Stihl RB 800 Parts Diagram Overview

The functionality and efficiency of any outdoor tool depend significantly on its individual components. Understanding how these parts interact can greatly enhance maintenance practices and troubleshooting efforts. In this section, we will delve into the essential elements that make up a specific model, highlighting their roles and connections within the machine.

Visual aids can be invaluable for users aiming to comprehend the structure and arrangement of components. By studying a visual representation, one can identify various sections and their corresponding functions. This knowledge facilitates effective repairs and optimizes performance during operation.

Additionally, familiarizing oneself with the assembly and layout of these components not only aids in addressing issues but also empowers users to perform routine maintenance. A well-informed approach can lead to prolonged equipment life and improved efficiency in tasks, ensuring that users can achieve optimal results with their machinery.

This section will explore the essential elements that make up the machinery, focusing on their functions and interconnections. By understanding these components, users can gain insights into the equipment’s operation and maintenance, ensuring optimal performance and longevity.

- Overview of Main Components

Identify and describe the crucial parts that play a significant role in the machine’s functionality. Highlight their importance in the overall structure and performance.

- Functionality of Each Element

Examine how each part contributes to the operation of the equipment. Discuss the interactions between different components and their collective impact on efficiency.

- Common Issues and Solutions

Address frequent problems related to the various components and provide practical solutions. This section will aid users in troubleshooting and maintenance.

- Maintenance Tips for Longevity

Offer guidance on caring for the essential parts to prolong their lifespan. Include best practices for cleaning, inspecting, and replacing worn elements.

Essential Parts Overview

This section provides a comprehensive understanding of the key components that make up a specific type of equipment. Each element plays a vital role in the overall functionality, ensuring smooth operation and efficiency. By familiarizing yourself with these critical parts, you can enhance your maintenance practices and troubleshoot any potential issues effectively.

The assembly comprises various integral sections, including the engine, transmission, and fuel systems, which collectively contribute to the performance of the machine. Understanding the function of each component is crucial for effective management and upkeep. This knowledge empowers users to identify worn-out or malfunctioning parts, ensuring optimal performance and longevity of the equipment.

Additionally, it is essential to consider the various accessories that may complement the primary units. These add-ons can significantly improve usability and adaptability, making the equipment more versatile in various applications. Regular inspection and familiarity with these components will promote better care and maintenance, ultimately leading to enhanced productivity and reliability.

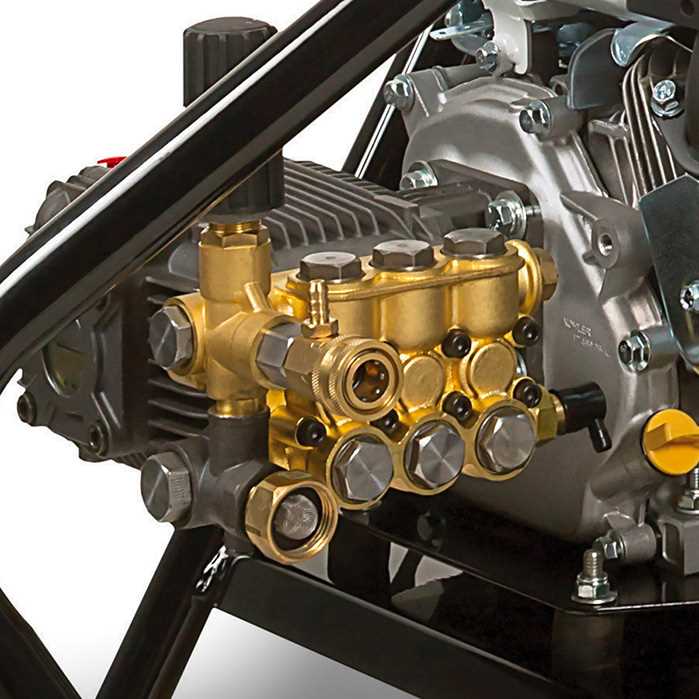

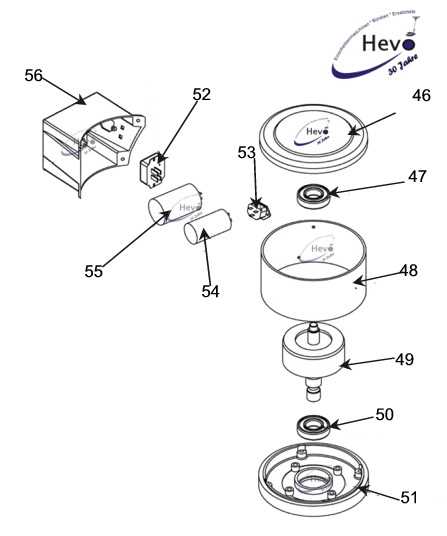

Diagrammatic Representation of Parts

This section offers a visual breakdown of various components within a specific machinery model. A well-structured illustration aids in understanding the arrangement and functionality of individual elements, making it easier for users to familiarize themselves with the equipment.

