for maintenance and optimal performance. A clear visual representation can significantly enhance your understanding of the assembly and functionality.

Within this section, we will explore the intricate details of a specific model, focusing on the layout and relationship of its vital components. By delving into this information, users can gain the ultimate insight necessary for troubleshooting and repairs.

Comprehending the arrangement of parts can streamline the repair process and ensure that each element is functioning at its best. This knowledge not only aids in the longevity of your equipment but also empowers users to tackle issues with confidence.

Understanding Stihl HTA 85 Overview

This section aims to provide a comprehensive understanding of a specific battery-operated gardening tool designed for efficient tree maintenance and landscaping tasks. The focus will be on its key features, functionality, and the advantages it offers to both professional users and enthusiasts.

Key Features

Equipped with a powerful electric motor, this tool delivers remarkable cutting performance without the noise and emissions associated with gas-powered alternatives. Its lightweight design ensures easy handling, making it ideal for extended use. Additionally, the ergonomic structure enhances user comfort during operation.

Benefits of Use

Using this innovative equipment allows for greater flexibility in garden management. The absence of fuel requirements translates to lower operational costs and minimal maintenance needs. Users can also appreciate the quiet operation, enabling work in residential areas without disturbing the peace.

Importance of Parts Diagrams

Understanding the components of any machinery is essential for effective maintenance and repair. Visual representations of these elements offer clarity, enabling users to identify and address issues swiftly. Such illustrations not only enhance comprehension but also streamline the troubleshooting process.

Benefits of Visual Representations

- Facilitates quick identification of components.

- Improves accuracy in ordering replacements.

- Aids in assembly and disassembly tasks.

- Enhances communication among technicians.

Efficiency in Maintenance

- Reduces downtime by expediting repairs.

- Promotes regular upkeep through better understanding.

- Helps in training new personnel.

Main Components of HTA 85

The electric pruning tool features several essential elements that contribute to its efficient operation and ease of use. Understanding these components helps users appreciate the design and functionality of this equipment, ensuring optimal performance during tasks such as trimming and shaping plants.

| Component | Description |

|---|---|

| Power Unit | The core of the tool, providing the necessary energy for operation. |

| Cutter Bar | A cutting edge that allows for precise trimming of branches and foliage. |

| Chain | Essential for movement along the cutter bar, enabling effective cutting action. |

| Handle | Designed for comfort and control, allowing the user to maneuver the tool easily. |

| Battery | Supplies power to the unit, ensuring portability and convenience during use. |

| Safety Features | Includes various mechanisms to protect the user during operation, enhancing overall safety. |

Identifying Common Issues

Recognizing frequent problems with outdoor power equipment can significantly enhance its performance and longevity. Many users encounter similar challenges, and understanding these can aid in effective troubleshooting. By identifying these issues early, you can save time and resources while ensuring your tool operates smoothly.

Electrical Failures

One of the primary concerns is electrical malfunction. If the device fails to start, it may indicate a drained battery or faulty connections. Inspecting the wiring and ensuring all components are securely connected can often resolve these issues. Additionally, check for any signs of corrosion that may affect electrical flow.

Mechanical Problems

Another common issue relates to mechanical components. Worn-out blades or damaged parts can hinder efficiency. Regular maintenance is crucial; sharpening blades and examining for cracks or breaks can prevent larger problems down the line. Moreover, listen for unusual noises during operation, as these can signal underlying mechanical failures that need immediate attention.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. By following a few essential practices, you can enhance performance and extend the lifespan of your tools. Regular maintenance not only prevents breakdowns but also optimizes functionality, making your tasks more efficient.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean the exterior | After each use | Prevents debris buildup and rust |

| Inspect blades or cutting components | Weekly | Ensures sharpness and effectiveness |

| Check battery health | Monthly | Maximizes power and longevity |

| Lubricate moving parts | Every few months | Reduces friction and wear |

| Replace worn components | As needed | Maintains optimal performance |

Adhering to these guidelines will not only preserve your equipment but also improve your overall experience. Regular attention to maintenance can prevent costly repairs and ensure that your tools remain reliable for years to come.

How to Order Replacement Parts

When it comes to acquiring components for your equipment, understanding the process can save time and ensure accuracy. Here’s a concise guide to streamline your ordering experience.

- Identify the specific component you need, referencing any available manuals or online resources.

- Visit the official website or authorized dealers for reliable sourcing.

- Utilize the search feature by entering the model number or description to locate the item quickly.

Once you’ve found the desired item, follow these steps:

- Add the item to your cart, confirming the details.

- Proceed to checkout and provide necessary shipping information.

- Select your preferred payment method and finalize the transaction.

Keep your order confirmation handy for tracking and future reference. This methodical approach ensures you receive the correct items efficiently.

Using the Diagram Effectively

Understanding visual representations of components can greatly enhance your ability to maintain and repair equipment. These illustrations provide a clear overview of how different elements interact, making it easier to identify issues and perform necessary tasks. Familiarity with these visuals can ultimately lead to more efficient troubleshooting.

