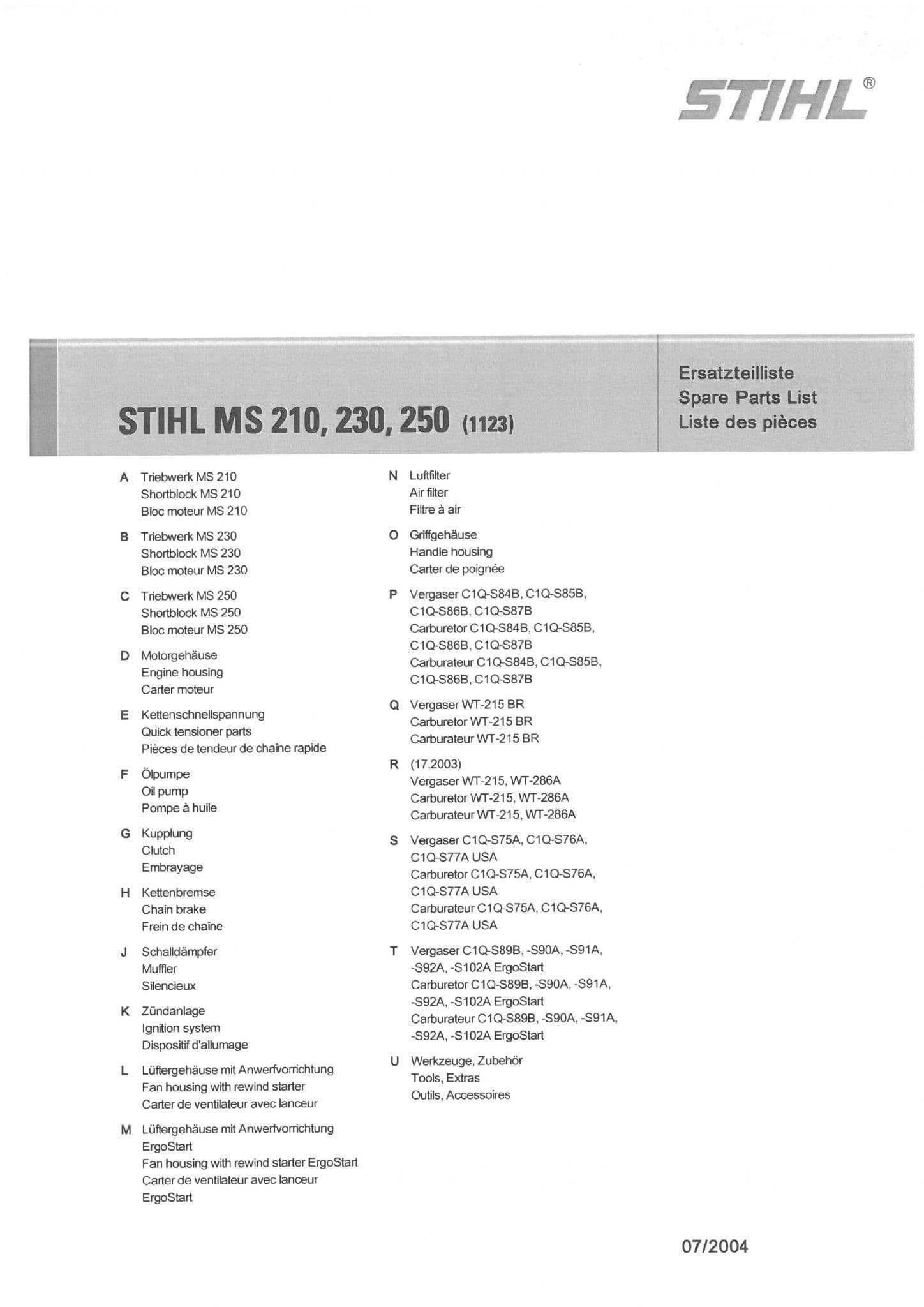

Comprehensive Guide to Stihl MS250C Parts Diagram

The intricate design of a cutting tool is essential for optimal performance and longevity. Grasping how each component functions allows users to maintain their equipment effectively, ensuring it operates smoothly during demanding tasks.

By exploring the various elements that make up this machinery, one can identify potential issues before they escalate. Whether you’re a seasoned user or a novice, having a comprehensive understanding of these components is vital for any maintenance or repair endeavors.

In this guide, we will delve into the specific assembly of your cutting tool, providing clarity on its functionality. This knowledge not only enhances your technical skills but also empowers you to make informed decisions when seeking replacements or upgrades.

Understanding Stihl MS250C Components

Comprehending the various elements of a chainsaw is crucial for effective maintenance and optimal performance. Each component plays a vital role in ensuring that the equipment operates smoothly and efficiently. By familiarizing oneself with these parts, users can troubleshoot issues more effectively and enhance the longevity of their tools.

The primary components of a typical chainsaw include the following:

- Engine: Powers the device and determines its cutting capabilities.

- Bar: The long metal part that holds the chain in place and allows for cutting.

- Chain: The sharp loop that rotates around the bar to slice through wood.

- Handle: Provides grip and control for the user during operation.

- Fuel System: Supplies energy to the engine, including the tank and filter.

- Oiling Mechanism: Ensures that the chain remains lubricated for smooth operation.

Each of these elements can be examined individually for signs of wear or damage. Regular checks can prevent minor issues from escalating into major problems.

- Perform routine inspections.

- Replace worn-out components as necessary.

- Keep the tool clean to avoid debris build-up.

Understanding the intricacies of these elements not only aids in maintenance but also enhances safety during operation. Users equipped with this knowledge can ensure their equipment remains reliable for various tasks.

