Comprehensive Guide to Stihl MS 171 Parts Diagram

When it comes to maintaining outdoor power equipment, having a clear understanding of its internal structure is essential. Each element plays a pivotal role in the overall performance and reliability of the tool. By familiarizing yourself with these components, you can ensure optimal functionality and longevity of your device.

Visualizing the assembly of your chainsaw is crucial for effective maintenance and repair. A detailed representation of the various segments allows users to identify specific parts and understand their interconnections. This knowledge not only aids in troubleshooting but also empowers users to conduct repairs with confidence.

Whether you are a seasoned professional or a weekend warrior, knowing the intricate details of your chainsaw’s design can enhance your experience. Empower yourself with the right information to keep your equipment in peak condition, ensuring that it serves you well during those demanding tasks in the great outdoors.

Understanding the Stihl MS 171

This section delves into the essential components and functionalities of a popular power tool, emphasizing its design, usage, and maintenance. Gaining insight into these elements can significantly enhance user experience and tool longevity.

Key aspects to consider include:

- Engine specifications and performance

- Cutting capabilities and chain options

- Ergonomic design and user comfort

- Maintenance requirements for optimal operation

By comprehensively understanding these features, users can make informed decisions regarding their tool’s operation and care.

Common features that contribute to its effectiveness:

- Power-to-weight ratio for easier handling

- Fuel efficiency to extend operational time

- Safety features to prevent accidents

- Durability of materials used in construction

Ultimately, familiarizing oneself with these elements fosters not only efficiency but also safety during use.

Key Features of the Chainsaw

The chainsaw is a versatile and powerful tool designed for cutting and trimming tasks in various environments. Its design and functionality cater to the needs of both professionals and hobbyists, making it an essential asset for anyone involved in forestry, landscaping, or home maintenance. Understanding the key attributes of this equipment can help users maximize its efficiency and safety during operation.

Engine and Performance

The heart of any chainsaw is its engine, which plays a crucial role in determining the tool’s power and efficiency. Typically, these machines feature two-stroke engines that provide a high power-to-weight ratio, ensuring optimal performance without unnecessary bulk. Moreover, advanced models incorporate features that enhance fuel efficiency and reduce emissions, promoting environmental sustainability.

Safety Features

Safety is paramount when using cutting tools. Modern chainsaws are equipped with several safety mechanisms to protect the user. These include chain brakes, which stop the chain rapidly in case of kickback, and anti-vibration systems that minimize fatigue during prolonged use. Additionally, many models offer ergonomic handles designed to improve grip and control, further enhancing user safety.

| Feature | Description |

|---|---|

| Engine Type | Two-stroke for high power and efficiency |

| Fuel Efficiency | Optimized for reduced fuel consumption |

| Chain Brake | Quickly stops the chain during kickback |

| Anti-Vibration | Reduces operator fatigue during use |

| Ergonomic Handles | Enhances grip and control |

Importance of Parts Diagrams

Understanding the intricate components of any mechanical device is crucial for effective maintenance and repair. Visual representations that detail the individual elements and their relationships serve as essential guides for users, enhancing their ability to troubleshoot and resolve issues efficiently.

Clarity in identifying various components allows technicians and enthusiasts alike to grasp the assembly and functionality of the machine. By providing a comprehensive overview, these illustrations facilitate a deeper understanding of how each part contributes to overall performance.

Moreover, these visuals play a vital role in communication between users and service professionals. When discussing repairs or replacements, having a clear reference can minimize misunderstandings and ensure that the right components are targeted for attention.

Lastly, using such illustrations can significantly enhance efficiency during the repair process. By following a structured layout, users can systematically approach disassembly and reassembly, reducing the likelihood of errors and saving valuable time.

