Comprehensive Parts Diagram for Stihl MS381

Maintaining the functionality of your chainsaw is crucial for ensuring optimal performance. A thorough understanding of its components can help in troubleshooting issues and making informed decisions regarding repairs or upgrades. Each element plays a vital role in the overall operation, contributing to the efficiency and reliability of the machine.

In this section, we will explore the intricate layout of the different sections that comprise your cutting tool. By familiarizing yourself with these individual pieces, you can enhance your ability to identify potential problems and address them effectively. Knowing how everything fits together allows for a deeper appreciation of the technology behind these powerful devices.

Whether you are an experienced user or a newcomer, gaining insights into the various components can empower you to make better choices for maintenance and replacement. This knowledge not only aids in prolonging the life of your equipment but also ensures that you can tackle any task with confidence.

Stihl MS381 Overview and Features

This section provides a comprehensive overview of a well-regarded tool known for its robust performance and reliability in various applications. Designed for efficiency, it caters to both professional users and enthusiasts, making it an essential piece of equipment for many tasks.

Key Characteristics

- Powerful engine for enhanced cutting capabilities

- Lightweight design for improved maneuverability

- User-friendly features for effortless operation

- Durable construction ensuring long-lasting performance

- Versatile applications suitable for various projects

Benefits of Using This Equipment

- Increased productivity due to efficient design

