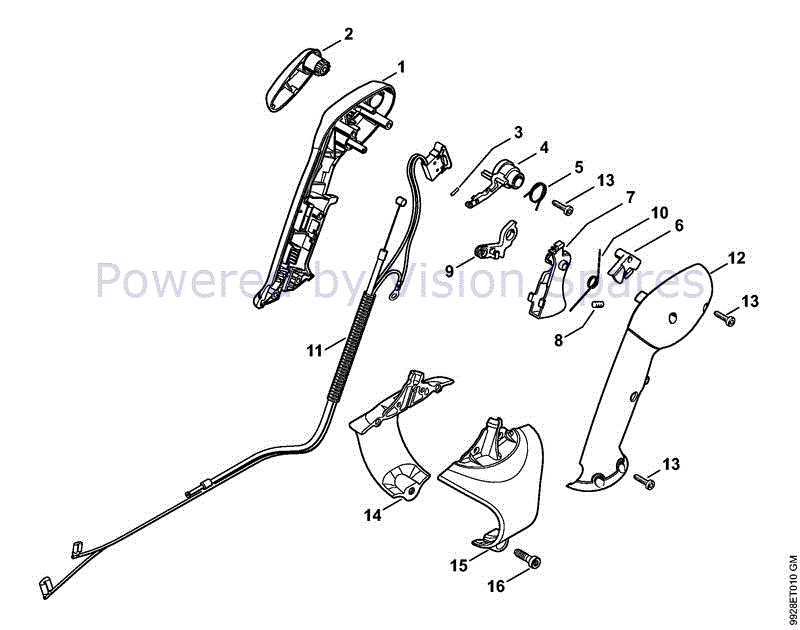

Comprehensive Parts Diagram for Stihl RB 200

Maintaining outdoor machinery requires a solid grasp of its inner workings. Familiarity with each element not only enhances performance but also extends the lifespan of the equipment. This section aims to illuminate the intricate relationships between various components, providing a comprehensive overview.

For users seeking to enhance their operational knowledge, a detailed exploration of the specific elements is essential. Recognizing how each part functions within the whole system allows for informed decisions regarding maintenance and repair. Whether you’re a novice or a seasoned operator, this understanding is crucial for optimal performance.

Additionally, visual aids can significantly improve comprehension. By examining graphical representations of the machinery, users can easily identify and locate individual components. This guide serves as a valuable resource, facilitating a deeper dive into the essential elements that contribute to the ultimate efficiency of your equipment.

Understanding Stihl RB 200 Parts

Gaining familiarity with the components of outdoor power equipment is essential for effective maintenance and troubleshooting. Each element plays a vital role in ensuring optimal performance and longevity of the machine. This section aims to break down the essential elements, highlighting their functions and importance.

Key Components Overview

Here are some of the primary elements that contribute to the overall functionality:

- Engine: The heart of the machine, responsible for generating power.

- Fuel System: Ensures the correct mixture of fuel and air for efficient combustion.

- Air Filter: Prevents dirt and debris from entering the engine, maintaining performance.

- Transmission: Transfers power from the engine to the wheels or working attachments.

- Wheels: Provide mobility and stability during operation.

Maintenance and Replacement Tips

To keep your equipment in peak condition, consider the following maintenance tips:

- Regularly check and replace the air filter to ensure proper airflow.

- Inspect the fuel system for leaks or clogs to maintain efficiency.

- Clean the engine periodically to remove debris and prevent overheating.

- Examine the wheels and transmission for wear and tear, replacing as needed.

Understanding the roles of these components will help users maintain their equipment effectively, ensuring it runs smoothly for years to come.

Overview of RB 200 Specifications

This section provides a comprehensive look at the key features and technical details of the specified model, highlighting its design, performance, and functionality. Understanding these specifications is crucial for users to fully appreciate the machine’s capabilities and ensure it meets their needs.

The device is equipped with a powerful engine that delivers efficient performance while maintaining low fuel consumption. Its lightweight construction facilitates easy handling, making it suitable for both residential and commercial use. Additionally, the ergonomic design ensures user comfort during operation.

Key attributes include a robust frame that enhances durability and resistance to wear. The model boasts an adjustable height feature, allowing users to customize the working conditions based on specific requirements. Furthermore, its innovative design minimizes maintenance needs, ensuring reliability over time.

Overall, this equipment combines efficiency, comfort, and durability, making it an excellent choice for various applications. Whether for professional landscaping or personal gardening, understanding these specifications will help users maximize their investment and achieve optimal results.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and functionality of machinery. They serve as essential guides for both novices and experts, ensuring efficient maintenance and repair processes.

Enhanced Understanding

- Clarifies the relationships between various elements.

