Understanding the Stihl MS170 Parts Diagram for Easy Repairs

For enthusiasts and professionals alike, a comprehensive understanding of a chainsaw’s inner workings is essential. This section aims to provide insights into the various elements that contribute to the overall performance and functionality of your equipment. By exploring these components, users can ensure optimal maintenance and effective operation.

Identifying each piece is crucial for troubleshooting and repairs. Recognizing how individual parts interact can enhance your knowledge and confidence when handling any issues that may arise. Furthermore, having a clear visual representation of these components can simplify the process, making it more accessible for everyone.

As we delve into the specifics, you’ll discover the ultimate guide to navigating your chainsaw’s structure. This will not only help you in maintenance but also empower you to make informed decisions about upgrades and replacements. Understanding the anatomy of your tool is a valuable step towards achieving peak performance.

Understanding the Stihl MS170 Overview

This section aims to provide a comprehensive insight into a popular model in the realm of outdoor power equipment. Known for its reliability and efficiency, this tool is widely appreciated among both professional landscapers and DIY enthusiasts.

Key features include:

- Lightweight design for easy handling

- Powerful engine for efficient cutting

- User-friendly controls for enhanced convenience

- Durable construction for long-lasting performance

When considering this equipment, it is essential to understand its core components, which contribute to its overall functionality:

- Engine: The heart of the machine, providing the necessary power.

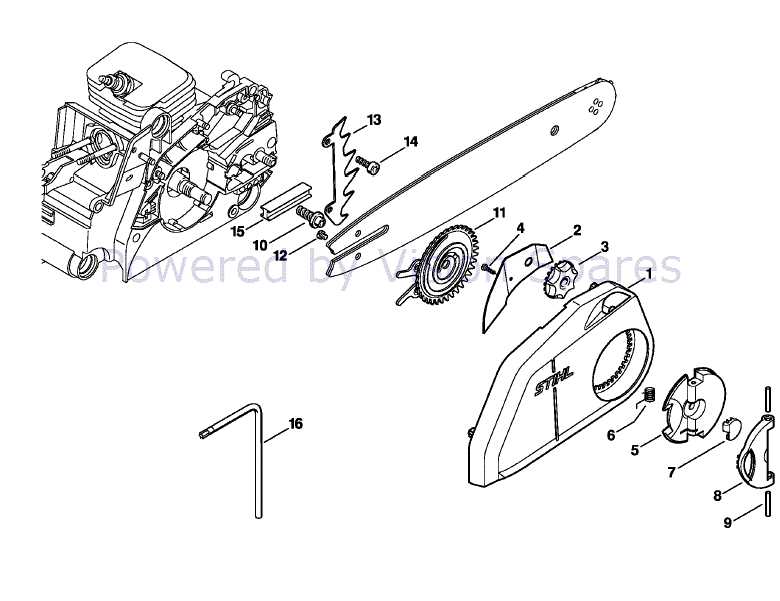

- Guide bar: Essential for directing cuts with precision.

- Chain: The cutting element that interacts with the wood.

- Fuel system: Ensures optimal performance through effective fuel delivery.

By familiarizing oneself with these aspects, users can maximize the effectiveness and longevity of this versatile tool.