- Reduced fatigue with ergonomic handling

- Enhanced safety features for worry-free operation

- Easy maintenance for prolonged usability

- Compatibility with a range of accessories for customization

Identifying Key Components of MS381

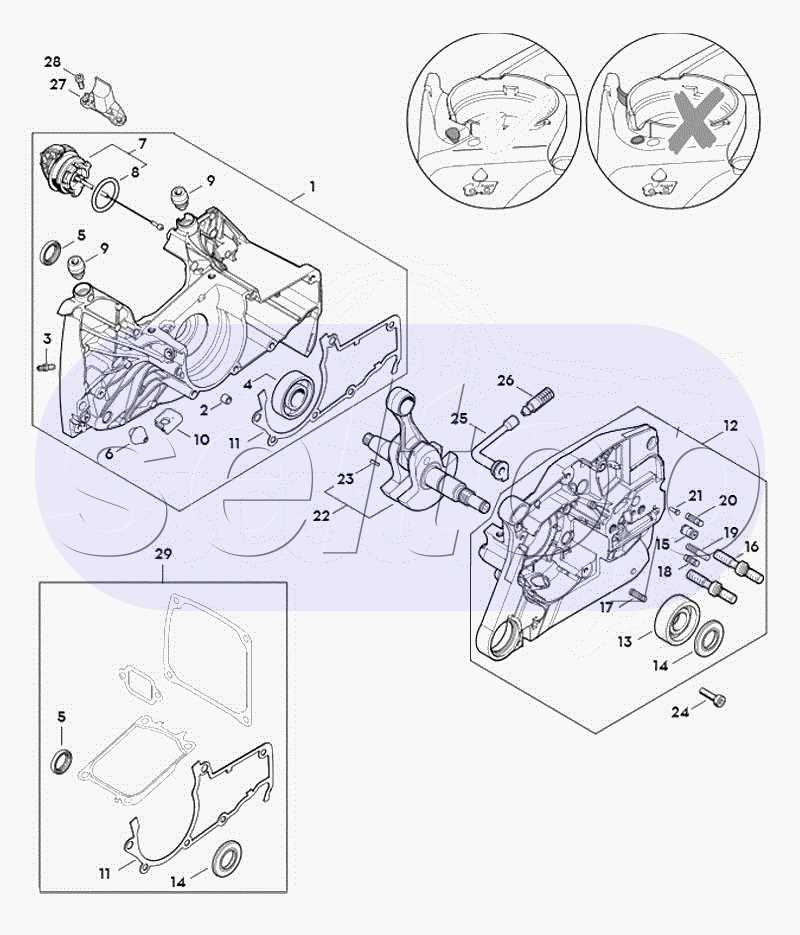

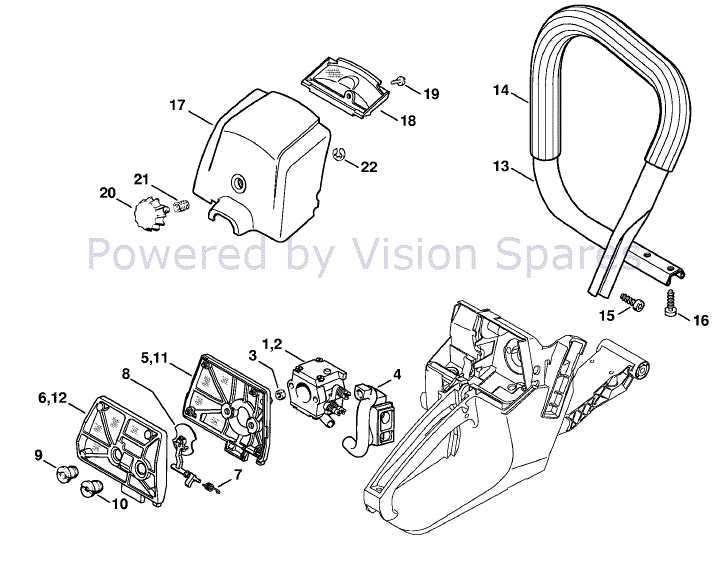

Understanding the main elements of a power tool is essential for effective operation and maintenance. Each component plays a crucial role in the overall functionality, contributing to the efficiency and performance of the device. This section delves into the various parts, highlighting their significance and interrelations.

- Engine: The heart of the tool, providing the necessary power to drive the machine. It converts fuel into mechanical energy, facilitating movement and operation.

- Guide Bar: A crucial element that supports the cutting chain. It provides stability and direction during operation, ensuring precise cutting.

- Chain: This component is responsible for the actual cutting action. Its design and sharpness are vital for achieving efficient performance.

- Air Filter: A protective element that ensures only clean air enters the engine, enhancing performance and extending the lifespan of the machine.

- Fuel Tank: This reservoir holds the mixture of fuel and oil necessary for engine operation. Proper maintenance of this component is critical for optimal performance.

- Handle: Provides the user with a secure grip and control during operation. Its ergonomic design is essential for comfort and safety.

Each of these components plays a vital role in the functionality of the tool. Familiarity with these elements will aid in troubleshooting and maintenance, ensuring longevity and reliability.

