Comprehensive Guide to Stihl Spare Parts Diagrams

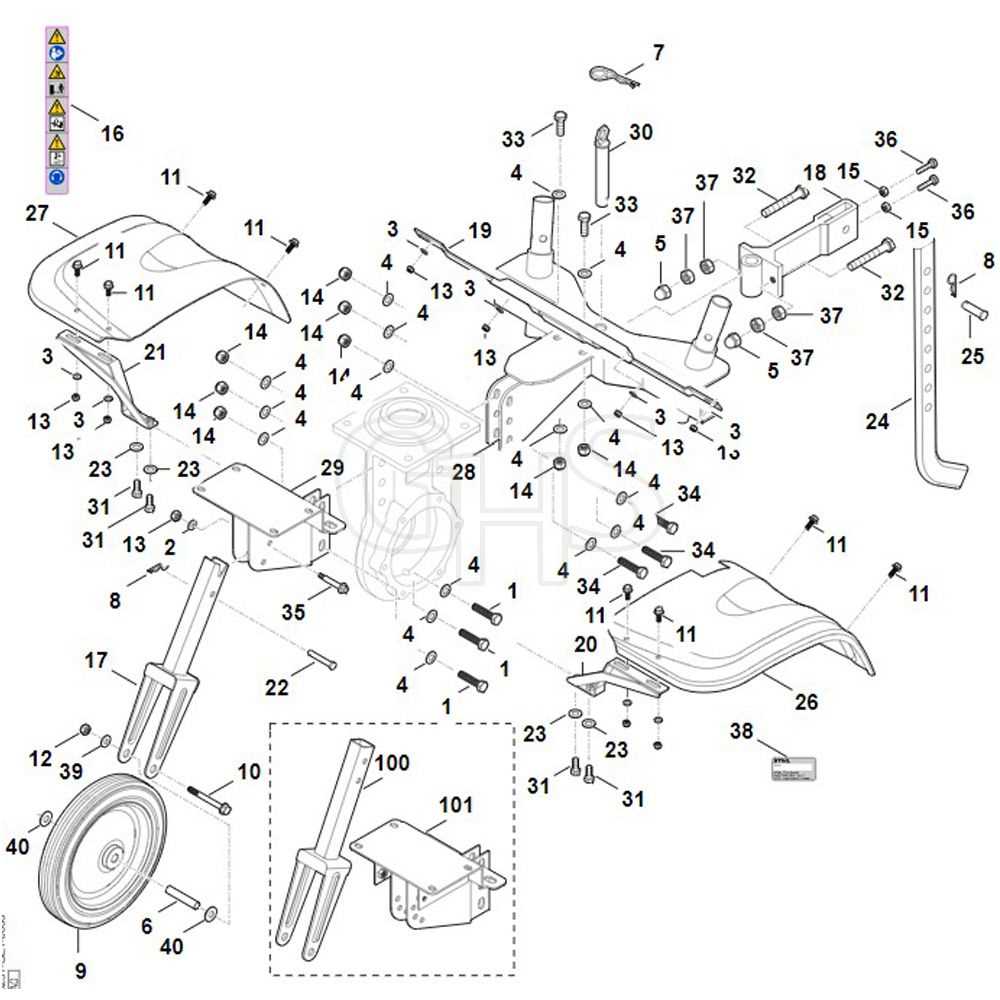

When it comes to maintaining machinery, having a clear understanding of its internal structure is crucial. Detailed breakdowns of each element involved can simplify repairs, ensuring that each component is properly addressed during routine maintenance or troubleshooting. These illustrations provide essential guidance, helping users navigate the complex framework of various systems.

For anyone tasked with restoring a machine to peak condition, visual layouts offer a roadmap. They allow for the accurate identification of various elements, making it easier to pinpoint potential issues or worn-out areas. By referring to these structured guides, even intricate systems become more manageable to disassemble and reassemble with confidence.

