Comprehensive Guide to Stihl MS880 Parts Diagram

When it comes to maintaining and optimizing powerful machinery, a clear understanding of its internal elements is crucial. These essential components work together seamlessly to ensure efficiency and reliability in operation. Exploring their arrangement provides valuable insights into the functionality and potential enhancements of these robust devices.

Familiarizing oneself with the layout and interconnections of these crucial parts allows for better troubleshooting and maintenance practices. Enthusiasts and professionals alike benefit from a detailed examination, as it reveals how each piece contributes to the overall performance. Furthermore, this knowledge can ultimately lead to improved longevity and effectiveness.

By delving into the specifics, users can identify wear and tear or other issues that may arise over time. Understanding these intricacies empowers individuals to make informed decisions regarding repairs and upgrades, ensuring their tools remain in peak condition for any task.

Understanding the Stihl MS880 Chainsaw

This section aims to provide insight into a powerful tool designed for demanding tasks. Known for its durability and efficiency, this model is often favored by professionals in forestry and construction. It combines advanced technology with user-friendly features, making it a reliable choice for heavy-duty applications.

Key Features

- High-performance engine for exceptional cutting speed

- Ergonomic design for improved handling

- Robust construction to withstand harsh conditions

- Easy maintenance for prolonged lifespan

Common Applications

- Logging and timber harvesting

- Tree trimming and felling

- Land clearing and site preparation

- Firewood processing

Understanding the functionality and versatility of this saw is essential for maximizing its performance and ensuring safety during operation. Proper knowledge of its components and maintenance can greatly enhance user experience and productivity.

Key Features of the MS880 Model

The advanced cutting tool is designed for high performance and durability, catering to the needs of professionals in demanding environments. Its robust engineering ensures efficiency and reliability, making it a preferred choice for heavy-duty tasks.

Powerful Engine: The model boasts a high-capacity engine that delivers exceptional cutting power, enabling users to tackle the toughest jobs with ease.

Lightweight Design: Despite its strength, the device maintains a lightweight structure, allowing for extended use without causing fatigue, which is essential during long working hours.

Enhanced Safety Features: Equipped with multiple safety mechanisms, this tool prioritizes user protection, reducing the risk of accidents during operation.

Ease of Maintenance: The engineering design facilitates quick access to key components, simplifying routine maintenance tasks and ensuring longevity.

Precision Cutting: The cutting mechanism is optimized for precision, providing clean cuts that enhance the overall quality of work.

Versatile Applications: This model is suitable for various applications, from felling trees to limbing and bucking, making it a versatile addition to any professional’s toolkit.

Importance of Parts Diagrams

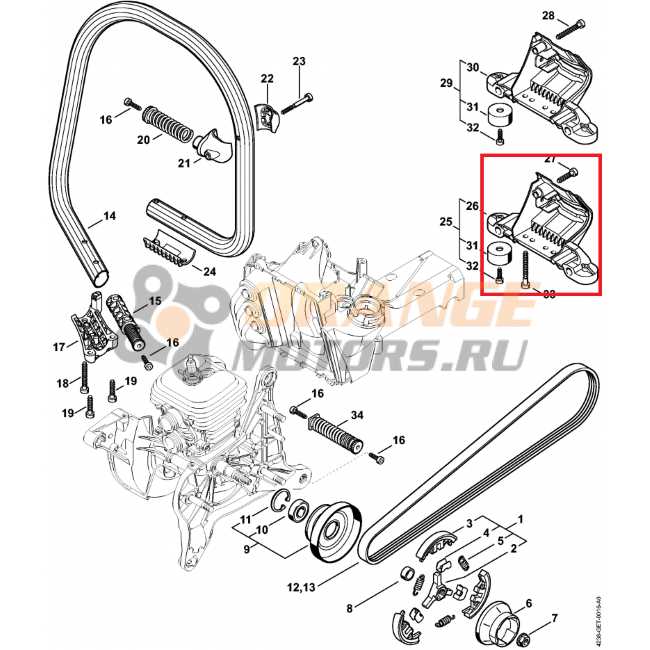

Understanding the intricacies of machinery requires a clear visualization of its components and how they interact. A detailed illustration serves as a crucial tool for both novice users and experienced technicians, enabling them to identify elements, troubleshoot issues, and facilitate repairs with precision. Such visuals not only enhance comprehension but also streamline maintenance processes, ultimately extending the lifespan of the equipment.