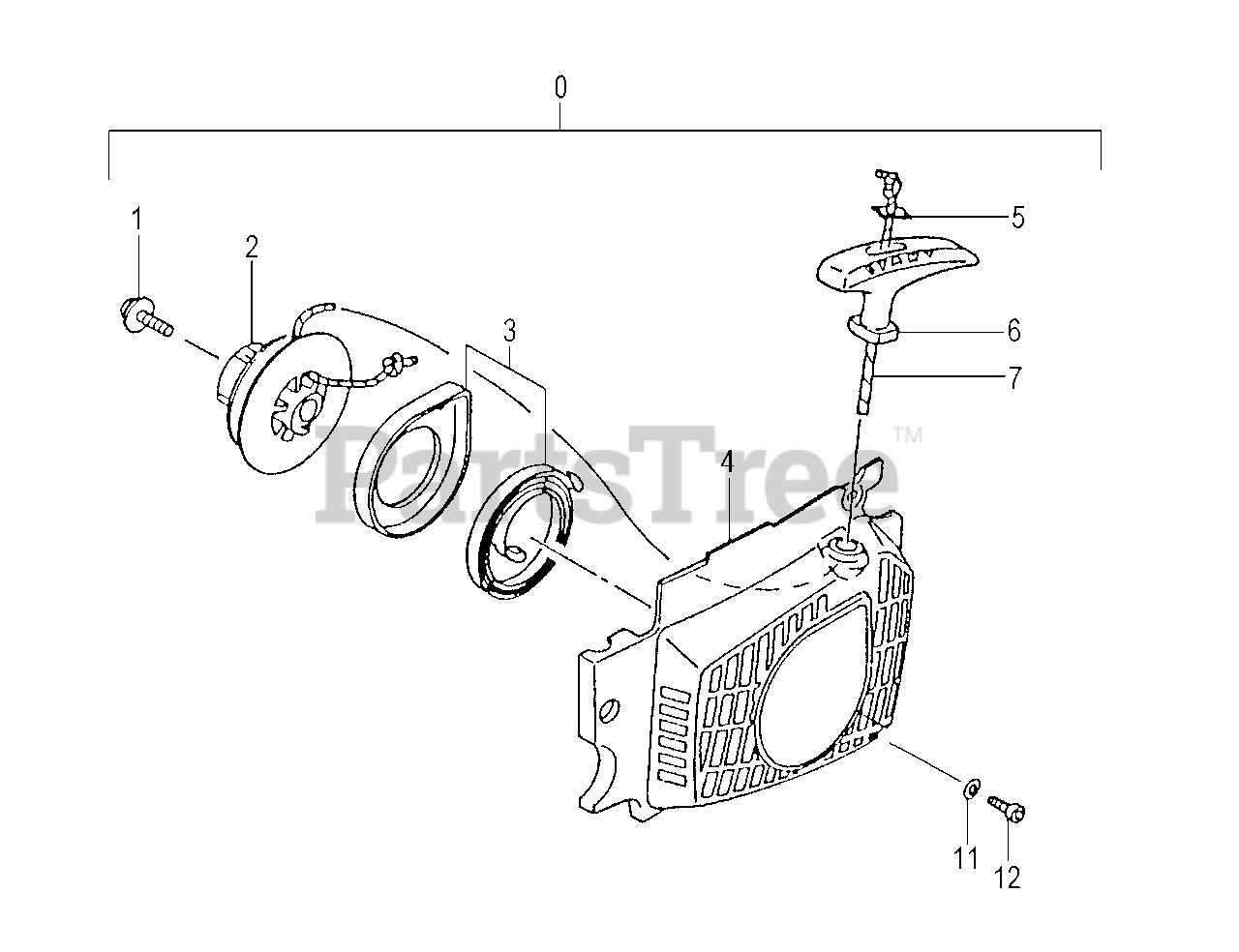

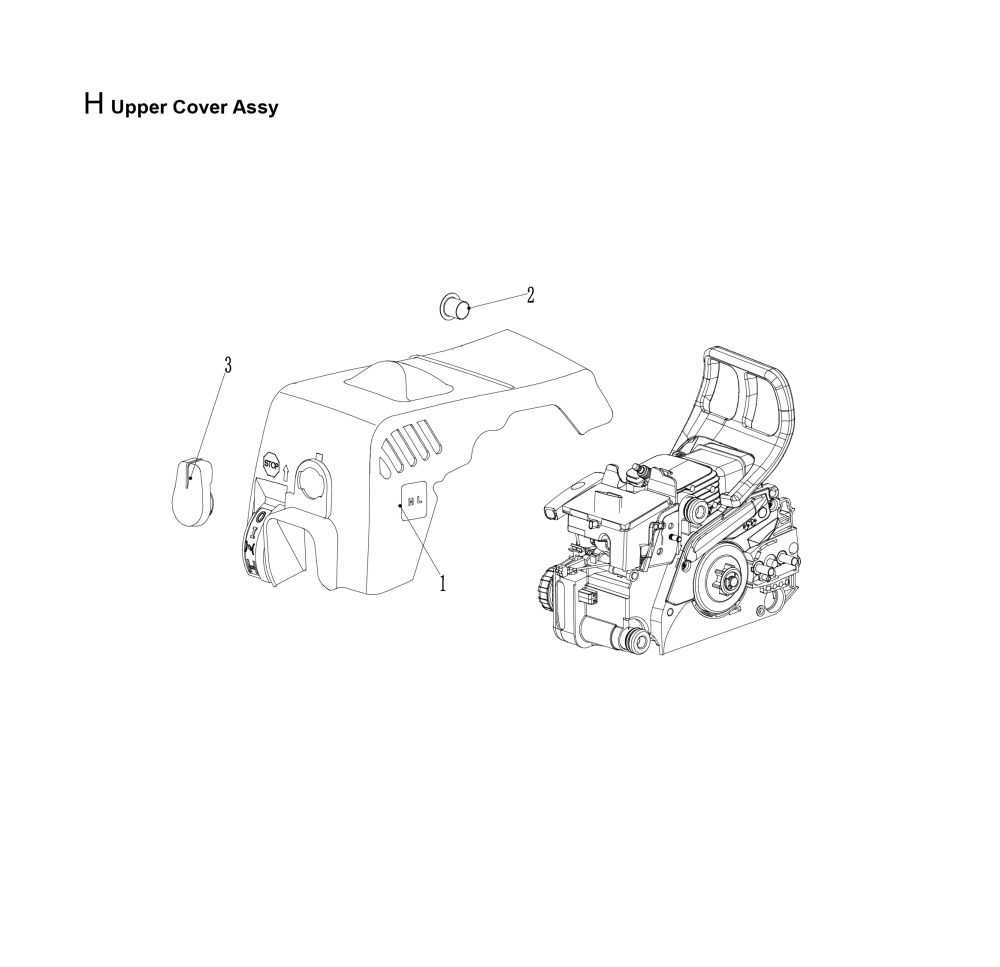

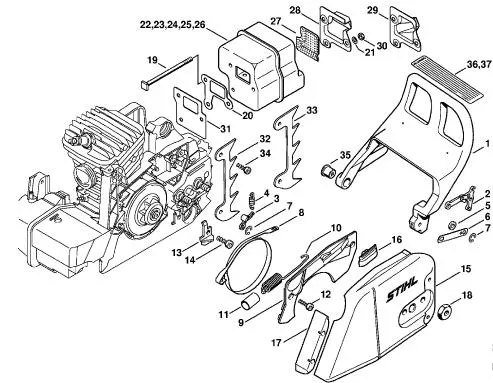

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding how mechanical devices function. These illustrations provide a clear view of individual elements, their arrangement, and interconnections within a complex assembly. By simplifying the intricate design of equipment, they enable users to comprehend how each piece contributes to overall performance and efficiency.

Enhancing Maintenance and Repair

Utilizing schematic visuals is essential for effective upkeep and troubleshooting. Technicians can identify specific components that require attention, facilitating accurate repairs and minimizing downtime. This clarity ensures that every aspect of the machinery is properly serviced, prolonging its lifespan and enhancing reliability.

Facilitating Assembly and Disassembly

These visual aids serve as a guide for assembling and disassembling equipment. They allow users to follow step-by-step instructions, ensuring that all elements are correctly fitted. This process reduces the risk of errors, making it easier for individuals to work confidently with complex systems.

| Benefit | Description |

|---|---|

| Clear Visualization | Offers a straightforward view of each component and its role. |

| Efficient Repairs | Helps technicians locate and fix issues swiftly. |

| Accurate Assembly | Guides users in the correct fitting of components. |

| Enhanced Understanding | Improves knowledge of how the device operates as a whole. |

How to Use Parts Diagrams

Utilizing visual representations of components can greatly enhance your understanding of mechanical systems. These illustrations serve as a guide for identifying various elements and their interconnections, facilitating effective assembly, disassembly, and troubleshooting. Whether you are a novice or an experienced technician, these resources are invaluable in ensuring accuracy during maintenance tasks.

