Understanding the Stihl RB 600 Parts Diagram for Optimal Maintenance

When it comes to maintaining your outdoor machinery, grasping the intricacies of its structure is essential. Each segment plays a vital role in ensuring optimal performance, and knowing how they interconnect can greatly enhance your maintenance efforts.

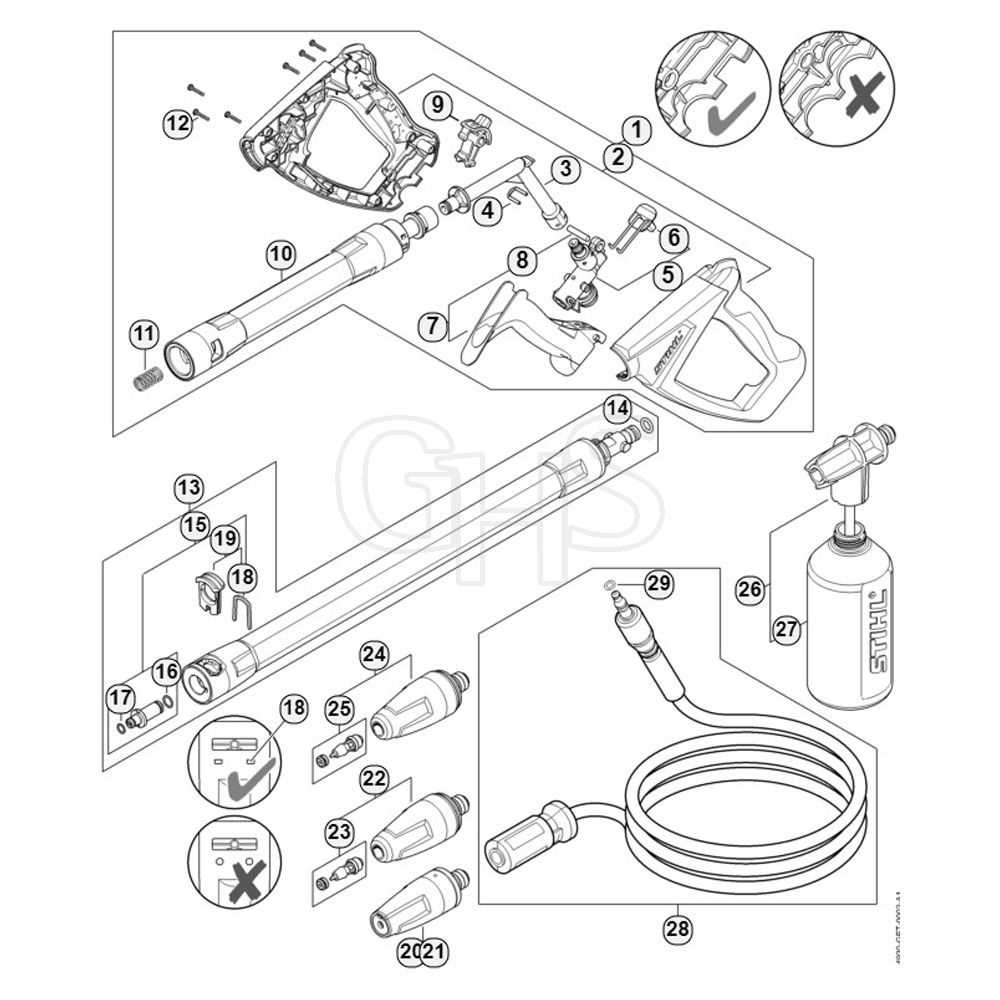

Visual aids can significantly simplify the process of understanding these elements. By examining a comprehensive layout, you can easily identify the various sections and their functionalities, enabling you to tackle repairs with confidence.

Moreover, being familiar with the specifics of each part not only aids in troubleshooting but also empowers you to make informed decisions when seeking replacements. Delving into the details of these components will ultimately lead to a more efficient and productive experience.

Understanding Stihl RB 600 Components

The efficient operation of any outdoor power equipment relies heavily on its individual elements. A comprehensive grasp of these components not only enhances functionality but also simplifies maintenance and repair tasks. Familiarity with each part allows users to maximize the machine’s performance and longevity.

