Understanding the Parts Diagram of Stihl MS 250 C

In the realm of outdoor power equipment, comprehending the various elements that make up a widely-used chainsaw can greatly enhance its maintenance and functionality. Each segment plays a pivotal role in the overall performance, and familiarity with these pieces is essential for any enthusiast or professional.

When exploring this topic, one can delve into the intricate layout of components, illustrating their connections and interactions. This knowledge not only aids in troubleshooting but also empowers users to execute repairs with confidence. Recognizing the ultimate function of each part ensures longevity and reliability in operation.

As we navigate through this guide, a closer examination of the essential elements will reveal how they collectively contribute to the efficiency of this indispensable tool. Whether you are a novice or an experienced operator, understanding these basics is key to optimal performance.

Understanding the Stihl MS 250 C

When it comes to high-performance cutting tools, having a clear comprehension of their components and functionality is essential for optimal operation. This knowledge not only enhances the user experience but also aids in maintenance and troubleshooting.

This particular model stands out for its reliability and efficiency. Here are some key aspects to consider:

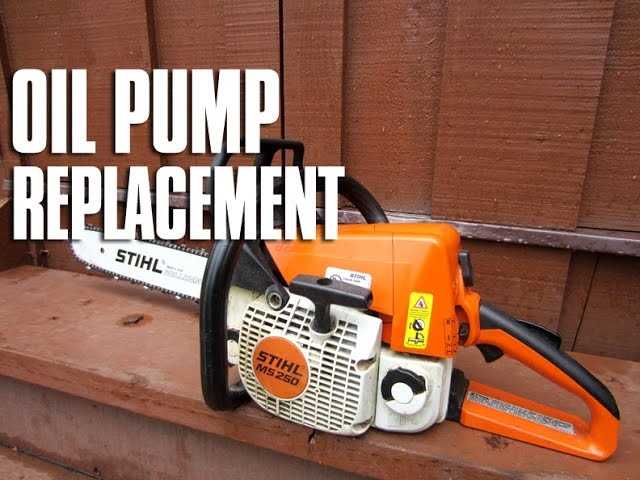

- Engine Performance: The power unit is designed for robust operation, ensuring smooth performance during heavy-duty tasks.

- Weight Distribution: A well-balanced design minimizes user fatigue, making it suitable for extended use.

- Safety Features: Integrated safety mechanisms help prevent accidents, making it a user-friendly choice for both novices and seasoned professionals.

Understanding the essential components can significantly improve the longevity and functionality of the tool. Consider familiarizing yourself with the following:

- Fuel System: Knowledge of fuel types and mixing ratios is crucial for efficient operation.

- Cutting Mechanism: Familiarity with the chain and bar specifications will ensure optimal cutting performance.

- Maintenance Practices: Regular upkeep is vital for sustaining performance and preventing breakdowns.

Ultimately, a thorough understanding of this tool’s features and maintenance requirements will empower users to maximize their productivity while ensuring safety and efficiency in their tasks.

