Stihl MS 362 Parts Diagram PDF Guide

When working with modern machinery, understanding the organization and placement of its individual elements is crucial for both routine maintenance and repairs. Having access to a detailed overview of internal systems can greatly simplify tasks, allowing for quicker troubleshooting and more efficient use of time.

Whether you’re dealing with regular upkeep or a more in-depth overhaul, having clear and well-structured references makes all the difference. The layout of various mechanical elements ensures smooth functioning, and a well-prepared reference document can be an invaluable asset in your toolkit.

By exploring an organized visual breakdown of key components, you can confidently address any technical challenges that arise. Proper documentation enhances understanding and provides a structured approach to handling complex tasks.

Comprehensive Overview of Stihl MS 362 Components

In this section, we will explore the essential mechanisms and features of a well-known chainsaw model, examining each element in detail. Understanding how the various components function together is crucial for maintaining peak performance and extending the lifespan of your equipment. Below, we will take a closer look at the key parts that make up the system.

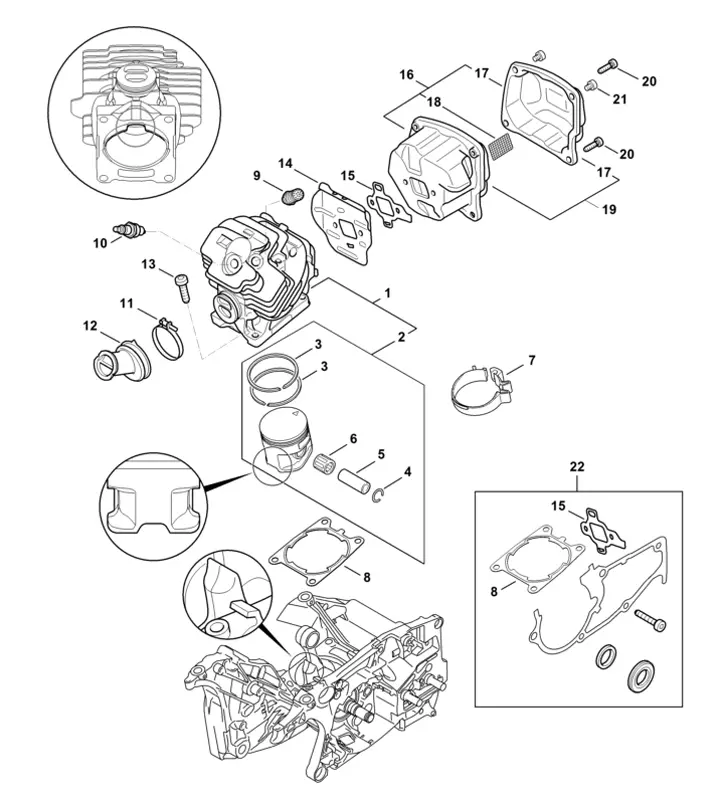

Key Engine Components

The engine serves as the heart of the machine, ensuring reliable power output and efficient operation. Let’s break down some of the vital elements:

- Cylinder: This is where combustion occurs, providing the power necessary for the machine to operate.

- Piston: A crucial part that moves up and down within the cylinder, driving the crankshaft.

- Crankshaft: Converts the reciprocating motion of the piston into rotational motion, essential for cutting actions.

Chain and Bar Mechanism

The cutting efficiency depends heavily on the proper functioning of the chain and guide bar. These elements work together to ensure precise and

Understanding the Structure of a Professional Chainsaw

A well-built chainsaw is a complex tool designed to handle heavy-duty tasks efficiently. It consists of various interconnected components that work together to provide power, balance, and precision. The overall structure is crafted to ensure durability and performance, whether used for cutting through thick timber or handling more delicate tasks in forestry. Knowing how the machine is put together allows for better maintenance and long-term use.

The core elements include a powerful engine, a robust cutting mechanism, and a secure handling system. Each of these sections is crucial for the machine’s functionality, offering smooth operation and safety. The design focuses on user comfort while maintaining high performance under demanding conditions.

To ensure optimal performance, it’s important to understand how each component interacts with the others. This understanding not only enhances the user’s ability to operate the machine efficiently but also helps in identifying potential issues early on, preventing damage and costly repairs.

Key Components for Efficient Operation

For optimal performance, understanding the crucial elements that ensure smooth and reliable functionality is essential. These components work together to deliver powerful results, ensuring that the equipment operates efficiently under various conditions. Proper maintenance and attention to these elements can significantly extend the lifespan and enhance the overall performance of the machine.

Engine Mechanics

The heart of the system, the engine, powers the entire operation. Its precision and design allow for high energy output while maintaining fuel efficiency. Regular inspection and servicing of the engine ensure long-lasting durability and consistent performance.

