Understanding the Stihl KM 131 Parts Diagram for Better Maintenance

When it comes to maintaining your outdoor machinery, having a clear understanding of its components is essential. A well-organized representation of the various elements not only aids in effective repairs but also enhances overall performance. Whether you are a seasoned user or new to the world of landscaping tools, familiarizing yourself with the assembly can significantly improve your experience.

In this section, we delve into the intricate arrangement of parts that make up these powerful devices. By exploring the various sections and components, users can identify each piece’s function and the role it plays in the equipment’s operation. This knowledge empowers you to troubleshoot issues more efficiently and ensures that your tools remain in top-notch condition.

Additionally, understanding the structure can lead to informed decisions when it comes to replacements and upgrades. By gaining insight into the specifics, you can ensure that your outdoor equipment is equipped with the right features for your unique needs. This guide will serve as a valuable resource for anyone looking to optimize their machinery’s performance.

Understanding Stihl KM 131 Components

Exploring the intricacies of a versatile tool requires an understanding of its various elements. Each component plays a vital role in ensuring efficiency and effectiveness during operation. Familiarity with these elements not only aids in maintenance but also enhances performance.

Key Elements of the Tool

- Engine: The powerhouse that drives the machine, providing the necessary energy for operation.

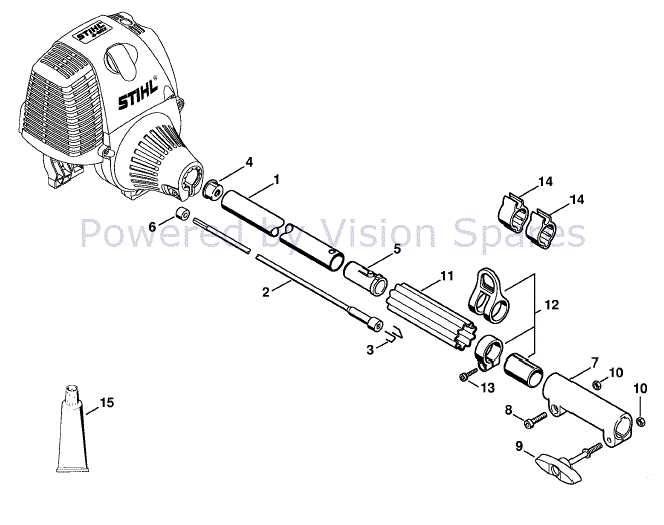

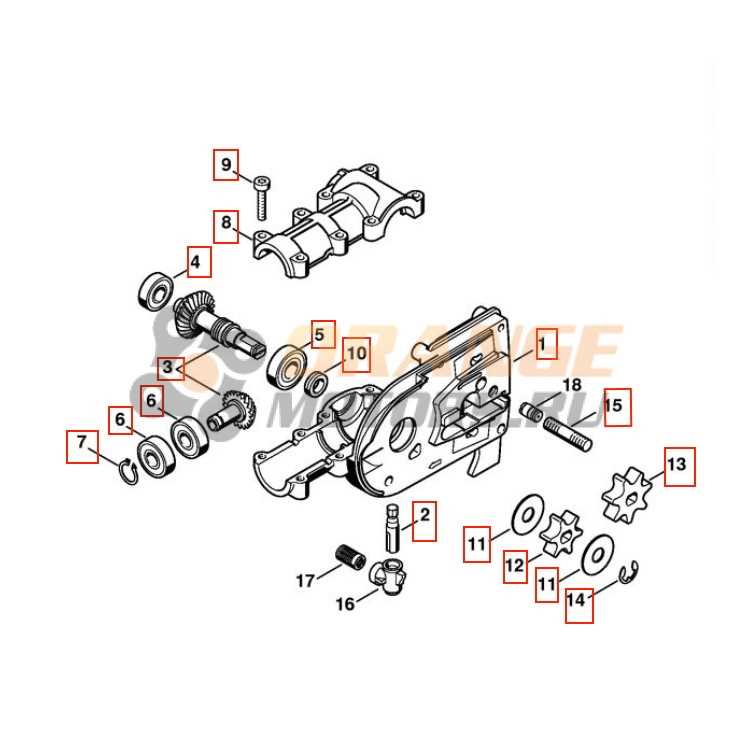

- Drive Shaft: A crucial link that transmits power from the engine to the working attachments.

- Attachment Coupler: The interface that allows for easy interchangeability of various accessories.

