Exploring the Stihl MS 460 Parts Diagram for Ultimate Maintenance

Maintaining a powerful and efficient cutting tool requires a solid grasp of its inner workings. Each segment plays a crucial role in ensuring optimal performance, and knowing how they fit together can be invaluable for troubleshooting and repairs. This section aims to enhance your familiarity with the various elements that contribute to the machine’s overall functionality.

From the engine assembly to the cutting mechanism, understanding the relationships between these components can lead to better care and longevity of your equipment. With a comprehensive overview, you can delve into the specifics of each part, ensuring you know what to look for during maintenance or when seeking replacements.

Equipped with the right information, you will be better prepared to address any issues that arise. The ultimate goal is to empower you with the knowledge necessary to keep your tool running smoothly and efficiently, thereby maximizing its performance and extending its lifespan.

Understanding Stihl MS 460 Components

Exploring the various elements of a chainsaw reveals a complex interplay of mechanical components, each serving a specific purpose. Gaining insight into these individual pieces enhances the user’s ability to maintain and troubleshoot effectively, ensuring optimal performance and longevity of the equipment.

Key Elements Overview

Each component contributes to the overall functionality, from power generation to cutting efficiency. Understanding their roles can simplify repair processes and improve user experience.

Component Table

| Component | Function |

|---|---|

| Engine | Powers the chainsaw, providing necessary torque. |

| Bar | Supports the chain, guiding it during operation. |

| Chain | Cutting element that engages with the material. |

| Clutch | Engages and disengages the chain from the engine. |

Overview of MS 460 Features

This section highlights the key characteristics and advantages of a powerful cutting tool designed for professional use. Its robust design and advanced engineering provide exceptional performance and reliability, making it a top choice for demanding tasks.

- Powerful Engine: The machine is equipped with a high-performance engine that delivers impressive cutting speed and efficiency.

- Lightweight Design: Despite its strength, the tool remains lightweight, allowing for easy maneuverability during extended use.

- Ergonomic Handling: The ergonomic handles reduce operator fatigue and enhance comfort, promoting prolonged usage without strain.

- Advanced Chain System: The cutting system is designed for optimal performance, providing smooth and fast cutting action.

- Durability: Constructed from high-quality materials, this equipment is built to withstand rigorous conditions and heavy usage.

Each feature contributes to its overall functionality, making it suitable for a wide range of applications, from professional forestry work to landscaping tasks.

Importance of Accurate Parts Diagram

Having a precise visual representation of components is crucial for effective maintenance and repairs. It ensures that each element is correctly identified and installed, reducing the likelihood of errors during assembly.

Benefits of a Detailed Representation

- Facilitates quick identification of components.

- Enhances understanding of assembly processes.

- Reduces the risk of misplacing or damaging parts.

Impact on Efficiency

- Streamlines the repair process, saving time.

- Improves overall functionality of the equipment.

- Ensures longevity and optimal performance of machinery.

Common Issues with Stihl MS 460

When operating powerful outdoor equipment, users may encounter various challenges that can affect performance and efficiency. Understanding these common issues can help in timely maintenance and ensure a smoother experience. This section highlights some frequent problems faced by users of this specific model and offers insight into potential causes and solutions.

Frequent Problems

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Difficulties | The machine may struggle to start or may not start at all. | Check fuel levels, inspect the spark plug, and ensure the air filter is clean. |

| Overheating | Excessive heat can cause the engine to shut down unexpectedly. | Ensure proper ventilation, clean the cooling fins, and check for fuel blockages. |

| Chain Stalling | The cutting chain may stop unexpectedly during operation. | Check chain tension, inspect for damage, and lubricate the chain properly. |

Maintenance Tips

Regular maintenance is key to preventing these issues. Always refer to the manufacturer’s guidelines for service intervals and recommended practices. Keeping the machine clean, ensuring proper lubrication, and replacing worn components can significantly enhance its longevity and reliability.