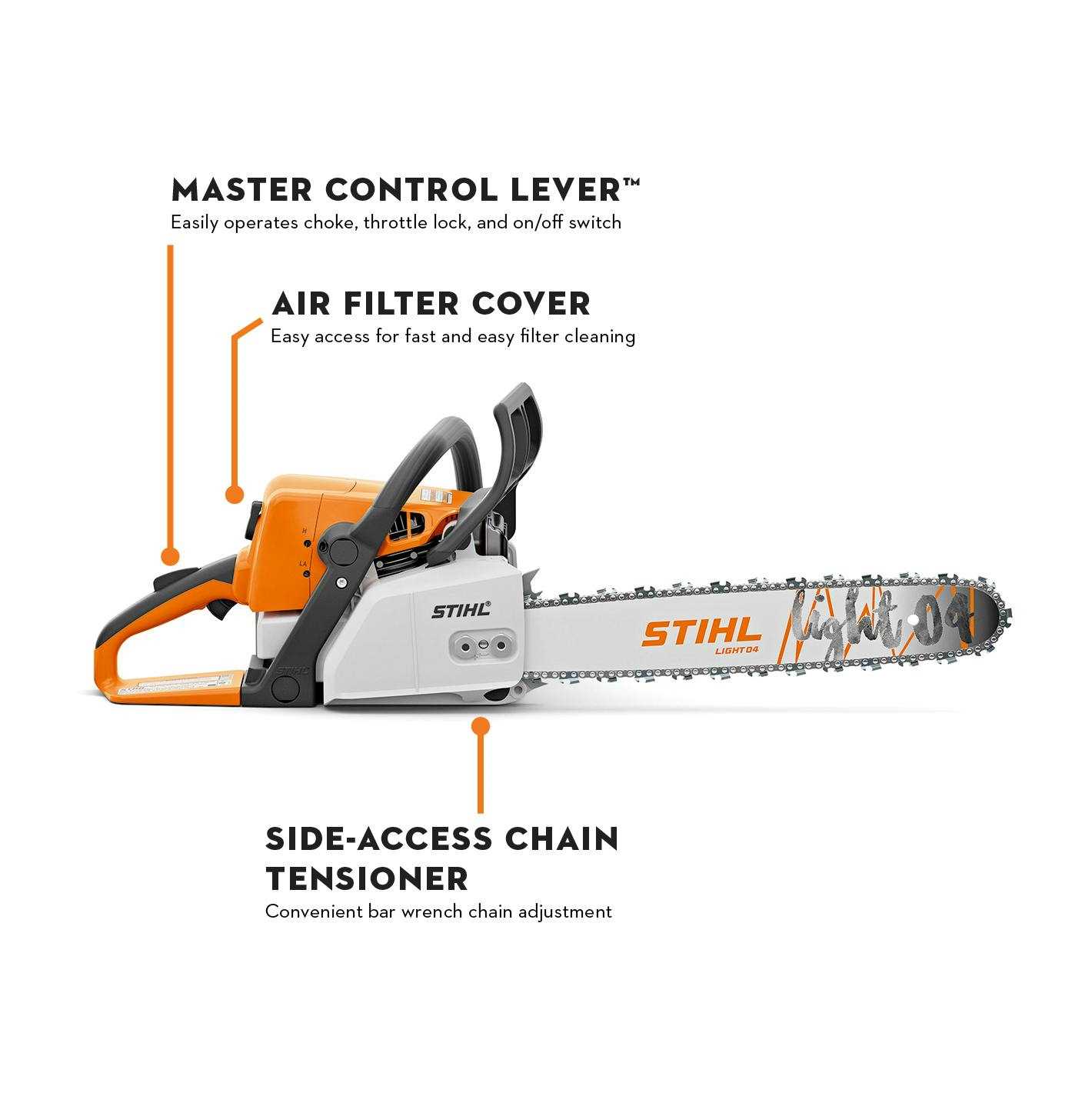

Key Features of the Chainsaw

Understanding the essential characteristics of a chainsaw is crucial for both novice and experienced users. These features determine not only the efficiency of the tool but also its suitability for various tasks in cutting and trimming.

Powerful Engine: A robust engine ensures optimal performance, allowing for smooth operation even in demanding conditions.

Lightweight Design: A lightweight construction enhances maneuverability, reducing user fatigue during prolonged use.

Safety Mechanisms: Advanced safety features, such as chain brakes and throttle interlocks, protect users from potential accidents.

Ease of Maintenance: Simplified access to components facilitates regular upkeep, ensuring longevity and reliability.

Adjustable Chain Tension: This feature allows for quick and easy adjustments, promoting efficient cutting without interruptions.

Versatile Attachments: Compatibility with various accessories expands the functionality, catering to different cutting needs.