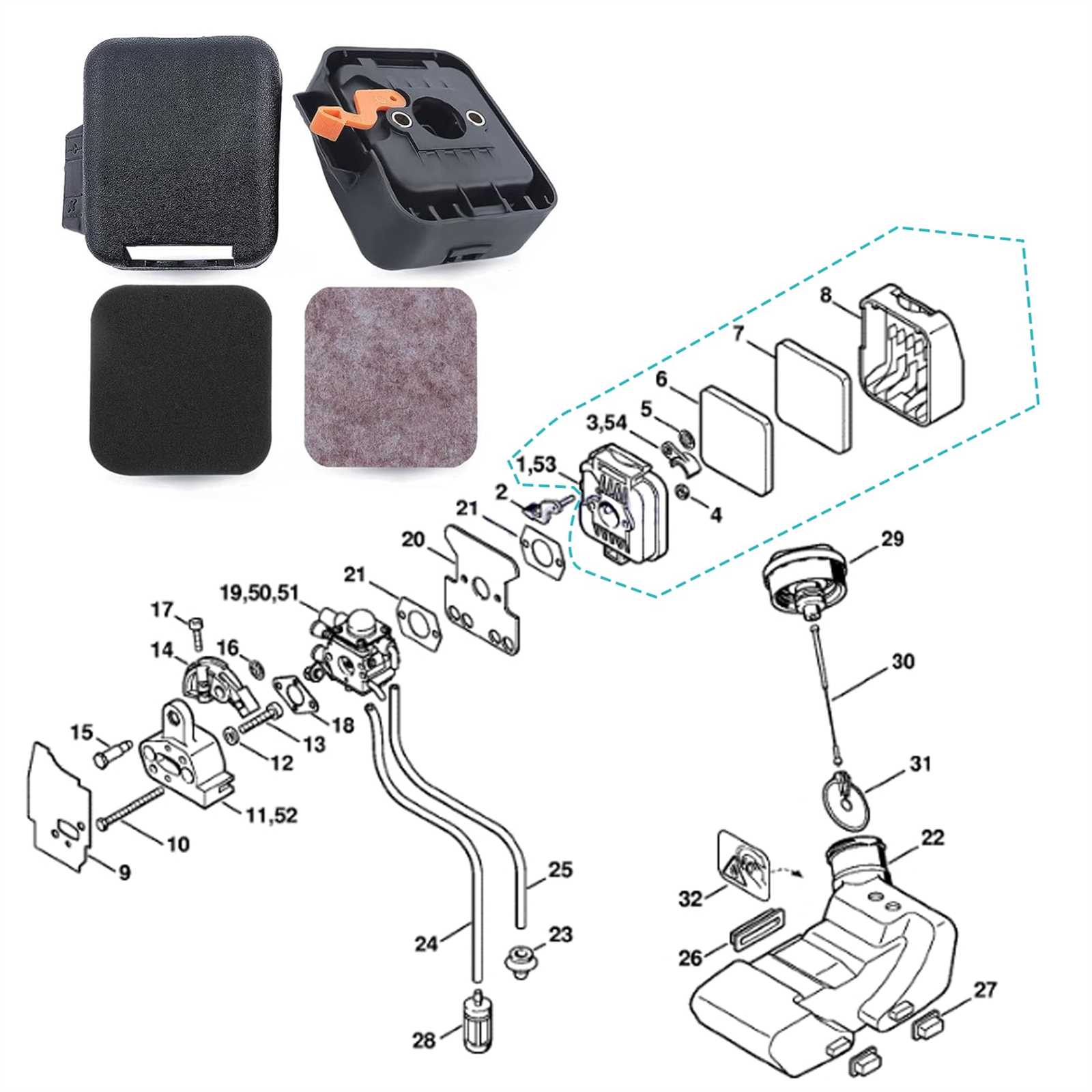

- Air Filter: Essential for maintaining engine efficiency by preventing dust and debris from entering.

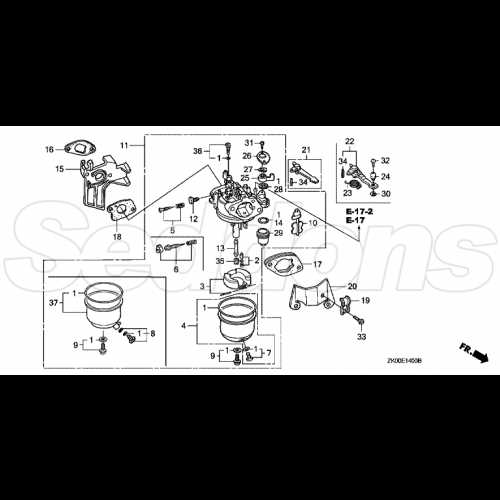

- Fuel System: Responsible for delivering the appropriate mixture to the engine for combustion.