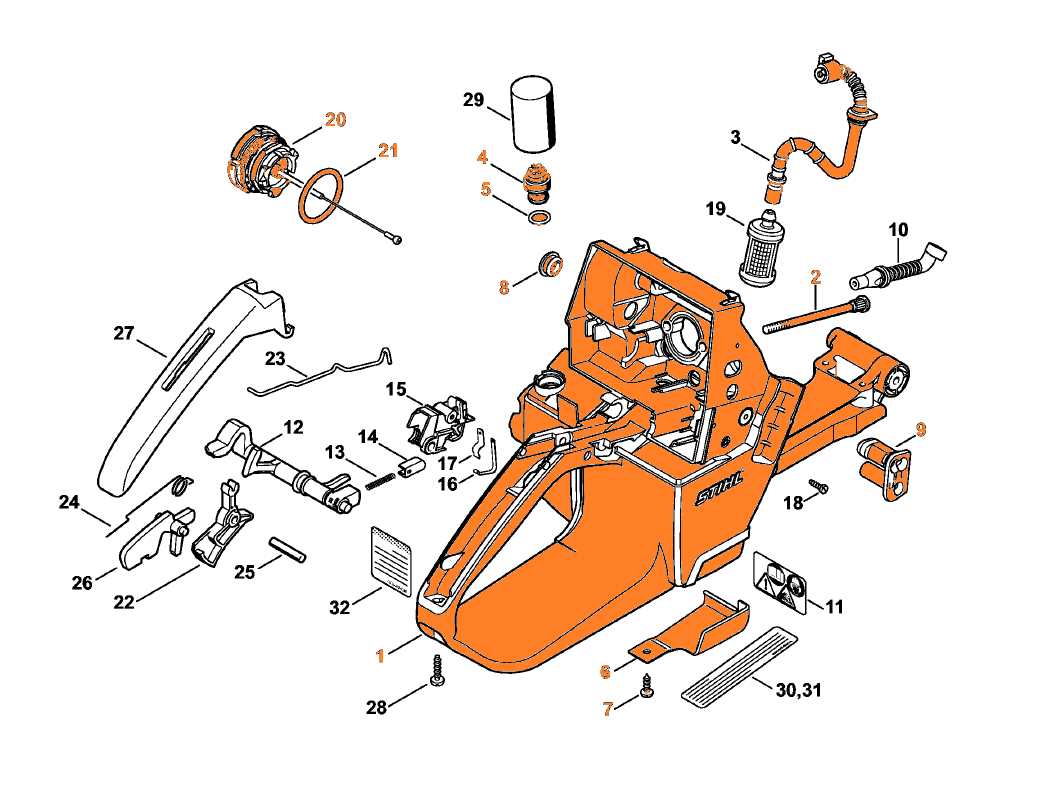

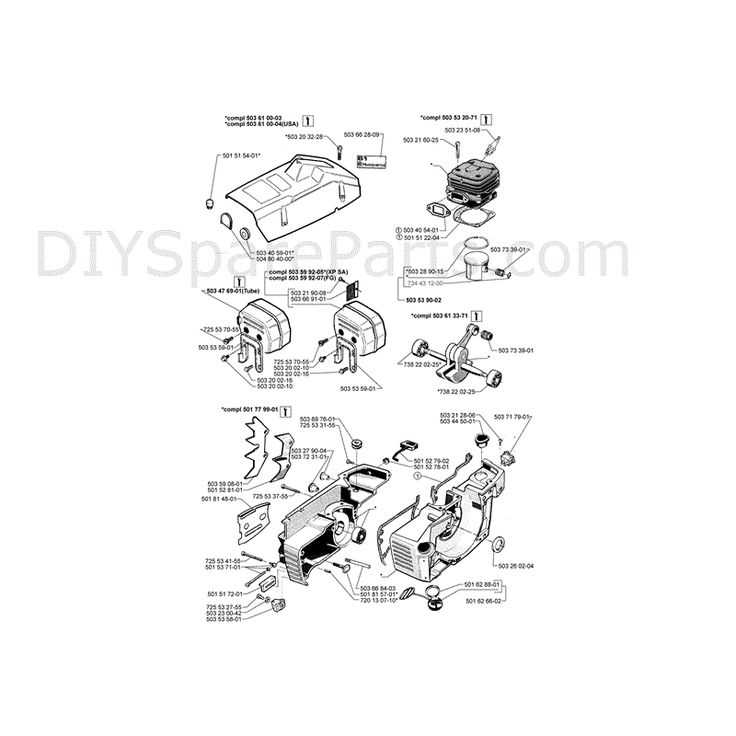

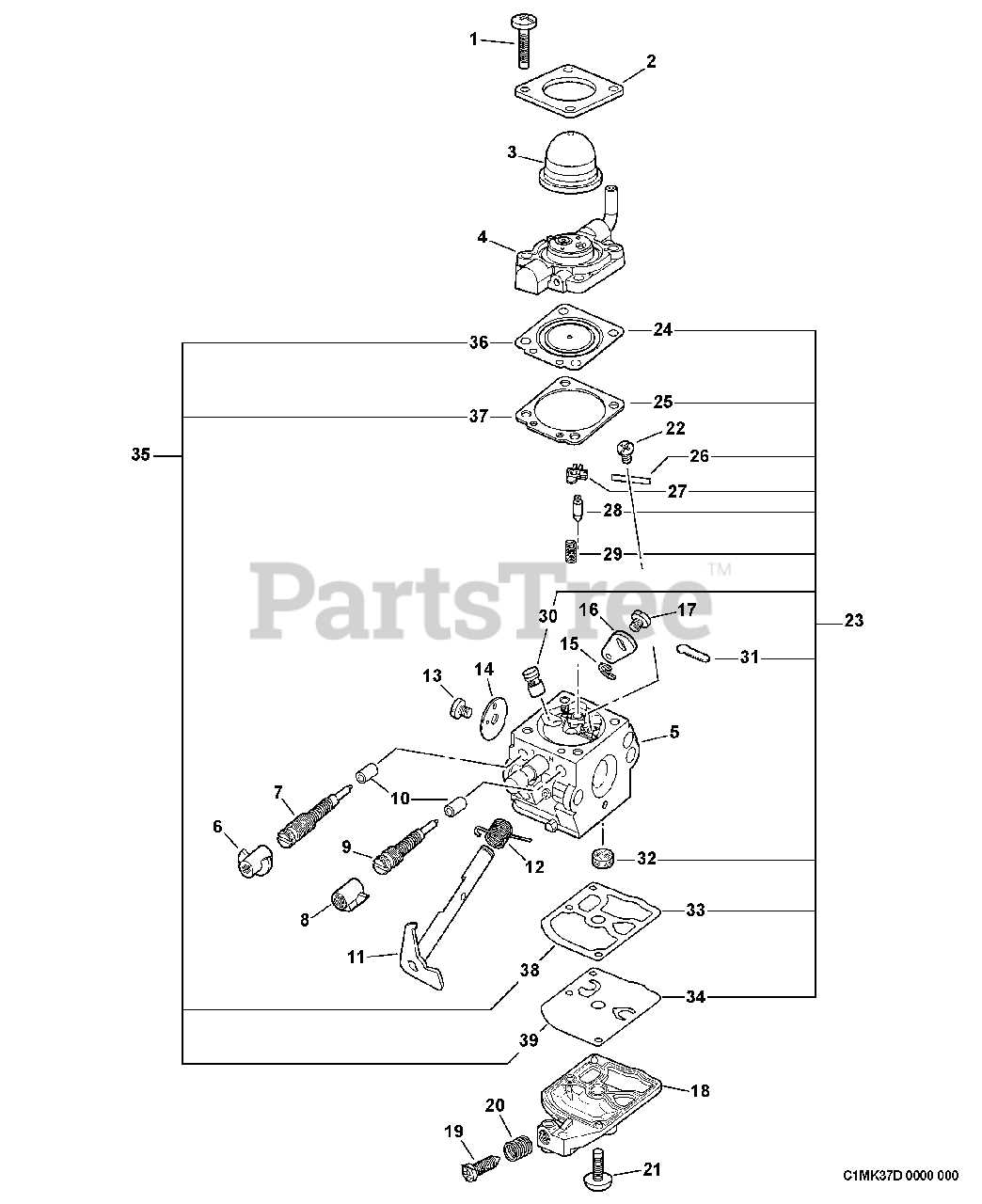

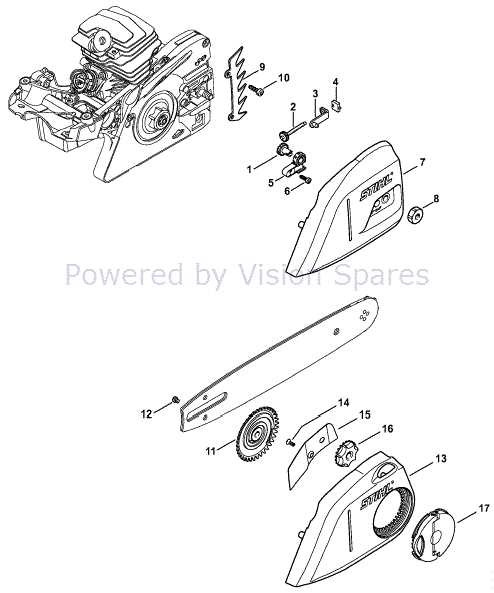

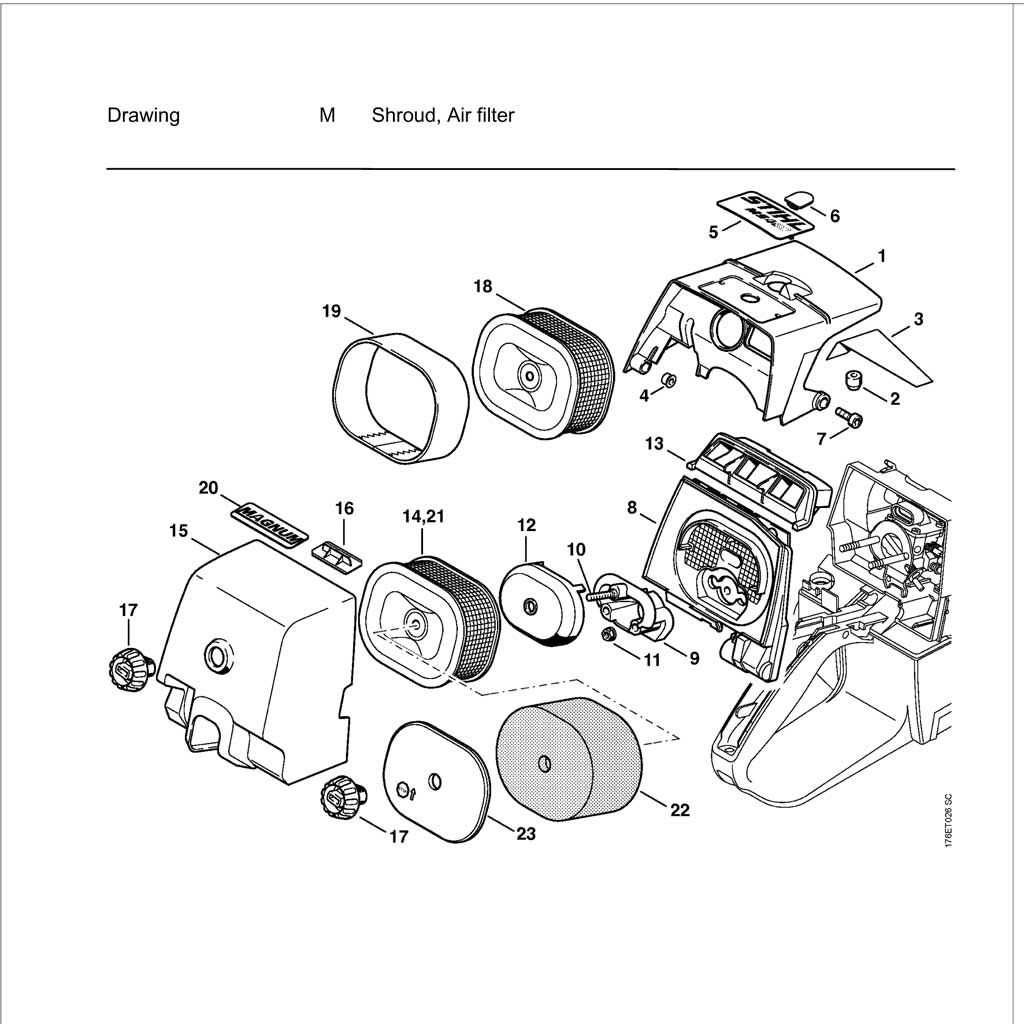

Identifying Parts in the Diagram

Understanding the layout of components in a mechanical illustration is essential for effective maintenance and repair. Each element plays a vital role in the overall functionality of the machine. By familiarizing oneself with the visual representation, users can identify specific components quickly and accurately, ensuring efficient troubleshooting and part replacement.

Key Components to Recognize

When examining the visual guide, focus on the following essential elements:

- Engine Assembly

- Fuel System

- Air Filter

- Chain and Bar

- Starter Mechanism

- Clutch Assembly

