Clean or replace

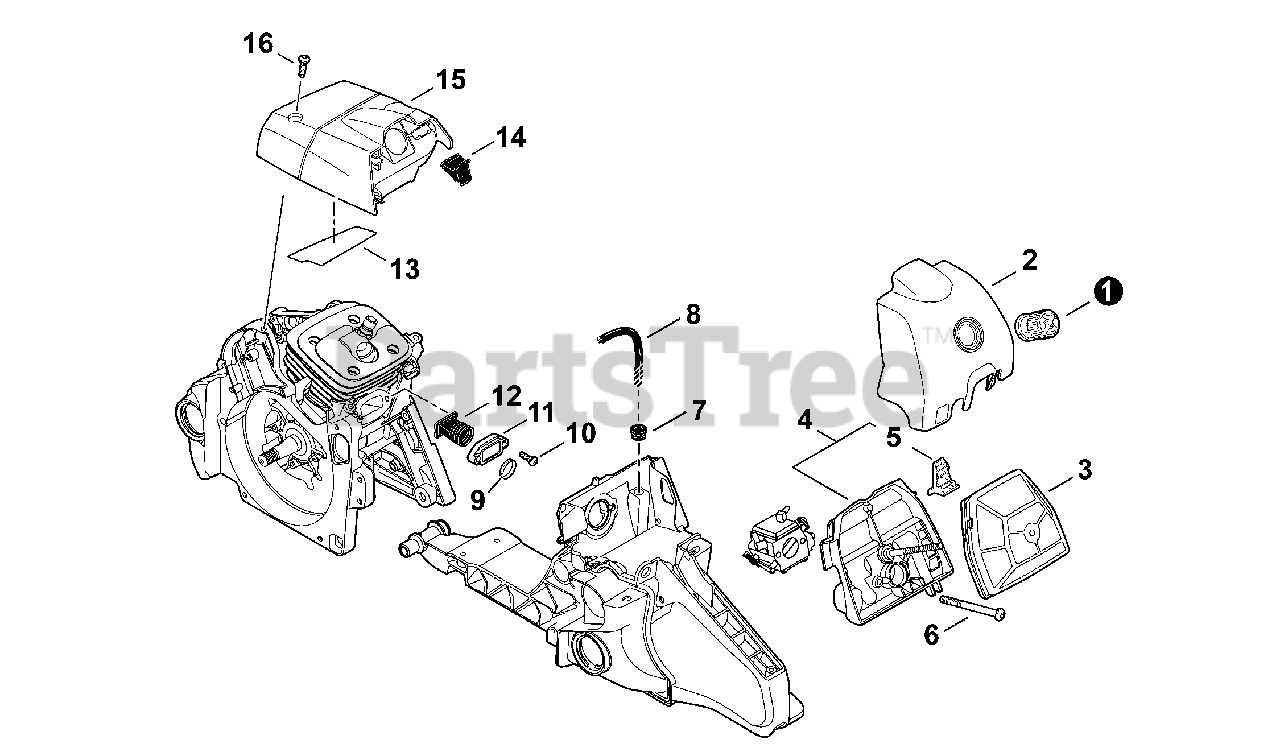

Fuel Tank and Lines Structure

The fuel system is designed to ensure a consistent supply of fuel for optimal engine performance. This section covers the essential components responsible for delivering fuel from the tank to the engine, highlighting their arrangement and how they function together to maintain efficient operation.

Fuel Tank Design

The container holds the fuel, serving as the primary storage unit. It is typically constructed from durable materials to resist pressure and potential damage. Inside, baffles might be included to minimize sloshing, which helps maintain balance and consistent fuel delivery even during movement.

Fuel Lines and Connections

The lines transport the fuel from the storage container to the engine’s combustion system. These lines are made of flexible yet tough materials, resistant to wear and pressure changes. Each connection is securely fastened to prevent leaks, ensuring a continuous and steady flow of fuel.