Detailed visual resources not only assist in repairs but also in planning for future upkeep. They empower users to preemptively address problems by clearly illustrating how each component functions within the larger system. This foresight ensures the longevity of equipment and smooth operation over time.

Comprehensive Guide to Stihl Components

Understanding the various elements that make up mechanical systems is crucial for anyone involved in maintenance, repair, or assembly. This guide provides a clear overview of the essential units and how they function together, offering insights that can help improve performance and extend the longevity of your equipment.

Key Structural Elements

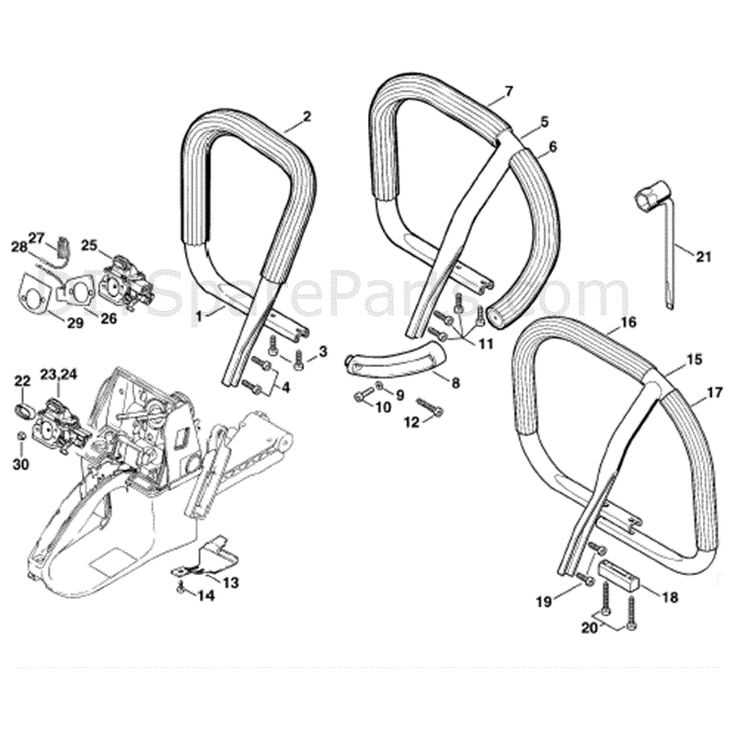

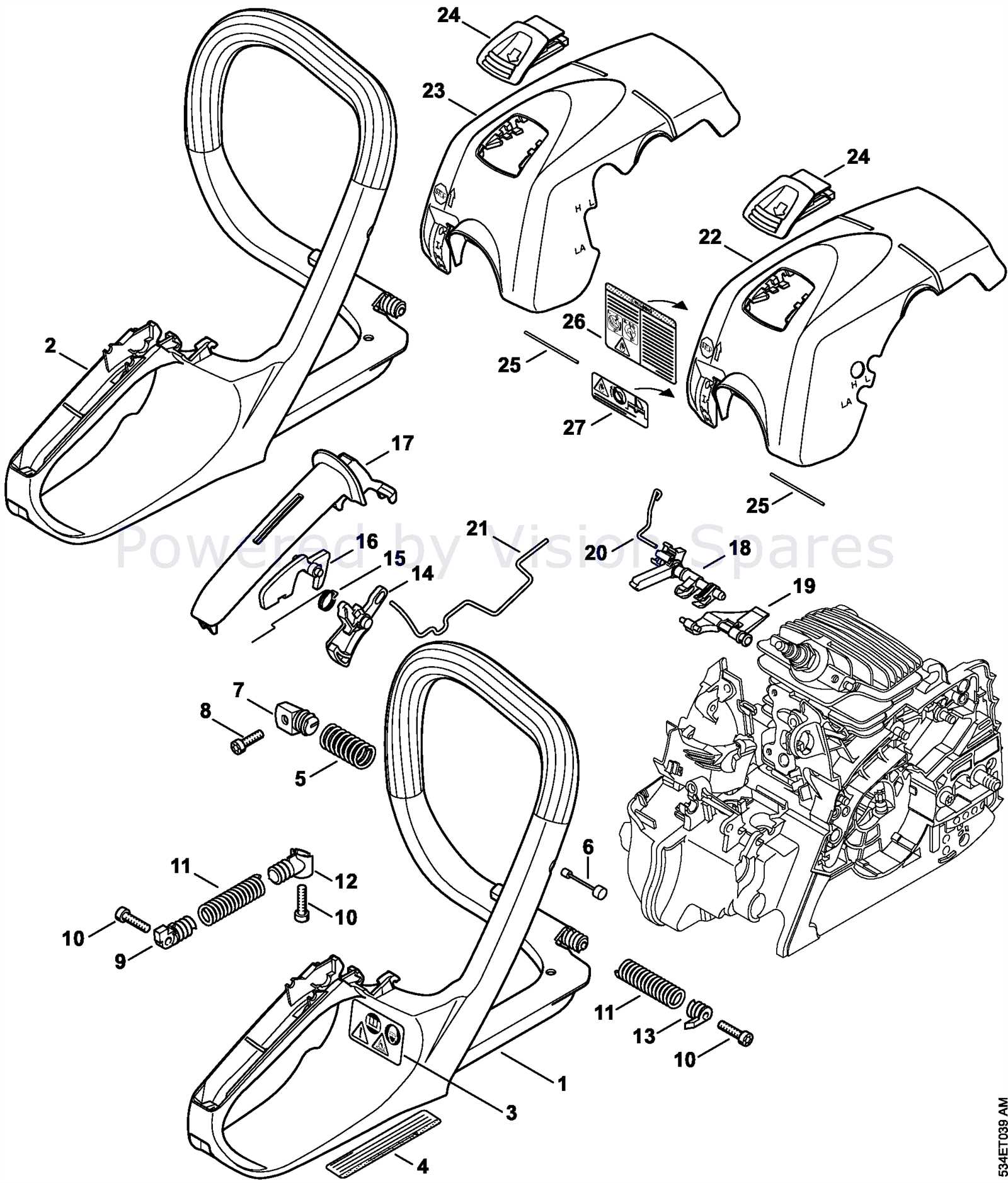

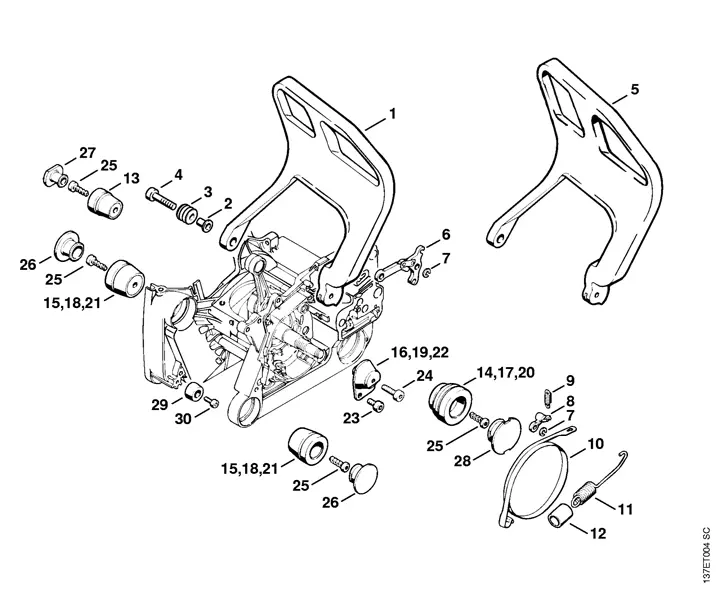

At the heart of any mechanical device lies a set of interconnected structures. These elements include frameworks that support operations, moving units that create motion, and connectors that ensure stability. Each component plays a role in maintaining balance and ensuring smooth operation, all working together to achieve efficiency.