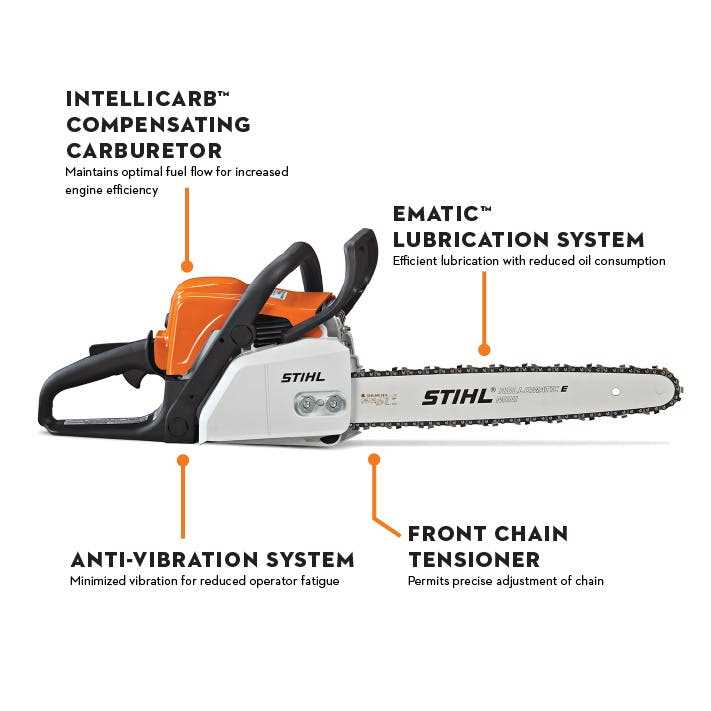

Key Features of the MS170 Chainsaw

This powerful cutting tool is designed for both beginners and experienced users, offering an excellent combination of performance, ease of use, and reliability. Its innovative features ensure efficient operation while maintaining safety standards, making it an ideal choice for various tasks around the home or in the garden.

Power and Performance

Equipped with a robust engine, this model delivers impressive cutting speed and efficiency. The lightweight design enhances maneuverability, allowing users to tackle branches and logs with ease. Its exceptional power-to-weight ratio makes it suitable for a wide range of applications, from trimming to more demanding cutting tasks.

User-Friendly Features

Ease of operation is a hallmark of this chainsaw. Its ergonomic handle provides a comfortable grip, reducing fatigue during extended use. Additionally, the quick-release air filter and tool-free fuel cap facilitate hassle-free maintenance, ensuring the equipment remains in optimal condition with minimal effort.

| Feature | Description |

|---|---|

| Engine Power | Efficient engine delivers strong performance for cutting tasks. |

| Lightweight Design | Easy to handle, reducing user fatigue. |

| Ergonomic Handle | Comfortable grip enhances control and reduces strain. |

| Quick-Release Air Filter | Simplifies maintenance and improves engine longevity. |

| Tool-Free Fuel Cap | Allows for easy refueling without the need for tools. |

Importance of Parts Diagrams

Understanding the intricacies of machinery often requires a visual representation of its components. Such illustrations serve as essential tools for both novices and experts, facilitating the identification and organization of various elements within a system. These visuals enhance comprehension, allowing users to grasp complex relationships and functionalities more easily.

One of the primary benefits of these schematics is their role in maintenance and repair tasks. When users can pinpoint specific sections and components, they are better equipped to troubleshoot issues effectively. This clarity not only streamlines the repair process but also minimizes the risk of errors that could arise from misidentification.

Moreover, these representations promote a deeper understanding of the overall structure, enabling users to appreciate how each element contributes to the functionality of the whole. This knowledge fosters confidence in handling equipment, encouraging proactive care and timely interventions when problems arise.

In educational contexts, such illustrations are invaluable. They serve as visual aids that can enhance learning experiences, making complex concepts more accessible and engaging for learners. By breaking down machinery into understandable parts, these resources can ignite interest and inspire further exploration of engineering and technology fields.

Common Replacement Parts for MS170

Regular maintenance is essential for keeping your chainsaw in optimal condition. Understanding the most frequently replaced components can help you ensure that your tool operates smoothly and efficiently. Here, we will explore key elements that may require replacement over time, allowing for prolonged use and performance enhancement.

Essential Components

One of the primary items that often needs to be changed is the cutting chain, which endures significant wear from continuous use. Additionally, the guide bar may also require attention, as it can become worn or damaged. Fuel filters are crucial for maintaining engine health and should be replaced periodically to avoid clogging and operational issues.