Importance of Visual Guides

Visual representations serve as essential tools for both maintenance and assembly tasks. By depicting each element clearly, users can easily identify where parts fit into the overall structure, facilitating efficient repairs and replacements.

Exploring Component Relationships

Understanding how different parts interact within the machinery is crucial. A comprehensive visual layout reveals the connections between components, highlighting their roles and the impact of each element on overall performance. This clarity enhances the user experience and promotes effective troubleshooting.

Functionality of Each Component

Understanding the roles of various elements within a machine is crucial for optimal operation and maintenance. Each part contributes uniquely to the overall efficiency, ensuring that the device performs its intended tasks effectively. This section delves into the specific functions of individual components, highlighting their importance in the broader context of the machinery.

Key Elements and Their Roles

Engines serve as the powerhouse, converting fuel into mechanical energy. This transformation allows the machine to undertake various operations with ease.

Supporting Structures

Chassis provides stability and support, ensuring that all components are securely mounted. Its design affects the overall balance and maneuverability of the equipment.

Understanding each component’s functionality not only aids in troubleshooting but also enhances the user’s ability to perform maintenance effectively.

Maintenance Tips for Durability

Ensuring the longevity of your equipment involves regular upkeep and attention to detail. Proper maintenance not only enhances performance but also minimizes the risk of breakdowns, ultimately saving you time and resources. By following a systematic approach to care, you can significantly extend the life of your machinery.

Here are some essential tips to consider:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Clean Air Filter | Every 25 hours | Remove and clean the air filter to prevent dirt buildup and ensure optimal airflow. |

| Inspect Blades | After each use | Check blades for wear and damage; sharpen or replace as necessary for efficient operation. |

| Check Fuel System | Monthly | Examine fuel lines and connections for leaks or wear to ensure safe operation. |

| Lubricate Moving Parts | Every 50 hours | Apply lubricant to all moving components to reduce friction and wear. |

| Inspect Tires | Monthly | Check tire pressure and tread condition to maintain stability and performance. |

By adhering to these maintenance guidelines, you can help ensure that your equipment remains in optimal condition, thus enhancing its durability and reliability in the long run.

Common Issues with Parts

When working with equipment, various components can experience wear and tear, leading to operational challenges. Identifying these issues early can enhance performance and prolong the lifespan of the machine. Below are some frequent problems associated with these essential components.

| Issue | Description | Possible Solutions |

|---|---|---|

| Wear | Components may wear down over time, affecting efficiency. | Regular inspections and timely replacements are recommended. |

| Loose Connections | Connections can become loose, leading to malfunctions. | Tighten all connections and check for secure fittings. |

| Corrosion | Rust and corrosion can develop, particularly in damp conditions. | Use protective coatings and store in a dry environment. |

| Blockages | Debris can accumulate, obstructing flow and operation. | Regular cleaning and maintenance to remove blockages are essential. |

Replacement Guidelines for Components

When it comes to ensuring the optimal performance of your machinery, understanding the procedures for replacing various elements is crucial. Proper maintenance and timely replacements can significantly extend the lifespan of your equipment and enhance its efficiency. This section outlines essential considerations and recommendations for effectively replacing key components.

Identifying Components Needing Replacement

Recognizing the signs of wear and tear is the first step in the replacement process. Regular inspections should be conducted to detect any discrepancies in functionality. Look for unusual noises, reduced efficiency, or physical damage to components. Keeping a maintenance log can also aid in tracking performance trends and identifying when a replacement is necessary.

Choosing Quality Replacements

Opting for high-quality replacements is vital for maintaining performance standards. When selecting new components, consider factors such as compatibility, durability, and warranty. It is advisable to source replacements from reputable suppliers to ensure you are getting genuine products that meet industry standards. Proper installation following manufacturer guidelines will also help in achieving optimal results.

Tools Needed for Assembly

When assembling equipment, having the right tools is crucial for ensuring a smooth and efficient process. Proper tools not only facilitate the assembly but also contribute to the overall quality and durability of the final product. Below is a list of essential instruments required for effective assembly.

