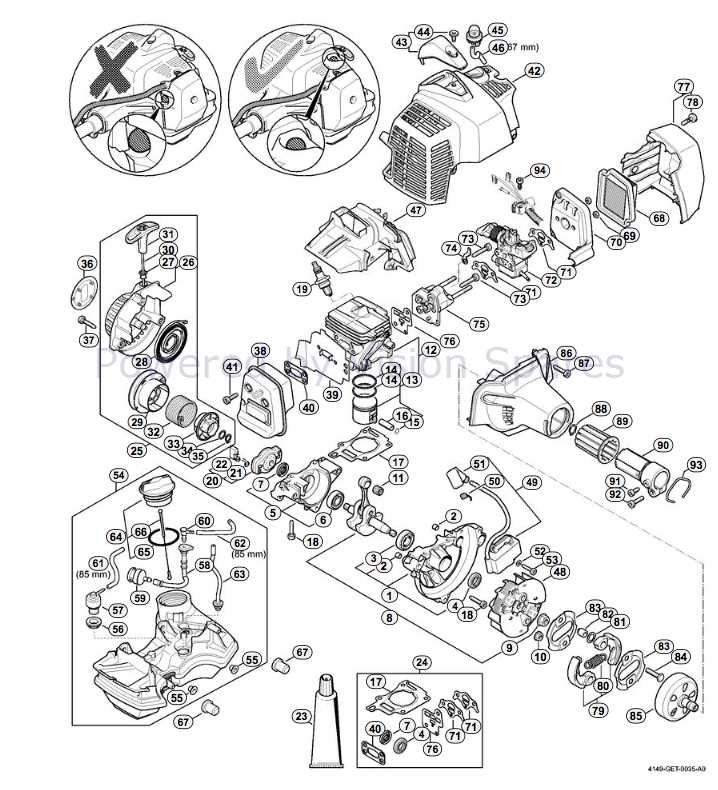

Complete Parts Diagram for Stihl KM 55 RC

Maintaining the efficiency of your outdoor equipment relies heavily on a thorough comprehension of its individual elements. Each component plays a vital role in ensuring optimal performance, whether it’s for trimming, edging, or various other gardening tasks. A clear visualization of these elements can significantly enhance your understanding and facilitate effective upkeep.

By delving into the intricate relationships between these parts, users can better diagnose issues, perform repairs, and even upgrade their machines. This knowledge empowers you to take control of your maintenance routine, ensuring that your gardening tool remains in peak condition.

In this section, we will explore the layout and functionality of each essential piece. A well-organized representation of these components will serve as a valuable resource for both novice and experienced users, allowing for informed decisions in repair and enhancement processes. Embrace the opportunity to familiarize yourself with your equipment’s inner workings for a more productive gardening experience.

Understanding Stihl KM 55 RC Parts

When delving into the components of a versatile gardening tool, it’s essential to grasp how each element contributes to its overall functionality. This understanding aids users in maintaining and optimizing performance, ensuring longevity and efficiency during operation.

Each segment plays a vital role, whether it’s the engine that powers the device or the various attachments that enhance its capabilities. Recognizing the function of each piece can simplify troubleshooting and facilitate effective repairs, allowing for a smoother experience in garden care tasks.

Moreover, familiarizing oneself with the construction and arrangement of these elements can help users make informed decisions about upgrades or replacements. Proper knowledge ensures that the tool operates at peak performance, meeting the diverse needs of both casual gardeners and professionals alike.

Ultimately, a comprehensive understanding of these components empowers users to maximize their gardening tool’s potential, fostering a more efficient and rewarding gardening experience.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations that detail individual elements not only enhance comprehension but also facilitate smoother troubleshooting processes. When users can easily identify each part, they can ensure proper functionality and longevity of the equipment.

Enhanced Communication

Clear illustrations serve as a universal language, bridging gaps between manufacturers and users. This clarity helps in communicating issues and solutions more effectively, minimizing misunderstandings during repairs.

Improved Efficiency

When technicians or users can quickly reference a visual guide, it accelerates the repair process. This efficiency is vital in reducing downtime, ultimately leading to better performance and satisfaction.

