Stihl MS170 Parts Breakdown and Diagram PDF Guide

When working with power tools, particularly those used for cutting and trimming, it is crucial to have a clear understanding of their various components. This knowledge not only enhances the efficiency of the tool but also simplifies maintenance and repairs. A comprehensive visual representation of these elements can significantly aid in identifying each part’s function and interrelation.

Accessing detailed illustrations or charts showcasing the intricate assembly of these machines provides valuable insights. Such resources can assist users in troubleshooting issues and performing regular upkeep effectively. By familiarizing oneself with the tool’s structure, operators can ensure optimal performance and longevity.

Whether you are a seasoned professional or a casual user, having access to well-organized information about the machinery you utilize is essential. It empowers you to make informed decisions regarding repairs, replacements, and upgrades, ultimately leading to a safer and more efficient working environment.

Stihl MS170 Parts Breakdown Overview

This section provides a comprehensive overview of the components and assemblies found in a popular chainsaw model. Understanding these elements is crucial for proper maintenance, repair, and overall performance enhancement of the equipment. By examining the various sections and components, users can ensure their machine operates efficiently and safely.

Key components include:

- Engine assembly

- Fuel system

- Ignition system

- Cutting mechanism

- Bar and chain assembly

- Handle and control features

Each of these categories consists of individual parts that contribute to the functionality of the device. Below is a brief description of each key component:

- Engine Assembly: This includes the cylinder, piston, and other internal mechanisms that generate power.

- Fuel System: Comprising the fuel tank, filter, and lines, this system is responsible for delivering fuel to the engine.

- Ignition System: This element encompasses the spark plug and ignition coil, essential for starting the engine.

- Cutting Mechanism: This involves the chain and guide bar, which are vital for the cutting action.

- Bar and Chain Assembly: The combination of the guide bar and chain ensures effective cutting and maneuverability.

- Handle and Control Features: These include the throttle trigger, brake, and handles, which allow for safe operation.

Understanding these assemblies will aid users in troubleshooting and performing necessary repairs, ultimately prolonging the lifespan of the equipment.

Key Components of the Stihl MS170 Chainsaw

The efficient operation of a chainsaw relies on several essential elements that work in harmony to deliver optimal performance. Understanding these key components is crucial for users seeking to maintain and troubleshoot their equipment effectively. Each part plays a significant role in ensuring the smooth functionality of the tool, ultimately enhancing its cutting capabilities.

| Component | Description |

|---|---|

| Engine | The powerhouse of the chainsaw, providing the necessary energy for operation. |

| Guide Bar | This long metal bar serves as a track for the chain, allowing for precise cutting. |

| Chain | The rotating loop of sharp teeth that engages the wood, facilitating the cutting process. |

| Air Filter | A critical element that prevents dust and debris from entering the engine, ensuring its longevity. |

| Fuel Tank | This component holds the mixture of fuel and oil required for engine operation. |

| Starter Mechanism | The system that allows the user to ignite the engine, typically involving a pull cord. |

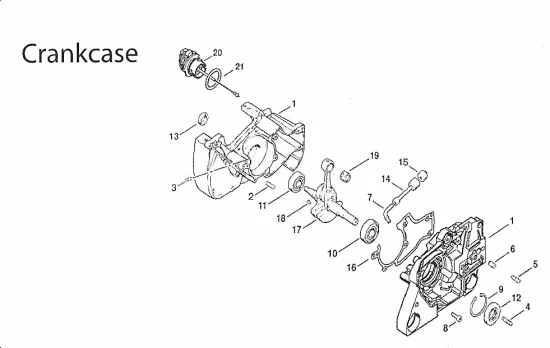

Guide to Understanding the MS170 Parts Diagram

Understanding the intricacies of a machine’s components is essential for effective maintenance and repair. This section aims to provide insights into how to interpret the visual representation of various elements of a specific model, highlighting their functions and interrelationships. A well-structured illustration can serve as a valuable reference for both novice users and experienced technicians.

Importance of Component Identification

Recognizing each component’s role within the assembly is crucial for troubleshooting and performing replacements. When you familiarize yourself with the layout, you can easily identify the areas that require attention or servicing. This knowledge enhances your ability to carry out repairs efficiently, ensuring that the machinery operates smoothly and reliably.

Navigating the Visual Representation

The visual reference is typically organized into distinct sections, each representing different functional groups. Pay close attention to the labels and numbers associated with each item, as they will guide you in sourcing the correct replacements. Additionally, understanding the connections and placements can prevent errors during reassembly, saving both time and resources.

Essential Maintenance Tips for Stihl MS170

Proper upkeep of your outdoor power equipment is vital for ensuring optimal performance and longevity. Regular maintenance helps prevent issues that can lead to costly repairs and extends the life of the tool. Here are some essential tips to keep your equipment running smoothly.

- Regular Cleaning: Keep the exterior of your equipment clean by removing dirt, debris, and residue. This helps prevent corrosion and ensures efficient operation.

- Inspect Filters: Regularly check and replace air and fuel filters to maintain proper airflow and fuel flow, enhancing engine performance.