Maintenance Considerations

- Regularly check the air filter for clogs to ensure optimal airflow.

- Inspect the drive shaft for any signs of wear or damage.

- Keep the fuel system clean to avoid performance issues.

- Ensure that all couplers are securely attached to prevent accidents during use.

- Follow manufacturer guidelines for engine maintenance to extend the lifespan of the tool.

Understanding these components and their functions is crucial for anyone looking to maximize the performance and longevity of their equipment. Proper care and attention to each part can lead to more efficient and effective use in various tasks.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements provide clarity, helping users identify and locate each part quickly. This knowledge enhances the overall efficiency of servicing equipment.

Benefits of Visual Representation

- Enhanced Clarity: Visual aids simplify complex systems, making it easier for users to grasp the arrangement and function of each element.

- Efficient Troubleshooting: Identifying issues becomes more straightforward when one can reference a visual guide, leading to faster resolutions.

- Accurate Assembly: Proper reassembly is facilitated, reducing the risk of errors during maintenance or repair.

Facilitating Training and Knowledge Transfer

- Visual tools are invaluable for training new technicians, providing a clear roadmap of the system.

- They serve as reference materials, aiding experienced professionals in refreshing their knowledge.

- Effective communication of technical information is achieved, bridging gaps between users and technical support.

How to Access the Diagram

To locate the schematic representation of your equipment, you need to follow a series of steps that will guide you through the process. This visual guide is essential for understanding the components and their arrangements, which is crucial for maintenance and repair tasks.

Online Resources

The first place to check is the manufacturer’s official website. They often provide downloadable resources that include schematics. Look for a section dedicated to support or documentation, where you can enter your model number to find the relevant visuals.

User Manuals and Guides

Another useful source is the user manual that came with your device. These manuals typically contain detailed illustrations that help identify parts and their functions. If you don’t have a physical copy, many companies offer digital versions on their websites.

In addition, community forums and discussion boards can be valuable. Enthusiasts and experts often share resources and links that can lead you to the specific illustrations you need. Don’t hesitate to engage with the community to find the information you’re looking for.

Key Features of the KM 131

The versatile power tool offers an array of impressive characteristics that enhance its performance and user experience. Designed for both professionals and hobbyists, this equipment is engineered to handle a variety of outdoor tasks with ease and efficiency.

Engine Performance

Equipped with a robust engine, this model delivers high power output while maintaining fuel efficiency. Its design ensures:

- Strong torque for demanding tasks

- Reduced emissions for environmentally friendly operation

- Reliable starting mechanism for convenience

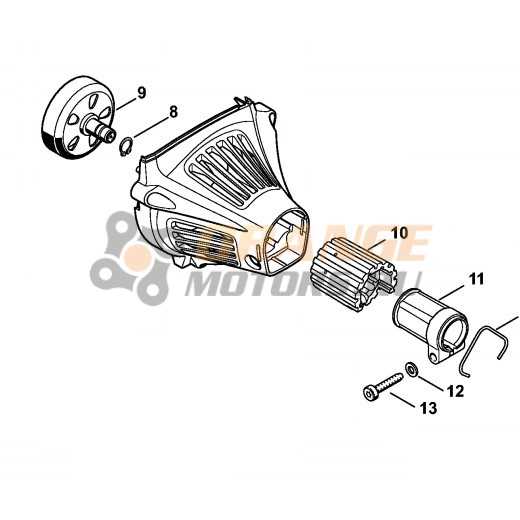

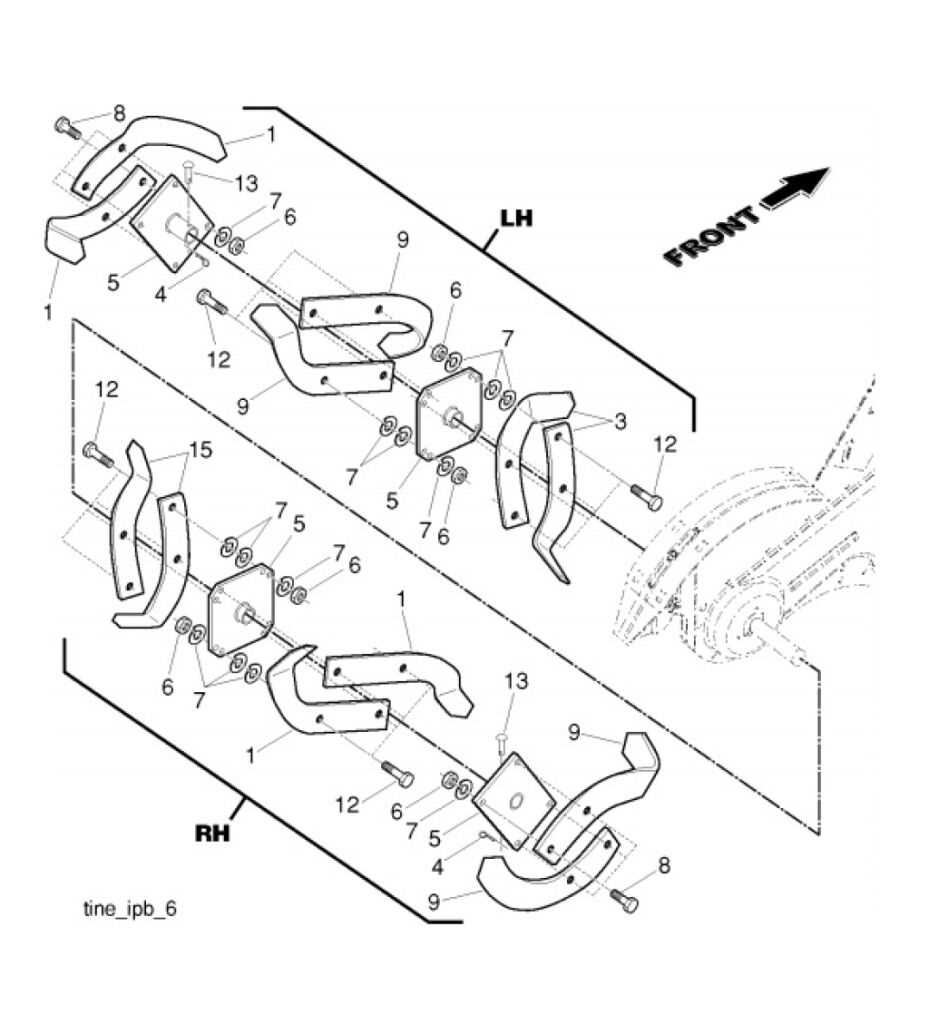

Interchangeable Attachments

The flexibility of this tool is one of its standout features. Users can quickly switch between different attachments to accomplish various tasks. Some popular options include:

- String trimmers for precise grass cutting

- Hedge trimmers for maintaining shrubs

- Blowers for clearing debris

This adaptability allows users to optimize their workflow and save time during yard work.

Common Replacement Parts Explained

Understanding the various components that may need to be replaced can enhance the longevity and performance of your outdoor equipment. Regular maintenance often involves addressing wear and tear on specific elements, ensuring your machine operates efficiently.

Below are some frequently replaced components and their functions:

- Filters:

- Air Filter: Prevents dirt and debris from entering the engine, promoting optimal performance.

- Fuel Filter: Keeps contaminants from clogging the fuel system, ensuring smooth operation.