Operational Components

The operational side is driven by a series of functional units that engage directly with power and movement. These include energy converters, regulators for controlling flow, and systems that manage friction and wear. Together, they form the backbone of the machine’s functionality, delivering reliability even under demanding conditions.

Identifying Key Parts in Stihl Equipment

Understanding the core elements within outdoor power tools is essential for maintaining peak performance and ensuring longevity. By recognizing the most vital components, users can enhance their knowledge, making repairs and maintenance more efficient.

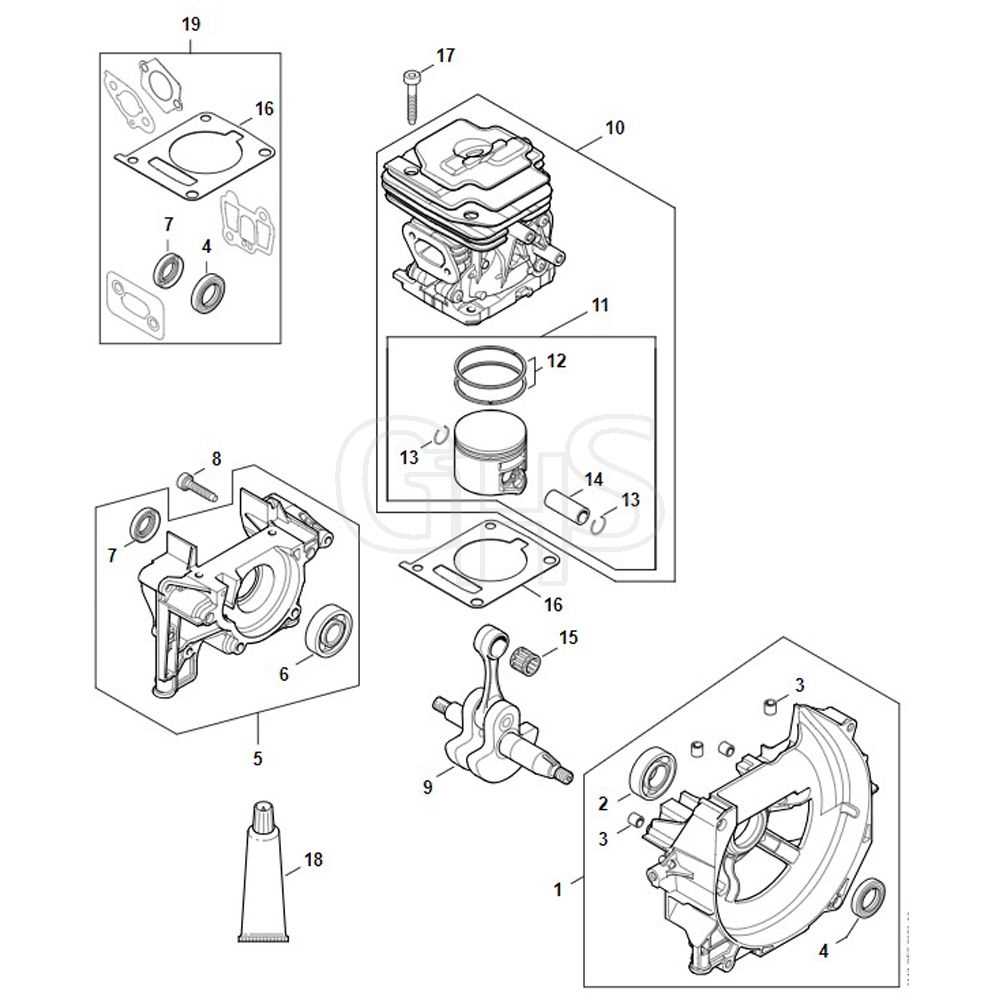

- Engine Components: The heart of any equipment, these elements drive the machine’s power and efficiency. Proper care and timely inspection are crucial for optimal performance.