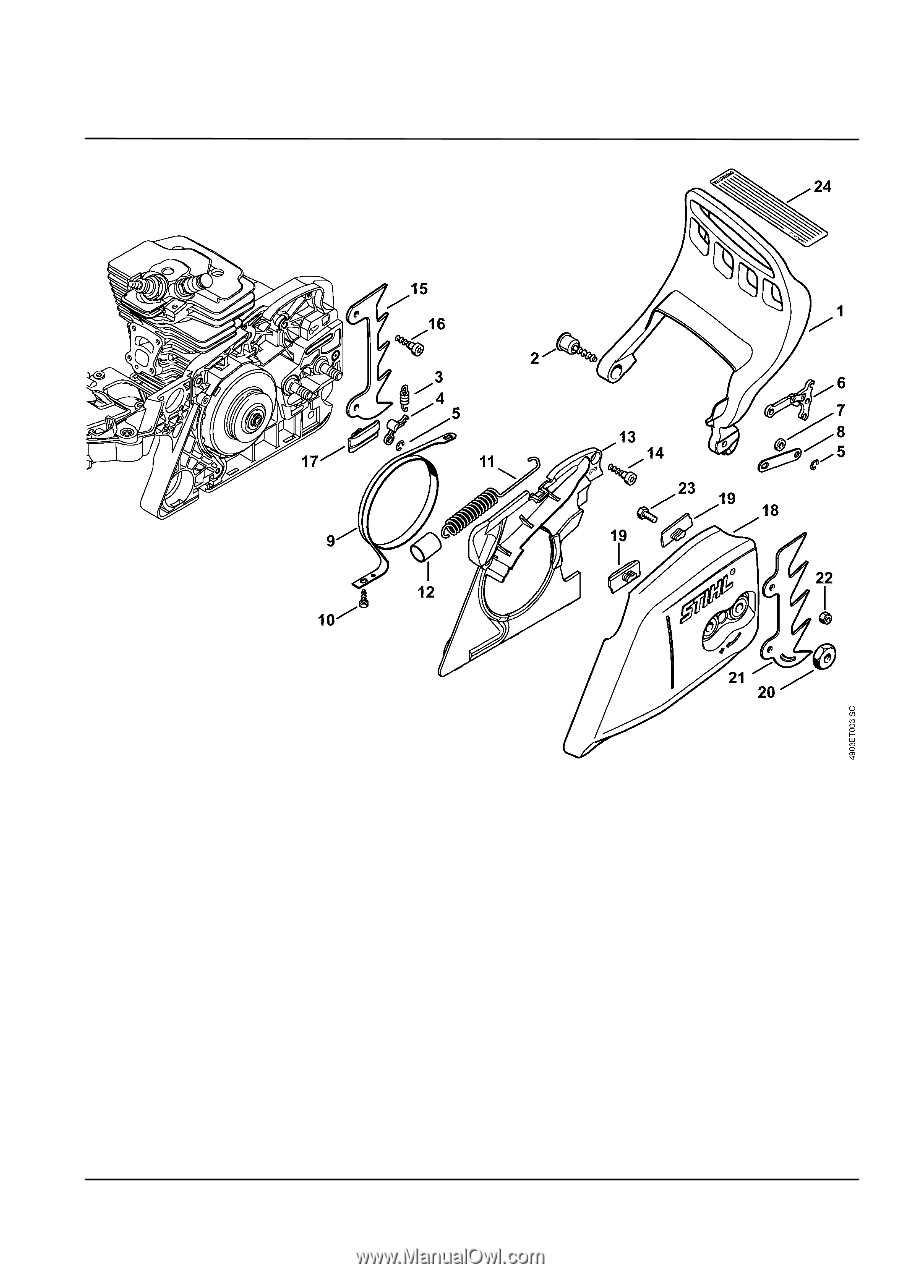

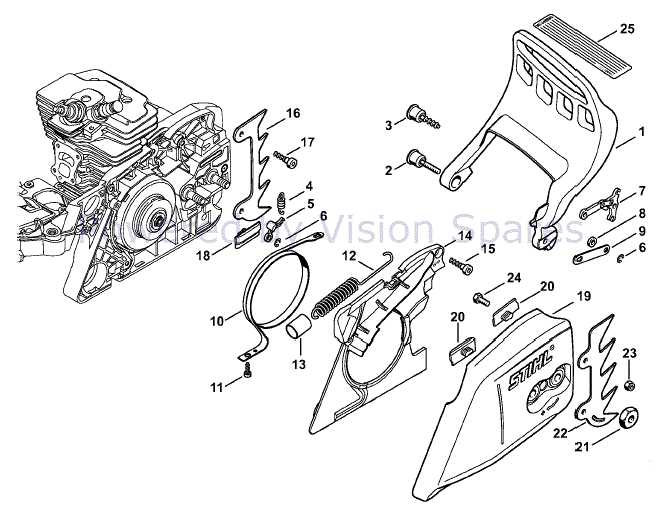

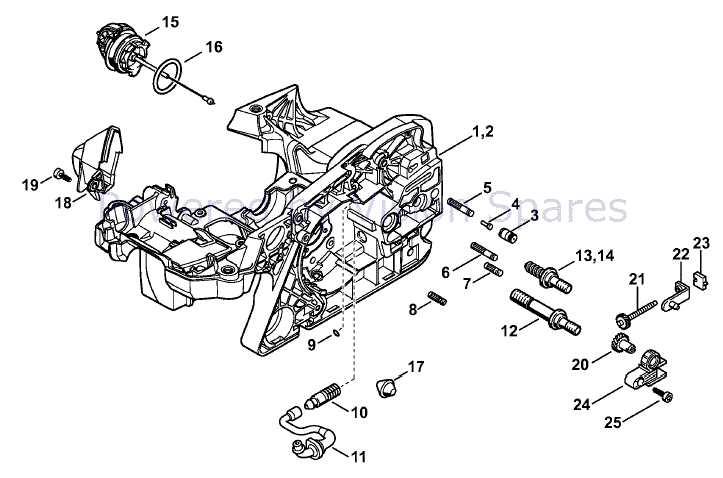

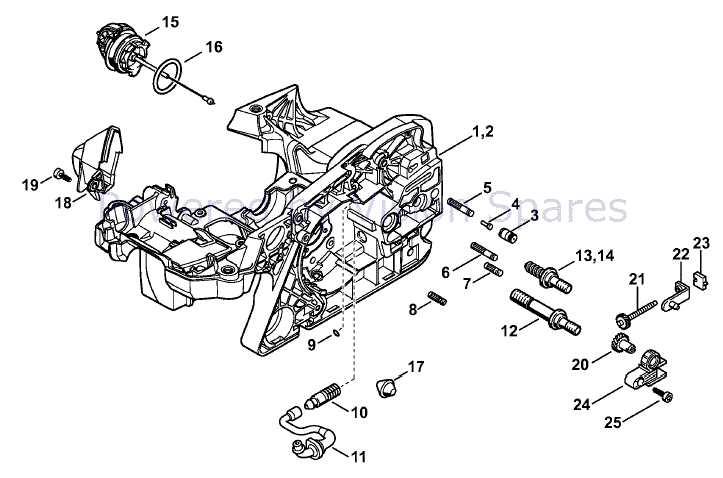

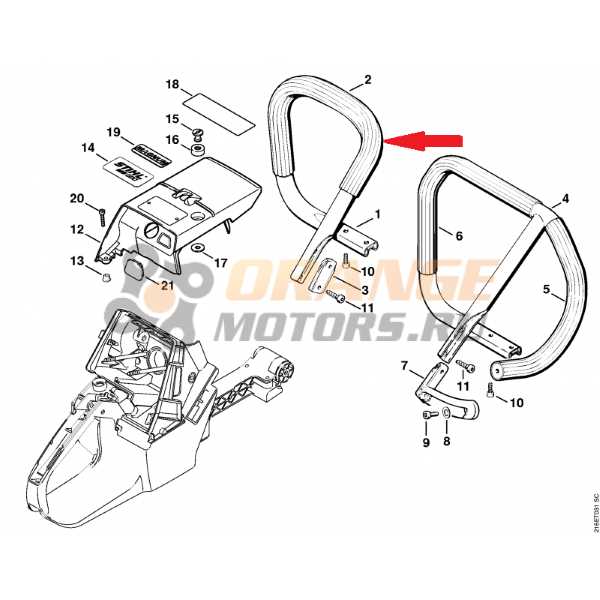

Guide Bar and Chain Assembly

The guide bar and chain form an essential part of a cutting tool, ensuring efficient and smooth operation. Proper assembly and maintenance are critical for optimal performance. These components work together to deliver precise cuts and enhance the tool’s overall effectiveness.