Moreover, these representations play a significant role in ensuring safety. When individuals are aware of the specific arrangement and function of each piece, they can operate the machinery with greater confidence, minimizing the risk of accidents or malfunctions.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Clarifies the relationship between components. |

| Improved Troubleshooting | Facilitates quick identification of faults. |

| Streamlined Maintenance | Guides users through effective repair processes. |

| Increased Safety | Reduces risk through informed operation. |

In summary, visual representations of machinery components are indispensable for effective management, maintenance, and safe operation. By utilizing these resources, users can ensure their equipment remains in optimal condition, ultimately leading to better performance and longevity.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide a detailed overview, showing the arrangement and relationships between various elements. By familiarizing yourself with these visuals, you can identify parts and their functions more easily.

Identifying Key Components

Begin by noting the labeled sections, which usually correspond to different assemblies or groups. Each section often highlights specific components, making it simpler to locate what you need. Pay attention to any reference numbers or codes that indicate the corresponding parts.

Understanding Connections and Assembly

Look for lines or arrows that illustrate how components connect. These indicators can guide you in understanding the assembly process, helping you visualize how parts fit together. Recognizing these connections is crucial for troubleshooting and reassembly.

Common Replacement Parts for MS880

Regular maintenance and timely replacements are essential for ensuring optimal performance of any high-powered tool. Certain components tend to wear out or become damaged over time, necessitating their replacement. Understanding which elements commonly require attention can significantly enhance the longevity and efficiency of your equipment.

| Component | Description | Function |

|---|---|---|

| Cylinder | The chamber where the combustion occurs. | Essential for powering the engine. |

| Piston | The moving part that compresses the fuel-air mixture. | Creates the necessary pressure for ignition. |

| Fuel Filter | Removes impurities from the fuel. | Ensures clean fuel reaches the engine. |

| Chain | The loop that connects to the bar and cuts through materials. | Provides cutting action. |

| Bar | The metal guide that holds the chain. | Directs the chain’s path during cutting. |

| Air Filter | Prevents debris from entering the engine. | Maintains airflow for combustion efficiency. |

| Spark Plug | Ignites the fuel-air mixture. | Essential for engine start and operation. |

Maintenance Tips for Your Chainsaw

Regular upkeep is essential for ensuring the longevity and efficiency of your cutting tool. Implementing a consistent maintenance routine will not only enhance performance but also improve safety during use. Below are key practices to keep your chainsaw in top condition.

Regular Cleaning

- Remove debris from the chain and bar after each use.

- Inspect and clean the air filter periodically.

- Use a soft brush to clear dust and dirt from the casing.

Lubrication and Tensioning

- Check and adjust the chain tension regularly to avoid damage.

- Ensure proper lubrication to prevent overheating and wear.

- Replace bar oil as needed, especially during heavy use.

Identifying Issues with Parts Diagrams

Understanding the layout of components in machinery is crucial for effective troubleshooting. Recognizing potential discrepancies in these visual representations can lead to improved maintenance and repair processes. When users encounter unclear illustrations, it can hinder their ability to address mechanical problems efficiently.

Common Misinterpretations

One frequent issue arises from overlapping elements that obscure individual pieces. This can create confusion regarding the correct orientation and arrangement, leading to improper assembly or disassembly. Additionally, unclear labeling can contribute to misunderstandings, as users may misidentify essential parts.

Best Practices for Clarity

To enhance comprehension, it’s advisable to cross-reference multiple sources when examining component layouts. Utilizing high-quality resources and ensuring proper lighting during examination can significantly reduce errors. Engaging with online forums or support groups can also provide valuable insights from fellow users, fostering a clearer understanding of any complexities.