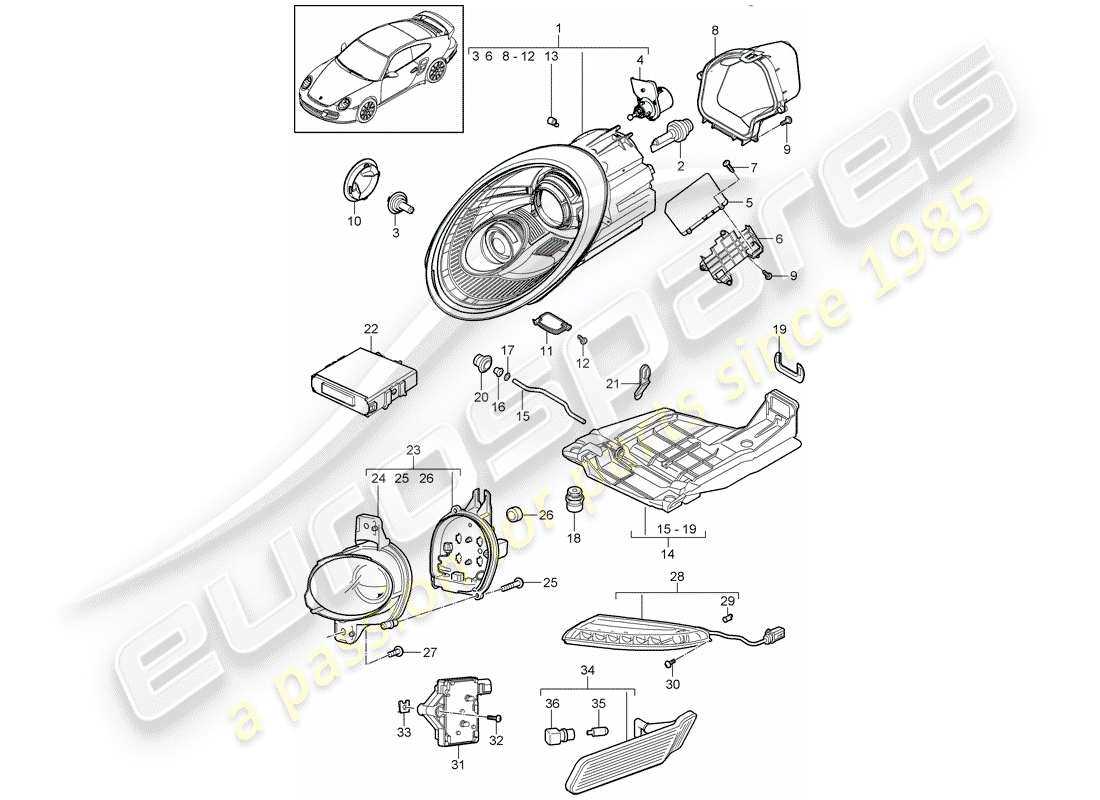

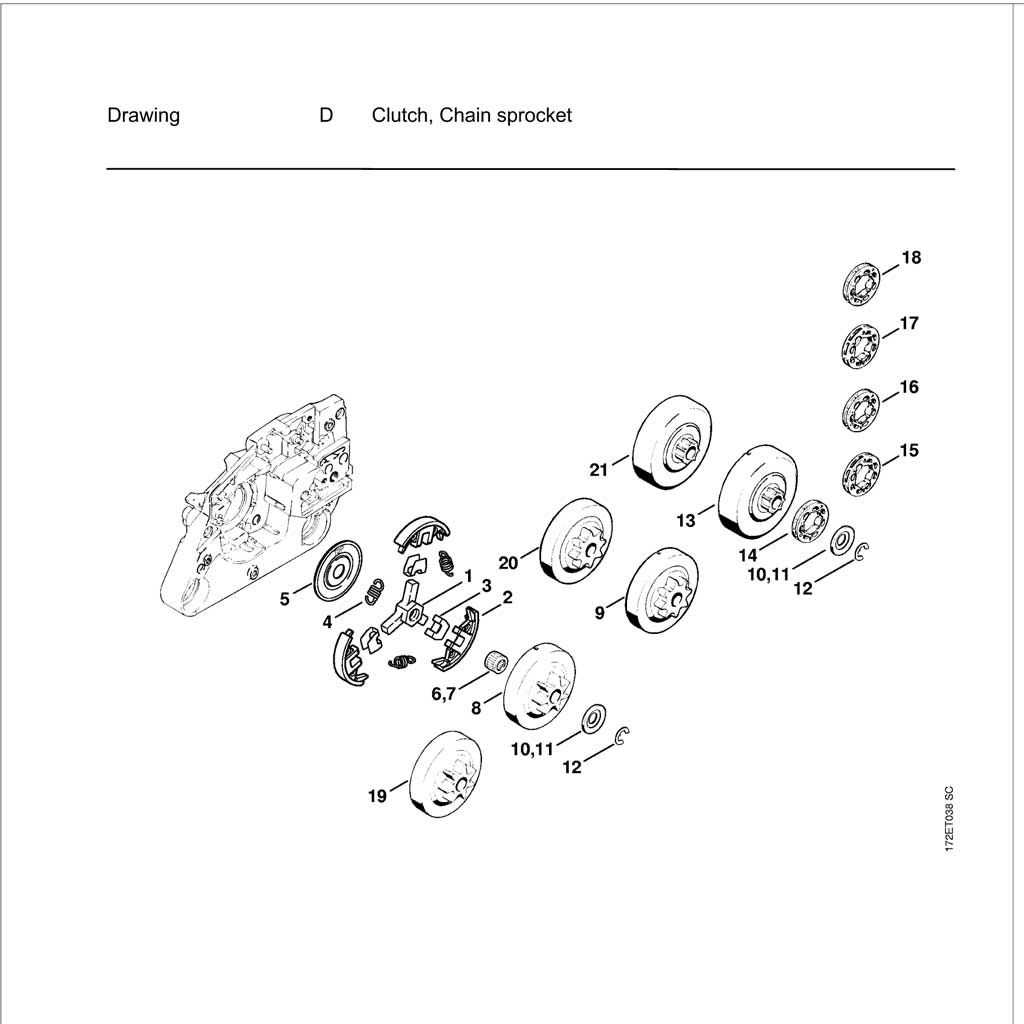

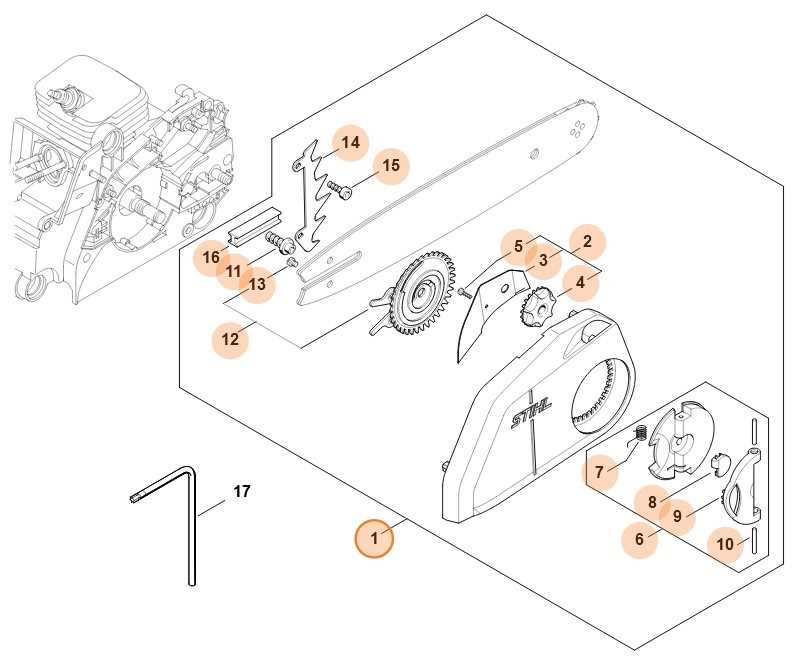

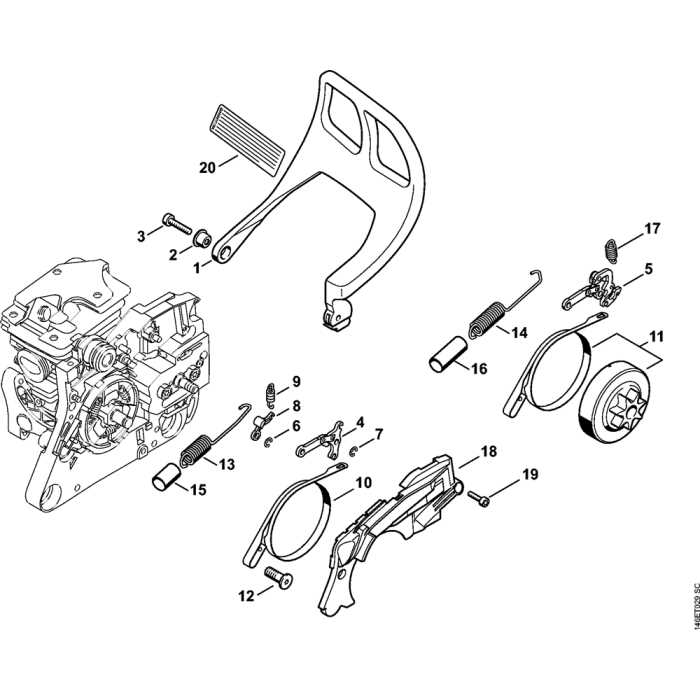

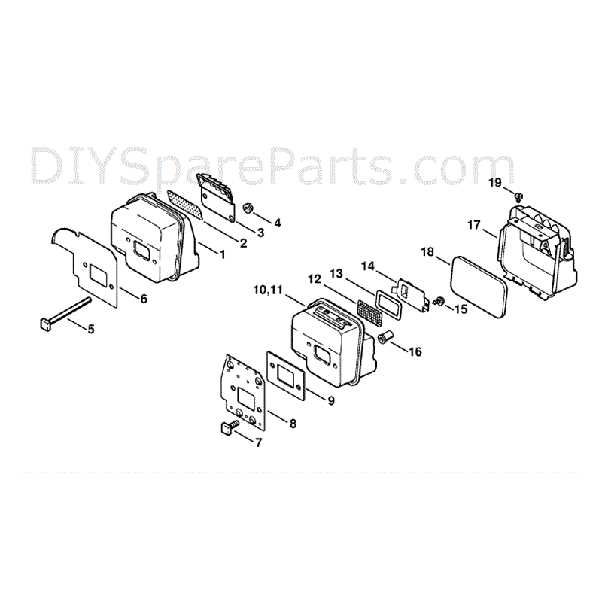

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential guides, allowing users to identify each element’s function and placement within the overall structure. This clarity not only enhances the repair process but also prolongs the lifespan of equipment.

Accurate identification of individual pieces helps in troubleshooting issues quickly and efficiently. When users can easily locate and comprehend the function of each component, they can make informed decisions during repairs or replacements.

Moreover, these illustrations foster a deeper understanding of the equipment, empowering users to take proactive measures in care and upkeep. This knowledge is the ultimate key to ensuring optimal performance and reliability.