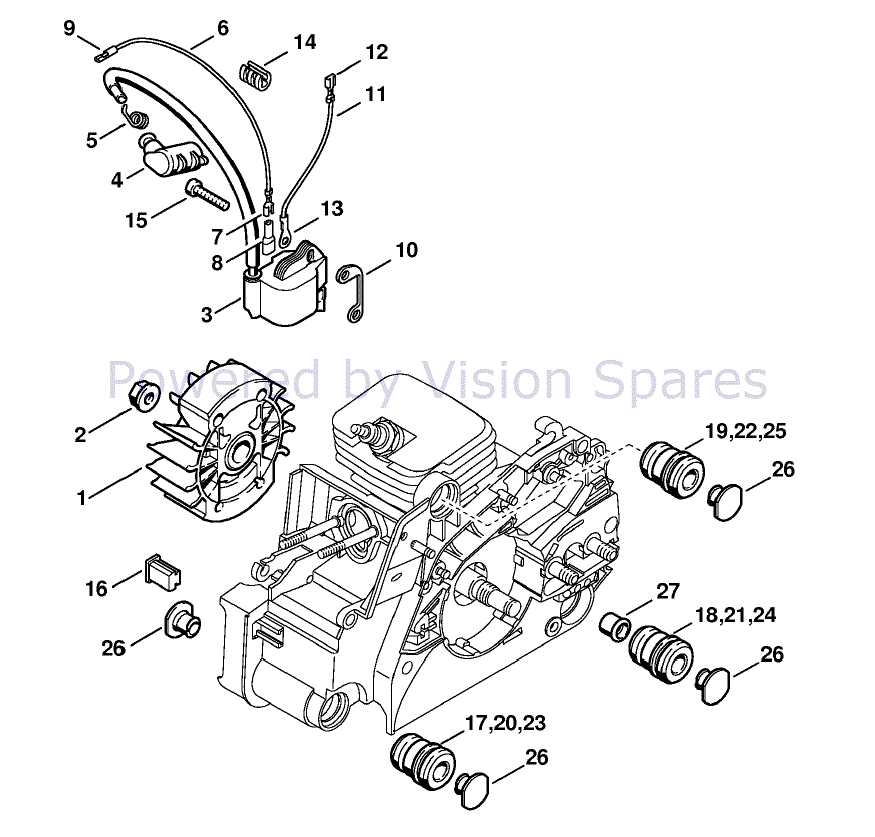

Maintenance Items

Another critical component is the spark plug, which plays a vital role in starting the engine and ensuring smooth combustion. Air filters should also be checked regularly, as a clogged filter can lead to decreased performance. Lastly, inspecting the oiler and fuel lines is important to prevent leaks and ensure proper lubrication during operation.

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for ensuring optimal performance and longevity. Understanding where to seek these items can save time and enhance the reliability of your tools.

Authorized Dealers

One of the most reliable sources for original components is through authorized dealers. They offer:

- Quality assurance

- Expert advice

- A full range of items specific to your equipment

Online Resources

The internet provides a wealth of options for purchasing genuine items. Consider the following:

- Manufacturer’s official website

- Reputable online retailers

- Dedicated forums and communities

These platforms often feature user reviews that can guide your selection process.

