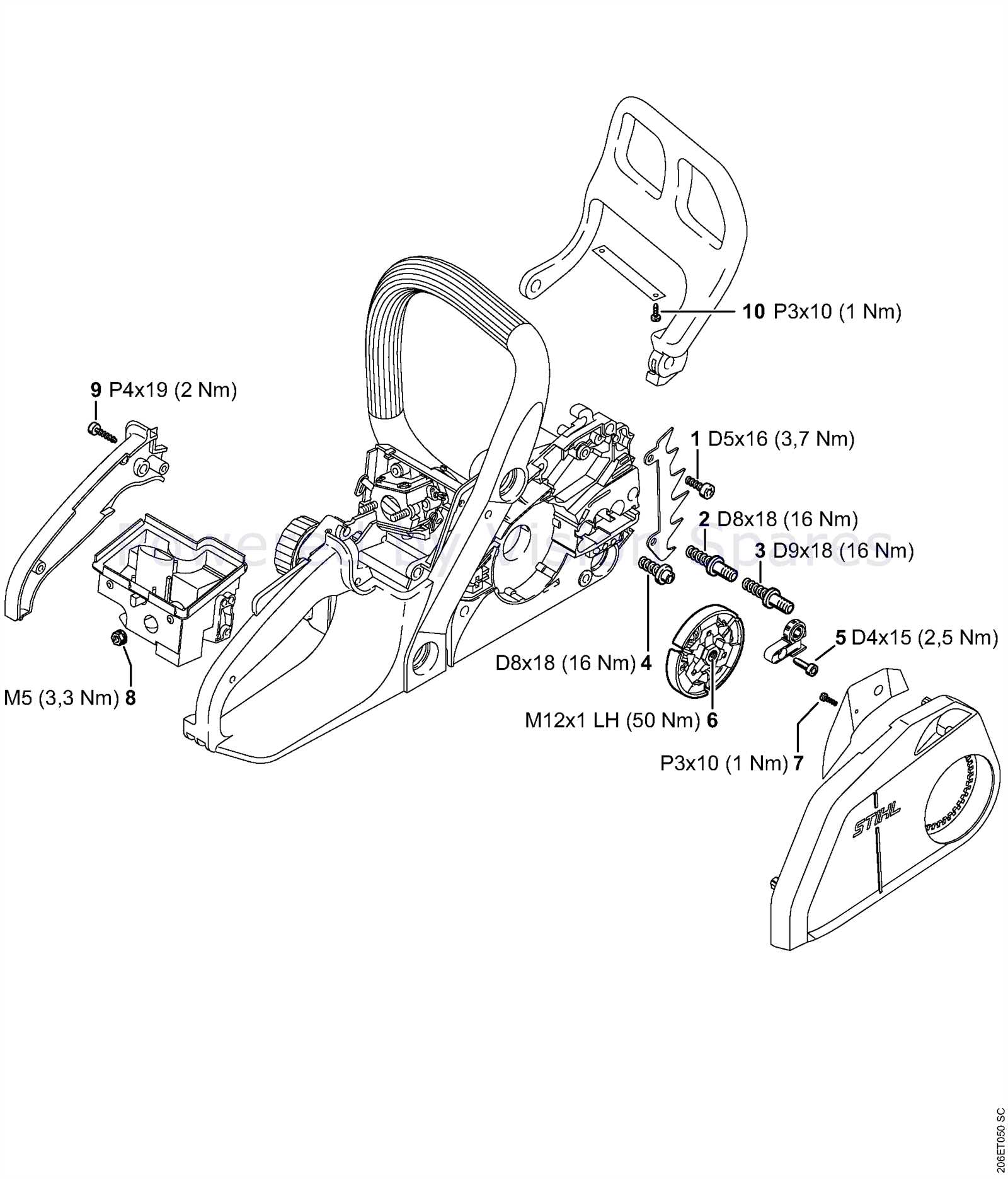

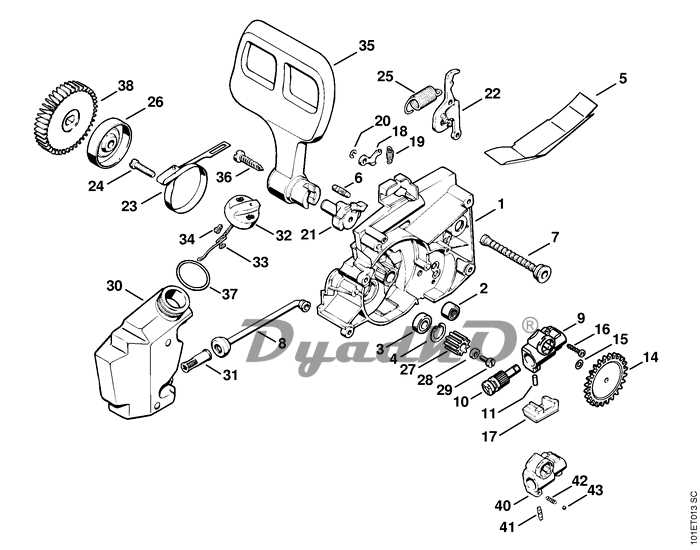

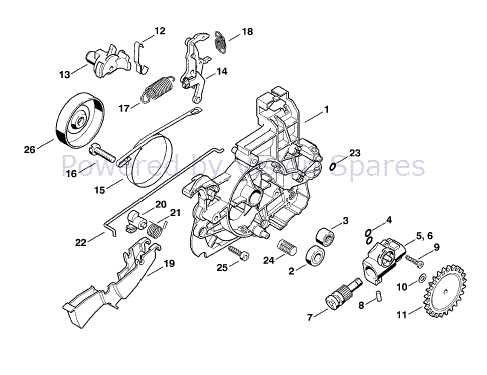

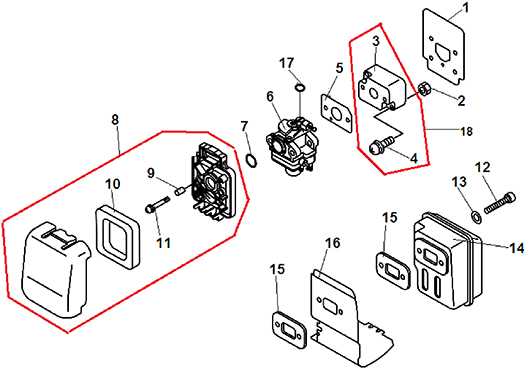

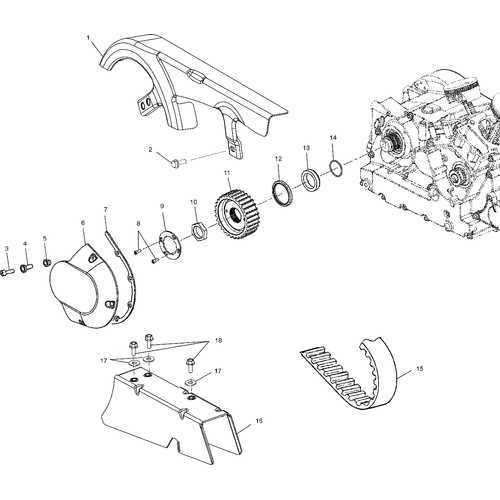

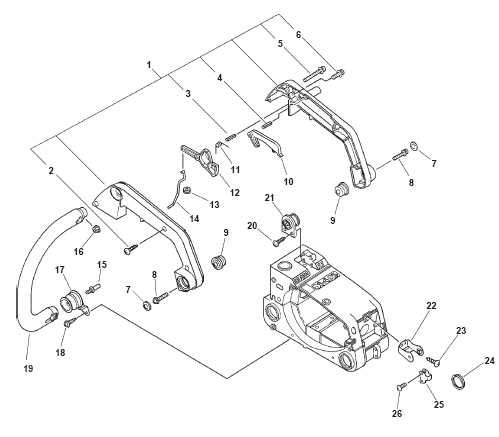

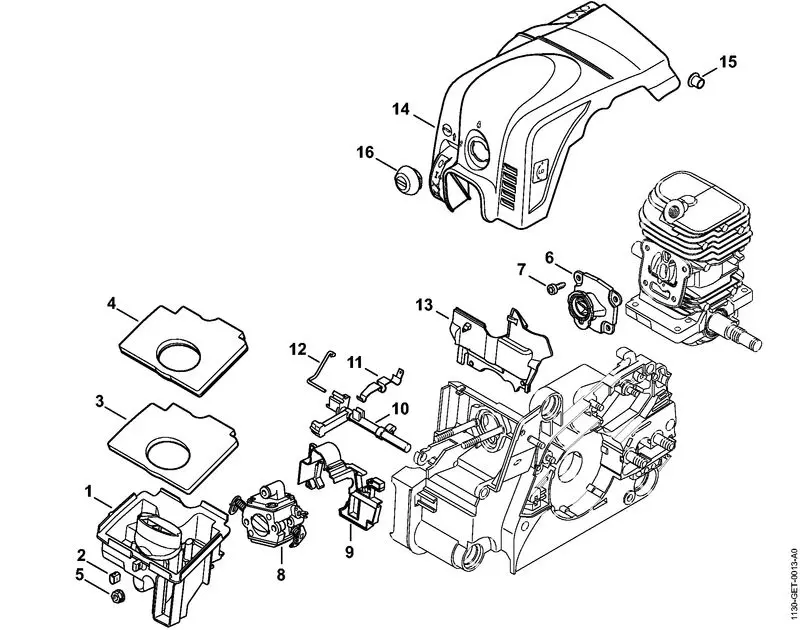

Comprehensive Parts Diagram for Stihl MS180C Chainsaw

In the world of outdoor power equipment, maintaining peak performance is crucial for both safety and efficiency. A thorough understanding of the intricate elements that comprise your cutting tool is essential for effective repairs and upkeep. This section delves into the various components that make up a high-performance chainsaw, providing you with the knowledge needed to keep your machine running smoothly.

Knowing how each part interacts can significantly enhance your ability to troubleshoot and perform necessary maintenance. Familiarity with these elements not only helps in identifying wear and tear but also aids in making informed decisions about replacements or upgrades. This guide aims to shed light on the layout and functions of each component, ensuring you are well-equipped to handle any challenges that may arise.

Additionally, having a visual representation of these parts can serve as a valuable reference during your repair process. Understanding the arrangement and relationship between different pieces allows for a more organized approach, ultimately leading to a more efficient workflow. Explore the details and gain confidence in managing your equipment like a pro.