Tips for Effective Identification

To enhance your ability to recognize various components, consider these strategies:

- Refer to the legend or key provided with the illustration, which often highlights each part’s function.

- Use a magnifying glass for detailed examination, especially for smaller components.

- Take notes on the arrangement and interconnections between different elements.

- Practice identifying parts in real-life scenarios to reinforce your knowledge.

By following these tips, you can develop a clearer understanding of the machine’s inner workings and improve your repair skills significantly.

How to Use the Parts Diagram

Understanding a component illustration is essential for effective maintenance and repair. This visual guide provides a comprehensive overview of the assembly, enabling users to identify individual elements and their functions within the larger system.

Identifying Components

Begin by familiarizing yourself with the layout of the illustration. Each element is typically labeled with a unique identifier, allowing for easy reference when ordering replacements. Take note of the various sections and their specific roles, as this knowledge will enhance your repair skills.

Planning Repairs

Before starting any maintenance tasks, consult the illustration to determine which parts you may need to replace. Planning ahead can save time and ensure you have the necessary tools and components on hand. Thoroughly review the assembly to anticipate any challenges you may encounter during the process.

Maintenance Tips for MS 460

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following specific care practices, you can prevent common issues and enhance efficiency. This section outlines effective maintenance strategies that will keep your machine in excellent condition.

Routine Checks

Conducting routine inspections is vital. Look for wear and tear on components, ensuring all parts are securely fastened. Regularly check the air filter and fuel system, as clean filters promote better airflow and fuel efficiency.

Cleaning and Lubrication

Maintaining cleanliness is crucial for peak performance. Remove any debris from the exterior and interior of the unit. Additionally, regular lubrication of moving parts minimizes friction, enhancing functionality and preventing premature wear.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect Air Filter | Every 10 hours | Replace if clogged |