Understanding Symbols and Labels: Each visual representation includes specific symbols and labels that denote different elements. Familiarizing yourself with these notations is crucial for effective interpretation. Take the time to study the accompanying legends or keys that explain the various markings, as this will simplify the process of locating and identifying parts.

Following Assembly Instructions: Visual aids provide a sequential approach to assembly processes. By following the order presented in the illustrations, you can ensure that all components are fitted correctly. Pay close attention to orientation and alignment, as incorrect installation can lead to operational issues.

Facilitating Troubleshooting: When diagnosing issues, these visual aids can help pinpoint areas of concern. By cross-referencing the illustrated components with the actual system, you can identify discrepancies or damaged parts. This methodical approach aids in developing an effective repair strategy.

Maintaining Your Equipment: Regular consultation of these resources can contribute to the longevity of your equipment. By understanding the layout and function of individual components, you can carry out preventative maintenance tasks more efficiently, ensuring optimal performance and reducing the likelihood of future failures.

Common Replacement Parts for MS381

When maintaining any machinery, it’s essential to know which components may need to be replaced over time to ensure optimal performance. Regular upkeep can significantly enhance the longevity of your equipment, making it crucial to identify the most frequently replaced items.

Here are some of the common components that may require replacement:

- Fuel Filter: Keeps contaminants from entering the engine, ensuring clean fuel flow.