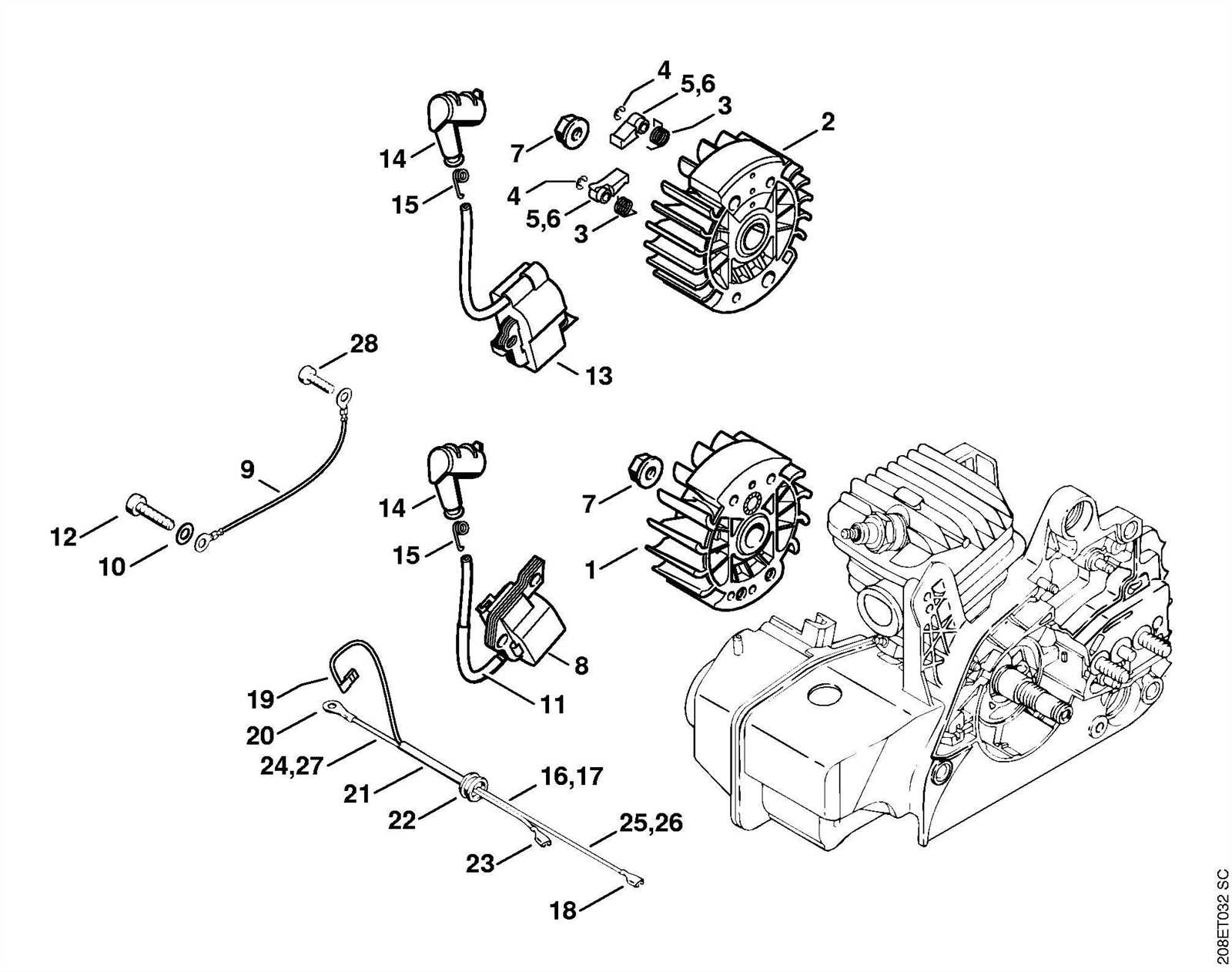

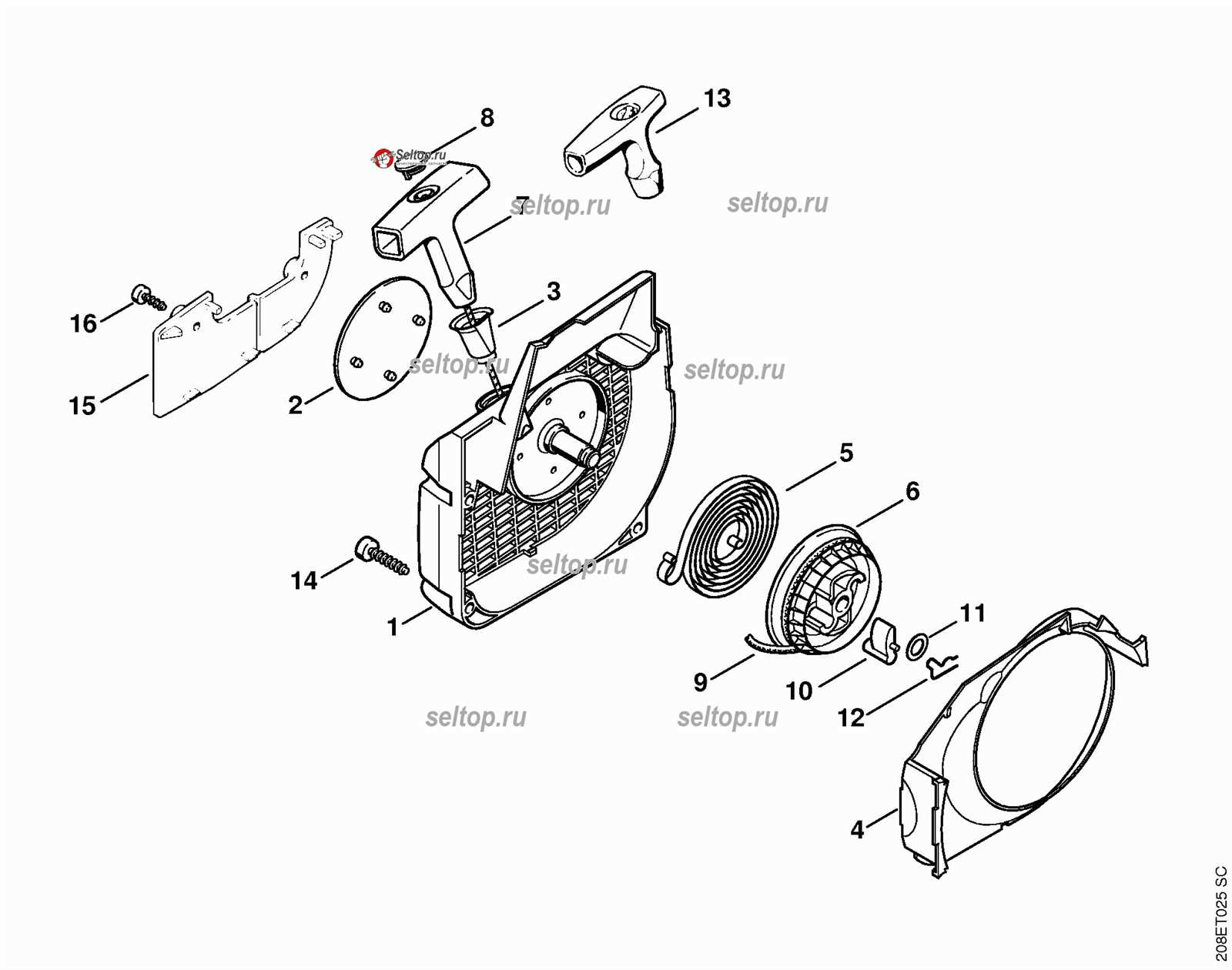

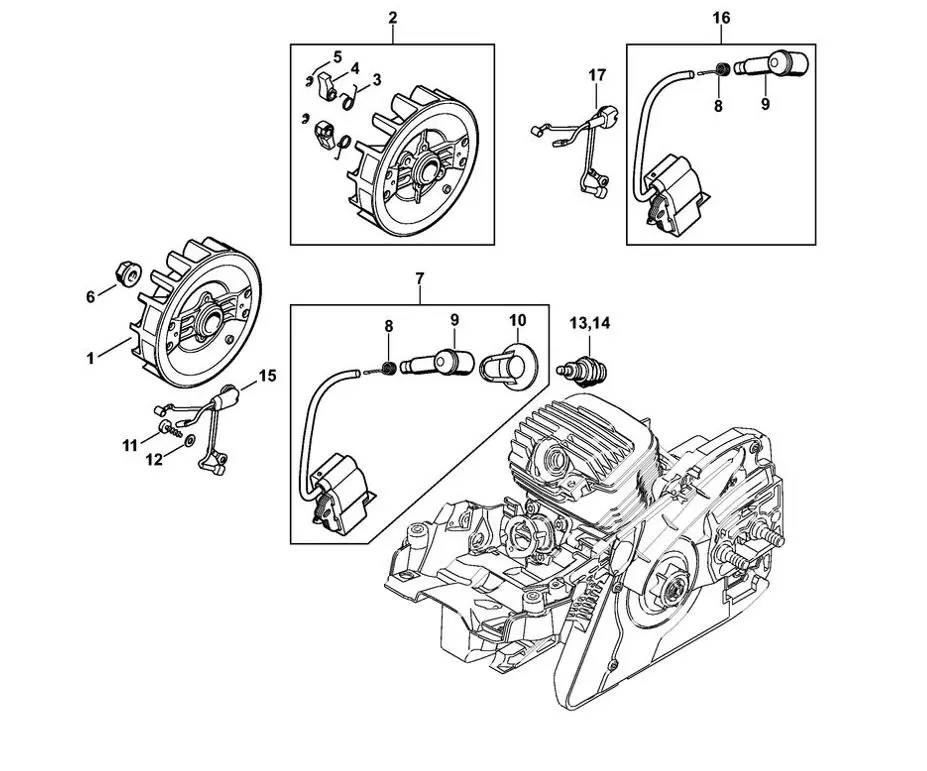

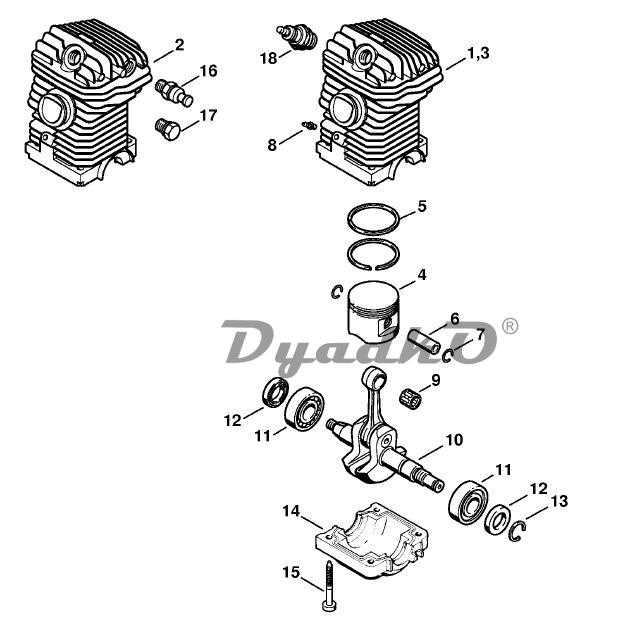

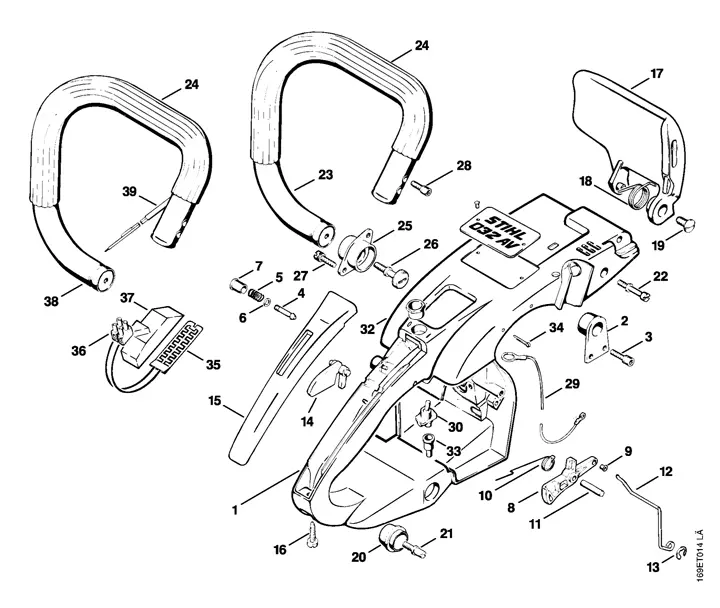

Parts Breakdown for Easy Repair

Understanding the components of your equipment is essential for effective maintenance and repair. A clear overview of each element not only simplifies the process but also enhances your ability to troubleshoot issues. By familiarizing yourself with the arrangement and function of various pieces, you can ensure a smoother experience when it comes time to make adjustments or replacements.