Understanding the Stihl MS180C Components

Gaining insight into the various elements of a chainsaw is essential for optimal performance and maintenance. Each component plays a critical role in the overall functionality, contributing to the efficiency and safety of the tool. Familiarity with these individual parts allows users to troubleshoot issues, perform repairs, and ensure longevity.

The engine serves as the powerhouse, converting fuel into mechanical energy. Its components, including the cylinder and piston, work in unison to generate the necessary power. Ignition systems initiate combustion, while fuel delivery systems ensure a steady supply of energy.

Another vital section is the bar and chain assembly, where the cutting action occurs. The bar provides a guide for the chain, which consists of sharp teeth designed for efficient cutting through wood. Regular inspection and maintenance of this assembly are crucial for performance and safety.

Additionally, the safety features such as chain brakes and throttle controls are designed to protect the user. Understanding how these mechanisms operate can significantly reduce the risk of accidents during use. Familiarity with the entire assembly enhances both efficiency and safety, making it essential for any user to comprehend these intricate details.

Key Features of the Stihl MS180C

This compact and efficient tool is designed for various cutting tasks, making it a favorite among both professionals and hobbyists. Its lightweight design and powerful engine deliver a perfect blend of performance and ease of use, ensuring that even extended sessions do not lead to fatigue.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a robust engine, this model provides excellent cutting power for a range of applications. |

| Lightweight Design | The tool’s lightweight construction facilitates easy handling and maneuverability, allowing for extended use without strain. |

| Easy Start System | Featuring a simplified starting mechanism, it ensures a quick and hassle-free ignition every time. |

| Safety Features | Incorporates multiple safety mechanisms to protect the user, including a chain brake and hand guard. |

| Fuel Efficiency | Designed for optimal fuel consumption, this tool reduces operational costs while minimizing environmental impact. |

| Durability | Constructed with high-quality materials, it is built to withstand rigorous use and challenging conditions. |

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repairs. Visual representations that illustrate each element and its relation to others serve as invaluable tools for technicians and DIY enthusiasts alike. These illustrations simplify complex assemblies, making it easier to identify parts and comprehend their functions within the overall system.

Enhanced Repair Efficiency

Having access to visual guides streamlines the repair process. When a breakdown occurs, a clear illustration allows for quick identification of the faulty component, reducing downtime and minimizing frustration. This efficiency not only saves time but also cuts down on potential labor costs.