- Screwdrivers: Various types including flathead and Phillips for securing components.

- Wrenches: Adjustable and fixed-size wrenches for tightening bolts and nuts.

- Pliers: Needle-nose and standard pliers to grip and bend materials as needed.

- Torque Wrench: Ensures bolts are tightened to the specified torque for safety and reliability.

- Hammer: A rubber or dead blow hammer to avoid damaging parts while fitting them together.

- Utility Knife: For cutting materials or removing packaging safely.

- Measuring Tape: To measure dimensions and ensure proper alignment of components.

- Hex Keys: Also known as Allen wrenches, necessary for assembling certain fasteners.

Having these tools at hand will greatly enhance the assembly experience and lead to a successful outcome. Proper preparation is key to avoiding delays and ensuring that every component is securely fitted.

Where to Find Original Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Original components are specifically designed to fit seamlessly and function effectively within your machine, thereby minimizing the risk of malfunctions or damage. Understanding where to locate these genuine items can significantly enhance your maintenance efforts.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealers. These distributors are certified to sell genuine items, ensuring that you receive high-quality products that meet the manufacturer’s specifications. Visiting an authorized retailer can provide you with expert advice and access to a wide range of components suitable for your specific model.

Online Marketplaces

Another option is to explore reputable online marketplaces that specialize in original components. These platforms often feature a diverse selection and can provide detailed information about each item, including compatibility and specifications. Ensure to check seller ratings and reviews to confirm that you are purchasing from a trustworthy source.

Identifying Compatible Accessories

When it comes to enhancing the functionality of your equipment, selecting suitable attachments and add-ons is essential. Knowing how to identify accessories that fit seamlessly with your machinery can improve performance and efficiency. Understanding compatibility will ensure that you make informed choices, maximizing the value of your investment.

Firstly, it’s crucial to consult the manufacturer’s recommendations to find compatible options. These guidelines typically provide details on specifications and features that match your equipment. Additionally, reviews and feedback from other users can offer insights into what works best in practice.

Moreover, taking note of the model’s specifications and dimensions will help in selecting accessories. Many manufacturers provide detailed descriptions that outline compatibility with various models, ensuring you choose items designed to perform effectively together. Always cross-reference these details to avoid mismatches that could hinder performance.

Lastly, exploring aftermarket options can be beneficial. Many third-party manufacturers create compatible accessories that can enhance your equipment’s capabilities. However, it’s important to verify that these alternatives meet safety and quality standards to avoid potential issues during use.

Customer Reviews on Part Performance

Feedback from users regarding the functionality and durability of components plays a crucial role in understanding their overall effectiveness. Insights gathered from various experiences help potential buyers make informed decisions and ensure they select the most suitable replacements for their equipment.

Positive Experiences

Many individuals have expressed satisfaction with the reliability of the replacement components. Users often highlight the longevity and robust construction, noting that these elements consistently perform well under demanding conditions. High-quality materials contribute significantly to the favorable reviews, allowing for prolonged use without frequent replacements.

Areas for Improvement

While numerous reviews are positive, some users have pointed out specific areas that could benefit from enhancement. For instance, a few customers have experienced challenges with the installation process, suggesting that clearer instructions would be beneficial. Additionally, feedback regarding compatibility with older models indicates a need for improved design to ensure seamless integration.

Safety Precautions During Repairs

When conducting maintenance or repairs on machinery, it is essential to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines can help ensure a secure working environment while handling tools and components.

1. Wear Protective Gear: Always equip yourself with appropriate safety attire, including gloves, goggles, and sturdy footwear. This protective equipment shields against potential hazards such as sharp objects and harmful substances.

2. Ensure a Clean Workspace: A tidy workspace reduces the risk of tripping or misplacing tools. Make sure your area is free from clutter, and keep essential items organized for easy access.

3. Disconnect Power Sources: Before starting any repair work, ensure that the machinery is completely powered off and unplugged. This step minimizes the risk of accidental starts that could lead to injuries.

4. Use the Right Tools: Utilize the appropriate tools for each task to avoid damaging components or causing harm. Improper tools can lead to inefficient repairs and increase the likelihood of accidents.

5. Follow Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for maintenance and repair procedures. Adhering to these instructions ensures that you perform tasks safely and effectively.

6. Seek Assistance if Necessary: If you encounter difficulties or uncertainties during repairs, do not hesitate to seek help from a qualified technician. It is better to ask for assistance than to risk injury by attempting to proceed alone.