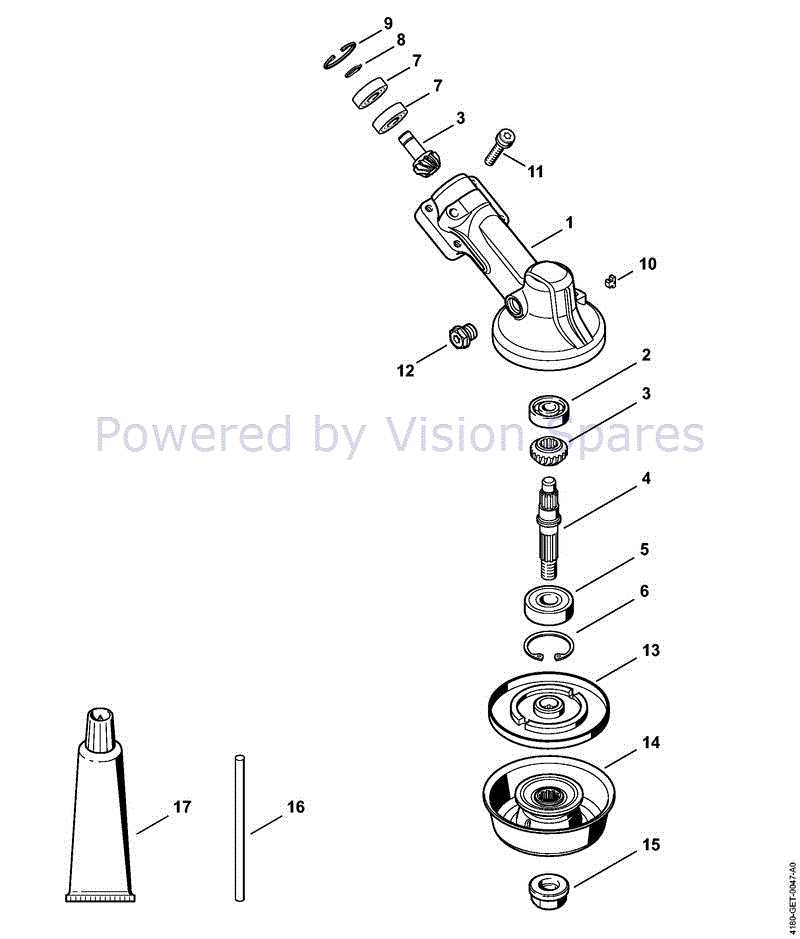

- Blades and Trimmers:

- Cutting Blades: Essential for maintaining a clean cut in grass and shrubs.

- Trimmer Heads: Allow for various cutting attachments, enhancing versatility.

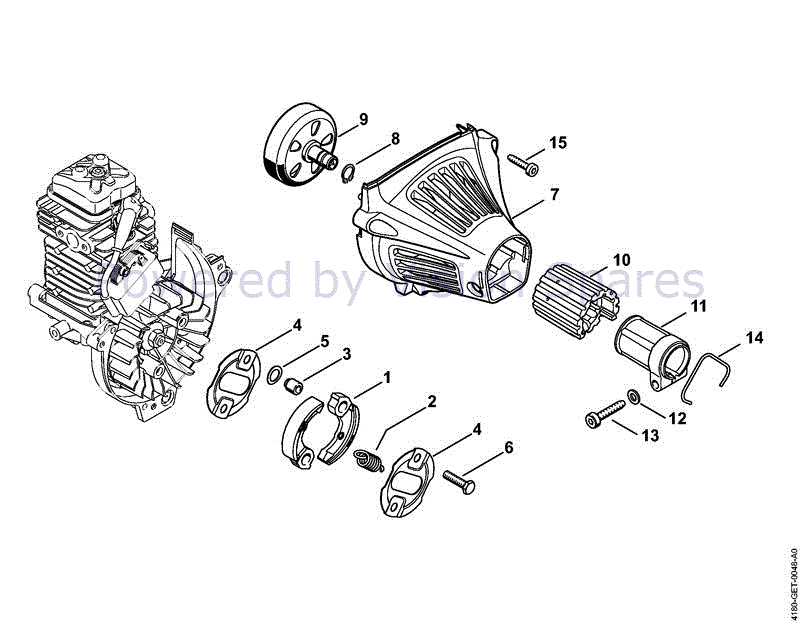

- Drive Components:

- Belts: Transfer power from the engine to the cutting mechanism, vital for functionality.

- Clutches: Engage and disengage the drive system, providing control during operation.

- Fuel System Parts:

- Carburetors: Mix air and fuel for combustion, crucial for engine performance.

- Hoses: Transport fuel from the tank to the engine, requiring regular inspection for leaks.

Being familiar with these components can help in recognizing when maintenance is needed, ultimately contributing to the effective functioning of your equipment.