Facilitates Proper Maintenance

Regular upkeep is essential for longevity and performance. Visual aids provide insight into the maintenance requirements of each component, guiding users on when and how to perform necessary checks or replacements. This proactive approach helps in avoiding major issues before they arise.

| Benefit | Description |

|---|---|

| Quick Identification | Facilitates rapid recognition of components needing attention. |

| Reduced Downtime | Minimizes the time machinery is out of service. |

| Cost-Effective | Helps avoid unnecessary repairs and labor expenses. |

| Informed Maintenance | Provides guidance on regular care and checks for parts. |

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair of machinery. These illustrations provide a detailed view of various elements, making it easier to identify and locate each piece. By familiarizing yourself with these visuals, you can streamline the process of troubleshooting and ensuring the longevity of your equipment.

Key Components of the Visual Representation

Each illustration typically includes several key features that aid in understanding the layout:

| Feature | Description |

|---|---|

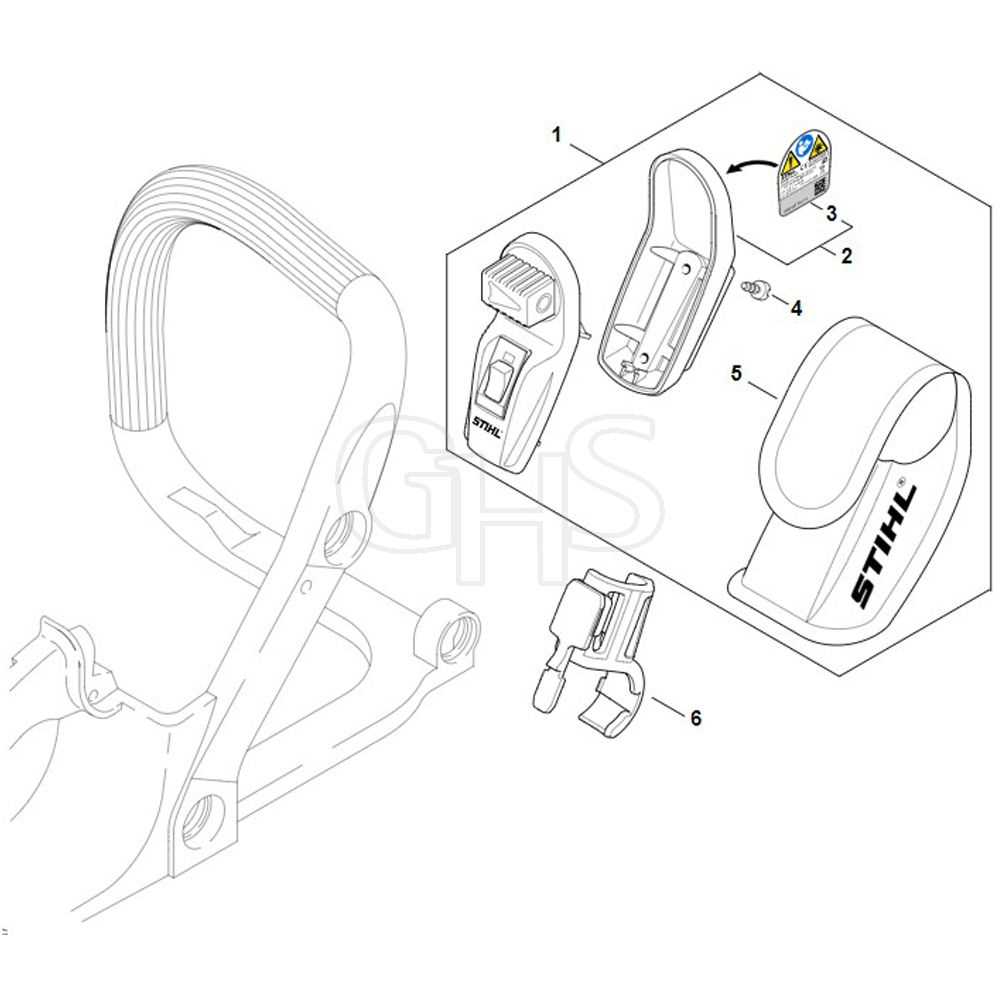

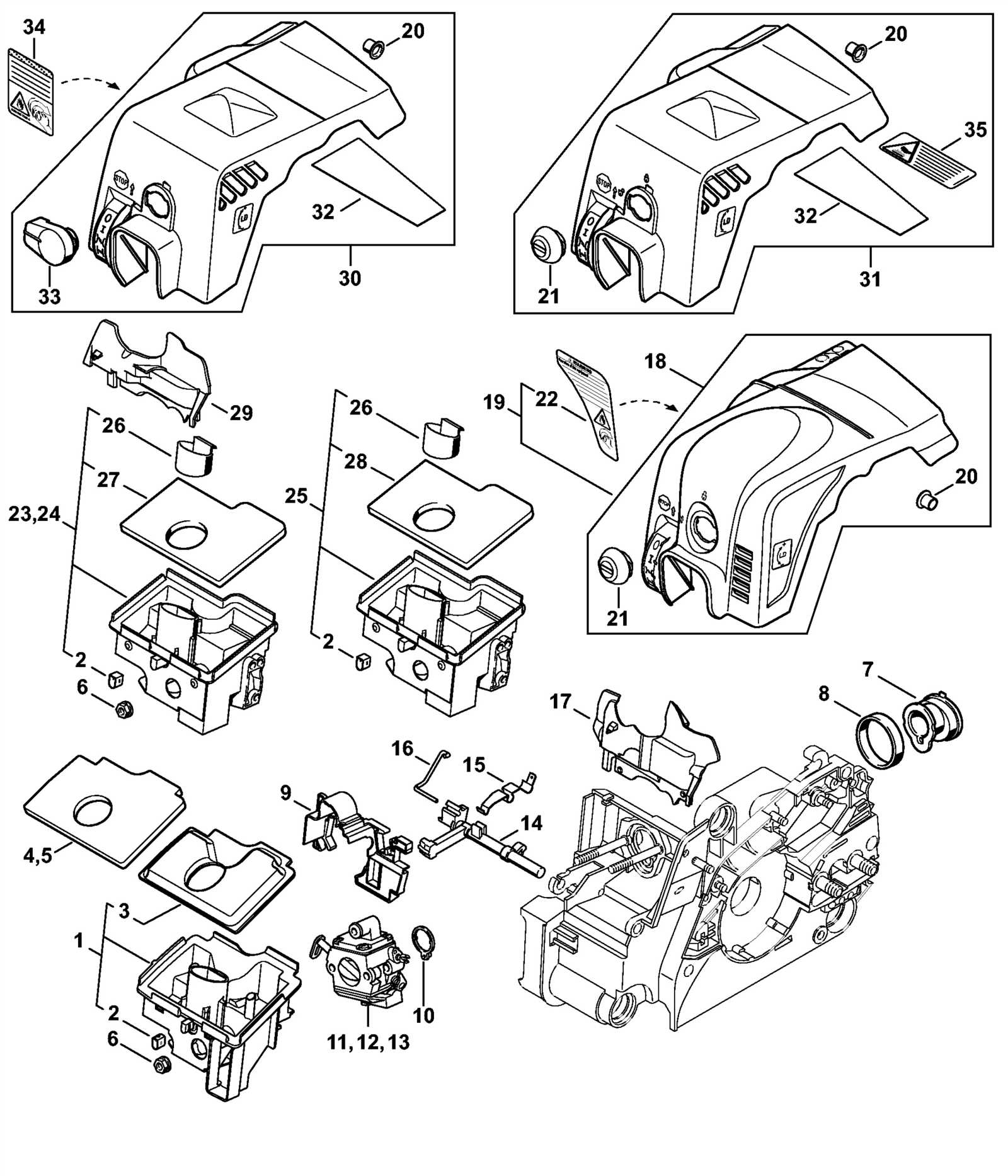

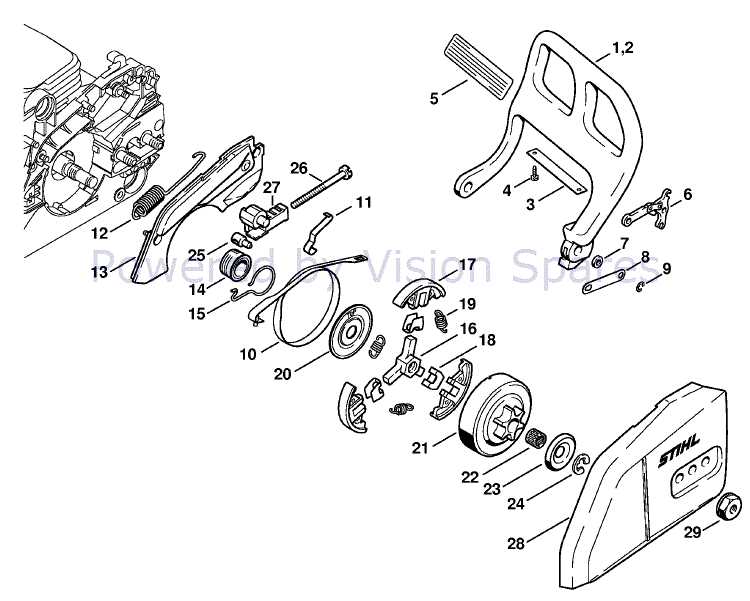

| Numbering | Each item is often labeled with a unique number for easy reference. |

| Legend | A guide explaining the symbols and terms used within the illustration. |

| Sections | Diagrams are usually divided into sections, making it easier to focus on specific areas. |

Interpreting the Information

To effectively interpret these visuals, start by locating the legend. This will clarify any symbols or abbreviations used. Next, follow the numbering system to trace the components relevant to your project. Pay attention to the layout, as it often reflects how parts fit together, providing insights into assembly and disassembly.

Common Issues with MS180C Parts