When you have a comprehensive breakdown, it becomes easier to identify which specific components may need attention. This knowledge empowers you to approach repairs with confidence, minimizing downtime and maximizing efficiency. Additionally, having a visual reference can significantly aid in locating parts and understanding how they interact with one another.

By systematically categorizing each section of your machinery, you can tackle any challenges that arise with a methodical approach. This not only saves time but also enhances your overall skill set as a user. Investing time in learning about the configuration and functionality of these essential elements will pay off in the long run.

Identifying Common Replacement Parts

Understanding the essential components of a tool is crucial for maintenance and longevity. Familiarizing oneself with frequently needed elements can streamline repairs and ensure optimal performance. This section highlights key components that often require attention, helping users to identify and address common issues effectively.

Key Components to Monitor

Several crucial elements play a significant role in the efficient functioning of your equipment. Regular inspection of these parts can prevent unexpected failures and extend the lifespan of the tool.

| Component | Function | Signs of Wear |

|---|---|---|

| Air Filter | Prevents dirt and debris from entering the engine | Reduced performance, increased fuel consumption |

| Chain | Facilitates cutting through materials | Visible damage, poor cutting efficiency |

| Spark Plug | Ignites the fuel-air mixture | Difficulty starting, engine misfires |

| Fuel Filter | Ensures clean fuel reaches the engine | Engine stalling, reduced power |

Maintenance Tips

Regular checks and timely replacements of these components can significantly enhance the tool’s performance. Keeping a maintenance schedule ensures that any signs of wear are promptly addressed, leading to a more reliable and efficient operation.

How to Use the Parts Diagram

Understanding the visual representation of components is crucial for maintenance and repairs. This guide will help you navigate the illustration effectively to identify and acquire the necessary elements for your equipment.

To make the most of this resource, follow these steps:

- Familiarize Yourself: Begin by examining the overall layout to grasp the arrangement of the components.

- Identify Key Sections: Locate sections that correspond to specific areas of the machinery, such as the engine or housing.

- Use Labels: Pay attention to any labels or numbers that indicate particular pieces, making it easier to reference them later.

- Cross-Reference: Compare the illustration with your service manual for additional details and specifications.

- Note Compatibility: Ensure that the components you identify are compatible with your specific model before purchasing.

By following these steps, you’ll enhance your understanding and efficiency when dealing with the equipment’s maintenance.

Maintenance Tips for Longevity

Ensuring the prolonged performance of your equipment requires a commitment to regular upkeep. By following a few essential practices, you can enhance efficiency and extend the lifespan of your tools. This not only saves you time and money but also helps maintain optimal functionality during use.

Regular Cleaning

Keeping your device free from debris is crucial. After each use, remove sawdust and other residues from the exterior and interior components. This helps prevent overheating and ensures smooth operation. Use a soft brush and compressed air for thorough cleaning, paying close attention to air intake and exhaust areas.

Routine Inspection and Lubrication

Conducting frequent checks on critical parts is vital. Look for signs of wear, such as cracks or unusual noises, and replace any damaged components immediately. Additionally, proper lubrication reduces friction and wear, allowing parts to function smoothly. Use recommended oils for different mechanisms, and follow the manufacturer’s guidelines for frequency.

By incorporating these maintenance strategies, you can ensure that your equipment remains reliable and efficient for years to come.