Cutting System

The cutting mechanism is a vital part of the tool’s overall effectiveness. Sharpening the blades and keeping the system clean is essential for achieving smooth and accurate cuts. Consistent upkeep of the cutting system helps maintain safety and precision during operation.

How to Access the Stihl MS 362 Parts Diagram

Finding the visual representation of your tool’s internal components can be essential for proper maintenance and repair. It allows users to identify the necessary components quickly and ensures accuracy during assembly. This guide will help you understand where and how to obtain the necessary illustrations and reference materials for your equipment.

- Visit the official website of the manufacturer for detailed guides and technical materials.

- Look for online resources, such as trusted forums or specialized websites, which often provide downloadable documents.

- Consider reaching out to authorized service centers that can provide official documents or guidance.

- Check with local retailers or shops, as they may offer printed versions or assistance in obtaining the necessary references.

By following these steps, you’ll be able to access the right resources to ensure your tool functions properly, aiding in both minor repairs and more complex projects.

Replacement Tips for Worn-out Chainsaw Parts

Maintaining a chainsaw in top condition requires timely replacement of essential components. Continuous use inevitably leads to wear and tear, making it necessary to change specific elements to ensure smooth and safe operation. Here are some practical suggestions on how to replace frequently worn-out components and extend the lifespan of your equipment.

- Inspect the chain regularly – Over time, the chain loses its sharpness and can become dull or even damaged. If sharpening no longer helps, it’s time to install a new one for efficient cutting performance.

- Check the bar for wear – The guide bar endures constant friction and pressure. If you notice uneven wear or a bent bar, it’s crucial to swap it out to prevent accidents and keep the cutting process smooth.

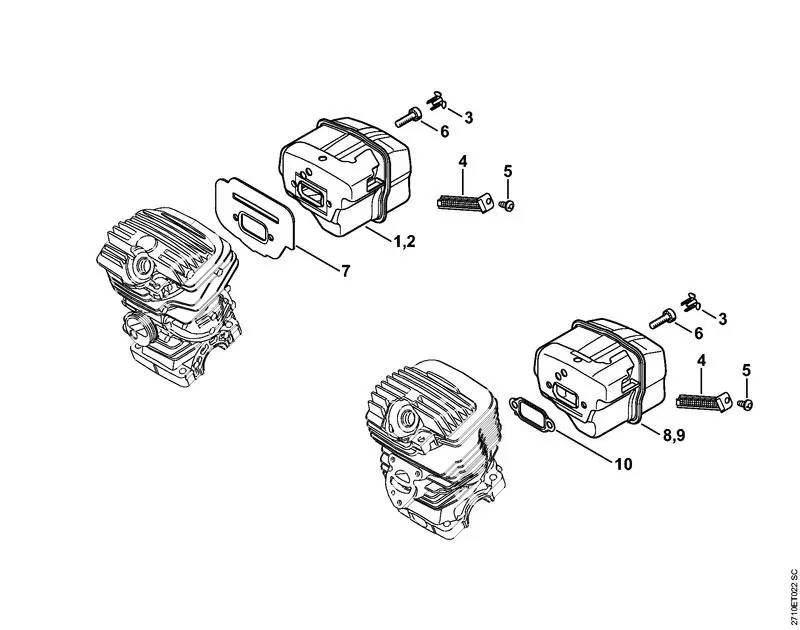

- Replace the air filter – A clogged air filter restricts airflow, reducing engine efficiency. Change it periodically to keep the motor running at full power and to avoid overheating.

- Monitor the spark plug – A worn-out spark plug can cause starting problems and reduced engine performance. Replacing it ensures consistent ignition and relia

Maintenance Guide for Critical Chainsaw Elements

Proper upkeep of essential components in a cutting tool is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also contributes to safety during operation. This guide highlights key areas that require attention and care.

1. Chain Inspection and Tensioning

The cutting chain is a vital part of any saw, and its condition directly affects cutting performance. Regularly inspect the chain for wear and damage. Ensure the tension is properly adjusted to prevent slippage or breakage. A well-maintained chain provides smoother cuts and reduces the risk of accidents.