Overview of the KM 55 RC Model

The KM 55 RC model is a versatile tool designed for various outdoor tasks, making it a valuable addition to any gardening or landscaping toolkit. Its compact design and powerful performance allow users to tackle a range of jobs with ease, from trimming and mowing to clearing debris. This equipment is particularly suited for both professional landscapers and home gardeners who require reliability and efficiency.

Key Features

This model stands out due to its lightweight construction and user-friendly operation. It incorporates an innovative engine that ensures optimal power output while maintaining fuel efficiency. The design emphasizes ergonomic handling, allowing users to work for extended periods without discomfort. Additionally, its modular nature permits easy attachment of various tools, enhancing its functionality.

Applications

Ideal for a multitude of applications, the KM 55 RC excels in residential and commercial settings alike. Whether used for precision trimming around flower beds or clearing larger areas, its adaptability ensures that it meets the diverse needs of users. This tool is particularly effective in maintaining neat and tidy landscapes, providing excellent results with minimal effort.

Main Components of the Engine

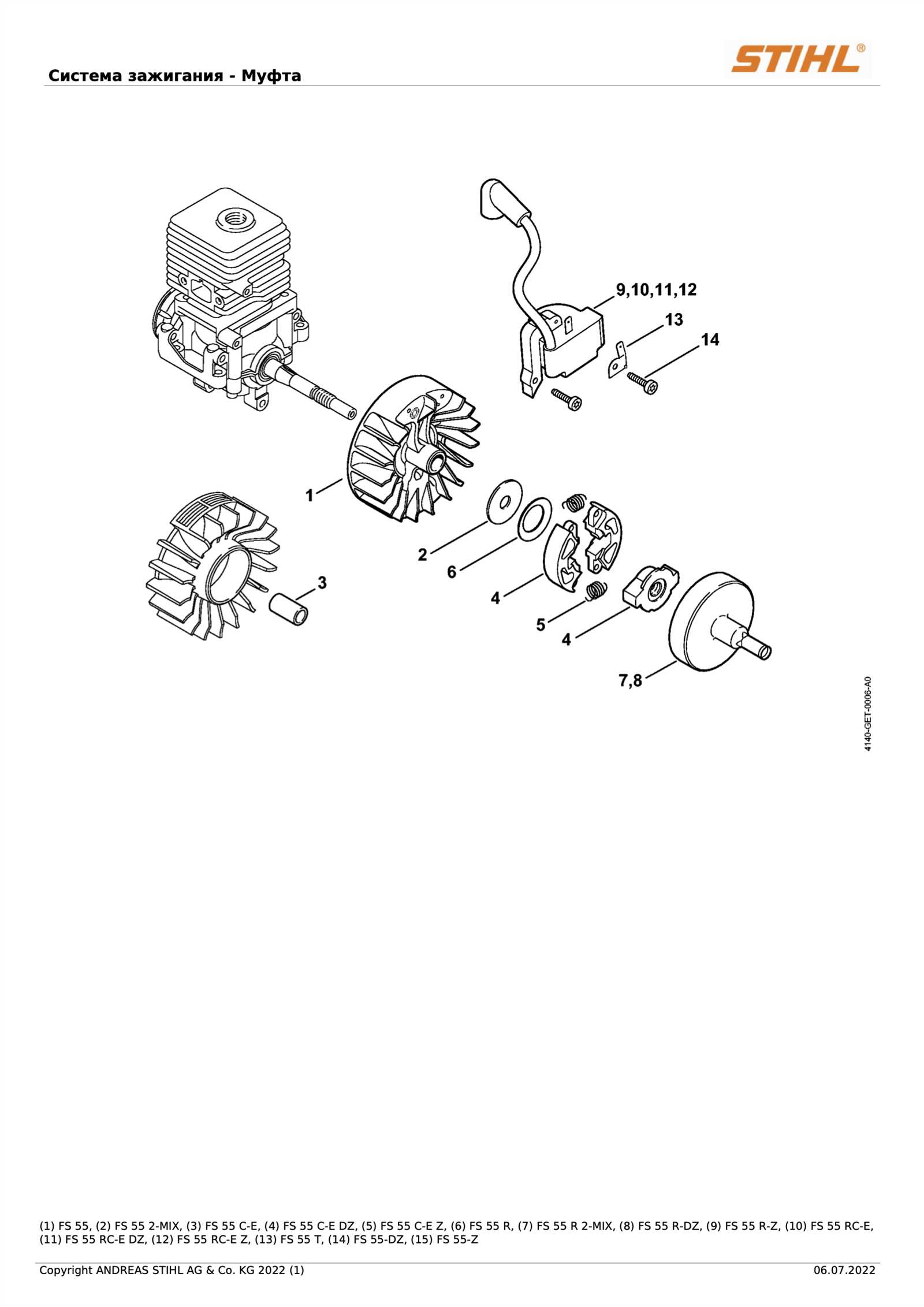

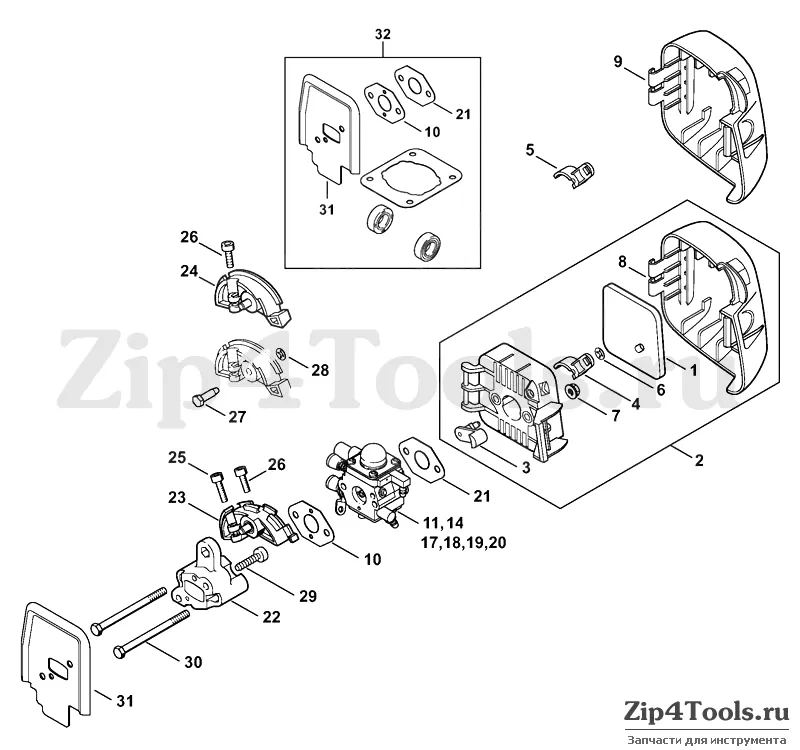

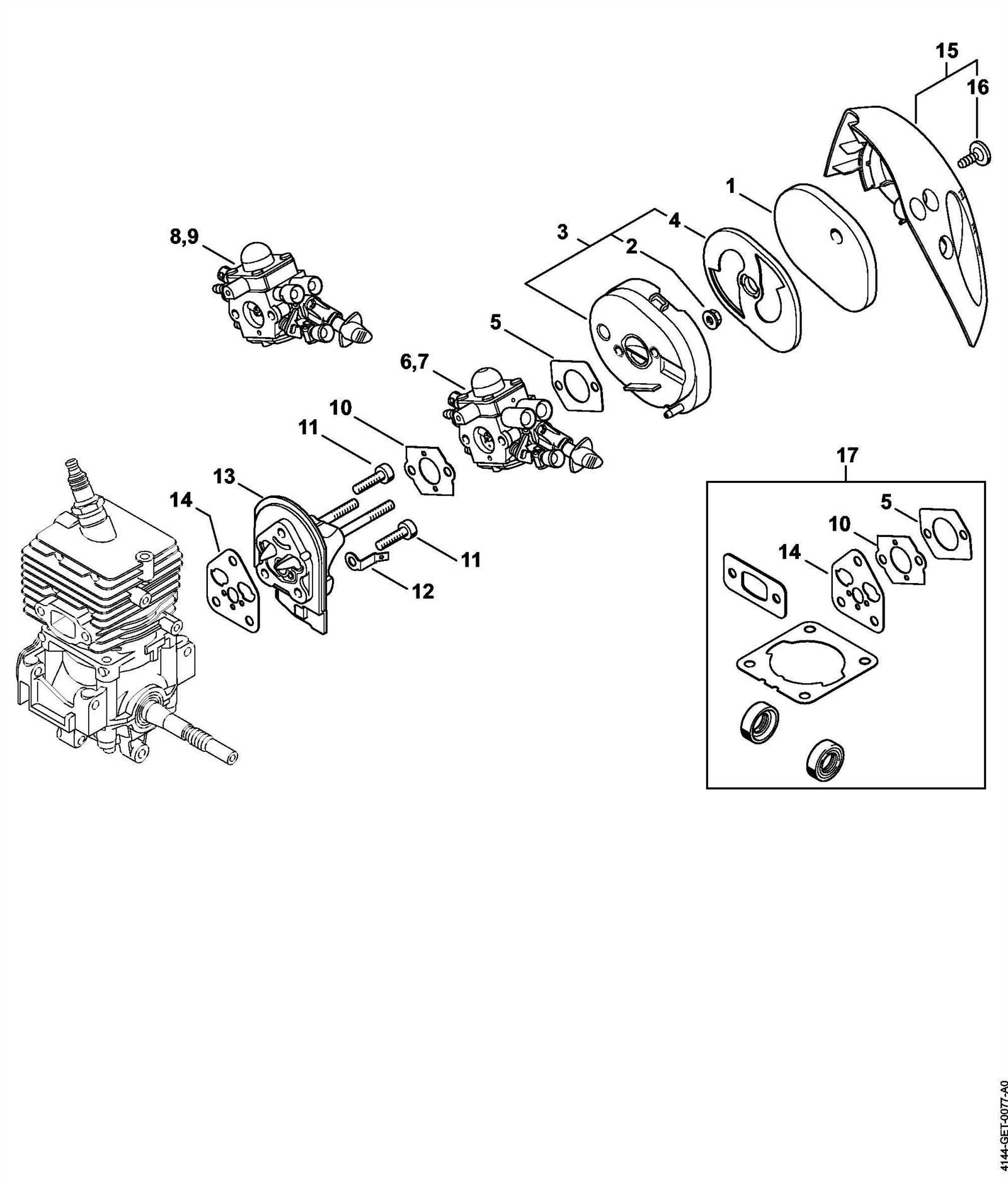

The engine serves as the heart of the machinery, driving its performance and efficiency. Understanding its main elements is crucial for maintenance and optimal operation.

Cylinder: The cylinder is where the fuel-air mixture ignites, creating the power needed for movement. Its design influences the engine’s capacity and efficiency.

Piston: This component moves within the cylinder, converting energy from combustion into mechanical work. Its smooth operation is vital for overall performance.

Crankshaft: The crankshaft transforms the piston’s linear motion into rotational force, enabling the machine to function effectively. A robust crankshaft is essential for durability.