Positioning the Guide Bar

Begin by carefully aligning the guide bar in the correct slot, ensuring it sits securely. It’s important that the bar is well-fitted to avoid any disruptions during use. This placement is fundamental to ensure the chain operates smoothly along its path.

Attaching the Chain

The chain should be placed around the guide bar with careful attention to its direction. Proper tension is key to avoiding slippage or unnecessary wear. Adjusting the chain correctly will also extend the lifespan of both the chain and bar, leading to better performance.

Final Adjustments

Once assembled, check the overall tension and alignment of both the bar and chain. A well-calibrated setup guarantees smoother operation, improved safety, and efficiency during cutting tasks. Regular checks and adjustments are recommended to maintain peak functionality.

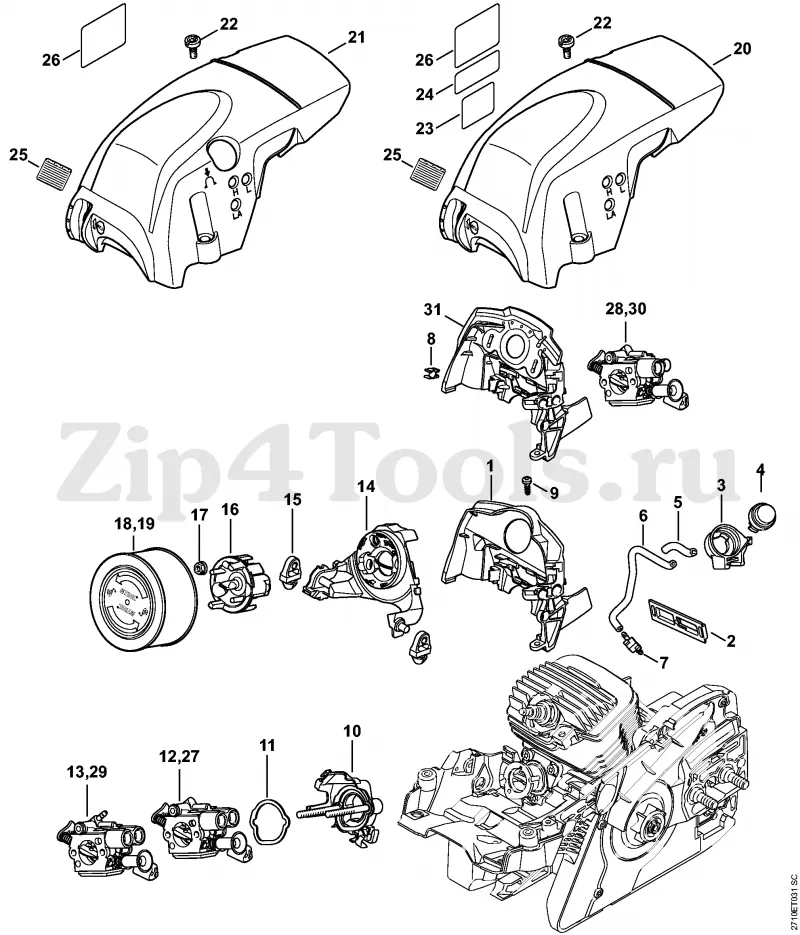

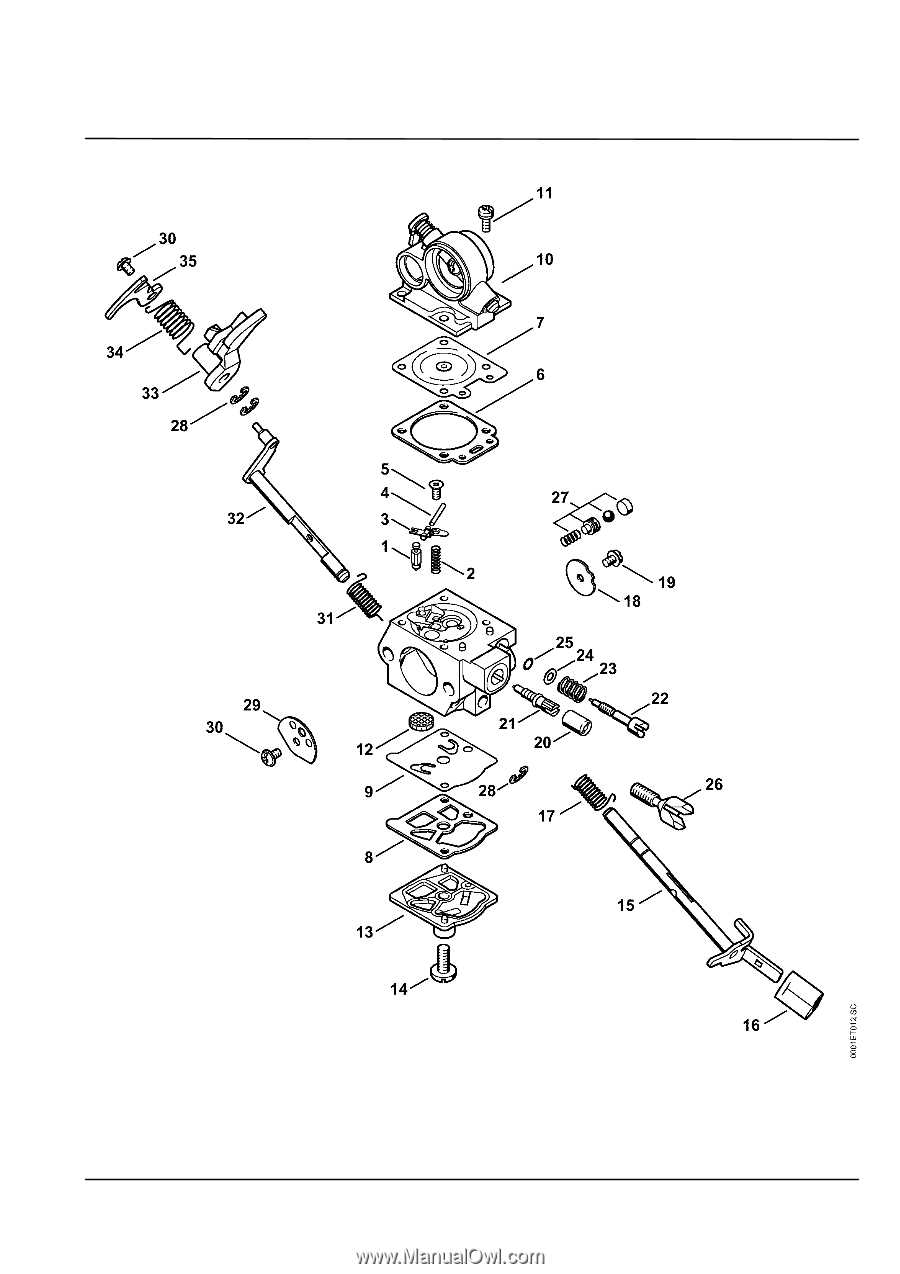

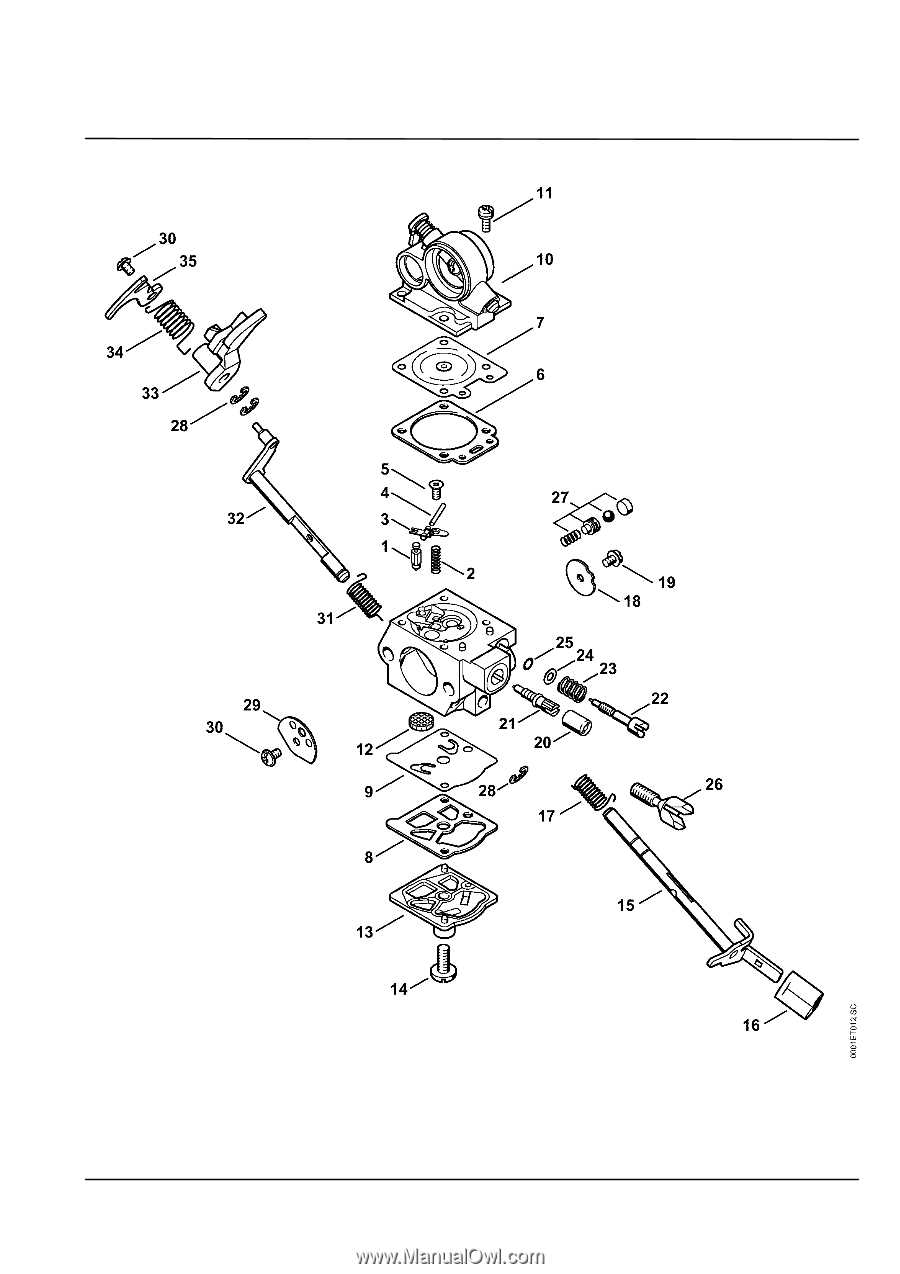

Carburetor Parts and Functions

The carburetor plays a crucial role in the engine’s performance by mixing air and fuel in the appropriate ratio. This process ensures that the engine operates efficiently and effectively, contributing to optimal power output and fuel economy.

Key components of the carburetor include the float chamber, which regulates the fuel level, and the venturi, where air flows rapidly to create a vacuum that draws fuel into the airstream. Additionally, the throttle valve controls the amount of air-fuel mixture entering the engine, directly impacting acceleration and power delivery.

Another important element is the idle circuit, which provides fuel at low speeds, allowing for smooth operation during idling. The main jet is responsible for delivering fuel at higher speeds, ensuring that the engine receives the right amount of fuel under various operating conditions. Understanding these components and their functions is essential for effective maintenance and troubleshooting.