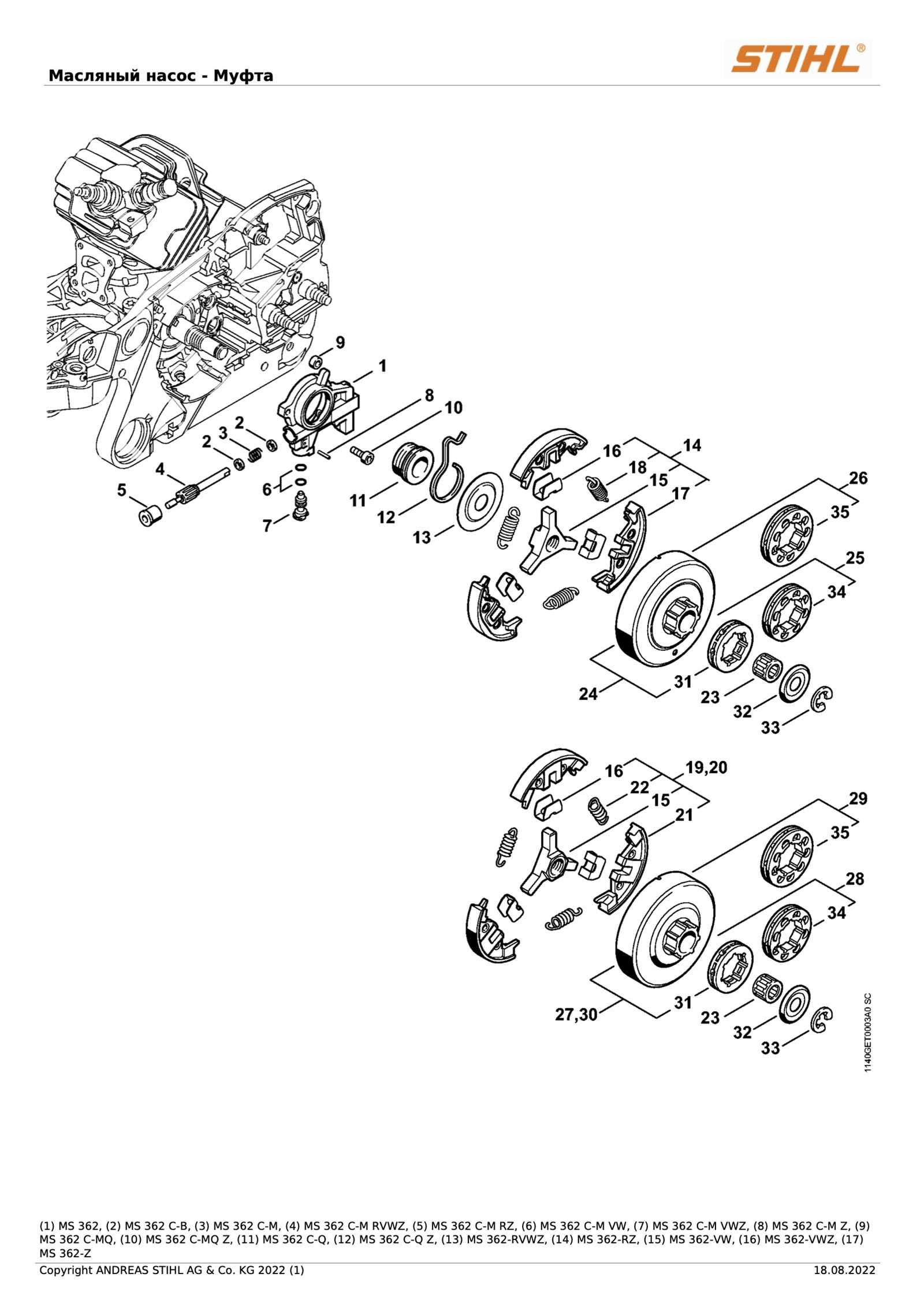

2. Bar Care and Lubrication

The guide bar, which supports the chain, should be kept clean and lubricated to ensure seamless operation. Check for any signs of bending or wear, as these can impact cutting accuracy. Apply lubricant as needed to minimize friction and prevent overheating during use. Regularly cleaning the bar helps extend its lifespan and improves cutting efficiency.

Choosing the Right Parts for Repairs

When it comes to maintaining outdoor power tools, selecting the appropriate components for replacements is crucial for ensuring optimal performance and longevity. Understanding the essential features and specifications of each element is vital for effective repairs. This section aims to guide you in making informed choices when sourcing components for your equipment.

Identifying Quality Components

Not all components are created equal; hence, it’s important to distinguish between genuine parts and aftermarket options. Authentic components are designed specifically for your machine, often resulting in better fit and performance. On the other hand, aftermarket options may be more affordable but could vary in quality and compatibility. Always consider the brand reputation and reviews before making a purchase.

Compatibility and Specifications

Before buying replacement items, ensure they are compatible with your machine. Check the specifications and model numbers carefully. Having a clear understanding of what your machine requires will save you time and resources. A well-organized table can help you compare various options and make the right decision.