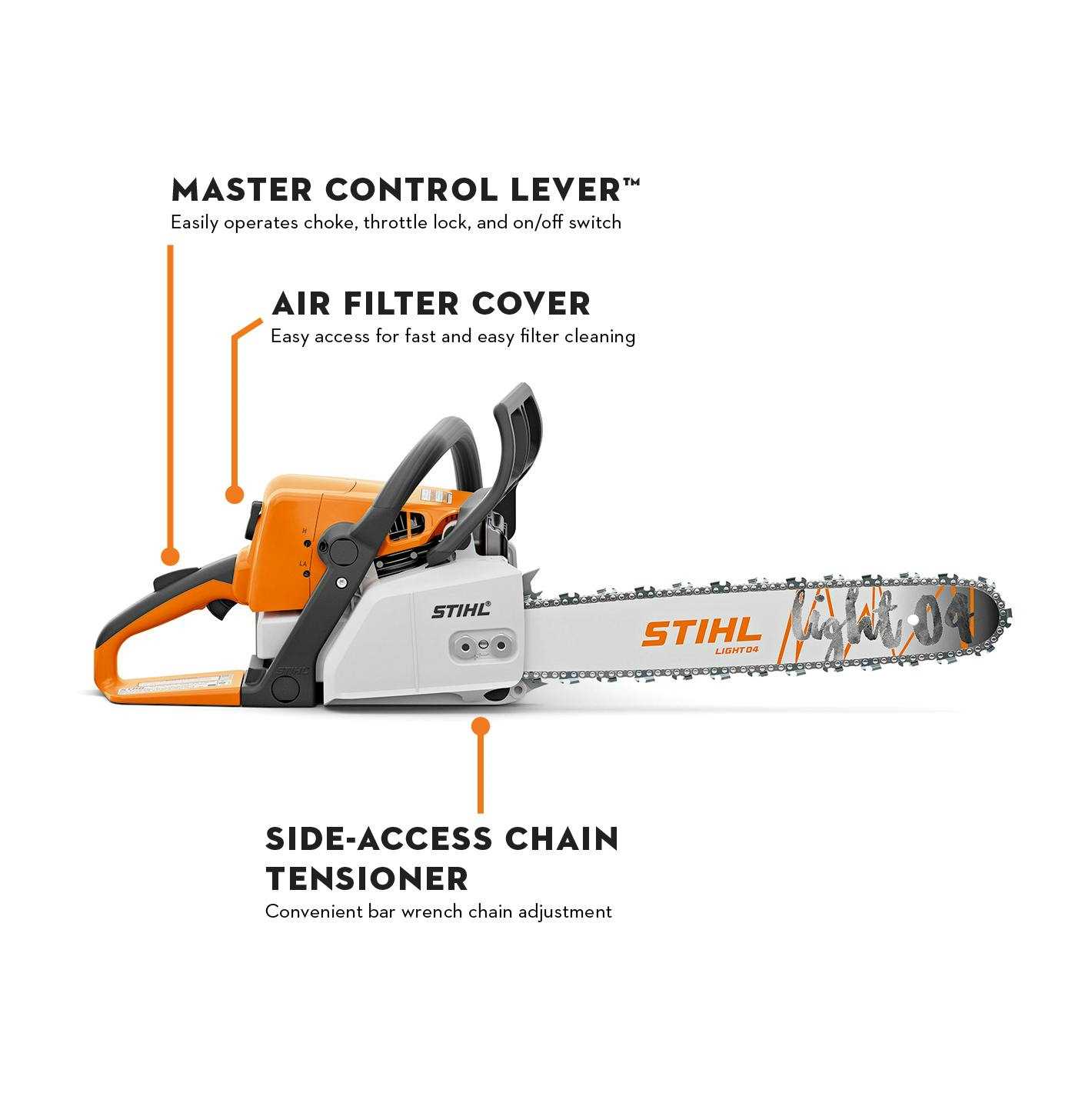

Key Features of Stihl MS250C

This powerful chainsaw is designed for efficiency and ease of use, making it an ideal choice for both professionals and enthusiasts. Its robust construction and advanced technology contribute to a seamless cutting experience, ensuring reliability during operation.

Lightweight Design: The tool’s compact structure reduces fatigue during extended use, allowing for better maneuverability and control.

Powerful Engine: Equipped with a high-performance motor, this model delivers impressive cutting power, making it suitable for various tasks, from trimming to felling.

Easy Start System: The innovative starting mechanism minimizes effort, allowing users to get to work quickly without the frustration of difficult starts.

Advanced Safety Features: Enhanced safety measures, including chain brake and throttle lock, help ensure user protection during operation.

Efficient Fuel Consumption: Designed with fuel efficiency in mind, this tool reduces emissions while maximizing performance, making it an environmentally friendly choice.

Durable Construction: Built with high-quality materials, it withstands the rigors of heavy use, ensuring longevity and reliability in demanding environments.

Overall, this chainsaw combines strength, convenience, and safety, making it a valuable addition to any toolkit.

Common Issues with MS250C Parts

When working with outdoor power equipment, certain components may encounter frequent challenges that affect performance. Understanding these common issues can help in maintaining efficiency and prolonging the lifespan of the machine. This section explores typical problems associated with essential elements of a popular model, providing insights for users to troubleshoot effectively.

1. Fuel System Failures: One of the most prevalent problems arises from the fuel system. Clogs in the fuel lines or issues with the carburetor can lead to starting difficulties or poor engine performance. Regular cleaning and inspection are crucial to avoid these setbacks.

2. Ignition System Issues: The ignition components may experience wear, resulting in misfires or an inability to start. Inspecting the spark plug and ignition coil for damage can prevent these complications.

3. Bar and Chain Problems: Over time, the cutting bar and chain may suffer from wear and tear, causing inefficient cutting or even safety hazards. Regular maintenance, including sharpening the chain and checking the bar for straightness, is essential.

4. Air Filter Blockages: A dirty air filter can restrict airflow, leading to reduced engine performance. It’s advisable to check and clean or replace the air filter periodically to ensure optimal function.

5. Vibration and Noise: Excessive vibrations or noise can indicate loose or worn components. Regular inspections can help identify and rectify these issues before they escalate into more serious problems.

By staying aware of these common challenges and conducting regular maintenance, users can enhance the reliability and performance of their equipment.