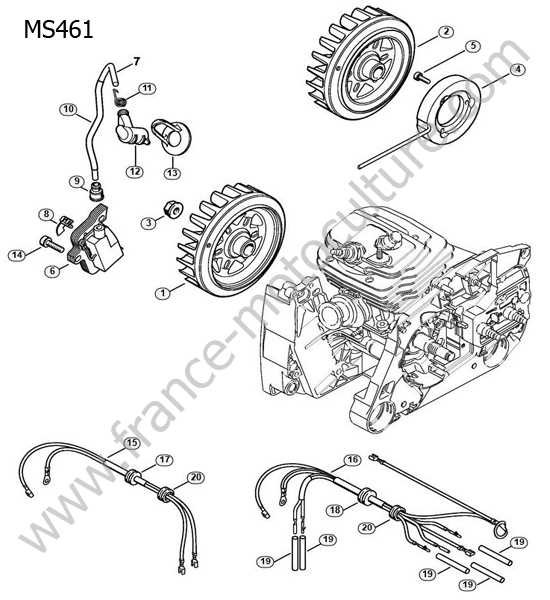

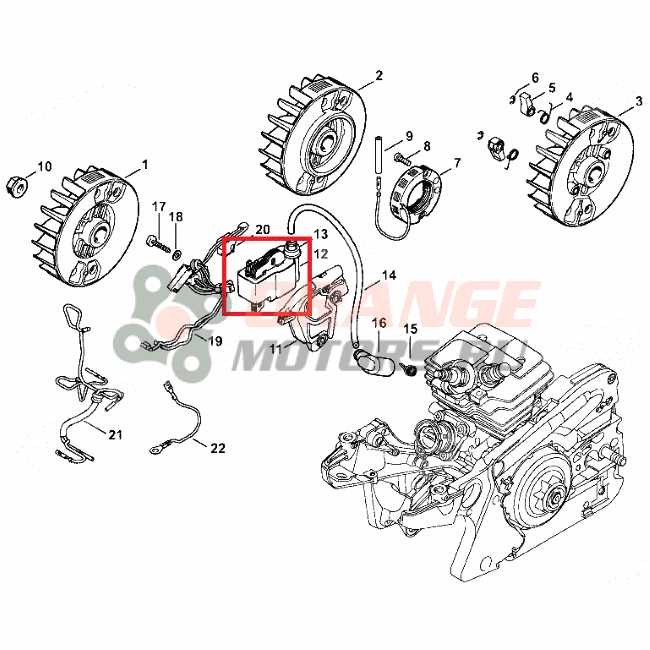

Clutch System Breakdown

The clutch system is a critical component in the operation of various cutting tools, facilitating smooth engagement and disengagement of the power source from the cutting mechanism. Understanding the inner workings and the individual elements of this system can greatly enhance maintenance and repair efforts, ensuring optimal performance and longevity of the equipment.

Components of the Clutch Mechanism

At the core of the clutch system are several key elements that work together seamlessly. These include the clutch drum, shoes, springs, and the drive shaft. The clutch drum is the component that rotates with the engine, while the shoes engage with it to transmit power. Springs play a vital role in controlling the engagement process, ensuring that the shoes only make contact when the engine reaches a specific RPM.

Maintenance Tips for the Clutch Assembly

Regular inspection and maintenance of the clutch assembly are essential to prevent wear and ensure reliable operation. One should periodically check for signs of wear on the clutch shoes, as excessive wear can lead to slippage and reduced cutting efficiency. Additionally, ensuring that the springs are in good condition and properly tensioned is crucial for effective engagement. Cleaning the components to remove debris and contaminants can also help maintain optimal function.