To maximize the benefits, begin by familiarizing yourself with the layout and symbols used in the representation. Each element typically corresponds to specific functions or areas, so taking the time to study them will pay off. Highlighting or annotating areas of interest can further aid in comprehension.

When working on repairs or maintenance, refer to the visual guide step-by-step, ensuring you don’t overlook any crucial details. This approach can save time and prevent potential mistakes, ultimately leading to a smoother experience. Additionally, keeping a copy handy while working will allow you to quickly resolve uncertainties that may arise during the process.

Comparing with Other Models

When evaluating different battery-operated cutting tools, it’s essential to consider various features and specifications that set them apart. Each model offers unique advantages that cater to specific needs, making it crucial for users to understand how these machines compare in terms of performance, efficiency, and versatility.

Performance Metrics

Power and runtime are key factors in determining the effectiveness of these tools. Users should look for models that provide optimal cutting speed and battery life to ensure productivity during extended use. Below is a comparison of selected models based on their performance attributes:

| Model | Power Output (W) | Battery Life (minutes) | Weight (kg) |

|---|---|---|---|

| Model A | 600 | 90 | 3.5 |

| Model B | 550 | 85 | 3.2 |

| Model C | 700 | 100 | 4.0 |

Additional Features

Beyond power and efficiency, the inclusion of user-friendly features can greatly enhance the overall experience. Factors such as ergonomic design, noise levels, and ease of maintenance should also be considered when making a choice. These elements contribute to both comfort and practicality during operation.

DIY Repair vs. Professional Help

When it comes to fixing equipment, individuals often face the decision between tackling repairs themselves or seeking expert assistance. Each approach has its advantages and drawbacks, influencing both time and cost efficiency. Understanding these factors can help determine the best path forward for any repair needs.

| Aspect | DIY Repair | Professional Help |

|---|---|---|

| Cost | Generally lower, limited to tools and materials | Higher, includes labor and expertise fees |

| Time | Variable; depends on skill level and complexity | Typically quicker, as experts are experienced |

| Skill Level | Requires basic to advanced knowledge | Professional experience ensures quality |

| Outcome | Varied success based on ability | Reliable results with warranty on services |

Ultimately, the choice between self-repair and hiring a specialist hinges on personal preference, capability, and the specific challenges presented by the equipment. Assessing these elements can lead to a more informed decision.

Safety Precautions During Repairs

When undertaking maintenance or repair tasks, ensuring personal safety is paramount. Proper precautions help mitigate risks and prevent accidents, allowing for a smoother and more effective workflow.

- Always wear appropriate protective gear, including gloves, goggles, and sturdy footwear.

- Ensure the workspace is well-lit and organized to avoid tripping hazards.

- Disconnect any power sources before starting repairs to prevent accidental activation.

- Keep tools and components properly stored to avoid misplacement and confusion.

By adhering to these safety measures, you create a secure environment conducive to efficient repairs.

Where to Find Authentic Parts

Ensuring the longevity and optimal performance of your equipment requires sourcing genuine components. Authentic pieces not only enhance functionality but also provide peace of mind regarding safety and reliability. Here are some effective ways to find these crucial items:

- Authorized Dealers: Seek out local authorized retailers who specialize in outdoor equipment. They typically offer a comprehensive selection of genuine items and can assist with any inquiries.

- Official Websites: Visit the manufacturer’s official site. Many brands have dedicated sections for replacement items, ensuring you access the correct specifications.

- Online Marketplaces: Utilize reputable online platforms that specialize in outdoor gear. Look for those that guarantee authenticity and provide customer reviews to help make informed choices.

- Service Centers: Reach out to certified service centers. These locations often stock original components and can perform installations or repairs, ensuring everything works seamlessly.

By prioritizing genuine components, you safeguard the integrity of your tools and enhance their overall performance.

Benefits of Regular Maintenance

Regular upkeep of tools and equipment is essential for ensuring their longevity and optimal performance. Consistent care not only enhances functionality but also minimizes the likelihood of unexpected breakdowns. By investing time in maintenance, users can enjoy a variety of advantages that contribute to the efficiency and reliability of their machinery.

Increased Lifespan

Routine maintenance significantly extends the operational life of equipment. Key benefits include:

- Prevention of wear and tear through timely interventions.

- Identification and resolution of potential issues before they escalate.

- Ensuring that components remain in peak condition, thus avoiding premature replacements.

Enhanced Performance

Keeping equipment in good working order leads to improved performance and productivity. Advantages include:

- Optimal functionality that allows for smoother operation.

- Increased efficiency, which can translate to cost savings in the long run.

- Consistency in output quality, leading to higher satisfaction in usage.

By prioritizing regular maintenance, users can reap these benefits and ensure their tools remain reliable and efficient for years to come.