- Facilitates identification of individual components.

- Assists in troubleshooting issues effectively.

Streamlined Repairs

- Provides a roadmap for assembly and disassembly.

- Reduces the risk of errors during repairs.

- Increases efficiency, saving time and effort.

Key Components of Stihl RB 200

Understanding the essential elements of this powerful outdoor equipment is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring efficiency and longevity, making it important to familiarize yourself with their functions and interactions.

Main Assembly Parts

- Engine: The heart of the machine, responsible for generating power.

- Chassis: The frame that supports all components and provides stability.

- Fuel System: Includes the tank, lines, and carburetor, ensuring the engine receives the right mixture for combustion.

Operational Features

- Air Filter: Maintains clean airflow to the engine, enhancing performance and efficiency.

- Starter Mechanism: Facilitates easy ignition, allowing for quick use.

- Wheels: Designed for maneuverability and ease of transport across various terrains.

How to Read a Parts Diagram

Understanding a visual representation of components can greatly enhance your ability to maintain and repair machinery. These illustrations serve as valuable tools, providing a clear overview of how different elements are arranged and connected within a device. By familiarizing yourself with the symbols and notations used in these visuals, you can effectively identify each piece’s function and its relation to others.

Firstly, take note of the legend or key that often accompanies the illustration. This section typically explains the various symbols used to represent components, helping you decipher what each symbol stands for. For example, certain shapes may denote electrical parts, while others could indicate mechanical elements. Recognizing these symbols is crucial for accurate interpretation.

Next, observe the layout of the components. Components are usually arranged in a logical sequence, reflecting their physical configuration in the device. Understanding how each element interacts with others can provide insight into assembly and disassembly processes, aiding in troubleshooting issues.

Lastly, pay attention to any annotations or notes included in the illustration. These can offer additional context, such as installation tips or maintenance recommendations, further enhancing your comprehension of the machinery’s structure and functionality. By mastering these aspects, you will become proficient at interpreting these valuable resources, enabling you to work confidently on your equipment.

Common RB 200 Issues and Solutions

When using a garden blower, various challenges may arise that can hinder its performance. Understanding these common problems and their respective solutions can significantly enhance the efficiency and longevity of your equipment. Below are some frequently encountered issues along with practical fixes.

Insufficient Airflow may occur due to clogged air filters or debris in the blower’s intake. Regularly check and clean the air filter to ensure optimal airflow. If the issue persists, inspect the intake area for any blockages and clear them away.

Starting Difficulties are often a result of fuel-related issues. Ensure that the fuel is fresh and appropriately mixed according to the manufacturer’s specifications. If the unit still won’t start, check the spark plug for wear or damage, and replace it if necessary.

Overheating can lead to decreased performance and potential damage. This problem often arises from prolonged use or a lack of proper ventilation. Allow the machine to cool down periodically and avoid operating it in confined spaces without adequate airflow.

Unusual Noises can indicate mechanical issues. If you notice grinding or rattling sounds, stop using the blower immediately and inspect for loose or damaged parts. Tightening loose screws or replacing damaged components can often resolve the issue.

By being aware of these typical challenges and their solutions, users can maintain their garden equipment effectively, ensuring smooth operation and extending its lifespan.

Maintaining Your Stihl RB 200

Proper upkeep of your outdoor power tool is essential for optimal performance and longevity. Regular maintenance not only ensures efficiency but also enhances safety during operation. Here are key practices to keep your equipment running smoothly.

- Regular Cleaning: Remove dirt, debris, and grass clippings from the unit after each use to prevent buildup that can affect performance.

- Inspecting Components: Routinely check the various components for wear and tear, including belts, filters, and blades. Replace any damaged parts promptly.

- Lubrication: Keep moving parts lubricated to minimize friction and wear. Use appropriate lubricants specified in the user manual.

- Fuel Management: Use fresh fuel and the recommended oil mixture to ensure the engine runs efficiently. Store fuel properly to prevent degradation.

Implementing these maintenance tips will not only prolong the life of your tool but also improve its overall performance. Ensure to consult the user manual for specific instructions and recommendations tailored to your equipment.

Where to Find Replacement Parts

When it comes to maintaining and repairing your equipment, locating suitable components is essential for optimal performance. There are various avenues to explore when seeking out the necessary items, ensuring your machine runs smoothly and efficiently.

Authorized Retailers and Service Centers

One of the most reliable sources for obtaining high-quality replacements is through authorized dealers and service centers. These establishments often carry a comprehensive selection of genuine components and can provide expert guidance on installation and compatibility. Additionally, they may offer warranty coverage on the parts purchased, adding an extra layer of assurance for users.