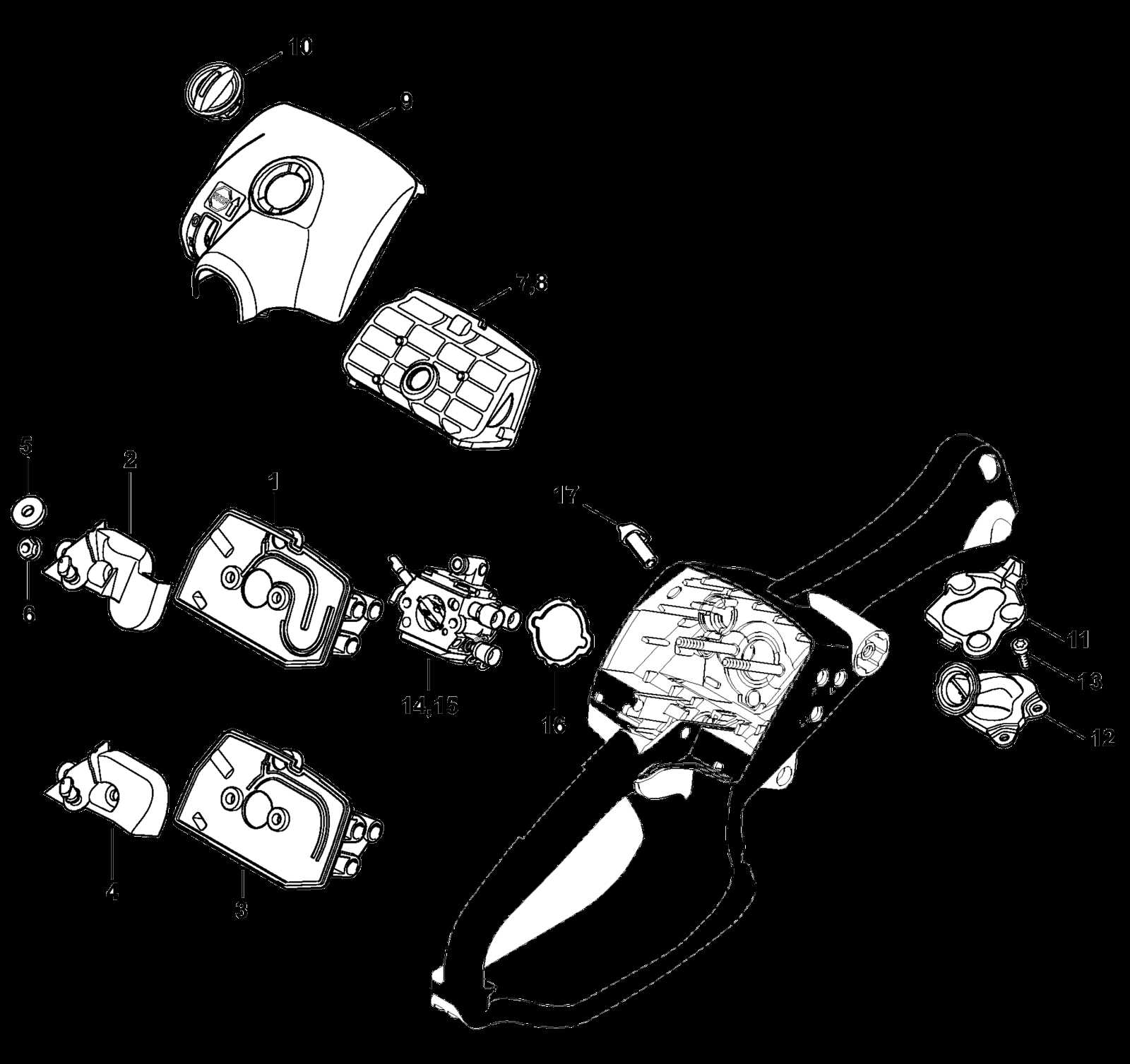

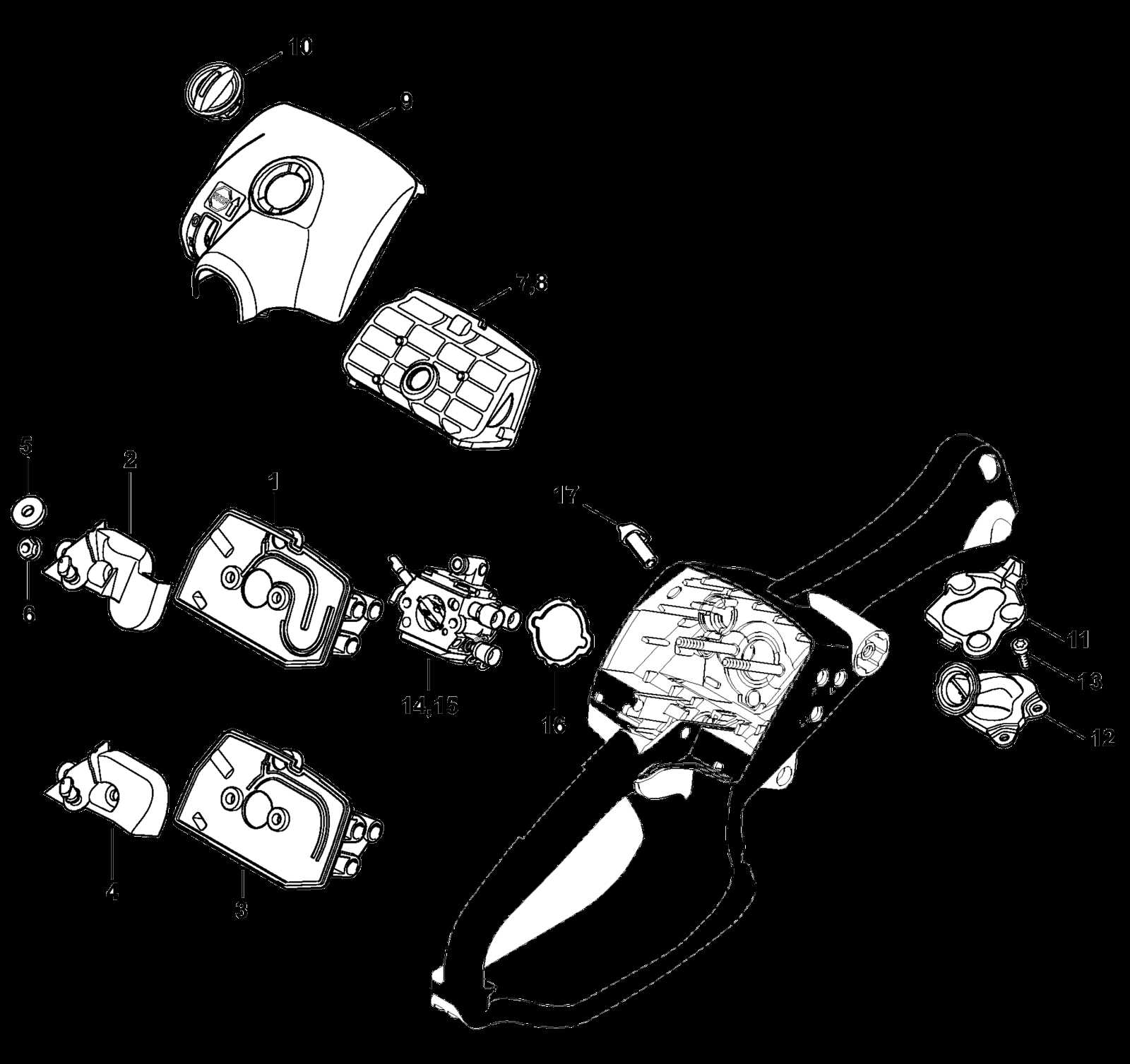

Air Filter and Intake Setup

The air filtration system is a critical component in ensuring optimal performance and longevity of your equipment. A clean and well-maintained air filter allows for efficient airflow, which is essential for the engine to function correctly. Proper setup and regular maintenance of this system can significantly affect the overall efficiency and reliability of the machine.

Installation of the Air Filter: Begin by carefully removing the cover that protects the air intake. Ensure that the area is clean to prevent debris from entering the engine. Position the new filter into its designated slot, making sure it fits snugly and seals properly to avoid any unfiltered air from entering.

Regular Maintenance: To maintain peak performance, it is important to check the air filter periodically. Depending on the working conditions, cleaning or replacing the filter may be necessary. A clogged filter can restrict airflow, leading to decreased power and efficiency.