- Sharpen the Blade: A sharp blade not only cuts more efficiently but also reduces strain on the engine. Sharpen it regularly or replace it when worn.

- Check the Spark Plug: Ensure the spark plug is clean and in good condition. Replace it as needed to promote smooth starting and efficient combustion.

- Oil Maintenance: Regularly check and change the oil to keep the engine lubricated and functioning optimally. Follow the manufacturer’s recommendations for oil type and change intervals.

- Inspect Cables and Hoses: Look for signs of wear, cracks, or damage in cables and hoses. Replace any faulty components to prevent leaks and ensure safety.

Following these maintenance tips will not only enhance performance but also contribute to the safety and reliability of your outdoor equipment. Establish a routine maintenance schedule to keep everything in top shape.

How to Identify Worn-Out Chainsaw Parts

Recognizing the signs of wear and tear in a chainsaw is crucial for maintaining its efficiency and ensuring safe operation. Regular inspections can help you spot issues before they escalate into more significant problems, ultimately prolonging the life of the tool. Below are some common indicators that may signal the need for replacement components.

Common Indicators of Wear

Several visual and functional cues can help you determine if certain elements of your cutting tool are worn out. For instance, the cutting efficiency may decline, and you might notice unusual vibrations or sounds during operation. Here are some specific components to check:

| Component | Signs of Wear |

|---|---|

| Guide Bar | Uneven wear, bending, or visible grooves |

| Chain | Stretched links, broken teeth, or dullness |

| Sprocket | Worn teeth or difficulty in chain movement |

| Air Filter | Clogging or visible damage |

Performing Routine Checks

Establishing a routine maintenance schedule is vital. Regularly inspecting these components will help you identify potential issues early. Ensure to consult the user manual for specific guidelines on how to examine each part effectively, as this can vary depending on the model. A proactive approach will not only enhance performance but also provide a safer working environment.

Replacing Key Parts in the MS170 Chainsaw

Maintaining optimal performance in a chainsaw often requires the replacement of essential components. Understanding how to effectively replace these elements is crucial for ensuring the longevity and efficiency of the tool. This section will guide you through the process of replacing critical parts, enhancing the chainsaw’s functionality and reliability.

Identifying Components for Replacement

Before beginning the replacement process, it’s important to identify which components need attention. Commonly replaced elements include the cutting chain, guide bar, and air filter. Regular inspections will help you determine wear and tear, allowing for timely replacements to prevent further damage.

Step-by-Step Replacement Process

To replace a component, start by ensuring the chainsaw is powered off and disconnected from any power source. For the cutting chain, remove the guide bar cover and take out the old chain. Install the new chain by threading it around the guide bar and securing it back in place. Similarly, replace the air filter by removing the cover, taking out the old filter, and inserting the new one. Ensure everything is tightened and secure before use.

Common Issues with Stihl MS170 Components

Many users encounter a variety of challenges when operating and maintaining their equipment. Understanding the common problems associated with different elements can help in identifying issues early and ensuring smooth functionality. Here are some frequent complications that may arise.

1. Fuel System Problems: Issues with the fuel system can lead to performance disruptions. Clogged filters or fuel lines can restrict the flow of fuel, causing the engine to sputter or stall. Regular inspection and cleaning are essential to prevent these problems.

2. Ignition System Failures: If the ignition system is malfunctioning, starting the equipment may become difficult. A faulty spark plug or ignition coil can result in weak or no spark, preventing the engine from firing properly. Checking these components periodically can help avoid such scenarios.

3. Chain and Bar Wear: Over time, the chain and bar may show signs of wear and tear, affecting cutting efficiency. Dull chains can lead to increased strain on the engine and may cause it to overheat. Regular sharpening and maintenance are crucial to extend the life of these components.

4. Air Filter Blockage: A dirty air filter can hinder airflow, causing the engine to run rich or lean. This not only affects performance but can also lead to potential engine damage. Regular cleaning or replacement of the air filter is recommended for optimal operation.

5. Oil Leakage: Oil leaks can indicate problems with seals or gaskets. Not only can this lead to loss of lubrication, but it can also cause environmental concerns. Regular checks for leaks can help maintain the equipment’s integrity and prevent costly repairs.

Accessing a PDF Diagram for MS170 Parts

Obtaining a visual reference for equipment components can significantly enhance understanding and ease of maintenance. A comprehensive schematic serves as a valuable tool for both novice and experienced users, providing detailed insights into the assembly and functionality of various elements. In this section, we will explore the best methods to access a visual guide that outlines the essential components of your tool.

Where to Find the Visual Reference

- Official Manufacturer’s Website: Many brands offer downloadable resources directly on their sites.

- Online Forums: User communities often share useful links and documents related to maintenance.

- Retailer Support Pages: Some authorized sellers provide access to technical documentation.

Benefits of Using a Visual Reference

- Improved Clarity: Visual aids make it easier to identify and understand each component.

- Enhanced Repair Skills: Knowledge gained from schematics can lead to more effective troubleshooting.

- Time Efficiency: Quick access to diagrams can save time during maintenance or repairs.