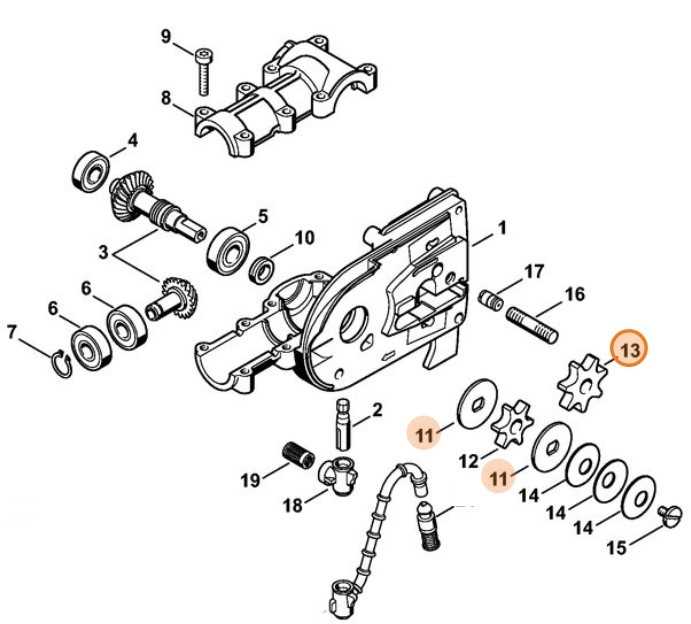

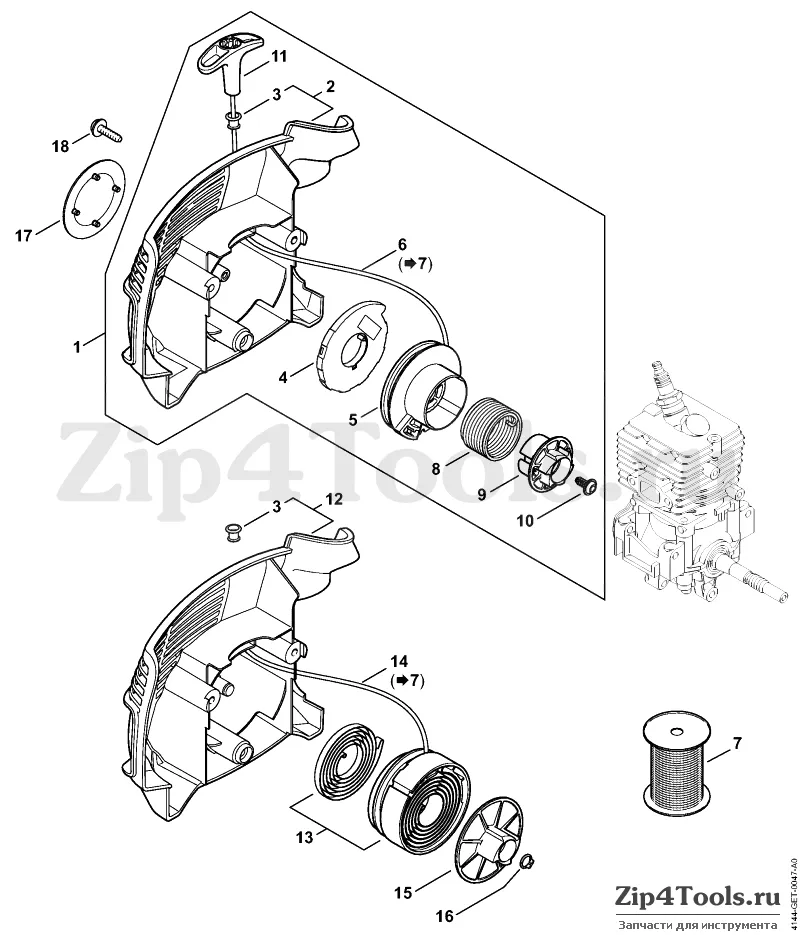

Identifying Parts by Number

Understanding how to recognize components through their numerical identifiers is essential for effective maintenance and repair. Each item is typically associated with a unique code that facilitates the identification process, ensuring that users can find the right replacement or accessory swiftly.

Importance of Accurate Identification

Accurate recognition of components not only streamlines the repair process but also enhances the performance of the equipment. Knowing the specific number allows for the selection of compatible items, reducing the risk of errors and improving overall efficiency. Additionally, this knowledge can save time and resources during maintenance tasks.

How to Use Part Numbers

To utilize numerical identifiers effectively, one should refer to the manufacturer’s reference materials, which often provide a comprehensive list of items alongside their corresponding codes. It’s advisable to cross-check these numbers when searching for replacements to ensure compatibility. Online databases and retailers frequently offer searchable catalogs that can assist users in locating the desired components swiftly.

Tools for Maintenance and Repairs

Proper upkeep and repair of equipment require a specific set of instruments that ensure efficiency and longevity. These tools not only facilitate routine checks but also allow for more extensive servicing when needed. Understanding which implements to use can greatly enhance the performance and reliability of your machinery.