Intake System Checks: Inspect the intake ducts for any signs of wear or damage. Ensuring that all connections are secure will prevent air leaks, which could compromise engine performance. Any blockages in the intake path should be cleared immediately to maintain proper airflow.

Conclusion: Keeping the air filtration and intake system in optimal condition is crucial for the effective operation of your equipment. Regular checks and maintenance not only enhance performance but also contribute to the longevity of the engine.

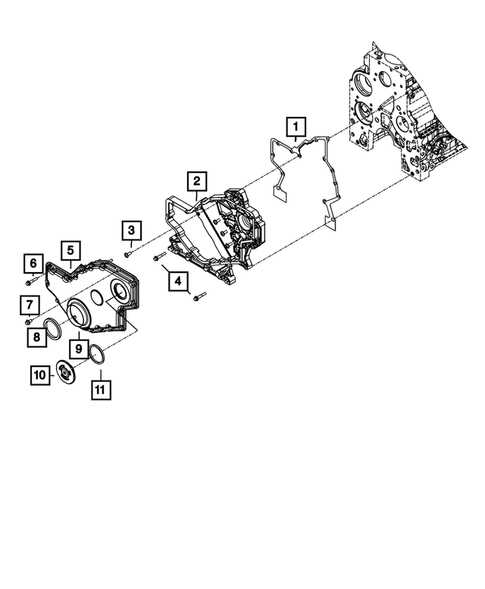

Oil Pump Mechanism and Placement

The oil pump is a crucial component of a chainsaw’s functionality, ensuring proper lubrication to maintain optimal performance and longevity. This mechanism is designed to deliver oil to the guide bar and chain, reducing friction and heat during operation. A well-functioning oil pump is essential for achieving efficient cutting and prolonging the life of the tool.

In terms of placement, the oil pump is typically situated near the engine, allowing for easy access to the oil reservoir. Its design facilitates seamless integration with the engine’s operation, enabling the pump to respond to the tool’s activity effectively. The positioning ensures that oil is delivered precisely where it is needed, enhancing the overall efficiency of the chainsaw.

Understanding the workings of this lubrication system is vital for users who wish to maintain their equipment. Regular checks and maintenance of the oil pump can prevent potential issues, ensuring that the chainsaw operates smoothly. Proper placement and functionality of the pump contribute significantly to the tool’s effectiveness and reliability.

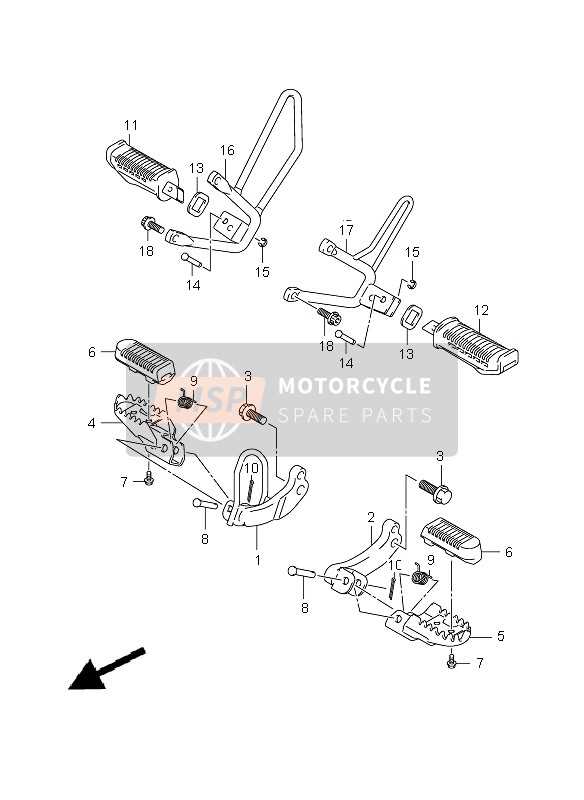

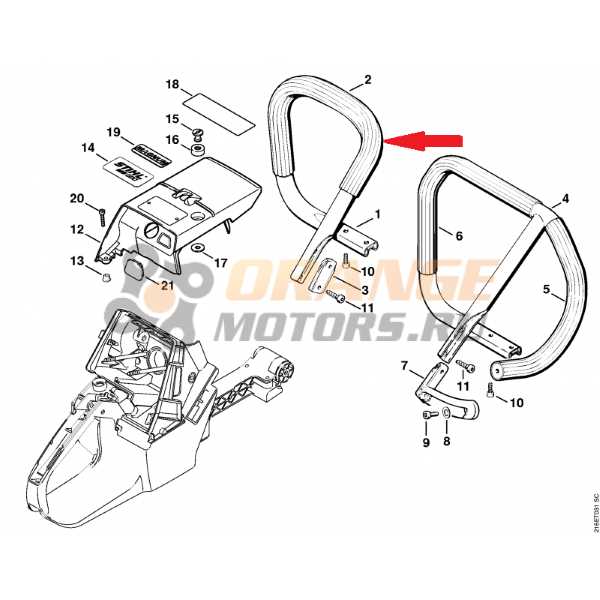

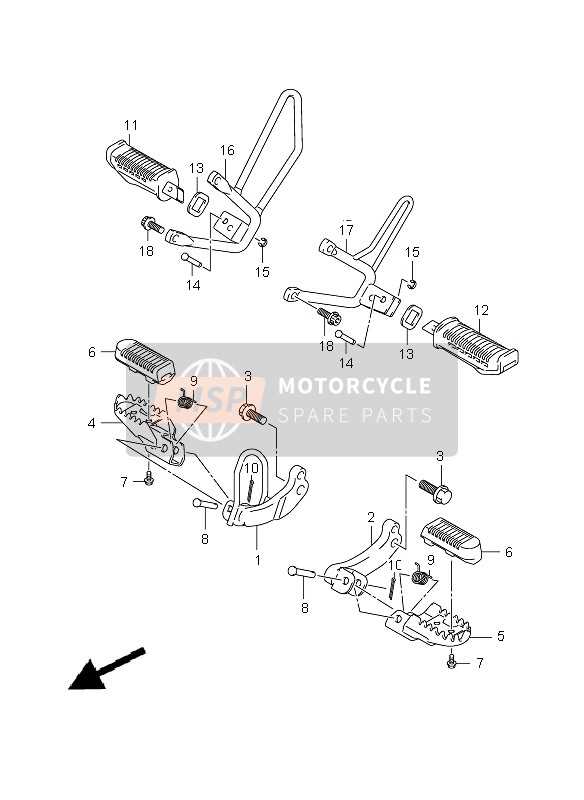

Handle and Control Arrangement

The configuration of handles and control elements is crucial for the effective operation of cutting equipment. An ergonomic design facilitates user comfort while ensuring precise control during use. Proper placement of controls not only enhances functionality but also minimizes the risk of accidents, allowing for a safer working environment.