How to Read a Parts Diagram

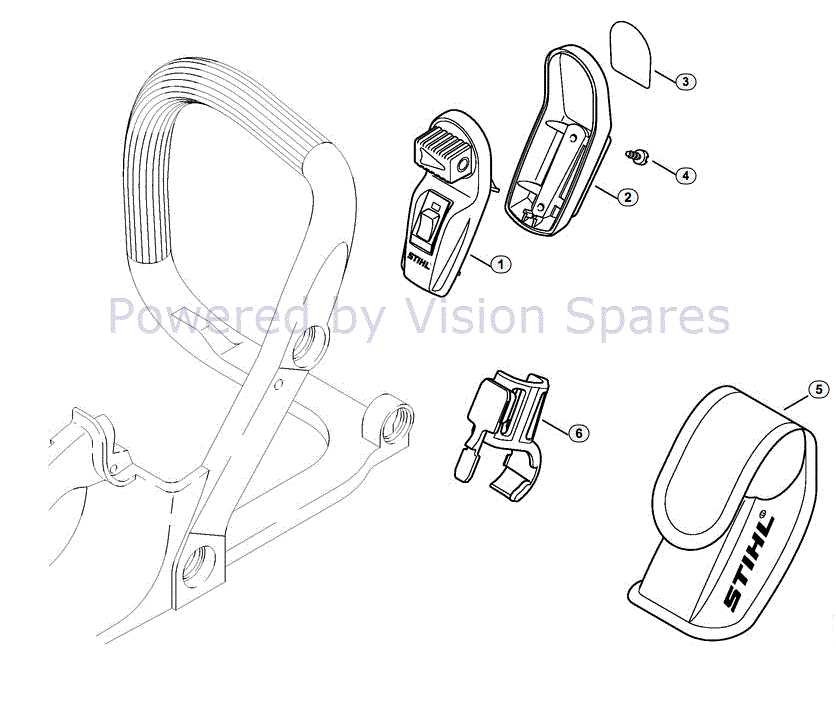

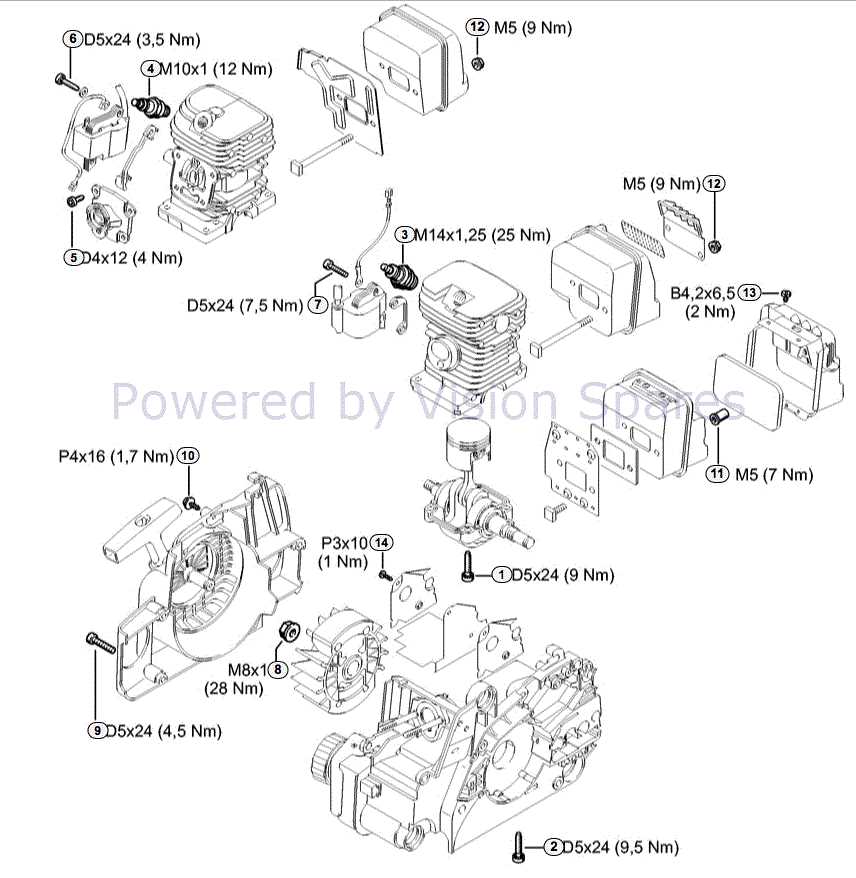

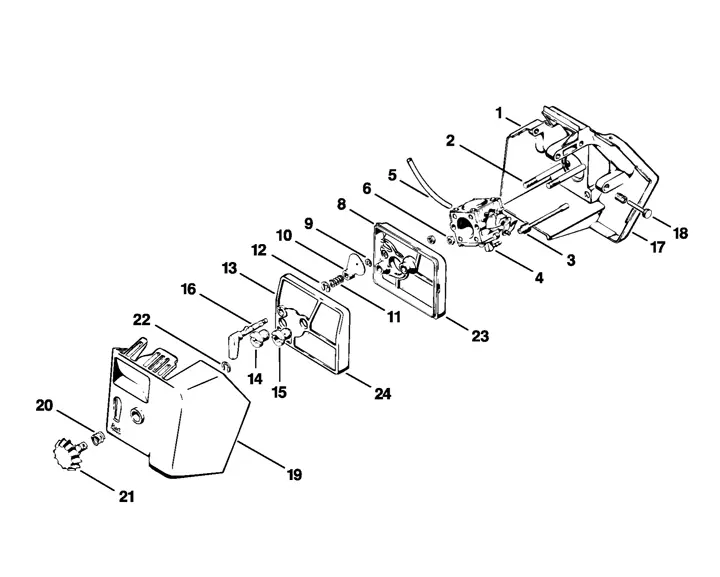

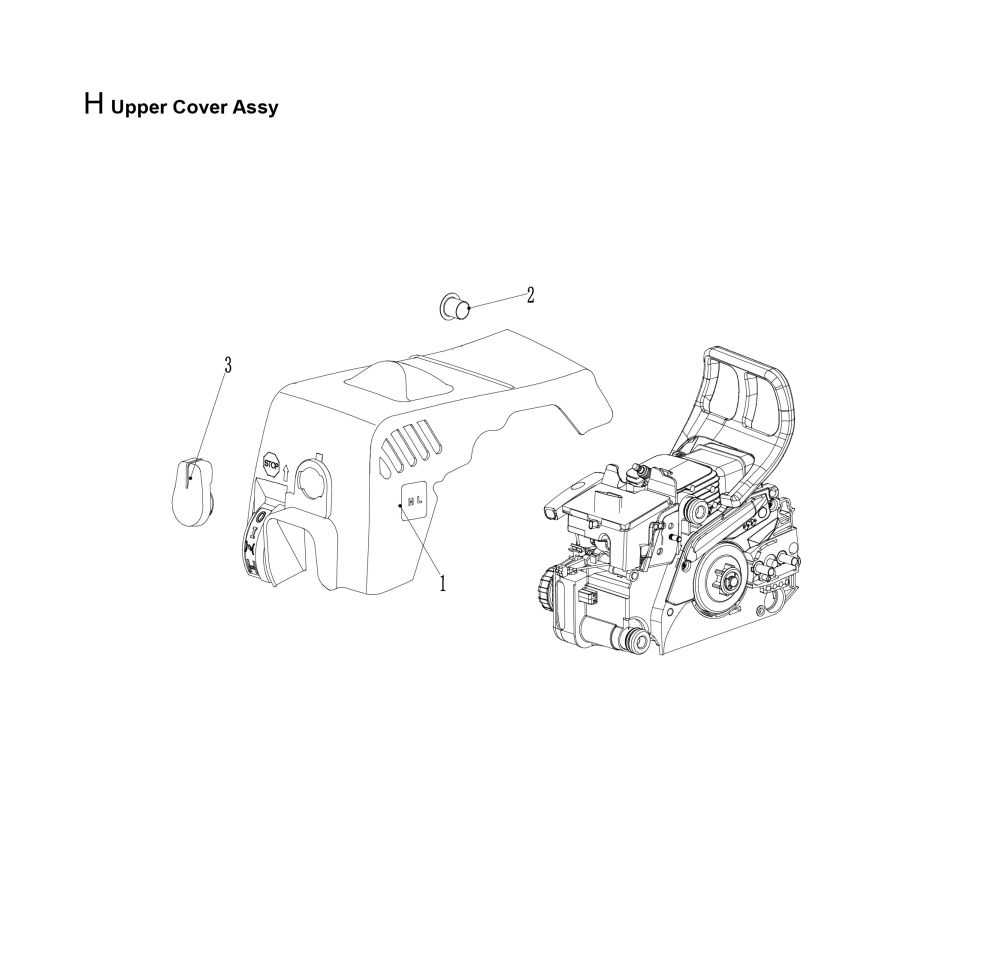

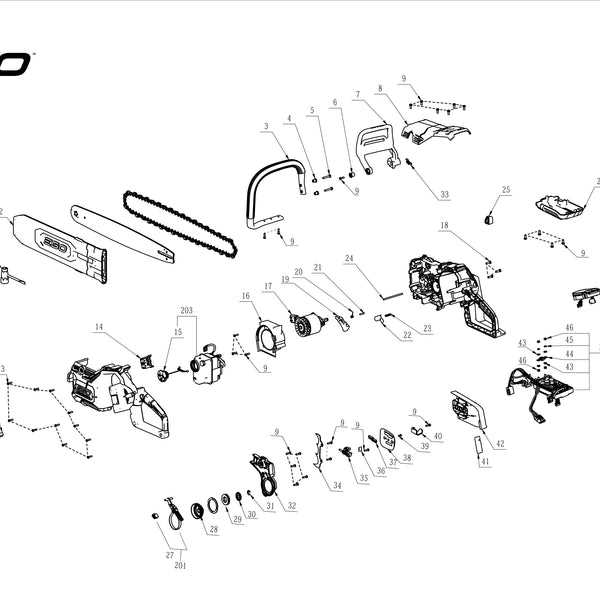

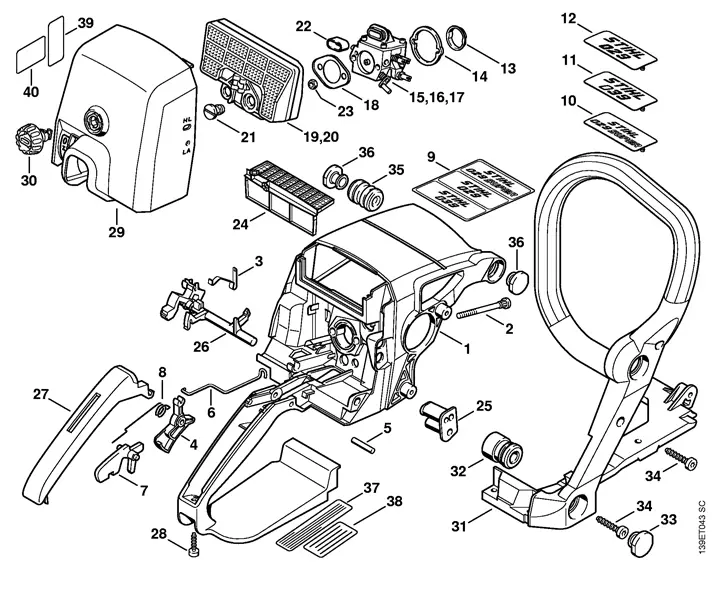

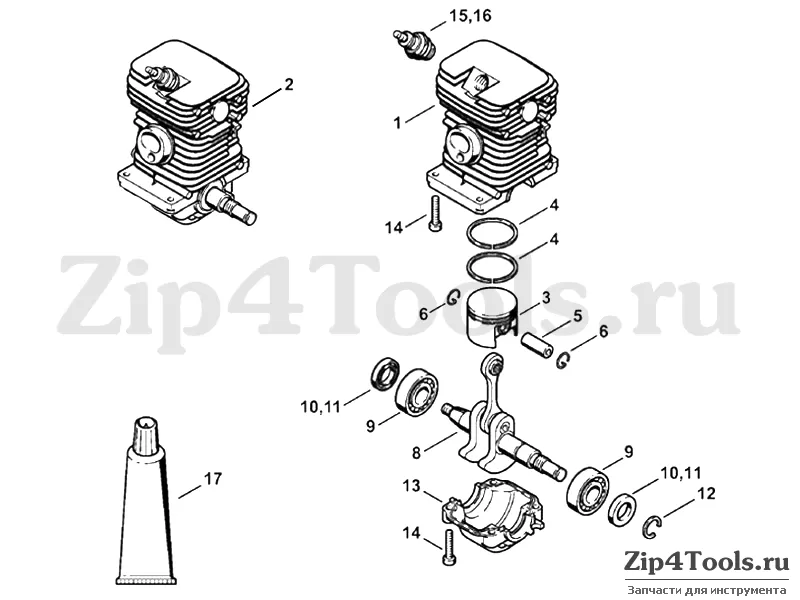

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations serve as guides, allowing users to identify various elements and their arrangements within a mechanical device. Familiarizing oneself with this type of graphic can enhance both troubleshooting and reassembly processes.

Components of the Illustration

Each visual typically includes labeled sections that correspond to specific pieces. The numbers or letters accompanying these sections direct users to a legend or list detailing each component’s name and, often, its function. Pay close attention to these markers, as they simplify the identification process and ensure accuracy in part selection.

Understanding the Layout

The layout usually follows a logical structure, grouping related components together. This organization helps in visualizing how parts interact and fit together, making it easier to spot missing or damaged items. Recognizing common patterns in these illustrations can significantly speed up the repair process.

Maintenance Tips for MS170

Proper upkeep of your cutting tool is essential for ensuring optimal performance and longevity. Regular maintenance helps prevent issues that could arise from wear and tear, allowing for smooth operation and efficiency during use. By following a few simple practices, you can extend the life of your equipment and enhance its reliability.

Regular Cleaning

Keep your tool clean by removing any debris or residue after each use. Pay special attention to the air filter, bar, and chain, as these areas tend to accumulate dirt and sap. A clean machine not only performs better but also reduces the risk of overheating and mechanical failures.

Lubrication and Inspection

Regularly lubricate moving parts to minimize friction and wear. Inspect the chain tension regularly; a properly tensioned chain ensures safer operation and reduces strain on the motor. Additionally, check for any signs of wear on the chain and bar, and replace them as needed to maintain performance.