Essential Instruments

Key tools for maintenance include wrenches, screwdrivers, and pliers, which are vital for making adjustments and replacements. Lubrication equipment, such as grease guns and oil cans, helps maintain optimal function and prevents wear. Additionally, having cleaning supplies on hand ensures that your equipment remains free of debris and operates smoothly.

Specialized Equipment

In more complex scenarios, specialized tools like torque wrenches and diagnostic devices become necessary. These instruments provide precise measurements and insights into the condition of various components, enabling more informed repair decisions. Investing in quality tools can lead to more effective maintenance practices, ultimately extending the lifespan of your machinery.

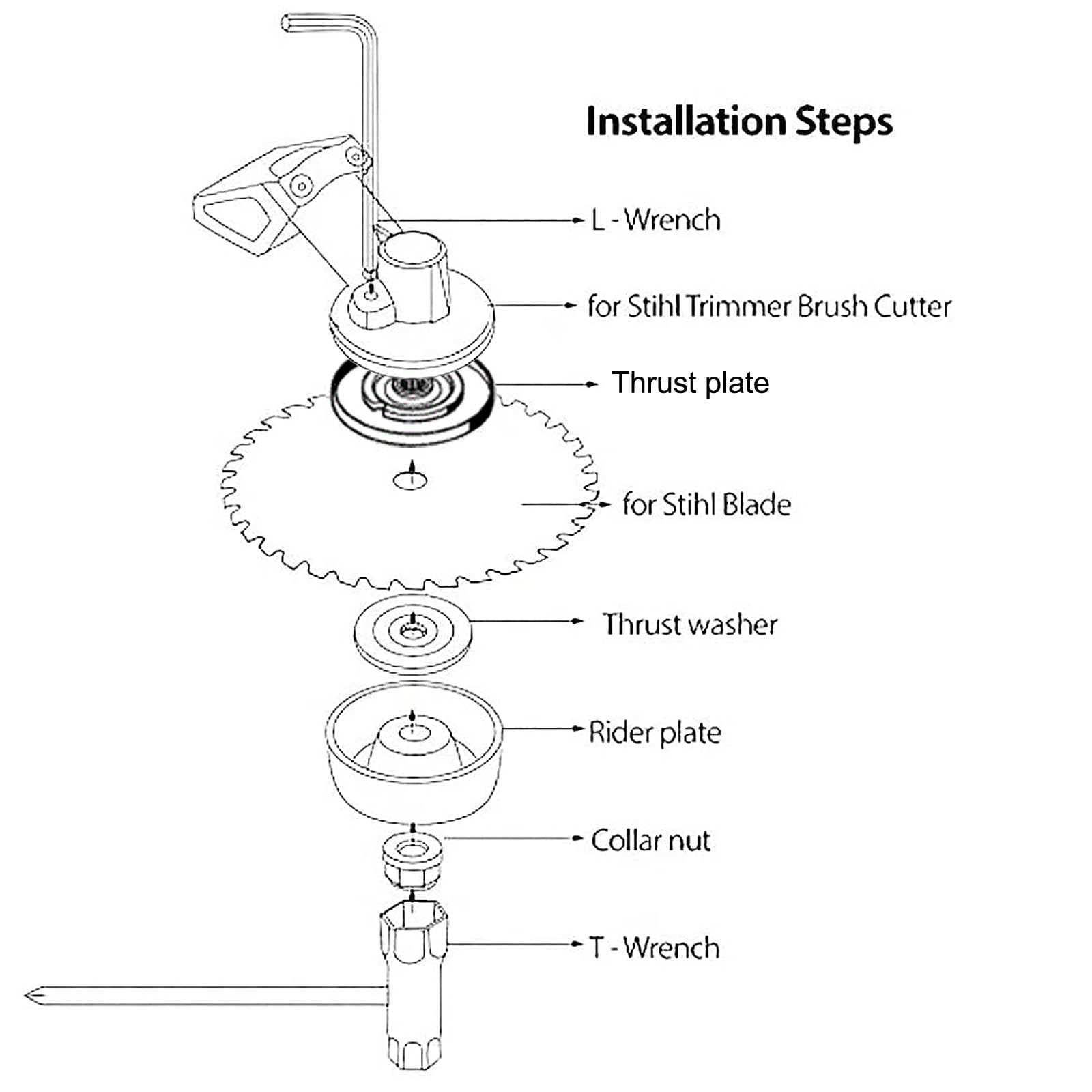

Assembly Instructions for Users

This section provides essential guidance for users to effectively piece together components of the equipment. Following a systematic approach ensures optimal performance and longevity of the machine.