Understanding the frequent problems associated with components can help in maintaining optimal performance and prolonging the lifespan of your equipment. This section outlines typical challenges faced with various elements, which can lead to operational inefficiencies or even complete breakdowns.

Frequent Component Failures

One of the main issues users encounter is wear and tear on specific elements. Over time, regular usage can lead to diminished functionality. Identifying these weak points can aid in preventive measures and timely replacements.

Signs of Malfunction

Noticing the signs of malfunction early can prevent larger issues down the line. Common indicators include unusual noises, difficulty in starting, or a significant drop in power. Addressing these signs promptly ensures your equipment continues to run smoothly.

| Component | Common Issue | Recommended Action |

|---|---|---|

| Fuel System | Clogged filter | Replace the filter regularly |

| Chain Bar | Worn out | Inspect and replace as needed |

| Air Filter | Blocked | Clean or replace frequently |

| Ignition System | Faulty spark plug | Check and replace if necessary |

Identifying Replacement Components

When maintaining or repairing equipment, recognizing the necessary components for replacement is crucial for optimal performance. Understanding the specific parts involved can prevent operational issues and enhance the longevity of your machine. This section focuses on how to effectively identify and select the appropriate elements needed for servicing.

Begin by consulting the manufacturer’s documentation, which typically includes a detailed list of components along with their specifications. This resource is invaluable for anyone looking to replace a malfunctioning part. Familiarize yourself with the terminology used to describe each component, as this will aid in accurate identification.