| Check Fuel System | Before each use | Ensure no leaks |

| Clean Exterior | After every use | Prevent buildup |

| Lubricate Moving Parts | Every 20 hours | Use recommended lubricant |

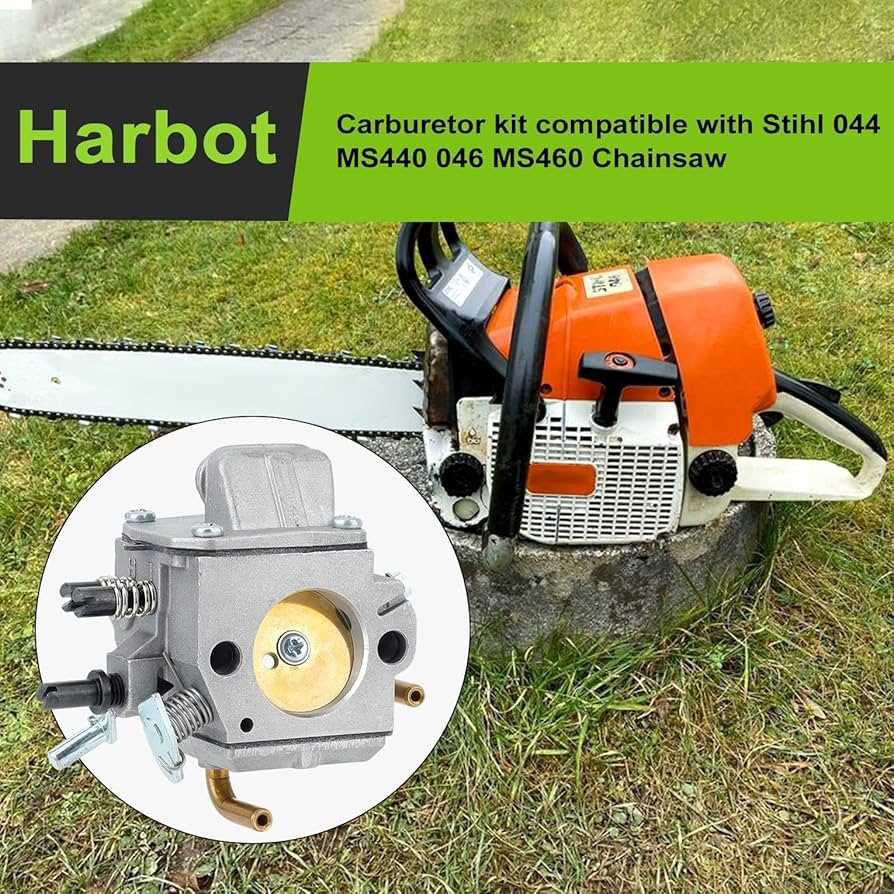

Replacement Parts for Stihl MS 460

Maintaining a high-performance cutting tool requires access to quality components. Whether it’s routine upkeep or necessary repairs, having the right elements ensures optimal functionality and longevity.

Key replacements to consider include:

- Chains

- Guide bars

- Filters

- Fuel lines

- Spark plugs

Regularly assessing these components can prevent downtime and enhance the overall performance of your equipment.

For those looking to explore further:

- Check compatibility with your specific model.

- Prioritize genuine components for best results.

- Consult user manuals for detailed information.

Investing in high-quality replacements is crucial for maintaining efficiency and reliability.

Cost Considerations for Repairs

When it comes to maintaining equipment, understanding the financial implications of repairs is crucial. This includes evaluating both the cost of replacement components and the potential labor expenses associated with service. Being informed can help in making sound financial decisions and prolonging the lifespan of your machinery.

Factors Influencing Repair Costs

Several elements can affect the overall expense of repairs. The age of the machinery, availability of components, and whether the work is done professionally or as a DIY project can significantly impact costs.

Estimated Cost Breakdown

| Cost Element | Estimated Range |

|---|---|

| Components | $50 – $300 |

| Labor | $40 – $100 per hour |

| Service Fees | $30 – $100 |

| Miscellaneous Supplies | $10 – $50 |

Where to Find Genuine Parts

When it comes to maintaining equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Genuine items not only guarantee compatibility but also provide peace of mind, knowing that quality standards have been met. Here are some reliable sources where you can find these essential components.

| Source | Description |

|---|---|

| Authorized Dealers | Visit certified retailers who specialize in equipment and offer a range of original components. These dealers are knowledgeable and can assist in identifying the right parts. |

| Official Websites | Many manufacturers have online platforms where you can browse and order genuine items directly. This ensures that you receive quality products that meet the necessary specifications. |

| Specialty Stores | Look for shops that focus on outdoor equipment. They often carry a selection of authentic components and can provide expert advice on maintenance and repairs. |

| Online Marketplaces | Reputable online platforms can be a good source for original components. Ensure that sellers are verified to avoid counterfeit products. |

By utilizing these resources, you can ensure that your equipment remains in top condition with reliable and authentic components.

Benefits of Regular Maintenance Checks

Routine upkeep is essential for the longevity and efficiency of any machinery. Regular inspections not only enhance performance but also prevent potential issues before they escalate. By staying proactive, users can ensure their equipment operates at its best, leading to increased productivity and reduced downtime.

Improved Performance

Consistent maintenance helps to identify and resolve minor problems that could hinder functionality. When machinery is well-maintained, it operates smoothly, allowing users to achieve optimal results in their tasks.

Cost Savings

Investing time in regular checks can lead to significant financial savings over time. By addressing issues early, users can avoid costly repairs and extend the lifespan of their equipment, making maintenance a wise investment.