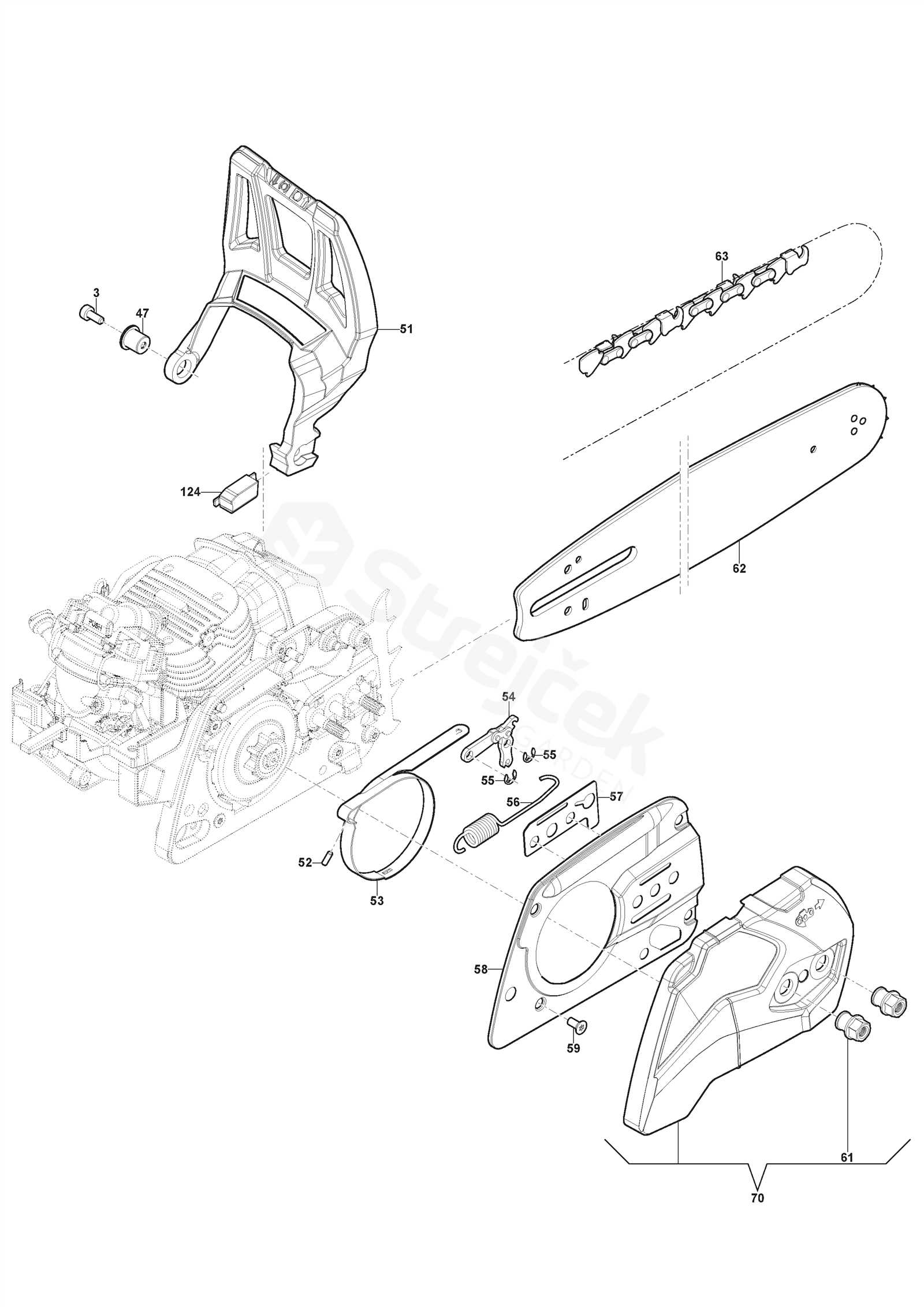

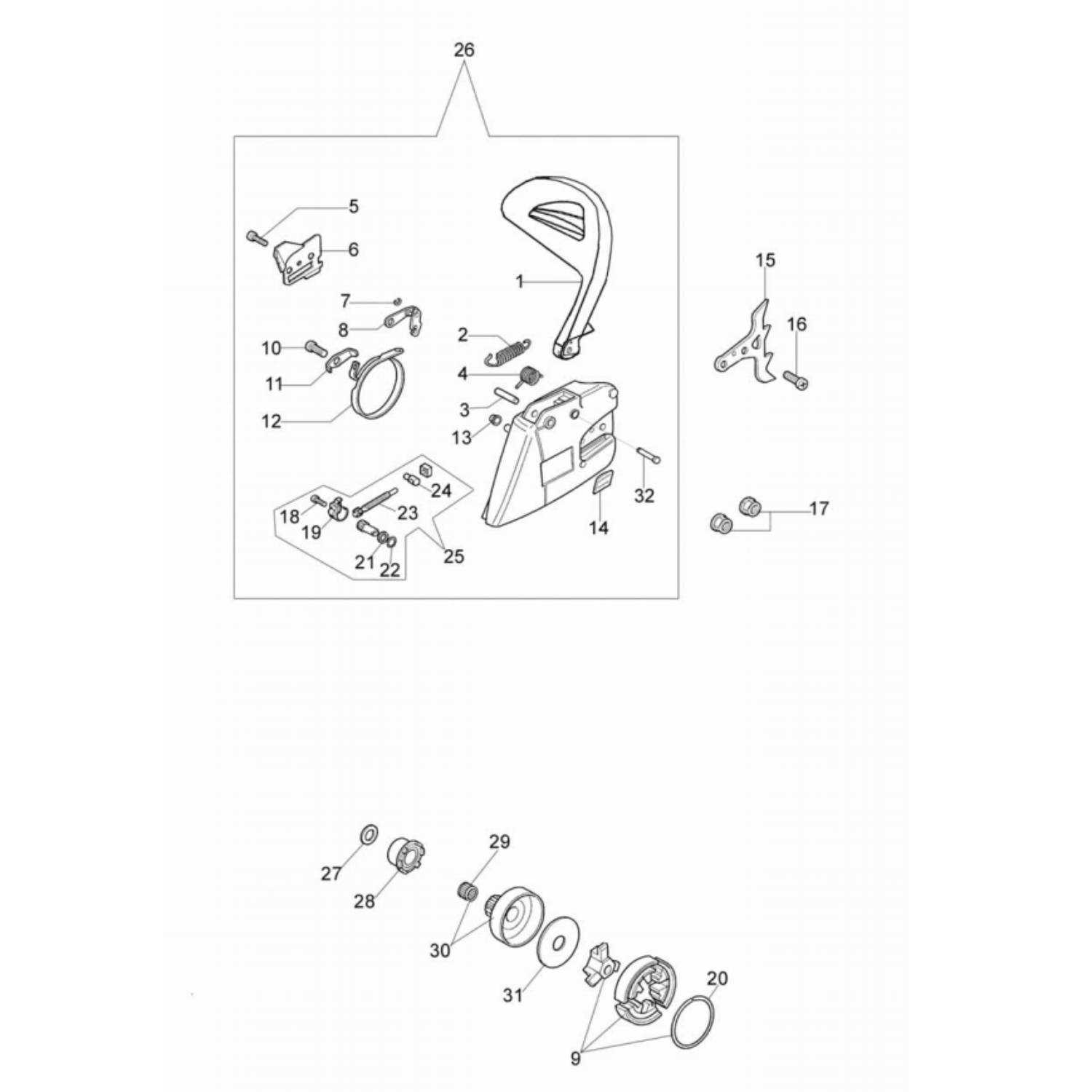

Identifying Components in Diagrams

Understanding the layout of machinery is crucial for effective maintenance and repair. By analyzing visual representations, one can identify essential elements and their functions. This knowledge is key to troubleshooting issues and ensuring optimal performance.

When examining these illustrations, it’s important to recognize various features and their interconnections. Below is a table summarizing common components you might encounter and their typical roles:

| Component | Description |

|---|---|

| Engine | The power source that drives the equipment. |

| Fuel Tank | Holds the fuel needed for operation. |

| Air Filter | Prevents debris from entering the engine. |

| Cylinder | Where the combustion process occurs. |

| Chain | Connects various components to facilitate movement. |

| Handle | Provides grip and control during use. |

Familiarity with these parts enhances understanding of how the machinery operates, leading to more effective maintenance practices.