In this context, the essential elements include the engine, fuel system, and cutting mechanisms, each playing a crucial role in the overall effectiveness of the tool. The engine serves as the powerhouse, converting fuel into the energy needed for operation. The fuel system ensures a consistent supply, allowing for smooth performance under various conditions.

Moreover, the cutting mechanisms are designed to provide precision and efficiency. Understanding how these components interact can lead to more informed decisions regarding upkeep and upgrades. Regular inspections and knowledge of each element’s function contribute significantly to the longevity and reliability of the equipment.

In summary, a well-rounded understanding of the individual components enables users to maintain their equipment effectively, ensuring it remains in optimal working condition for years to come.

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for efficient maintenance and repair. Visual representations play a crucial role in simplifying complex assemblies, allowing users to grasp how individual components interact within a system. These illustrations serve as valuable guides, ensuring that technicians can accurately identify and replace necessary elements.

Clarity is a primary benefit of such visuals. They provide a straightforward reference that minimizes confusion, particularly for those unfamiliar with the equipment. Additionally, these schematics enhance efficiency by streamlining the troubleshooting process, enabling users to quickly pinpoint issues and implement solutions.

Moreover, accurate depictions foster a deeper understanding of the machine’s structure, empowering users to delve into advanced maintenance practices. This knowledge ultimately contributes to improved performance and longevity of the equipment, making visual aids indispensable in any repair toolkit.

Key Features of Stihl RB 600

This robust piece of equipment is designed for efficiency and reliability, making it an essential tool for professionals and enthusiasts alike. Its powerful engine ensures optimal performance, enabling users to tackle demanding tasks with ease.

The lightweight design enhances maneuverability, allowing for comfortable use over extended periods. Additionally, the ergonomic handle contributes to user comfort, reducing fatigue during operation.

Durability is a standout feature, with high-quality materials ensuring longevity even under harsh conditions. The adjustable settings allow for customization based on specific needs, further enhancing its versatility.

Overall, this machine combines strength and functionality, making it a valuable asset in any outdoor maintenance toolkit.