- Air Filter: Prevents dirt and debris from entering the engine, promoting efficient operation.

- Chain: Essential for cutting, ensuring sharpness and functionality.

- Guide Bar: Supports the chain and allows smooth operation during use.

- Spark Plug: Facilitates ignition, ensuring your engine starts and runs smoothly.

- Gaskets: Help prevent leaks in various parts of the engine, maintaining pressure and efficiency.

- Starter Rope: Essential for starting the engine, often wears out with regular use.

Regularly inspecting and replacing these components can help maintain the efficiency and performance of your equipment, ensuring it runs smoothly for years to come.

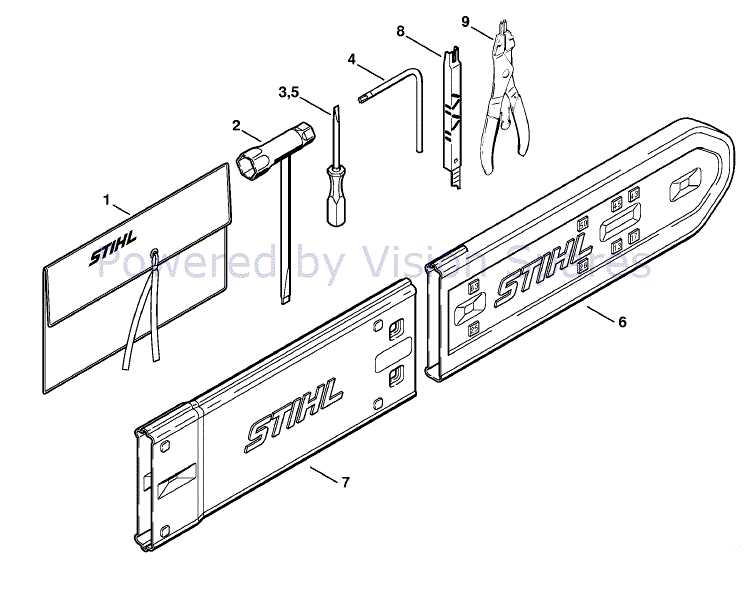

Tools Needed for MS381 Maintenance

Regular upkeep of your equipment is essential for optimal performance and longevity. To ensure everything operates smoothly, a specific set of instruments is necessary. These tools will assist in routine checks, adjustments, and any required repairs, making the maintenance process more efficient and effective.

Essential Hand Tools

A variety of hand tools should be included in your maintenance kit. Basic items like screwdrivers, wrenches, and pliers are crucial for performing adjustments and repairs. A torque wrench is also recommended for accurately tightening components, ensuring everything is secured to the manufacturer’s specifications.

Specialized Equipment

In addition to general tools, certain specialized equipment will enhance your maintenance efforts. A chain sharpening tool is vital for maintaining cutting efficiency, while a cleaning brush helps remove debris from critical areas. Having a fuel mixing container will also ensure that your fuel is prepared correctly, contributing to the overall performance of your machinery.

Steps for Disassembling MS381

Disassembling a chainsaw requires careful attention to detail and methodical procedures to ensure all components are handled properly. This guide outlines essential steps to dismantle the equipment efficiently while minimizing the risk of damage to its parts. Following these instructions will facilitate easy reassembly and maintenance.

Preparation and Tools Needed

Before starting the disassembly process, gather the necessary tools and prepare a clean workspace. Ensure that the device is completely powered off and has cooled down. The following tools are recommended:

| Tool | Purpose |

|---|---|

| Wrench set | For loosening bolts and screws |

| Screwdriver | To remove screws |

| Plier | For gripping and pulling |

| Clean cloth | To wipe off any debris or oil |

Disassembly Steps

Follow these sequential steps to effectively dismantle the equipment:

- Remove the housing cover by unscrewing the bolts that secure it in place.

- Take out the air filter and clean it thoroughly to prevent contamination during the process.

- Disconnect the fuel lines carefully, ensuring no fuel spills occur.

- Unscrew the carburetor, taking care to note its position and orientation for reassembly.

- Finally, detach the exhaust system by removing any attached screws or bolts.