Handle Design and Ergonomics

The design of the handle plays a significant role in how the operator interacts with the equipment. An ergonomically shaped handle can reduce strain during prolonged use, offering better grip and control. The materials used for the handles must provide durability while being comfortable to hold, even in challenging conditions.

Control Layout and Accessibility

Access to various controls should be intuitive, allowing for quick adjustments without compromising safety. Well-placed switches and levers enable the operator to make necessary changes swiftly, maintaining focus on the task. Additionally, clear labeling of controls enhances usability, making it easier to operate the equipment efficiently.

Muffler and Exhaust Configuration

The design and arrangement of the exhaust system play a crucial role in the performance and efficiency of outdoor power equipment. A well-constructed exhaust system ensures that the engine operates smoothly, minimizes noise levels, and reduces harmful emissions. Understanding the components and their configurations can help users maintain optimal engine performance and extend the life of the equipment.

Components of the Exhaust System

- Muffler: This component is responsible for reducing engine noise and controlling exhaust flow.

- Exhaust Pipe: Connects the muffler to the exhaust outlet, directing gases away from the engine.

- Gaskets: Ensure airtight seals between components, preventing leaks and optimizing performance.

- Heat Shield: Protects surrounding components from excessive heat generated by exhaust gases.

Configuration Considerations

- Ensure proper alignment of the exhaust components to prevent blockages.

- Regularly inspect gaskets and seals for wear to avoid leaks.

- Monitor muffler condition to maintain sound suppression and performance.

- Consider the use of aftermarket components for improved performance if necessary.

In summary, the exhaust system’s configuration significantly influences the overall operation of the equipment. Regular maintenance and attention to detail in the assembly of these components will contribute to better performance and longevity.

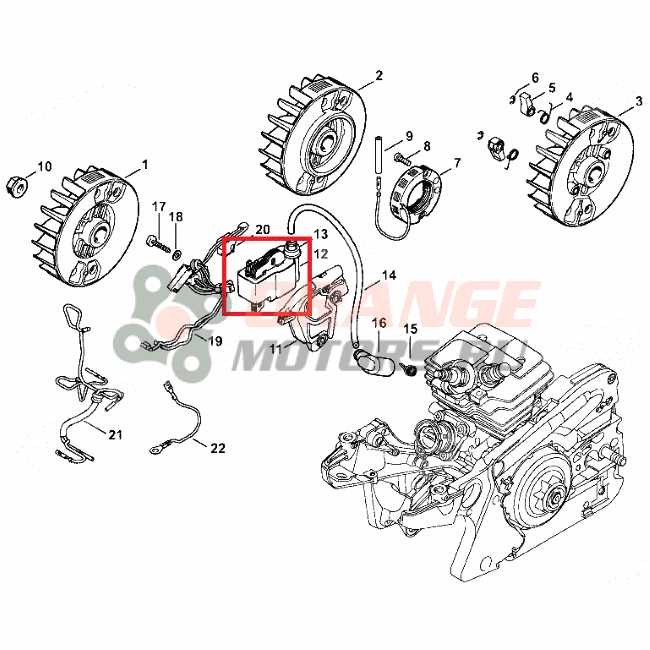

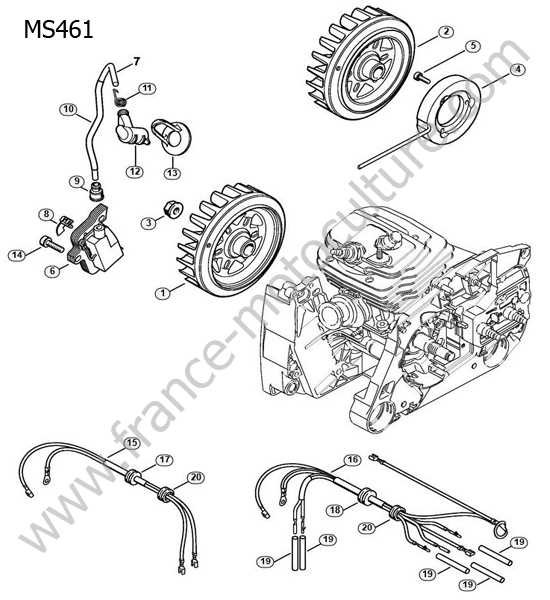

Recoil Starter Assembly Details

The recoil starter assembly is a crucial component that facilitates the engine’s ignition process. It is designed to provide the necessary force to initiate the engine’s operation, ensuring reliable performance. Understanding the structure and function of this assembly can enhance maintenance and troubleshooting efforts.

This assembly consists of several key elements:

- Starter Rope: A durable cord that the user pulls to engage the starter mechanism.

- Starter Pulley: A wheel that rotates when the starter rope is pulled, transmitting the force to the engine flywheel.

- Spring Mechanism: A coil spring that recoils the starter rope after the pull, allowing it to return to its original position.

- Casing: The outer shell that houses the components, providing protection and stability.

Regular inspection of these components can help ensure smooth operation. Signs of wear, such as fraying of the starter rope or difficulty in pulling, should be addressed promptly to prevent further issues. Proper maintenance practices include lubricating moving parts and checking for any loose connections.

By familiarizing oneself with the recoil starter assembly, users can effectively manage their equipment and ensure optimal performance during operation.