Common Replacement Parts Overview

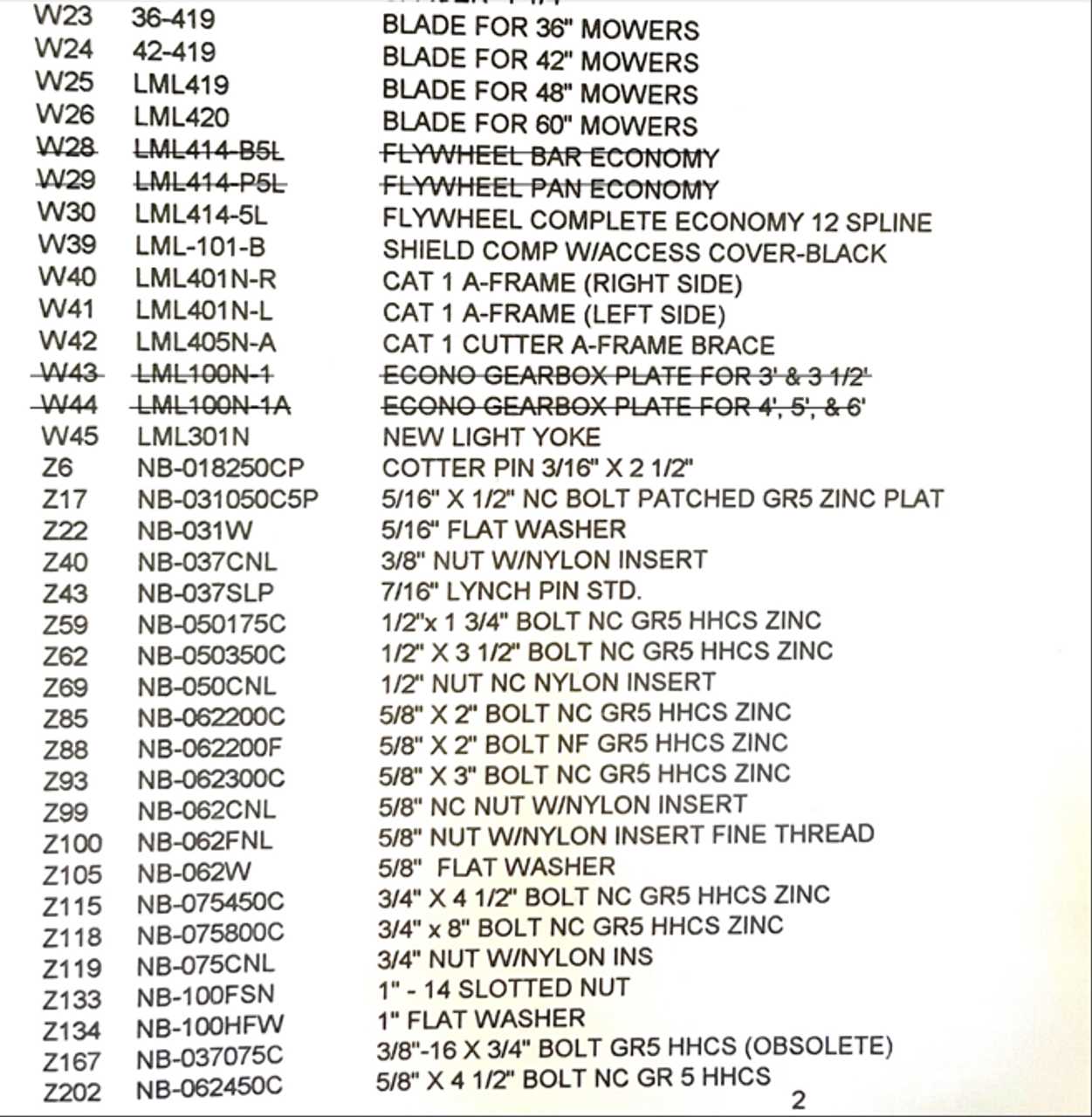

Maintaining outdoor power equipment requires a keen understanding of the components that may need regular updating. This section provides insights into frequently substituted elements that ensure optimal performance and longevity of your machinery.

Filters: These are essential for keeping the engine running smoothly. Regularly replacing air and fuel filters can significantly enhance efficiency and prevent potential damage.

Blades: Worn or damaged blades can affect cutting performance. It’s crucial to inspect and replace them periodically for effective operation.

Fuel Lines: Over time, fuel lines can degrade, leading to leaks or blockages. Replacing them ensures proper fuel flow and minimizes risks.

Spark Plugs: A vital component for ignition, spark plugs should be replaced as part of routine maintenance to ensure reliable starting and optimal engine performance.

Batteries: In battery-operated models, a failing battery can compromise functionality. Regular checks and timely replacements are key to uninterrupted use.

By focusing on these critical elements, users can delve deeper into maintenance practices, ultimately enhancing the efficiency and lifespan of their equipment.