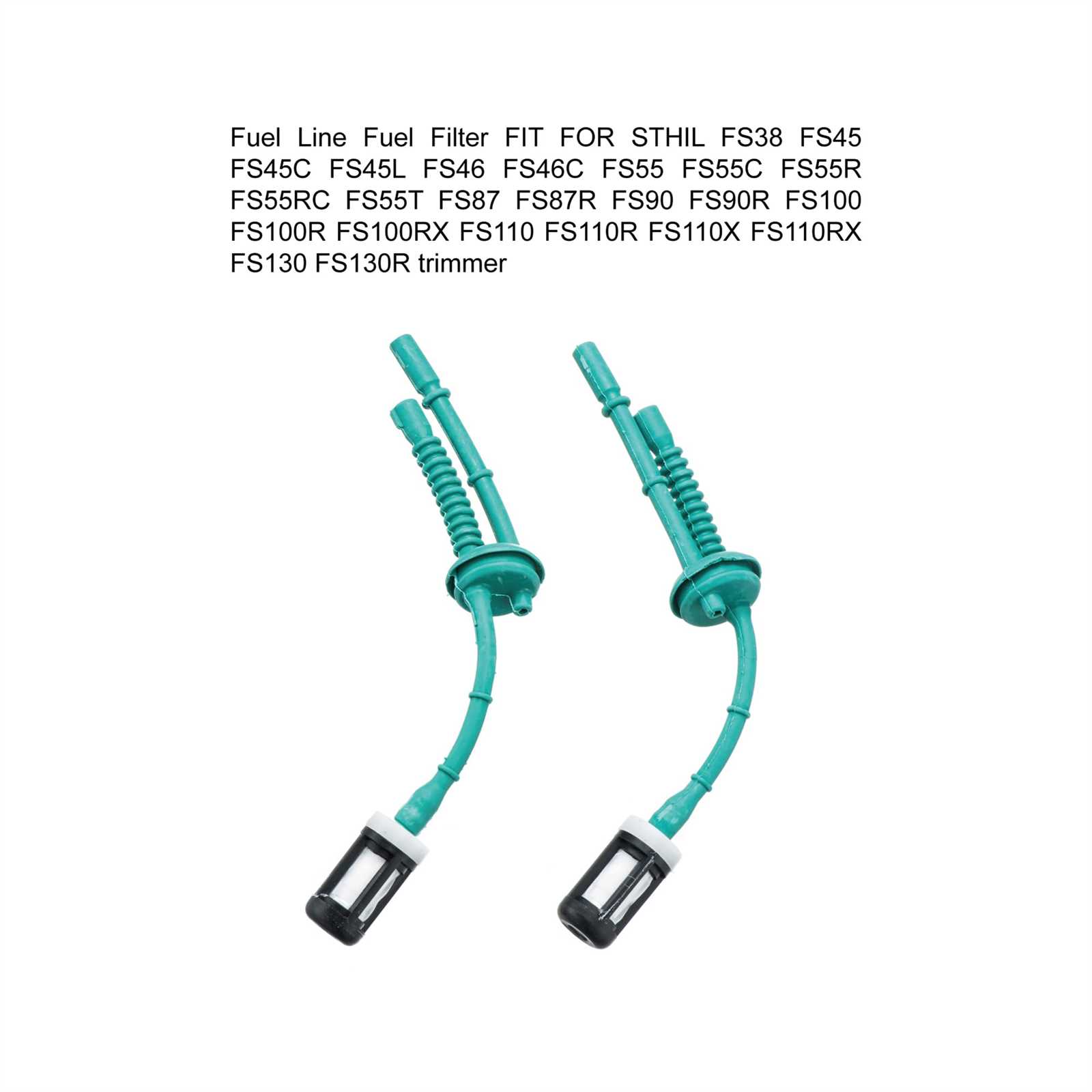

Fuel System: This system is responsible for delivering the right amount of fuel to the engine. It includes the tank, filter, and carburetor, each playing a key role in performance.

Ignition System: This component initiates combustion by generating a spark at the right moment. A reliable ignition system ensures smooth starts and efficient operation.

Cooling System: To prevent overheating, the cooling system dissipates excess heat generated during operation. Effective cooling is critical for maintaining engine longevity.

Each of these components works in harmony to ensure the engine operates at its ultimate potential, making regular checks and maintenance vital for longevity and performance.

Common Accessories for the KM 55

The versatility of the KM 55 allows users to enhance their experience with a variety of attachments and tools. These accessories expand functionality, making yard work and landscaping tasks more efficient and enjoyable.

Popular Attachments

- Brush Cutter

- Edger

- Hedge Trimmer

- Blower

Essential Add-ons

- Shoulder Strap

- Protective Gear

- Fuel Mixing Bottle

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires a consistent maintenance routine. Proper care not only enhances performance but also extends the lifespan of your machinery. By following a few essential practices, you can keep your tools operating efficiently for years to come.

Regular Cleaning

Keeping your device clean prevents buildup that can hinder functionality. Regularly removing debris and residues is crucial.

Routine Inspections

Frequent check-ups help identify wear and tear early. This proactive approach can save time and money on repairs.

| Maintenance Task | Frequency |

|---|---|

| Clean Filters | Every 10 hours of use |

| Inspect Cables | Weekly |

| Sharpen Blades | Monthly |

| Check Fuel System | Before each use |

Identifying Parts by Number

Understanding the components of a machine can enhance maintenance and repair efficiency. Each element is typically assigned a unique identifier, allowing users to easily locate and order replacements. By familiarizing oneself with these identifiers, one can ensure the longevity and optimal performance of the equipment.

Using Unique Identifiers

Unique identifiers serve as a crucial reference point. They often appear in manuals or online resources, enabling users to quickly find the specific components they need. This method streamlines the process of sourcing replacements, minimizing downtime and ensuring proper functionality.