Online Marketplaces and Specialty Websites

Another effective method for sourcing replacements is through online marketplaces and specialty websites dedicated to equipment supplies. These platforms typically feature extensive catalogs, allowing users to browse various options and compare prices. While shopping online, it’s crucial to ensure that the seller is reputable and offers quality assurance on the items listed.

Comparing RB 200 with Other Models

When evaluating a specific model against its counterparts, it’s essential to consider various attributes that define their performance and usability. Each machine in the lineup offers unique features that cater to different needs, making comparisons a valuable exercise for potential users seeking the best fit for their requirements.

Performance and Efficiency

In terms of performance, this particular model stands out with its remarkable power and efficiency. Compared to similar machines, it excels in fuel consumption and operational speed. Users often note that its ability to tackle challenging tasks without compromising effectiveness sets it apart from competitors.

Design and User Experience

The design elements of this model enhance user experience significantly. Its ergonomic build ensures comfort during extended use, a feature that is sometimes lacking in other models. Furthermore, the intuitive controls simplify operation, allowing both seasoned professionals and novices to adapt quickly. Overall, the combination of design and functionality makes this machine a popular choice among users.

Assembly Process for Stihl RB 200

The assembly procedure for this outdoor equipment involves a systematic approach to ensure optimal functionality and performance. Proper handling and organization of components are essential for a seamless build process.

Necessary Components

- Chassis

- Engine

- Fuel Tank

- Air Filter

- Handlebars

- Wheels

Step-by-Step Assembly

- Begin by securing the chassis on a stable surface.

- Install the engine onto the chassis, ensuring proper alignment with mounting points.

- Attach the fuel tank, making sure all connections are tight and leak-free.

- Fit the air filter into its designated compartment to maintain optimal airflow.

- Attach the handlebars, verifying that they are firmly secured for safe operation.

- Finally, install the wheels, ensuring they rotate freely and are properly aligned.

Once the assembly is complete, perform a thorough inspection to ensure all components are securely fastened and functioning correctly. Regular maintenance will prolong the lifespan of the equipment.

Tips for Troubleshooting Issues

When encountering problems with your equipment, it’s essential to follow a systematic approach to identify and resolve the issues effectively. By understanding the potential causes and applying practical solutions, you can enhance the performance and longevity of your device.

Common Symptoms and Their Solutions

Recognizing the symptoms of malfunction can guide you toward the appropriate remedies. For instance, if the machine fails to start, check the fuel supply, spark plug, and battery condition. Ensuring that these components are functioning correctly can often resolve the issue without requiring extensive repairs.

Maintenance Practices

Regular upkeep is crucial for preventing operational failures. Cleaning the air filter, inspecting the blades, and ensuring that moving parts are well-lubricated can significantly reduce the likelihood of breakdowns. Additionally, consulting the user manual for specific maintenance schedules can help keep your device in optimal condition.

Benefits of Using Genuine Parts

Utilizing authentic components for your machinery ensures optimal performance and longevity. Genuine items are designed specifically for your equipment, providing superior compatibility and reliability compared to generic alternatives. By choosing original parts, you can maintain the integrity of your tools while minimizing the risk of malfunctions and expensive repairs.

Enhanced Performance

Original components are engineered to meet the precise specifications required by your equipment. This attention to detail results in improved efficiency and effectiveness, allowing your machine to operate at its best. Authentic items also ensure that all systems function harmoniously, leading to a smoother overall experience.

Increased Durability

Investing in genuine items translates to a longer lifespan for your machinery. These components undergo rigorous testing and quality control, ensuring they can withstand the demands of regular use. By choosing authentic parts, you protect your investment and reduce the likelihood of premature wear and tear.

Upgrades and Accessories for RB 200

Enhancing the functionality and performance of your equipment can significantly improve its efficiency and longevity. There are various upgrades and accessories available that can elevate the experience and outcomes of your outdoor tasks. This section highlights several options that can optimize your tool’s capabilities.

- Performance Enhancements:

- High-efficiency air filters for improved airflow and engine performance.

- Upgraded fuel systems to ensure smoother operation and better fuel economy.

- Comfort and Usability:

- Ergonomic grips and padded handles to reduce fatigue during extended use.

- Adjustable harnesses for better weight distribution and comfort.

- Storage Solutions:

- Accessory bags for organized storage of tools and equipment.

- Universal toolboxes designed to protect and carry essential items.

- Maintenance Kits:

- Comprehensive maintenance kits that include lubricants, cleaning agents, and replacement components.

- Regular maintenance tools to keep your equipment in top shape.

Investing in these upgrades and accessories not only enhances performance but also contributes to the overall user experience, making outdoor tasks more efficient and enjoyable.