How to Read Parts Diagrams

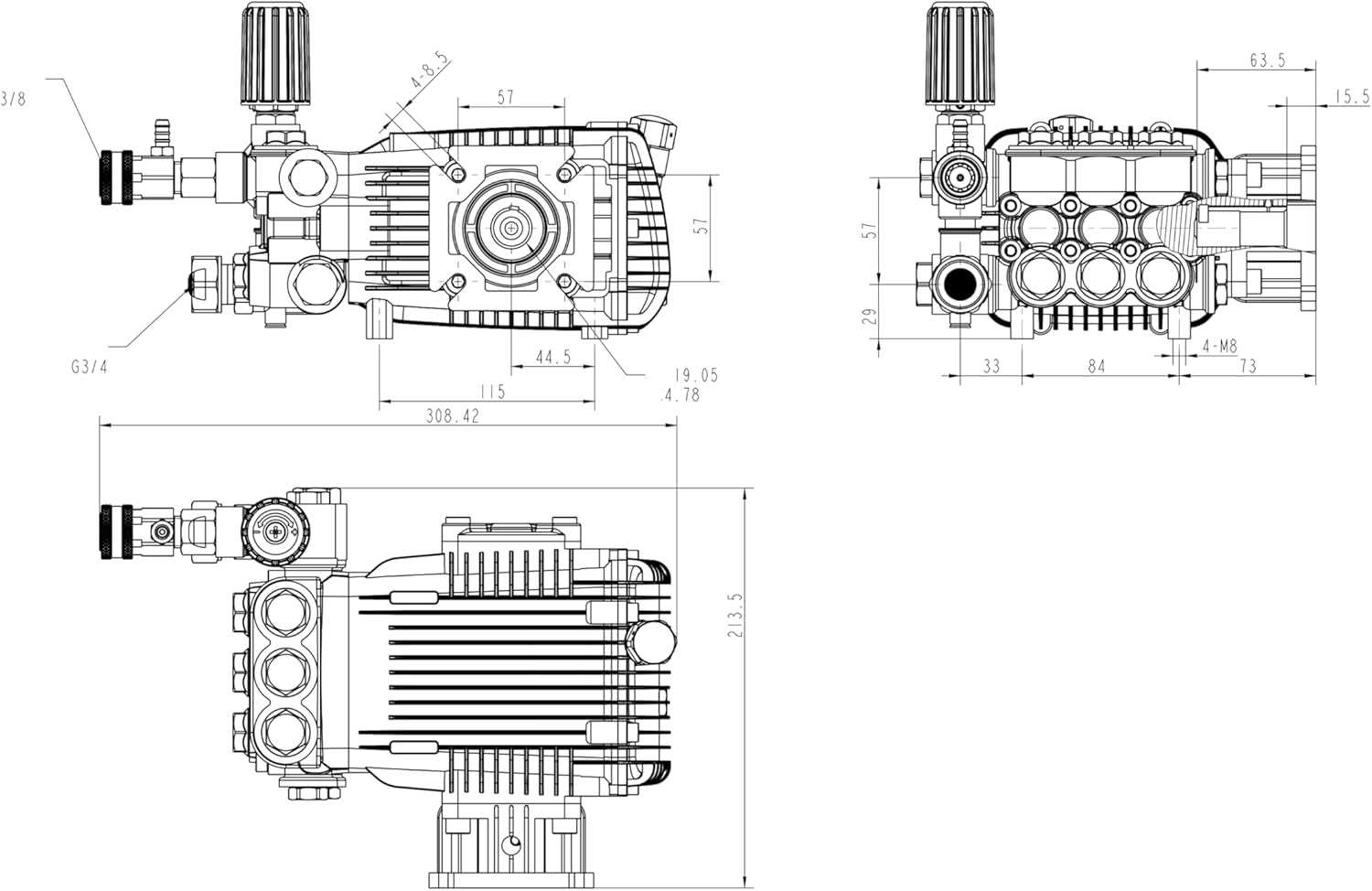

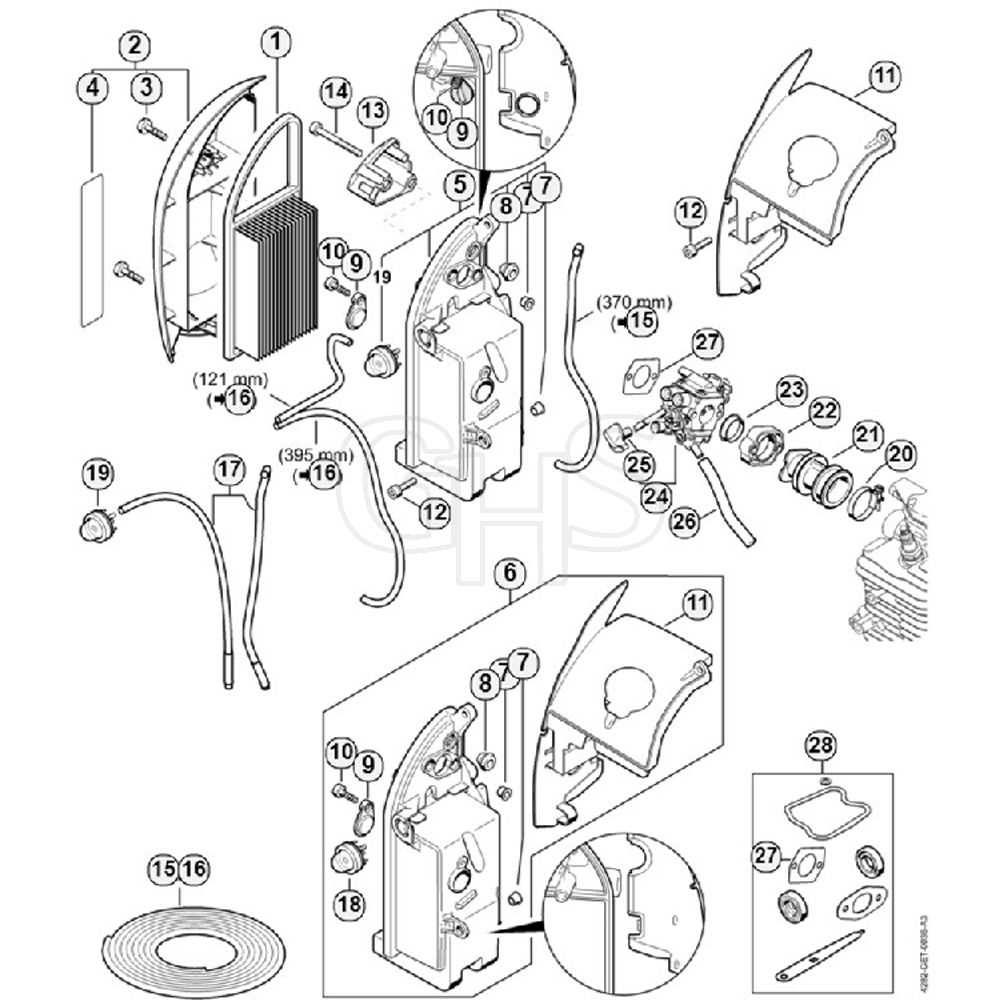

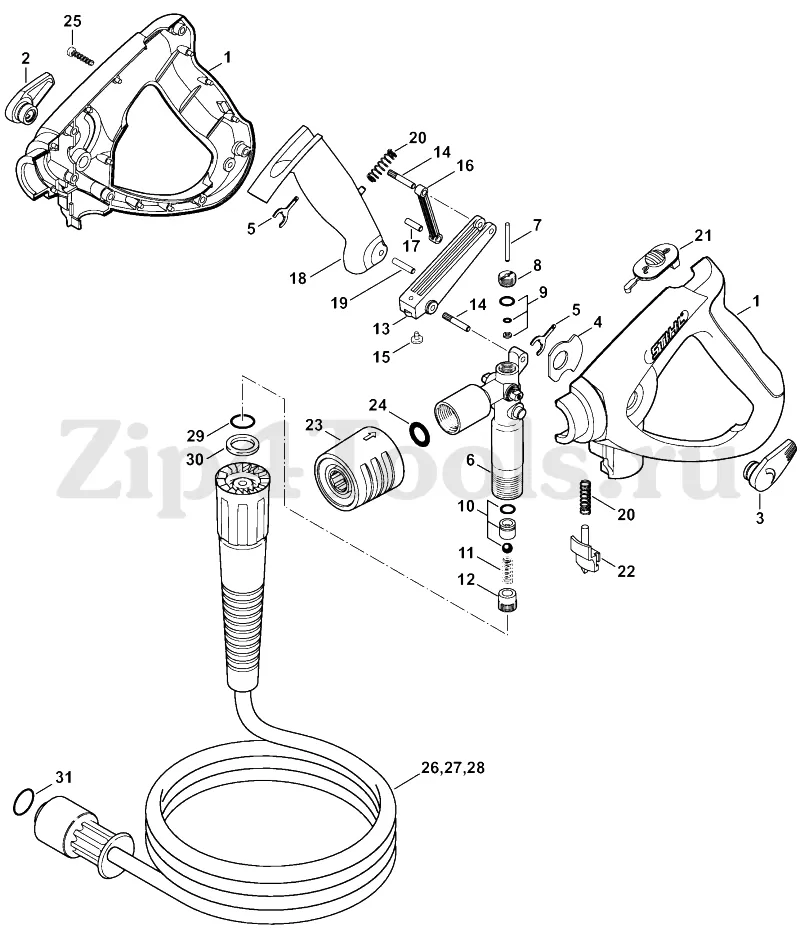

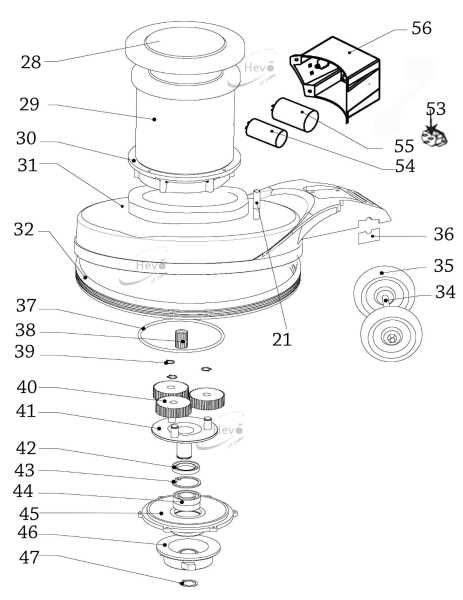

Understanding schematics is essential for anyone involved in maintenance or repair. These visual representations help identify components and their relationships within a system. By mastering the art of interpretation, you can efficiently locate issues and streamline the replacement process.