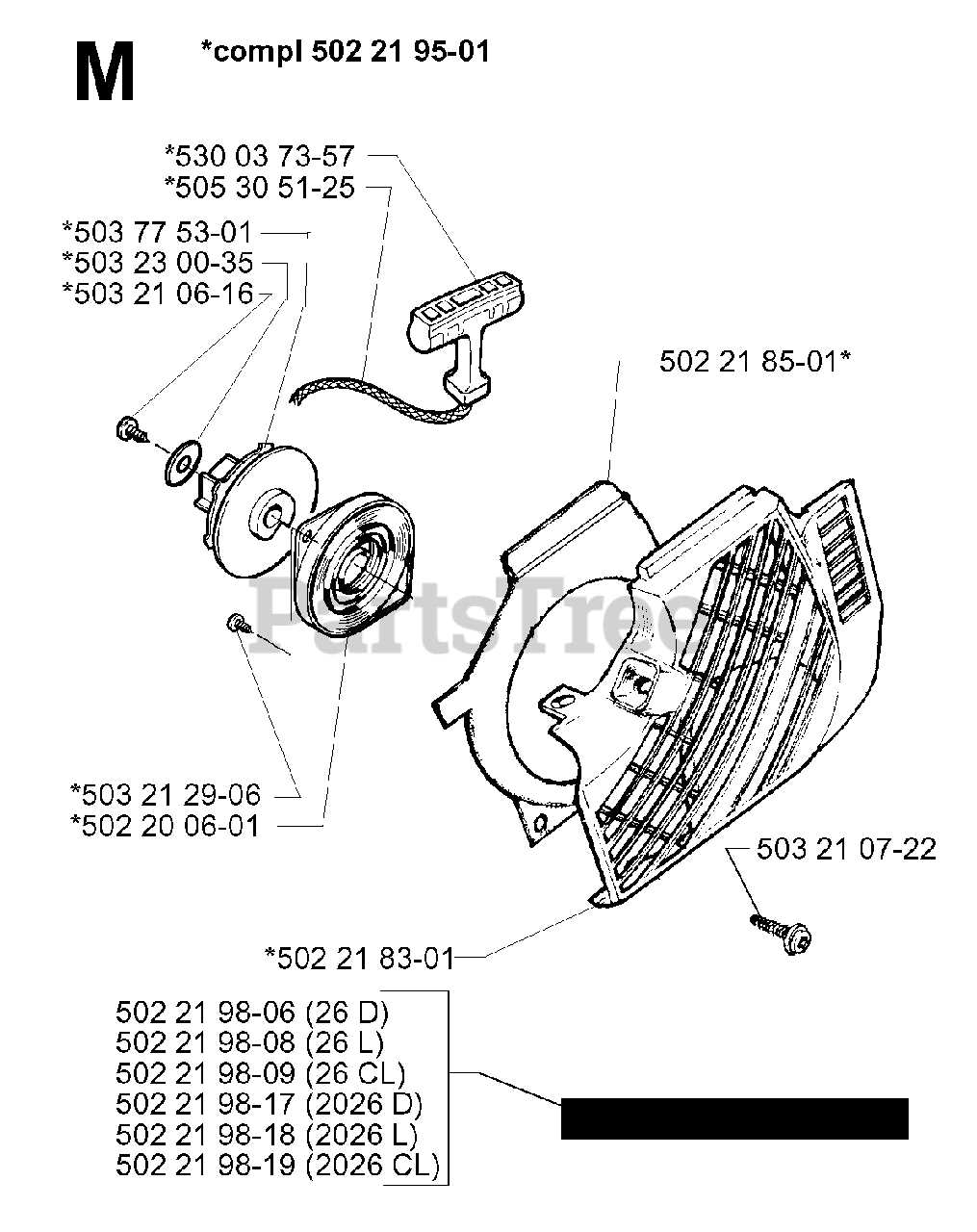

How to Read a Parts Diagram

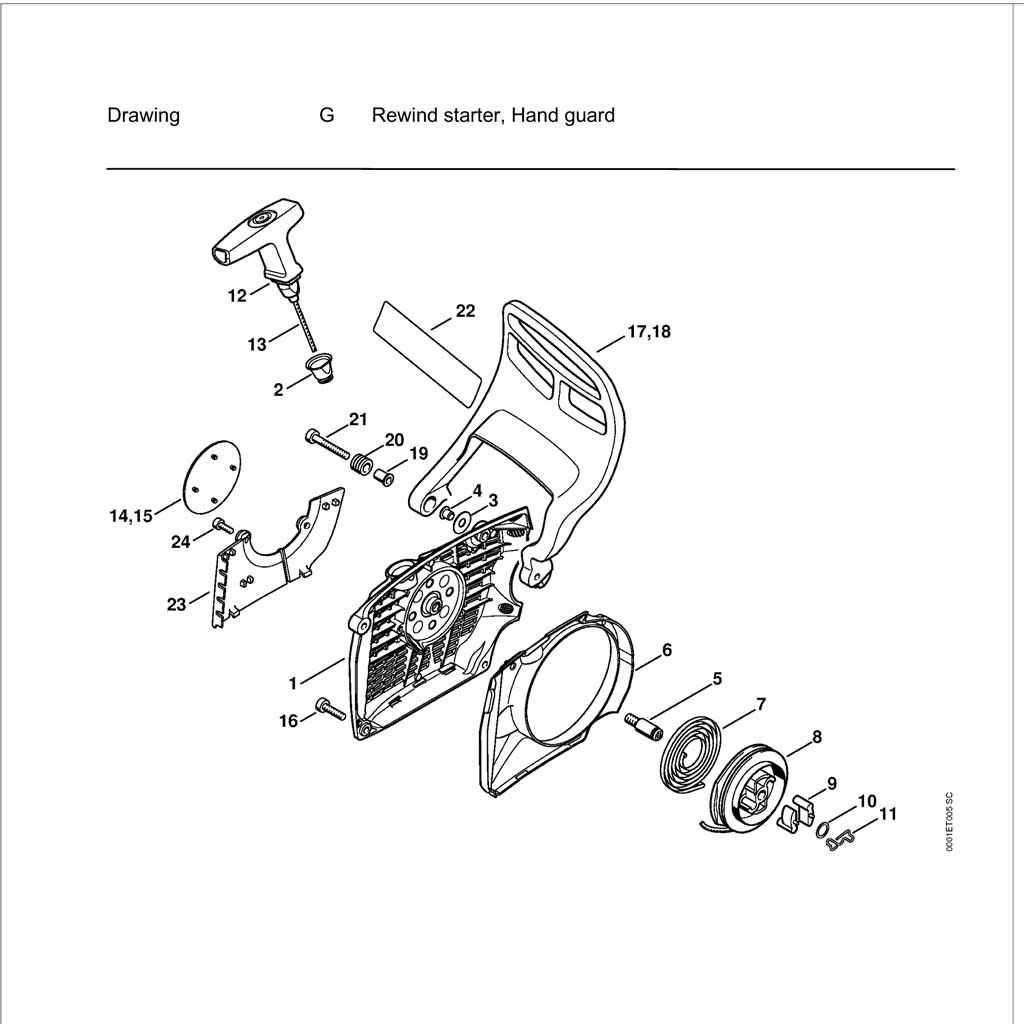

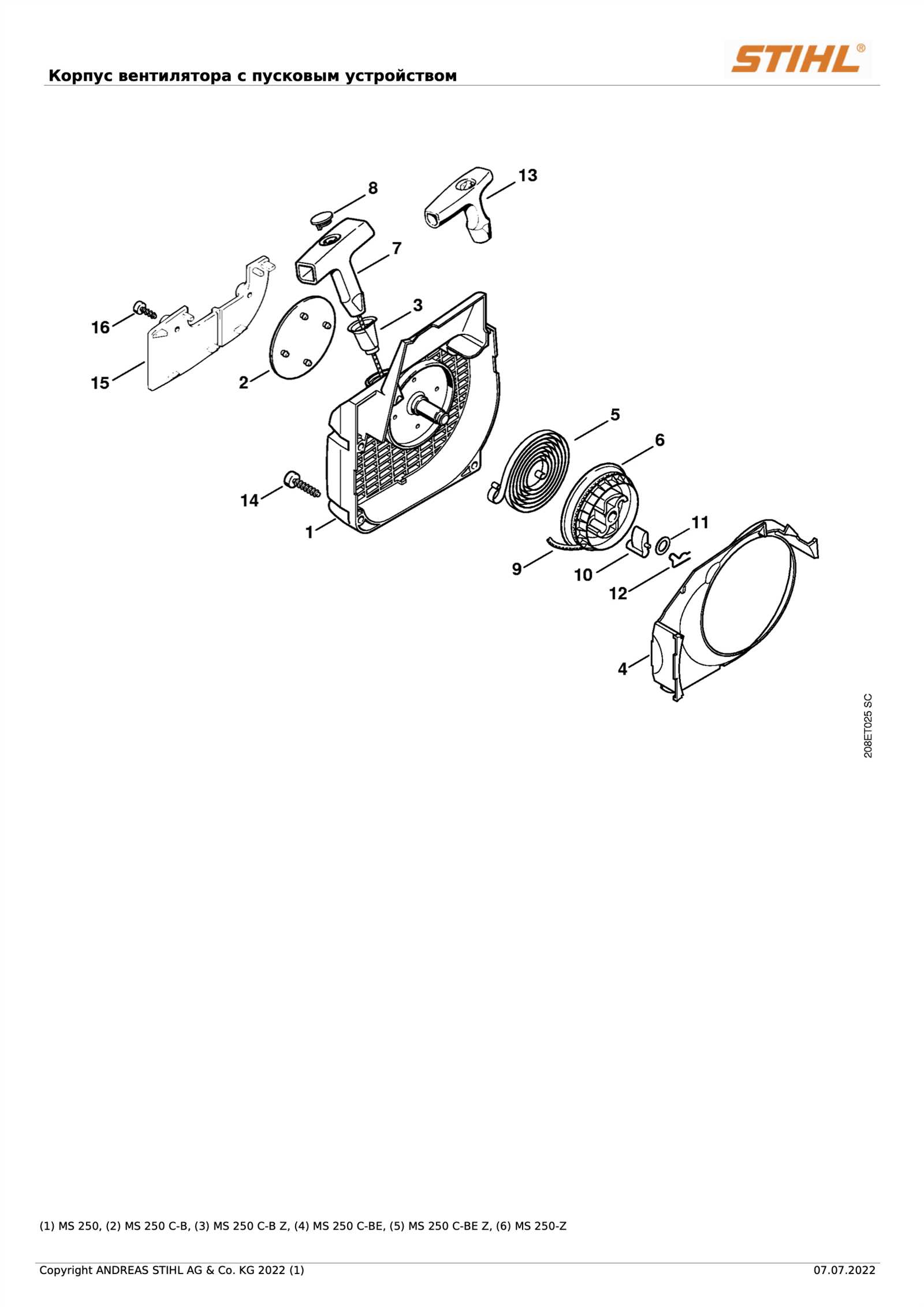

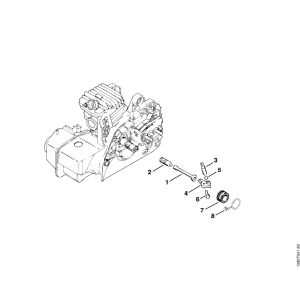

Understanding the layout of an assembly illustration is essential for effective maintenance and repair. These visual guides provide a comprehensive overview of components, allowing users to identify and locate individual pieces necessary for service or replacement. Familiarizing yourself with the structure and labeling of these illustrations can greatly enhance your ability to work efficiently with equipment.

Identifying Components

The first step in interpreting an assembly illustration is to recognize the various elements depicted. Each item is typically numbered or labeled, correlating with a legend that provides specific details such as part names and corresponding specifications. Pay close attention to the different shapes and sizes, as they often indicate the function and compatibility of each component.