Where to Find Genuine Stihl Parts

Locating authentic components for your outdoor power equipment is essential for maintaining performance and ensuring safety. Using original elements not only enhances the longevity of your machine but also guarantees optimal functionality. Below are some reliable sources to help you find what you need.

Authorized Dealers

- Visit local authorized retailers for a wide selection of original components.

- Consult the manufacturer’s website for a list of certified dealers in your area.

- Inquire about warranty and return policies when purchasing.

Online Marketplaces

- Explore reputable online platforms that specialize in outdoor equipment.

- Check customer reviews and ratings to ensure quality and authenticity.

- Look for sellers that offer guarantees on their products.

By utilizing these sources, you can ensure that you acquire the best components for your equipment, keeping it running smoothly for years to come.

Tools Required for MS880 Repairs

Proper maintenance and repair of high-performance machinery demand specific instruments to ensure efficiency and safety. Utilizing the right equipment not only streamlines the repair process but also enhances the longevity of the device. Below are essential tools that facilitate effective servicing.

Basic Hand Tools

Having a set of standard hand tools is crucial. Wrenches, screwdrivers, and pliers are fundamental for disassembly and reassembly tasks. Additionally, a torque wrench is vital for achieving the correct tightness on various components, ensuring optimal performance.

Specialized Equipment

For more intricate repairs, specialized tools are necessary. A chain sharpener ensures that cutting performance remains at its peak, while a compression tester is important for assessing engine health. Investing in these specific tools will greatly improve repair outcomes.

Comparing MS880 with Other Models

This section explores the distinctions and similarities between a particular high-performance chainsaw and its counterparts. By analyzing key features and specifications, users can gain insight into which model best suits their needs.

Key Features Overview

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 70 cc | 80 cc | 90 cc |

| Weight | 12 lbs | 13 lbs | 14 lbs |

| Bar Length | 16-20 in | 20-25 in | 25-30 in |

Performance Comparison

When considering operational efficiency, one model may excel in power output while another provides better maneuverability. Understanding these nuances allows for an informed choice, ensuring the selected equipment aligns with specific tasks and preferences.

Safety Precautions When Using Chainsaws

Operating a chainsaw requires careful attention to safety measures to prevent accidents and injuries. Understanding the potential hazards and implementing the appropriate precautions is essential for both novice and experienced users. Proper training, protective gear, and awareness of the environment can significantly reduce risks while using this powerful tool.

Protective Gear

Wearing the right protective equipment is crucial when handling a cutting machine. Ensure you have a high-quality helmet with a face shield, ear protection, and gloves designed for heavy-duty work. Cut-resistant clothing and sturdy boots will further shield you from possible injuries. Always check your gear for any wear and tear before starting your tasks.

Operational Awareness

Before beginning any cutting operation, assess the area for potential hazards, such as overhead branches or uneven terrain. Maintain a safe distance from bystanders and always inform others about your activities. Familiarize yourself with the equipment’s features and functionalities, ensuring you understand how to operate it safely. Never rush through a job, as taking your time helps maintain focus and reduces the likelihood of accidents.

Expert Advice on Chainsaw Maintenance

Maintaining a cutting tool is essential for ensuring optimal performance and longevity. Regular upkeep not only enhances efficiency but also significantly reduces the risk of accidents. Proper maintenance practices can keep your equipment in prime condition, allowing you to tackle any task with confidence.

Routine Checks

Performing regular inspections is crucial. Start by examining the chain for any signs of wear or damage. A dull or damaged chain can lead to inefficient cutting and increased strain on the machine. Always ensure that the tension is correctly adjusted; too tight can cause premature wear, while too loose can lead to accidents.

Cleaning and Lubrication

Cleaning the equipment after each use helps prevent the buildup of debris that can hinder performance. Pay special attention to the air filter and the guide bar. Lubrication is equally important; ensure that all moving parts are well-oiled to avoid unnecessary friction, which can lead to overheating.