Begin by familiarizing yourself with the layout, which typically includes labeled sections. Pay attention to the numbers or letters corresponding to each element, as these often indicate their specific identifiers. This key is crucial for ensuring you select the correct items during assembly or disassembly.

Next, observe how parts connect and interact with each other. Arrows or lines usually depict relationships, indicating how components fit together. Recognizing these links can aid in diagnosing problems and understanding functionality.

Lastly, consult the accompanying documentation for detailed descriptions of each item. This information enhances your grasp of the schematic and provides insights into the installation or removal process, ensuring you achieve the ultimate effectiveness in your repairs.

Identifying Wear and Tear

Understanding the signs of degradation in equipment is crucial for maintaining optimal performance and longevity. Regular inspections help to pinpoint areas that may require attention, ensuring that functionality is not compromised. By recognizing these indicators, users can take proactive measures to address issues before they escalate.

Common indicators include unusual noises, decreased efficiency, and visible damage to components. Pay close attention to parts that experience frequent friction or stress, as they are more prone to wear.

To delve deeper, check for cracks, rust, or discoloration, which often signal potential failure points. Additionally, ensure that all moving parts operate smoothly; any stiffness may indicate that lubrication is needed or that parts are beginning to seize.

Addressing these concerns promptly can lead to the ultimate prevention of more extensive repairs and ensure consistent operation.

Maintenance Tips for RB 600

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a few key practices, you can enhance efficiency and prevent potential issues down the line.

Routine Inspections

- Check all moving parts for wear and tear.

- Inspect filters and replace them as needed.

- Look for any signs of leaks or corrosion.

Cleaning Procedures

- Clean the air intake regularly to maintain airflow.

- Remove debris from external surfaces to prevent overheating.

- Use a soft brush to clear dust from internal components.

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for maintaining optimal performance and longevity. Whether you are a professional user or a DIY enthusiast, ensuring that you use original replacements can make a significant difference in functionality and reliability.

Authorized Dealers

The most reliable source for authentic components is through authorized dealers. These retailers are recognized by the manufacturer and provide a full range of original items. They often have knowledgeable staff who can assist with specific inquiries and help you find exactly what you need.

Online Resources

In addition to local retailers, many online platforms specialize in selling genuine components. These websites usually offer detailed descriptions and compatibility information, making it easier to find what you require. When purchasing online, always verify that the seller is reputable and offers a return policy for added security.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Reliable quality, expert advice | Possible higher prices |

| Online Retailers | Convenience, often wider selection | Check seller credibility |

Installation Guide for Stihl Parts

This section provides a comprehensive overview of the installation process for various components of outdoor equipment, ensuring optimal functionality and longevity. Understanding the correct procedure is essential for achieving the best performance from your tools.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. Ensure you have a clean workspace and refer to the manufacturer’s recommendations for any specific requirements.

Installation Procedure

| Step | Description |

|---|---|

| 1 | Disconnect the power source to avoid any accidents. |

| 2 | Remove the old component carefully, taking note of any attached parts. |

| 3 | Install the new component, ensuring it is aligned properly. |

| 4 | Reconnect any necessary parts and test the functionality. |

Frequently Asked Questions on RB 600

This section aims to address common inquiries regarding the equipment’s functionality, maintenance, and troubleshooting. Understanding these aspects can enhance user experience and efficiency.

What should I do if the machine won’t start?

If the equipment fails to ignite, check the fuel level, ensure the ignition switch is on, and inspect the spark plug for damage. Clean or replace any faulty components to restore functionality.

How often should I perform maintenance?

Regular upkeep is essential for optimal performance. It’s recommended to conduct a thorough inspection and servicing every 25 operating hours, including cleaning filters and checking belts. Regular maintenance extends the life of your equipment and improves its overall efficiency.