Common Issues and Solutions

Understanding potential challenges that may arise during the operation of your equipment is essential for maintaining its efficiency. By identifying common problems and their remedies, users can ensure smooth performance and prolong the lifespan of their tools.

Engine Starts but Fails to Operate

If the engine starts but doesn’t run smoothly, check for fuel issues, such as stale gasoline or improper mixture. Additionally, inspect the air filter for clogs, as a dirty filter can hinder airflow. Cleaning or replacing these components often resolves the issue.

Excessive Vibration During Use

Experiencing unusual vibrations can indicate loose or damaged parts. First, examine the attachment components for secure fitment. If the problem persists, inspect the drive system for wear and tear, as faulty components may require replacement to restore stability.

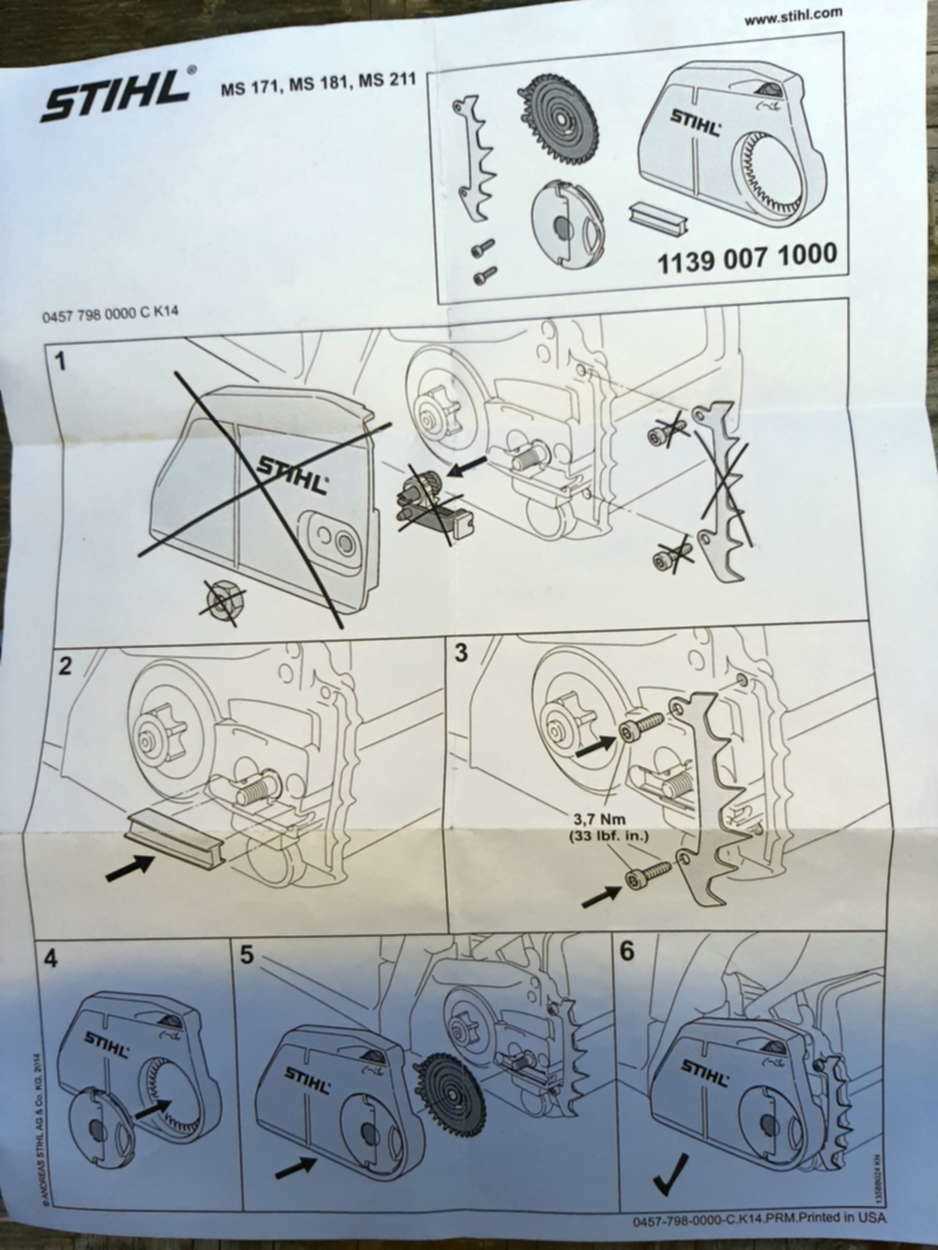

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. These illustrations serve as a visual guide, helping you identify and locate individual elements within a complex assembly. By familiarizing yourself with the layout and symbols used, you can enhance your troubleshooting skills and streamline your repair process.