Preparation Steps

Before starting the assembly, gather all necessary tools and components. Ensure that the work area is clean and well-lit to facilitate an efficient workflow.

Assembly Process

Follow the steps outlined in the table below for a successful assembly:

| Step | Description |

|---|---|

| 1 | Begin by connecting the main body to the support frame securely. |

| 2 | Attach the power unit to the designated slot, ensuring proper alignment. |

| 3 | Fasten all screws and bolts to prevent any loose components during operation. |

| 4 | Connect additional accessories as per the user manual guidelines. |

| 5 | Conduct a thorough inspection to confirm all parts are securely attached. |

Adhering to these instructions will help achieve the best results and ensure safe operation of the equipment.

Tips for Ordering Parts Online

When looking to acquire components for your equipment, navigating the online marketplace can be both convenient and overwhelming. To ensure a smooth experience, consider a few essential guidelines that can lead to the ultimate satisfaction with your purchase.

| Tip | Description |

|---|---|

| Research | Investigate various vendors to compare prices and reviews. |

| Compatibility | Verify that the item matches your machine’s specifications. |

| Shipping Options | Examine delivery times and costs to find the best option. |

| Return Policy | Check the vendor’s return policy in case the product is not suitable. |

| Customer Support | Ensure that assistance is available should you encounter issues. |

Signs Your Equipment Needs Repair

Recognizing when your machinery is in need of attention is crucial for maintaining efficiency and safety. Certain indicators can suggest that it’s time to assess your tools for potential issues. Ignoring these signs may lead to further damage or reduced performance.

- Unusual Noises: Listen for grinding, rattling, or other abnormal sounds during operation.

- Decreased Performance: Noticeable drops in power or speed can signal underlying problems.

- Vibrations: Excessive shaking or vibrations may indicate loose components or misalignment.

- Fluid Leaks: Any signs of leaking oil or fuel can point to seal or gasket failures.

- Overheating: Equipment that frequently overheats may have cooling system issues or airflow blockages.

Regular maintenance checks can help catch these issues early, ensuring your tools continue to operate effectively and safely.

Comparing KM 131 with Other Models

When evaluating various outdoor power tools, it’s essential to assess their performance, features, and compatibility. Different models serve unique purposes, and understanding these distinctions can guide users in making informed choices.

| Feature | Model A | Model B | Current Model |

|---|---|---|---|

| Engine Power | 25cc | 30cc | 27cc |

| Weight | 8.5 lbs | 9.0 lbs | 8.8 lbs |

| Fuel Efficiency | Excellent | Good | Very Good |

| Attachments | Limited | Versatile | Highly Versatile |

By comparing specifications, users can better understand which tool aligns with their specific needs and preferences, ultimately optimizing their outdoor tasks.

Frequently Asked Questions about Parts

This section aims to address common inquiries regarding components and their maintenance for outdoor equipment. Understanding these elements can enhance your experience and prolong the life of your tools.

How do I identify the right component for my equipment?

To pinpoint the correct component, refer to the user manual or the manufacturer’s website, which often provide detailed specifications and model numbers. Additionally, online forums and communities can offer valuable insights from fellow users.

What should I consider when replacing a component?

When replacing a component, assess the quality and compatibility with your existing equipment. Opt for reputable brands to ensure durability and performance, and consult with experts if you’re unsure about the specifications.

Finding a Reliable Parts Supplier

When it comes to sourcing components for your outdoor equipment, identifying a trustworthy supplier is crucial. A reliable vendor not only provides high-quality items but also ensures that you receive the necessary support throughout your purchasing journey. This can significantly impact the longevity and performance of your machinery.

Researching Suppliers

Start by exploring online reviews and testimonials to gauge the reputation of various vendors. Engaging with communities, such as forums or social media groups, can also yield valuable insights. Look for suppliers that offer a wide range of options, as this indicates their commitment to meeting diverse customer needs.

Evaluating Quality and Service

Once you have a list of potential suppliers, assess the quality of their offerings. Inquire about warranties and return policies, as these are good indicators of a company’s reliability. Additionally, prioritize those who provide exceptional customer service, as they will be more likely to assist you should any issues arise.