Chainsaw Engine Parts Explained

Understanding the components of a chainsaw engine is crucial for effective maintenance and operation. Each part plays a specific role in ensuring the saw functions optimally, providing the power needed for various cutting tasks. This section will delve into the essential elements that make up a typical chainsaw engine, offering insights into their functions and importance.

Key Components of a Chainsaw Engine

- Engine Block: The foundation of the chainsaw, housing various components and providing structural integrity.

- Piston: Moves up and down within the cylinder, compressing the air-fuel mixture to facilitate combustion.

- Crankshaft: Converts the linear motion of the piston into rotational motion, driving the chain.

- Cylinder: Encases the piston and is where the combustion process occurs.

- Carburetor: Mixtures air and fuel in the correct proportions for efficient combustion.

- Ignition System: Provides the spark needed to ignite the air-fuel mixture, starting the engine.

Supporting Elements

- Fuel Tank: Stores the fuel required for the engine to operate.

- Oil Reservoir: Contains lubricant for the chain and bar, ensuring smooth operation.

- Air Filter: Prevents dirt and debris from entering the engine, promoting longevity.

- Exhaust System: Channels combustion gases away from the engine, reducing emissions and improving efficiency.

Familiarity with these components helps in troubleshooting and performing necessary repairs or maintenance tasks, ensuring the chainsaw remains in peak condition for any project.

Proper Care for the MS170 Guide Bar

Maintaining the guide bar is essential for ensuring optimal performance and longevity of your cutting tool. Regular care not only enhances efficiency but also prevents potential issues that could arise from neglect. Proper upkeep involves several key practices that should be incorporated into your routine maintenance schedule.

Here are some important steps to follow for effective care:

- Regular Cleaning: Remove any debris, sawdust, and residue from the guide bar after each use. This helps prevent buildup that can affect performance.

- Lubrication: Ensure the bar is well-lubricated during operation. Use high-quality oil to reduce friction and heat, extending the bar’s life.

- Inspection: Frequently check for wear and tear. Look for cracks, bends, or other damage that could impair functionality.

- Bar Adjustment: Regularly adjust the tension of the chain to prevent unnecessary stress on the guide bar, ensuring it runs smoothly.

- Rotation: Periodically rotate the guide bar to promote even wear. This practice can help maintain its shape and performance over time.

By implementing these care techniques, users can enhance the performance and extend the lifespan of their guide bars, ensuring efficient and safe operation during cutting tasks.

Chainsaw Chain Tension and Replacement Guide

Maintaining the correct tension of the cutting chain is crucial for optimal performance and safety when using a power saw. Proper tension ensures effective cutting, prevents premature wear, and reduces the risk of accidents. This section outlines the necessary steps for adjusting the chain tension and replacing the chain when required.

Chain Tension Adjustment

Adjusting the tension of the cutting chain involves several key steps. First, ensure that the engine is turned off and the unit is disconnected from any power source. Following this, locate the tensioning mechanism, which typically comprises a screw or lever that modifies the position of the guide bar. Turn the adjustment screw clockwise to increase tension and counterclockwise to decrease it. The ideal tension allows the chain to move freely around the bar while maintaining a snug fit against the drive sprocket.

Chain Replacement Process

When a chain exhibits significant wear, damage, or stretching, it is essential to replace it to ensure the efficiency and safety of the tool. To begin the replacement process, remove the bar cover and take off the worn chain. Ensure that the new chain is compatible with the specific model of the power saw. Place the new chain around the guide bar, ensuring it follows the proper path over the drive sprocket and under the guide bar. Reattach the bar cover and adjust the tension as previously described to complete the replacement.

| Action | Procedure |

|---|---|

| Check Chain Tension | Inspect the chain for slack and adjust accordingly. |

| Adjust Tension | Use the tensioning mechanism to achieve optimal fit. |

| Remove Old Chain | Detach the bar cover and take off the worn chain. |

| Install New Chain | Place the new chain around the guide bar and reattach the cover. |

| Final Tension Adjustment | Ensure the new chain is properly tensioned before use. |

Buying Original Replacement Parts for Stihl MS170

When it comes to maintaining your equipment, selecting authentic replacement components is crucial for ensuring optimal performance and longevity. Utilizing genuine products not only enhances the efficiency of your machine but also provides peace of mind that you are investing in quality.

Here are several reasons why choosing original components is beneficial:

- Quality Assurance: Genuine items are manufactured to high standards, ensuring they fit perfectly and function effectively.

- Durability: Original replacements are designed to withstand rigorous use, offering a longer lifespan compared to aftermarket alternatives.

- Compatibility: Using authentic components guarantees that all parts work seamlessly together, minimizing the risk of operational issues.

- Warranty Protection: Many manufacturers offer warranties on their equipment, which can be voided if non-original items are used.

To ensure you are purchasing authentic replacements, consider the following tips:

- Purchase from authorized dealers or official websites to avoid counterfeit products.

- Check for certification marks and packaging details that indicate the item is genuine.

- Consult the user manual or product specifications to identify the correct components required for your equipment.

- Keep receipts and documentation to maintain warranty coverage.

By investing in original components, you can be confident that your equipment will perform at its best, providing you with reliable service for years to come.