Here are some key points to consider when interpreting these visual guides:

- Identify Sections: Typically, these illustrations are divided into sections, each representing different areas of the machine. Familiarize yourself with these divisions to navigate the image more easily.

- Legend and Symbols: Look for a legend or key that explains various symbols used in the illustration. Understanding these can clarify the function and relation of each component.

- Component Numbers: Pay attention to the numbering system, which usually corresponds to a list of items. This list can provide additional information such as part names and specifications.

- Assembly Order: Some schematics may indicate the order of assembly, helping you understand how components fit together and the sequence in which they should be assembled or disassembled.

- Contextual Clues: Observe surrounding components and their connections. This context can offer insights into how each piece interacts with others, which is crucial for effective repairs.

By practicing these tips, you can develop a deeper understanding of these visual aids, ultimately leading to more efficient maintenance and repairs.

Maintenance Tips for Stihl MS 171

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns. Here are some practical tips to keep your tool in excellent working condition.

- Regular Cleaning: After each use, clean the exterior to remove dirt, sap, and debris. Pay special attention to air filters and cooling fins.

- Check the Chain: Inspect the cutting chain for wear and tear. Sharpen it regularly and replace it when necessary to ensure effective cutting.

- Oil Levels: Regularly check the oil reservoir to maintain proper lubrication of the chain. Always use the recommended type of oil.

- Inspect the Spark Plug: Examine the spark plug for carbon buildup. Clean or replace it as needed to ensure efficient ignition.

Following these maintenance steps will help prolong the life of your tool and ensure it operates at its best. Implement a regular schedule to perform these checks, and you’ll be rewarded with reliable performance during every use.

Where to Find Replacement Parts

Locating suitable components for your equipment can enhance its performance and longevity. Whether you’re looking to replace worn-out items or upgrade your machine, various resources can help you find exactly what you need.

Here are some reliable sources for sourcing necessary items:

| Source | Description |

|---|---|

| Authorized Dealers | These retailers provide genuine components and expert advice, ensuring compatibility and quality. |

| Online Marketplaces | Platforms like eBay or Amazon often have a vast selection, allowing you to compare prices and find the best deals. |

| Local Hardware Stores | Many community shops stock common items and can offer personalized service and recommendations. |

| Manufacturer’s Website | The official site typically features a catalog of available components and may offer direct purchasing options. |

| Specialty Shops | Stores focused on outdoor equipment may have a more comprehensive range of specific items tailored to your needs. |

Utilizing these sources can help ensure that you find the right items to maintain or enhance your equipment’s functionality.

Exploring Aftermarket Options

When seeking alternatives to original components for your equipment, aftermarket choices can provide a cost-effective and reliable solution. These products, often produced by third-party manufacturers, aim to deliver similar quality and functionality while enhancing the overall user experience. By considering these options, users can potentially find enhancements or replacements that better suit their needs.

One significant advantage of exploring alternative offerings is the vast array of choices available. From improved durability to innovative features, aftermarket suppliers frequently introduce advancements that can optimize performance. Furthermore, many enthusiasts appreciate the flexibility to customize their tools with unique modifications that might not be available through traditional channels.

However, it is essential to approach the selection of aftermarket components with caution. Researching the reputation of suppliers and reading reviews can help ensure that you invest in high-quality items. Additionally, verifying compatibility with your specific model is crucial to avoid potential issues down the line. By taking these steps, users can confidently enhance their experience while maintaining the integrity of their equipment.