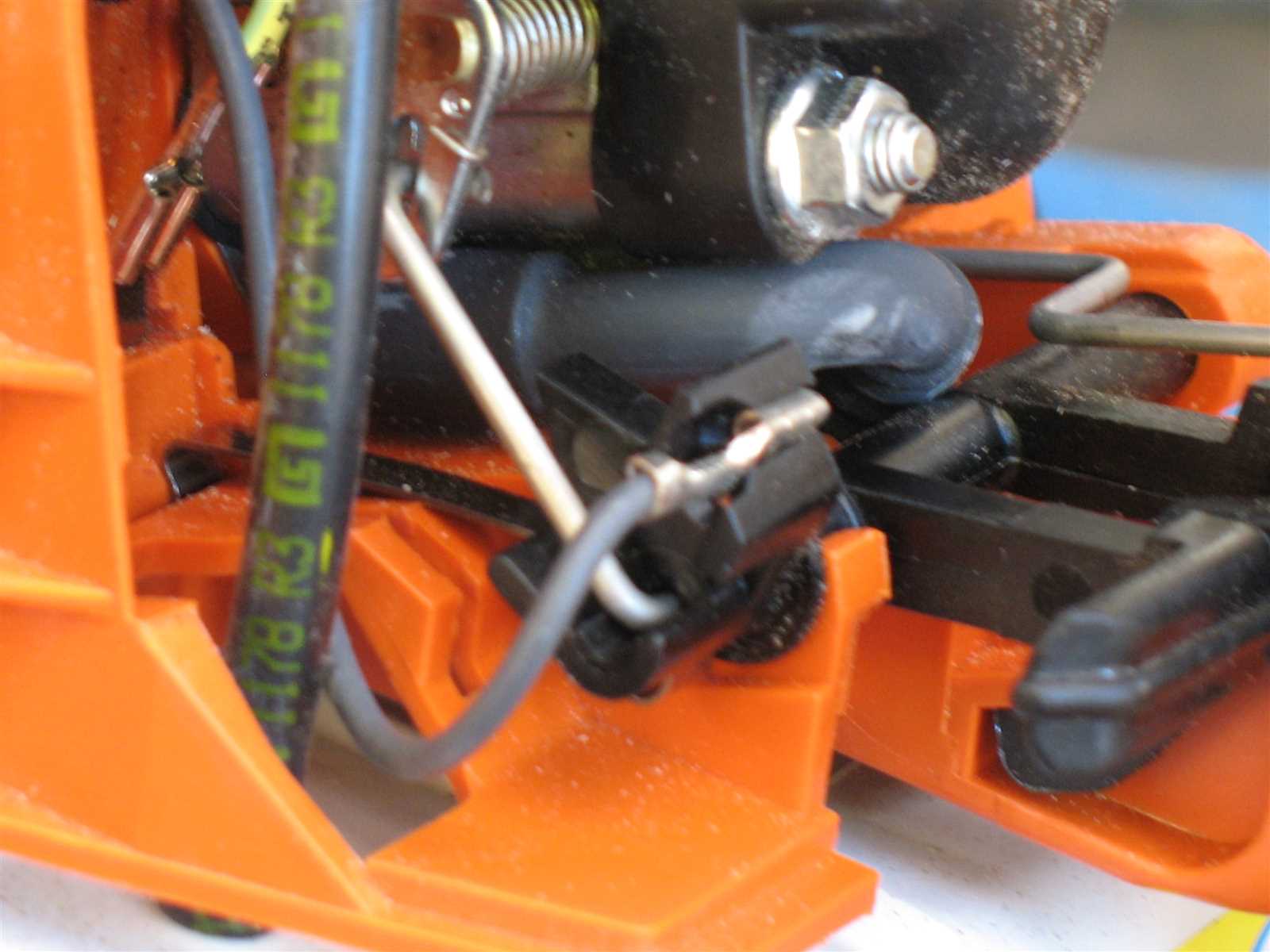

Understanding Connections and Assembly

Another critical aspect is grasping how the components fit together. Lines and arrows often indicate connections or relationships between parts, showing how they interact within the overall system. Take note of any highlighted areas that signify mounting points or fasteners, which are crucial for proper assembly. This understanding will aid in both disassembly and reassembly processes, ensuring that everything fits together seamlessly.

Essential Tools for Maintenance

Proper upkeep of machinery relies on having the right equipment at hand. These instruments not only enhance performance but also extend the lifespan of your tools. Investing in quality maintenance gear is crucial for any operator aiming to ensure their equipment runs smoothly and efficiently.

Basic Hand Tools

Essential hand tools include screwdrivers, wrenches, and pliers. These instruments are vital for making adjustments and repairs, allowing you to tackle minor issues promptly without needing professional assistance.

Cleaning Supplies

Keeping your equipment clean is imperative for optimal performance. Use brushes, cloths, and appropriate cleaning agents to remove debris and prevent rust, ensuring longevity and reliability in your machinery.