Component Type Compatibility Notes Chainsaw Chain Model Number Required Choose based on length and pitch. Air Filter Specific to Engine Type Replace regularly for optimal airflow. Spark Plug Check Manufacturer Specifications Correct gap size is essential for ignition. Decoding the Parts Diagram for Beginners

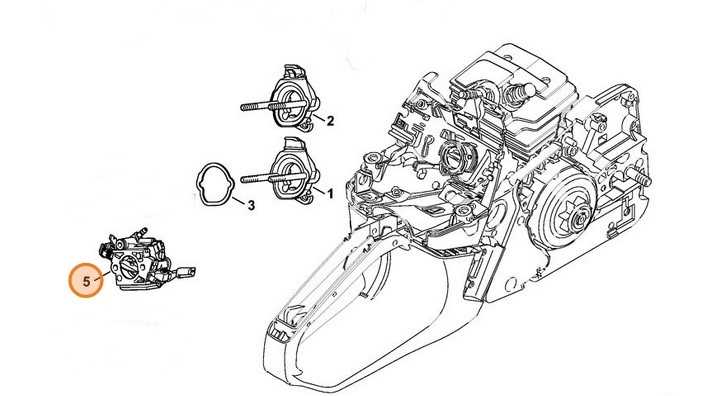

Understanding the visual representation of components in machinery is essential for anyone looking to perform maintenance or repairs. These illustrations serve as a guide to identify each individual piece, helping users navigate the complexities of mechanical systems. By familiarizing oneself with these visuals, beginners can effectively manage their tools and enhance their skills.

When interpreting these representations, it’s important to recognize the symbols and labels that correspond to various elements. Each section typically includes a list detailing the specifications and functions of each item, which aids in the assembly or disassembly processes. Below is a simplified overview of common features found in such representations:

Label Description A Base unit that houses the main engine B Handle designed for user comfort and control C Cutting blade utilized for various tasks D Fuel tank for storing the necessary energy source E Air filter that maintains optimal performance By becoming acquainted with these elements and their respective functions, newcomers can confidently approach repair tasks and improve their proficiency with machinery.

Preventive Care for Stihl MS 362 Chainsaw

Regular maintenance is crucial for ensuring the longevity and efficient performance of your cutting tool. By implementing a routine care schedule, users can prevent potential issues and enhance the overall functionality of their equipment. This proactive approach helps to identify wear and tear early, allowing for timely interventions.

One essential aspect of upkeep involves cleaning the air filter, which ensures optimal airflow to the engine. A clogged filter can lead to reduced power and increased fuel consumption. Additionally, regularly inspecting and sharpening the cutting chain will improve cutting efficiency and minimize strain on the motor.

Lubrication is another vital component of maintenance. Ensuring that the guide bar and chain are properly lubricated can prevent overheating and excessive wear. Always check the oil reservoir and refill it as needed to maintain a smooth operation.

Lastly, storing the equipment correctly when not in use is essential for prolonging its life. Keeping it in a dry, cool place will prevent rust and damage from moisture. By adhering to these preventive measures, users can enjoy a reliable and effective tool for their cutting tasks.

Essential Safety Components and Their Function

Ensuring the safe operation of power tools requires a thorough understanding of their vital safety elements. These components are designed to protect the user from potential hazards while enhancing the overall functionality of the equipment. By familiarizing oneself with these crucial parts, operators can maintain a secure working environment and minimize the risk of accidents.

Key Safety Features

- Chain Brake: This mechanism halts the chain’s movement in the event of kickback, preventing injury.

- Throttle Lock: A device that requires deliberate action to engage the throttle, reducing the chance of accidental activation.

- Safety Guard: Shields the user from debris and accidental contact with the cutting chain.

Additional Protective Mechanisms

- Anti-Vibration System: This feature reduces the vibrations experienced by the operator, helping to prevent fatigue and potential long-term health issues.

- Ergonomic Handles: Designed for comfort and control, these handles help ensure a secure grip while reducing strain during extended use.

- Wear Indicators: These markings inform the user when components require maintenance or replacement, promoting safe and efficient operation.

Steps to Download the Parts Diagram PDF

Obtaining the schematic representation of a device can be essential for maintenance and repair. This guide will help you navigate the process of accessing the necessary documentation for your equipment efficiently.

Firstly, visit the official website dedicated to your equipment’s manufacturer. Look for a section typically labeled as “Support” or “Resources.” This is often where you will find manuals, illustrations, and other helpful resources.

Once on the appropriate page, utilize the search function, if available. Enter relevant keywords related to your equipment’s model to refine your search results. Be sure to check for any options that specify the documentation type you need.

After locating the desired document, there should be an option to download it. Click on the download link, and choose a suitable format if prompted. Ensure you save the file in a location that is easy to access later.

Finally, verify that the downloaded file opens correctly on your device. This will ensure that you have access to the needed information for future reference.