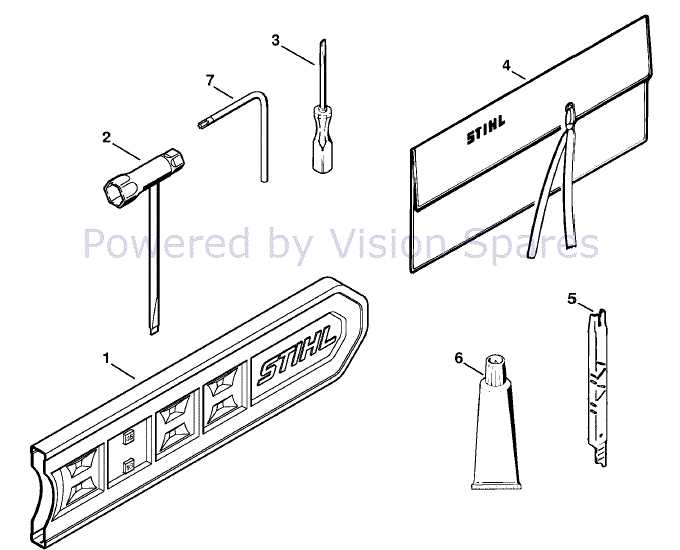

Tools Needed for Assembly

When assembling a complex machine, having the right tools at hand is essential for a smooth and efficient process. Proper equipment not only speeds up assembly but also ensures that all components fit together correctly, maintaining the functionality and longevity of the device.

Essential Tools

- Screwdrivers (flathead and Phillips)

- Wrenches (various sizes)

- Hex keys

- Socket set

- Pliers

- Torque wrench

Additional Accessories

- Safety goggles

- Gloves

- Workbench or sturdy surface

- Container for small parts

Troubleshooting Common Issues

When operating a cutting tool, users may encounter various challenges that can hinder performance. Identifying these problems quickly can save time and ensure the tool remains in optimal condition.

Engine Issues

- Hard Starting: Check fuel quality and spark plug condition.

- Stalling: Inspect the air filter and fuel lines for clogs.

Cutting Performance

- Inefficient Cutting: Ensure the chain is sharp and properly tensioned.

- Excessive Vibration: Verify the mounting of the bar and chain.

Where to Buy Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality components is crucial for optimal performance. Whether you’re tackling a repair or enhancing your tool’s functionality, knowing where to find reliable replacements can make all the difference.

Authorized Dealers

One of the most dependable options is to visit authorized retailers. These establishments often offer:

- Genuine components ensuring compatibility

- Expert advice from knowledgeable staff

- Warranty on products purchased

Online Marketplaces

For convenience and variety, online platforms provide a vast selection of items. Consider the following tips when shopping online:

- Check for seller ratings and reviews

- Compare prices across different websites

- Verify return policies before making a purchase

By exploring these options, you can confidently acquire the necessary components to keep your equipment running smoothly.

Safety Precautions While Repairing

Engaging in maintenance tasks requires a high level of awareness and adherence to safety protocols. Proper precautions not only protect the individual performing the repairs but also ensure that equipment functions efficiently and safely. Below are essential guidelines to consider before starting any repair work.

Essential Gear

- Always wear protective eyewear to shield your eyes from debris.

- Utilize gloves to protect your hands from sharp objects and chemicals.

- Wear sturdy footwear with slip-resistant soles to prevent falls.

- Consider using hearing protection if operating noisy machinery.

Work Environment

- Ensure your workspace is well-lit and organized to avoid accidents.

- Keep flammable materials away from the repair area.

- Use a stable workbench or surface to prevent equipment from slipping or tipping over.

- Maintain a clutter-free area to allow for easy movement and quick access to tools.

Understanding Warranty and Support

When purchasing outdoor equipment, it’s essential to comprehend the guarantees and assistance available to ensure long-term satisfaction. Manufacturers typically provide warranties that cover defects in materials and workmanship, offering peace of mind to users. Additionally, reliable customer support can greatly enhance the ownership experience by addressing concerns and providing guidance on maintenance and repairs.

Warranty Coverage

Warranties vary by manufacturer and model, but they generally encompass the following aspects:

| Aspect | Description |

|---|---|

| Duration | Typically lasts from one to three years, depending on the item. |

| Scope | Covers defects in manufacturing and materials under normal use. |

| Exclusions | Usually excludes damage from misuse, accidents, or lack of maintenance. |

Customer Support Options

Effective support services can significantly enhance the user experience. Many companies offer various resources to assist customers, including:

| Support Type | Description |

|---|---|

| Online Resources | User manuals, FAQs, and instructional videos available on the website. |

| Technical Assistance | Dedicated support lines for troubleshooting and repairs. |

| Service Centers | Authorized locations for professional maintenance and repairs. |