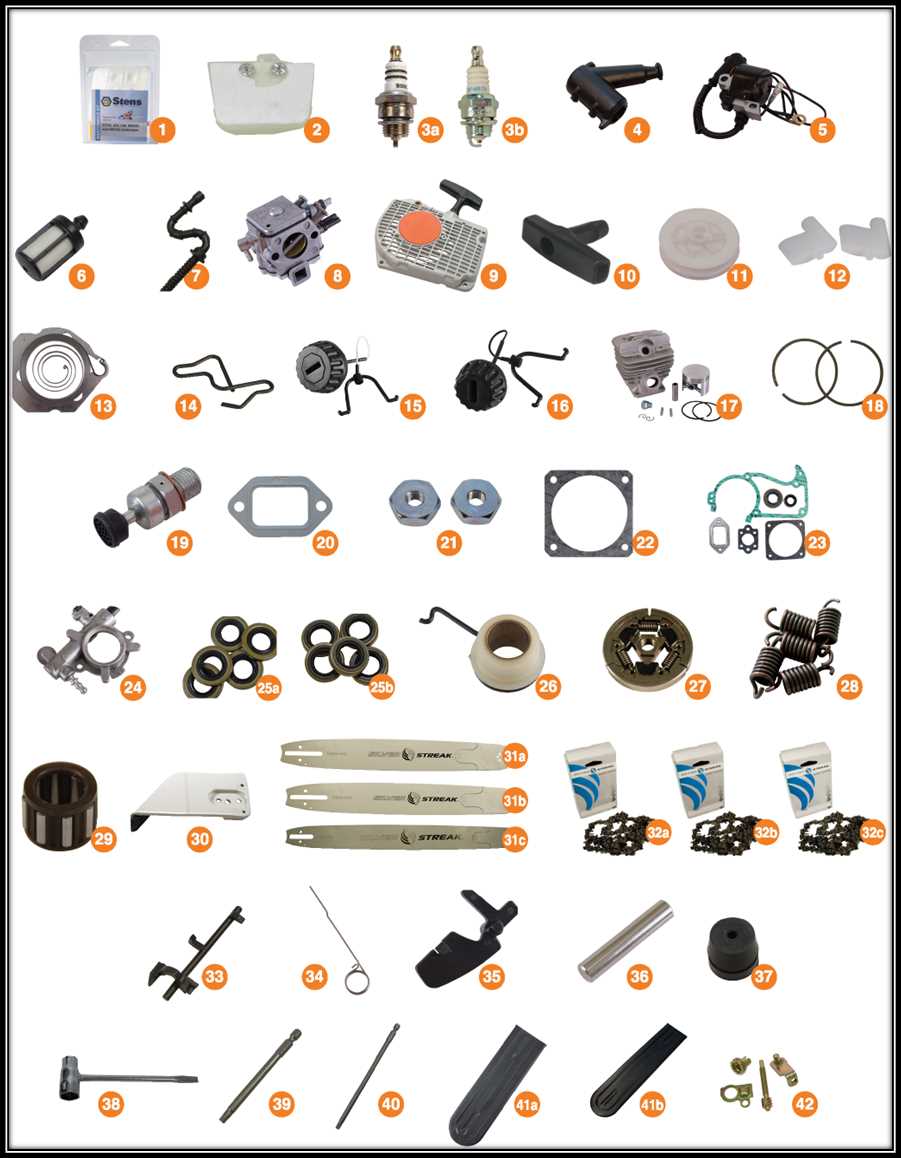

Ordering Replacement Parts Effectively

Ensuring the longevity and performance of your equipment often requires sourcing the right components. Effective ordering not only saves time but also enhances overall efficiency in maintenance and repairs. Understanding how to navigate the process can significantly impact the success of your endeavors.

Research and Identify

Begin by gathering information about the specific elements you need. Utilize reliable resources, including manuals and online forums, to pinpoint the exact components essential for your machinery. Accurate identification minimizes errors and leads to a smoother ordering process.

Choose a Reputable Supplier

Selecting a trustworthy vendor is crucial. Look for suppliers with positive reviews and a solid reputation in the industry. Establishing a good relationship with a reliable source ensures you receive quality items promptly, which is vital for timely repairs and maintenance.

Identifying OEM vs. Aftermarket Parts

Understanding the difference between original equipment manufacturer components and those made by third-party suppliers is essential for ensuring optimal performance and longevity of your equipment. Each option comes with its own set of benefits and drawbacks that can significantly impact functionality and reliability.

Quality and Compatibility

OEM components are crafted to meet the exact specifications set by the original brand, ensuring a seamless fit and reliable performance. In contrast, aftermarket alternatives can vary widely in quality, with some matching or exceeding OEM standards while others may fall short, leading to potential issues in operation.

Cost Considerations

While aftermarket options are often more budget-friendly, this lower price can come at the expense of durability or efficiency. Weighing the initial savings against possible long-term effects is crucial for making an informed decision.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for enhancing the lifespan of your equipment. By following specific guidelines, you can ensure optimal performance and reliability over time.

Regular Cleaning

- Remove debris after each use to prevent build-up.

- Clean air filters to maintain airflow and efficiency.

- Inspect and wipe down all external surfaces to avoid rust.

Routine Inspections

- Check spark plugs regularly for wear and replace as needed.

- Examine fuel lines for cracks or leaks.

- Monitor the condition of the chain and bar, replacing them when worn.

Incorporating these practices into your maintenance routine will significantly contribute to the durability and performance of your machinery.

Popular Accessories for Stihl Chainsaws

Enhancing the performance and versatility of your cutting tool can be achieved through various complementary items. These accessories not only improve efficiency but also provide added safety and convenience during use. Here, we explore some of the most sought-after enhancements that can elevate your cutting experience.

Protective Gear: Safety should always be a priority. Investing in high-quality protective equipment such as gloves, helmets, and chaps can significantly reduce the risk of injury. These items are designed to safeguard users from flying debris and sharp blades, making them essential for any operator.

Bar and Chain Oil: Proper lubrication is crucial for maintaining the longevity and performance of your tool. Specialized oil helps reduce friction, ensuring smooth operation and extending the life of the bar and chain. Regular application can prevent overheating and wear.

Chains and Bars: Different cutting tasks may require specific chains and bars. Upgrading to a more suitable bar length or a chain designed for particular wood types can enhance cutting efficiency. Consider options that improve speed or precision based on your needs.

Carrying Cases: To protect your equipment during transport and storage, a sturdy carrying case is essential. These cases help prevent damage and keep your tools organized, ensuring that everything is readily accessible when needed.

Maintenance Kits: Keeping your equipment in top shape is vital for performance. Maintenance kits typically include tools and supplies for cleaning, sharpening, and adjusting your device. Regular upkeep ensures reliability and efficiency during operation.

By equipping yourself with the right accessories, you can optimize your cutting tool’s performance and enjoy a safer, more efficient experience. Consider these enhancements to take full advantage of your equipment.

Safety Precautions During Repairs

Engaging in maintenance and repair tasks requires careful consideration of safety measures to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also ensure that the equipment remains in optimal condition. Adhering to recommended safety guidelines is essential for a successful and secure repair process.

Personal Protective Equipment

Before starting any repair work, it is vital to equip oneself with appropriate personal protective equipment (PPE). This includes gloves to protect hands from sharp edges and chemicals, safety goggles to shield the eyes from debris, and ear protection when dealing with noisy machinery. Wearing sturdy footwear can also prevent injuries from falling objects.

Work Environment Safety

Maintaining a clean and organized workspace is crucial for safety during repairs. Ensure that the area is well-lit and free of clutter, which can lead to tripping hazards. It is advisable to work on a stable surface, and using the right tools for the job can significantly reduce the risk of accidents. Always follow the manufacturer’s guidelines to ensure safe handling and operation of the equipment.

Expert Resources for Troubleshooting

When encountering issues with your equipment, having access to reliable resources can significantly streamline the troubleshooting process. Various platforms and materials can provide valuable insights, ensuring you can diagnose and resolve problems efficiently.

- Online Forums: Many enthusiasts and professionals gather in dedicated communities to share experiences, solutions, and tips. Engaging with these platforms can offer unique perspectives on common issues.

- Manufacturer Websites: Official sites often have troubleshooting guides, manuals, and FAQs that address frequent challenges faced by users. These resources are designed to be user-friendly and informative.

- Video Tutorials: Platforms like YouTube feature numerous instructional videos. Visual guides can be particularly helpful for complex repairs, offering step-by-step walkthroughs.

Utilizing these expert resources can enhance your understanding and ability to tackle equipment-related issues effectively.

- Identify the problem clearly before seeking solutions.

- Consult multiple resources to gather comprehensive information.

- Document your findings to help with future troubleshooting.