Visual aids, such as exploded views or labeled illustrations, can greatly assist in recognizing individual parts and understanding their arrangement within the assembly. These references help clarify how components interact and can guide you in determining which ones require attention.

Additionally, examining the physical condition of the existing parts can provide insights into what needs to be replaced. Look for signs of wear, damage, or corrosion that may indicate a need for new components. Taking note of the part numbers can streamline the replacement process, ensuring you acquire the correct items.

Ultimately, thorough research and careful observation are key to successfully identifying replacement components, paving the way for effective repairs and maintenance.

Maintenance Tips for Stihl Chainsaws

Regular upkeep is essential for ensuring the longevity and efficiency of your cutting tool. Proper maintenance not only enhances performance but also promotes safety during use. Adhering to a routine care schedule can prevent costly repairs and improve overall functionality.

Cleaning and Inspection

After each use, it is crucial to clean the equipment thoroughly. Remove any sawdust, debris, and oil buildup. Regularly inspect components such as the chain, guide bar, and air filter for signs of wear. Replace damaged parts promptly to maintain optimal performance. A clean machine operates more efficiently and safely.

Lubrication and Tensioning

Keep the chain well-lubricated to reduce friction and wear. Use appropriate chain oil and check the reservoir regularly. Additionally, ensure the chain is correctly tensioned. A loose chain can slip off, while an overly tight chain can damage the tool. Follow manufacturer guidelines for adjustments to ensure safe operation.

Where to Find Authentic Parts

Ensuring the longevity and efficiency of your outdoor equipment hinges on sourcing quality components. Authentic replacements not only enhance performance but also guarantee safety and reliability. Here are some trusted avenues to procure genuine items for your machinery.