Ordering Genuine Stihl Components

When it comes to maintaining outdoor power equipment, ensuring the use of authentic components is essential for optimal performance and longevity. Selecting genuine replacements not only guarantees compatibility but also upholds the manufacturer’s standards for quality and reliability. Understanding the process of ordering these components can significantly enhance your experience and the efficiency of your tools.

Finding Authorized Dealers

The first step in acquiring authentic components is to locate authorized dealers. These suppliers are specifically recognized by the manufacturer and provide assurance of authenticity. Most manufacturers maintain a directory of certified retailers on their websites, making it easy for you to find a reliable source near you.

Placing Your Order

Once you have identified a reputable dealer, you can proceed with your order. Providing the model number and specific part information will streamline the process. Many dealers also offer online ordering options, allowing for convenience and flexibility. It is advisable to inquire about warranty and return policies to ensure a smooth transaction.

Safety Guidelines for Chainsaw Use

Operating a power saw requires a keen awareness of safety practices to prevent accidents and injuries. Proper precautions are essential for both novice and experienced users, as the machinery can pose significant risks if not handled correctly. Understanding these guidelines helps ensure a secure working environment and promotes responsible usage.

1. Wear Protective Gear: Always don appropriate safety equipment, including a hard hat, eye protection, ear protection, gloves, and sturdy footwear. These items are crucial for safeguarding against flying debris and noise.

2. Inspect the Equipment: Before starting, thoroughly check the machine for any signs of wear or damage. Ensure that the chain is properly tensioned and lubricated. A well-maintained saw is less likely to malfunction.

3. Understand the Operating Manual: Familiarize yourself with the user manual provided by the manufacturer. This document contains vital information regarding safe operation, maintenance, and troubleshooting.

4. Maintain a Clear Work Area: Keep the surrounding area free from obstacles and debris. This helps to prevent tripping and allows for an unobstructed path when handling the saw.

5. Use the Equipment Properly: Always follow recommended operating procedures. Maintain a firm grip on the saw, and use both hands while cutting. Be mindful of your body position and avoid overreaching, as this can lead to loss of control.

6. Be Aware of Your Surroundings: Stay alert to potential hazards in the environment, such as falling branches, uneven terrain, or other people nearby. Communicate clearly with anyone in the vicinity.

7. Know When to Seek Help: If you are unsure about any aspect of operating the saw, seek assistance from a knowledgeable person. It’s always better to ask for help than to risk injury.

By adhering to these safety guidelines, users can significantly reduce the risk of accidents and injuries, ensuring a safer and more efficient experience with power cutting tools.

Resources for Stihl Owners

For enthusiasts and users of outdoor power equipment, having access to the right materials can significantly enhance the experience and ensure proper maintenance. This section aims to provide valuable resources that assist in the effective usage and upkeep of your tools.

Online Communities

- Forums dedicated to equipment enthusiasts

- Social media groups focused on sharing tips and advice

- Video channels featuring tutorials and troubleshooting techniques

Manuals and Guides

- Official user manuals available for download

- Maintenance guides to keep your tools in optimal condition

- Safety instructions to ensure a secure operating environment

Utilizing these resources can help you maximize the performance and longevity of your outdoor equipment, making your tasks easier and more efficient.

FAQs About Stihl MS 171 Parts

This section addresses common inquiries regarding components and their maintenance for a specific model of outdoor equipment. Understanding these details can enhance your experience and prolong the lifespan of your machinery.

| Question | Answer |

|---|---|

| What are the essential components I should regularly check? | Key elements include the chain, guide bar, air filter, and spark plug. Regular inspection ensures optimal performance. |

| Where can I find replacement parts? | Replacement components are available at authorized dealers, online retailers, and various hardware stores specializing in outdoor machinery. |

| How do I know if a part needs to be replaced? | Look for signs of wear such as unusual noise, difficulty in operation, or visible damage. Regular maintenance checks can help identify issues early. |

| Can I use generic parts? | While generic components may be compatible, using original parts is recommended for optimal performance and warranty coverage. |

| How often should I perform maintenance? | Regular maintenance should be done after a certain number of operating hours, typically outlined in the user manual. Regular checks can prevent major issues. |