Locating Resources

Many online platforms provide comprehensive listings of these unique identifiers. Utilizing these resources allows for efficient cross-referencing, ensuring that each component is accurately matched with its corresponding number. This ultimately aids in maintaining the integrity of the machine.

Where to Find Replacement Parts

Finding suitable components for your outdoor equipment can be crucial for maintaining optimal performance. Various resources are available to help you locate the necessary items, ensuring your tools remain in top condition.

Online Retailers

The internet offers a plethora of online shops specializing in outdoor equipment. Many of these retailers provide extensive catalogs and detailed descriptions, making it easier to find exactly what you need.

Local Dealers

Visiting local dealerships can also be beneficial. Knowledgeable staff can assist you in identifying the correct components and may even have them in stock, allowing for immediate replacement.

Comparing with Other Stihl Models

When evaluating various outdoor power tools from a well-known manufacturer, it’s essential to consider their similarities and differences. Each model caters to distinct needs and preferences, making the selection process intriguing. This section focuses on highlighting how one particular model stacks up against its counterparts in terms of functionality, efficiency, and design.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Weight | 10 lbs | 12 lbs | 9 lbs |

| Power Output | 1.5 kW | 1.8 kW | 1.3 kW |

| Fuel Type | Gas | Electric | Gas |

| Maximum Cutting Width | 16 inches | 18 inches | 14 inches |

By examining these specifications, users can determine which tool aligns best with their requirements, enabling them to make informed choices for their outdoor tasks.

Troubleshooting Common Issues

When working with outdoor power equipment, encountering problems is not uncommon. Recognizing and addressing these issues promptly can enhance performance and extend the life of your machinery. Below are some frequent challenges and their potential solutions to help you get back to work efficiently.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine won’t start | Fuel blockage, faulty spark plug, low battery | Check fuel lines, replace spark plug, recharge or replace battery |

| Overheating | Blocked air filter, low oil level, dirty cooling fins | Clean or replace air filter, check oil level, clear cooling fins |

| Unusual vibrations | Loose components, damaged blades, uneven wear | Tighten screws, inspect and replace blades, check for wear |

| Poor performance | Clogged fuel filter, old fuel, incorrect mixture | Replace fuel filter, use fresh fuel, ensure proper mixture ratio |

Assembly and Disassembly Guidelines

Understanding the procedures for assembling and disassembling your equipment is crucial for maintaining optimal performance and ensuring longevity. Proper techniques not only facilitate smoother operations but also prevent potential damage during the process. This section outlines the essential steps and precautions necessary for effective assembly and disassembly.

Preparation is key before you begin. Ensure that you have all necessary tools at hand, as well as a clean workspace to minimize the risk of losing small components. Wearing protective gear such as gloves and goggles can further safeguard you against any mishaps.

When disassembling, start by carefully removing any attachments. Take note of the order of removal and the orientation of each piece. It is beneficial to document these steps or take photographs, which can serve as a helpful reference during reassembly. Always consult the manufacturer’s recommendations for specific guidelines related to your model.

During assembly, follow the reverse order of disassembly. Ensure that all components fit snugly and are properly aligned. Pay attention to any locking mechanisms or clips, making sure they are securely fastened. After completing the assembly, perform a thorough inspection to confirm that everything is correctly positioned and tightened.

By adhering to these guidelines, you can effectively manage the assembly and disassembly of your equipment, enhancing its reliability and extending its lifespan.

Benefits of Using Genuine Parts

Utilizing authentic components ensures optimal performance and longevity of equipment. These high-quality pieces are specifically designed to fit seamlessly and work effectively, providing reliability that aftermarket alternatives often cannot match.

Enhanced Durability

Genuine components are manufactured with superior materials and precise engineering, leading to increased durability. This results in less frequent replacements and a more consistent user experience.

Improved Performance

When using authentic items, the machinery operates as intended, delivering better efficiency and effectiveness. Users can expect improved functionality and reduced risk of malfunctions.

| Feature | Genuine Components | Aftermarket Options |

|---|---|---|

| Quality | High-grade materials | Variable quality |

| Compatibility | Perfect fit | Potential misfit |

| Warranty | Often includes warranty | Limited or no warranty |