- Authorized Dealers: Visit certified retailers who specialize in your equipment brand. They typically carry a comprehensive selection of original components.

- Official Websites: Manufacturer websites often have dedicated sections for replacement items. This ensures you are purchasing genuine products directly from the source.

- Specialty Shops: Look for local stores that focus on outdoor machinery. They may offer a variety of authentic components and knowledgeable staff.

- Online Marketplaces: While many platforms offer convenience, always check for verified sellers with positive reviews to avoid counterfeit items.

By choosing the right sources, you can maintain the performance and durability of your equipment for years to come.

DIY Repair vs. Professional Help

When it comes to fixing equipment, individuals often face the choice between tackling repairs themselves or seeking assistance from a specialist. Each option carries its own set of advantages and disadvantages, influencing both the cost and the quality of the repair process. Understanding these factors can help users make an informed decision based on their specific circumstances and skill levels.

Opting for a do-it-yourself approach can be rewarding, providing an opportunity to learn and gain hands-on experience. This method often saves money, as it eliminates labor costs associated with hiring a technician. Additionally, individuals may find satisfaction in completing a project on their own, fostering a sense of accomplishment. However, without the necessary expertise, DIY repairs can lead to further complications or even damage to the equipment.

Conversely, relying on a professional offers a level of assurance that comes from expert knowledge and experience. Technicians typically have access to specialized tools and resources, enabling them to diagnose and resolve issues more efficiently. While this route may be more costly, it can ultimately save time and prevent additional problems that might arise from improper repairs. For those unsure of their skills or faced with complex issues, enlisting a professional is often the safest choice.

In summary, whether to repair equipment independently or seek professional help depends on various factors, including the complexity of the issue, personal skills, and budget considerations. Evaluating these elements can guide individuals toward the most effective solution for their repair needs.

Upgrading Your MS180C Components

Enhancing the performance and longevity of your equipment can significantly improve its efficiency and overall functionality. By focusing on specific upgrades, you can tailor the machine to better suit your needs, whether for professional use or personal projects.

Consider the following components for upgrades:

- Engine Performance: Explore options for improved air filters and spark plugs to boost efficiency.

- Bar and Chain: Upgrading to a longer or more durable bar can enhance cutting capability.

- Handles and Grips: Ergonomic grips can reduce fatigue and improve control during operation.

- Fuel System: Investing in a high-performance fuel line can increase reliability and reduce maintenance issues.

Before proceeding with any modifications, it’s essential to consult with experts or reference reliable sources to ensure compatibility and safety. Regular maintenance combined with thoughtful upgrades can lead to a more powerful and reliable tool.

Ultimately, the right enhancements can transform your equipment into a more effective asset, allowing you to tackle a wider range of tasks with confidence.

Safety Precautions During Repairs

When undertaking maintenance on mechanical equipment, ensuring personal safety and the integrity of the tools is paramount. Adhering to specific guidelines can help prevent accidents and injuries while promoting a more efficient repair process.

Here are essential safety measures to follow:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the work area is clean, well-lit, and free from any obstructions that could pose a tripping hazard.

- Disconnect the power source or fuel supply before starting any repair to prevent accidental activation.

- Use the right tools for the job to avoid damaging components and ensure safety during the repair process.

- Keep a first aid kit nearby to address any minor injuries promptly.

By following these precautions, you can create a safer environment that allows for effective and secure maintenance activities.

Customer Reviews on MS180C Parts

Feedback from users offers valuable insights into the performance and reliability of components used in outdoor power equipment. These reviews often highlight the experiences of owners, shedding light on quality, durability, and overall satisfaction with various replacements and accessories. Understanding these perspectives can guide potential buyers in making informed decisions.

Many customers appreciate the longevity and effectiveness of the items, noting that they significantly enhance the functionality of their tools. Users frequently mention how easy it is to install these components, which contributes to a smoother maintenance process. Positive remarks often focus on how the parts maintain the equipment’s efficiency, allowing for consistent and powerful performance.

Conversely, some reviews express concerns regarding specific elements that may not meet expectations. Customers occasionally report issues with fit or compatibility, urging others to double-check specifications before making a purchase. However, constructive feedback often leads to improved offerings in the market, demonstrating that user experiences can drive advancements in design and manufacturing.

In summary, the collective feedback from users serves as a crucial resource for anyone looking to enhance their outdoor machinery. By considering these reviews, individuals can better navigate their options and choose components that best suit their needs.