Troubleshooting Common Issues

When operating outdoor power equipment, encountering problems is not uncommon. Understanding how to diagnose and resolve frequent complications can significantly enhance performance and extend the life of the machinery. This section aims to guide users through typical challenges and their solutions, ensuring smoother operation and greater satisfaction.

Engine Won’t Start

If the engine fails to ignite, check the fuel level and ensure the mixture is correct. A clogged air filter or spark plug may also be at fault. Inspect these components and replace if necessary. Additionally, ensure the throttle is properly engaged to avoid unnecessary frustration.

Poor Performance

Experiencing a decline in efficiency often points to a need for maintenance. Examine the cutting chain for dullness or damage and consider sharpening or replacing it. Moreover, ensure that all components are securely fastened and free from debris, which can hinder optimal function.

Aftermarket vs. Genuine Parts

When it comes to maintaining your equipment, the choice between original and alternative components is crucial. Genuine items are designed specifically for optimal performance and longevity, while aftermarket options often promise cost savings and increased availability. Understanding the differences between these two categories can ultimately influence the reliability and efficiency of your machinery.

Original components typically ensure a perfect fit and compatibility, reducing the risk of malfunction or damage. Conversely, aftermarket alternatives can vary significantly in quality, with some providing excellent performance while others may fall short. It’s essential to evaluate the reputation of manufacturers and the specifications of the parts being considered.

In many cases, choosing genuine items can lead to peace of mind, knowing that they meet rigorous standards set by the original manufacturer. However, for those on a budget, quality aftermarket parts may offer a practical solution, provided thorough research is conducted. Ultimately, the decision should align with your priorities for performance, reliability, and cost.

Assembly and Disassembly Process

The process of assembling and disassembling equipment is crucial for maintenance and repair. Understanding the correct sequence of steps ensures efficiency and helps avoid potential damage to components. This section outlines the necessary actions to effectively take apart and reassemble the unit.

Disassembly Steps

- Gather necessary tools: Ensure you have the right tools, such as screwdrivers, wrenches, and safety gloves.

- Prepare the workspace: Clear the area to have ample space for parts and tools.

- Remove external components: Start by detaching any protective covers or external fixtures.

- Take out internal parts: Carefully unscrew and remove each internal component, keeping them organized.

- Document the process: Take notes or photos to assist with reassembly later.

Assembly Steps

- Inspect all parts: Check each component for wear or damage before starting the assembly.

- Follow the documented sequence: Use your notes or photos to guide the reassembly process accurately.

- Secure components: Ensure that all screws and fasteners are tightened according to specifications.

- Reattach external covers: Once the internal parts are secure, replace any outer fixtures.

- Conduct a final check: Verify that everything is assembled correctly and safely.

By following these guidelines, you can ensure that both disassembly and assembly are performed smoothly, extending the life of your equipment.

Upgrading Your MS170 Performance

Enhancing the capabilities of your chainsaw can significantly improve its efficiency and effectiveness. By focusing on specific components and adjustments, you can achieve a noticeable boost in performance, enabling smoother operation and longer-lasting power. Whether you’re a professional or a hobbyist, optimizing your tool will ensure you get the most out of each cutting task.

Engine Tuning is one of the primary ways to increase power output. Adjusting the carburetor settings can lead to better fuel-air mixture, enhancing combustion efficiency. It’s essential to follow the manufacturer’s specifications to avoid damaging the engine.

Bar and Chain Upgrade is another effective method. Choosing a longer bar or a more aggressive chain design can improve cutting speed and reduce the effort needed for tougher jobs. Ensure compatibility with your model for optimal results.

Air Filter Enhancement is crucial for maintaining engine performance. Upgrading to a high-flow air filter can increase airflow, resulting in improved combustion and power. Regular maintenance and cleaning are also vital to keep the filter functioning effectively.

Vibration Dampening systems can enhance user comfort and reduce fatigue during extended use. Adding vibration-absorbing handles or grips can make a significant difference, allowing for more precise control and reducing strain on the operator.

In conclusion, by implementing these upgrades, you can transform your chainsaw into a more powerful and efficient tool. Regular maintenance and thoughtful modifications will ensure it remains a reliable companion for all your cutting endeavors.