Safety Tips for Using Chainsaws

Using a power saw can be a rewarding experience, but it requires utmost caution and awareness. Proper safety measures are essential to prevent accidents and injuries while operating this equipment. Understanding the fundamental guidelines can help ensure a secure working environment.

Always wear appropriate protective gear. This includes a helmet, goggles, gloves, and steel-toed boots. Such equipment shields you from potential hazards, such as flying debris and accidental contact with the blade.

Before starting, inspect the tool for any damage or wear. Make sure the chain is sharp, properly tensioned, and that all components are securely attached. Regular maintenance enhances performance and safety.

Maintain a firm grip on the tool with both hands while operating it. This control reduces the risk of losing balance and improves accuracy. Additionally, ensure you have a stable stance on even ground.

Be aware of your surroundings. Check for obstacles such as branches, power lines, and uneven terrain. Ensure that bystanders are at a safe distance, as flying debris can pose a danger to others.

Follow the manufacturer’s instructions for starting and using the tool. Familiarize yourself with the controls and functions to enhance your understanding and handling of the equipment. This knowledge is vital for safe operation.

By adhering to these safety guidelines, users can enjoy the benefits of using a power saw while minimizing risks. Prioritizing safety is crucial for a successful and secure experience.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Genuine items ensure compatibility and reliability, significantly reducing the risk of malfunctions. Fortunately, there are several reliable avenues to obtain these essential elements.

Authorized dealers often provide the best selection of original components, guaranteeing their authenticity. Additionally, reputable online platforms specialize in offering a wide array of genuine parts, often at competitive prices. It’s essential to verify the credibility of the seller to ensure you receive quality items.

Here’s a summary of options to consider:

| Source | Description |

|---|---|

| Authorized Dealers | Official distributors with a complete inventory of authentic components. |

| Online Retailers | Websites that specialize in original parts, often with customer reviews and ratings. |

| Manufacturer’s Website | Direct source for authentic components, often with detailed product information. |

| Local Repair Shops | Some service centers offer genuine parts along with repair services. |

Understanding MS381 Troubleshooting Guide

When encountering issues with your equipment, having a comprehensive troubleshooting guide can significantly enhance your ability to identify and resolve problems effectively. This guide serves as a valuable resource for diagnosing common malfunctions, providing a step-by-step approach to ensure your machinery operates smoothly.

Common Symptoms

Many users experience a range of symptoms that may indicate underlying issues. These can include difficulty starting, inconsistent performance, or unusual noises during operation. Recognizing these signs is crucial for timely intervention.

Initial Checks

Before delving into complex diagnostics, it’s essential to perform initial checks. Ensure that all connections are secure, the fuel is fresh, and the air filter is clean. These simple steps can often rectify minor problems and save time.

Advanced Troubleshooting

If basic inspections do not resolve the issue, advanced troubleshooting may be necessary. This involves examining components such as the ignition system, fuel delivery, and compression levels. A methodical approach will aid in pinpointing the exact cause of the malfunction.

Consulting Resources

Utilizing manuals and guides dedicated to your specific model can provide additional insights. Diagrams illustrating assembly and disassembly processes can also assist in understanding the internal workings and facilitate repairs.

Final Recommendations

For persistent problems, seeking assistance from a professional technician may be advisable. Their expertise can offer a thorough analysis and ensure that your equipment is restored to optimal functionality.

Frequently Asked Questions About MS381

This section addresses common inquiries related to the equipment, aiming to provide clarity and assist users in understanding its features and maintenance. Below are some of the most frequently posed questions.

-

What is the recommended maintenance schedule?

Regular upkeep is essential for optimal performance. It’s advisable to check the oil level, clean the air filter, and inspect the chain and bar periodically.

-

How do I troubleshoot starting issues?

If the machine does not start, ensure the fuel is fresh, the spark plug is functioning, and that there are no blockages in the air intake.

-

What type of fuel should be used?

A high-quality fuel with a suitable octane rating is recommended. Additionally, a mix of oil is necessary to ensure proper lubrication.

-

How can I improve cutting efficiency?

Keeping the cutting chain sharp and well-tensioned can significantly enhance performance. Regularly check for wear and replace as needed.

-

Where can I find replacement components?

Replacement parts can typically be found at authorized retailers or online stores that specialize in equipment supplies.