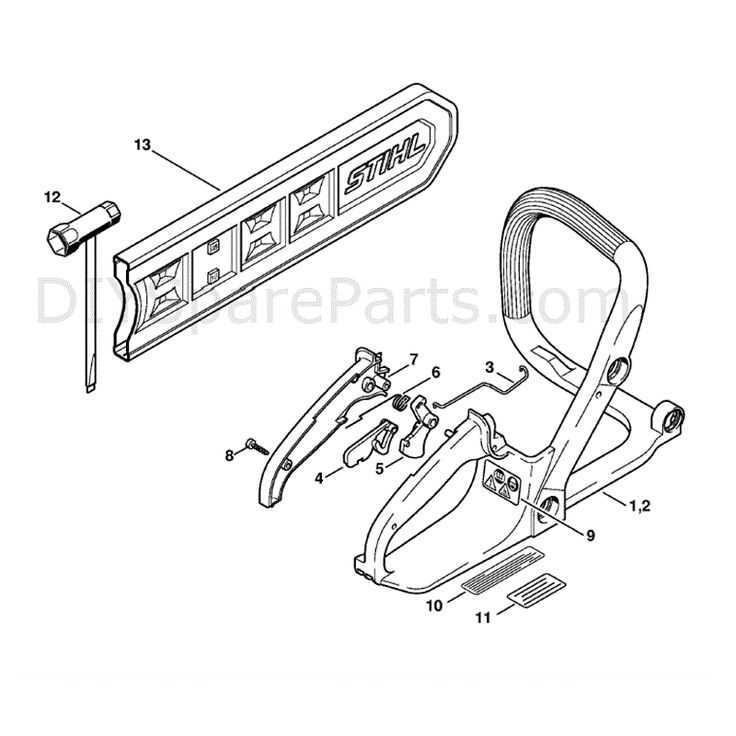

- Cutting Mechanisms: The section responsible for precise operations, it includes chains, blades, or other sharp edges depending on the tool. Regular maintenance helps ensure safety and precision.

- Fuel and Air Systems: These mechanisms work together to regulate the engine’s power output. Clean filters and unblocked channels are key to smooth functionality.

- Drive and Transmission: The parts responsible for transferring power from the engine to the working components. Any disruptions here can significantly affect performance.

- Handle and Controls: Ergonomics and safety are paramount. Properly functioning grips and switches ensure user control and reduce fatigue.

By recognizing these key areas, users can more effectively maintain their equipment and ensure it runs smoothly for years to come.

Maintenance Tips for Chainsaws

Proper care is essential to keep your chainsaw in top condition. Regular attention to key components will ensure reliable performance and extend its lifespan. By following a few simple steps, you can maintain its functionality and avoid costly repairs.

Cleaning and Lubrication

Keeping your equipment clean is one of the most critical aspects of maintenance. Make sure to remove any debris after use, especially around the cutting mechanism. Lubricating the moving parts ensures smooth operation and prevents excessive wear. It’s recommended to use the appropriate oils and lubricants as specified in the manual.

Sharpening the Blade

A dull blade can reduce efficiency and increase strain on the machine. Regular sharpening helps maintain cutting precision and minimizes the risk of accidents. Use a sharpening tool suited to the blade’s specific design to ensure even sharpening across all teeth. Always follow the proper techniques for best results.

Note: Regular inspections and timely adjustments will enhance overall performance, ensuring your chainsaw continues to operate smoothly for years to come.

How to Choose the Right Components

Selecting the correct elements for your equipment ensures smooth performance and longevity. Identifying what you need involves understanding the unique characteristics of each part and how it functions within the overall system. Careful consideration of compatibility is key to avoiding mismatches that could hinder efficiency.

Understand Your Equipment’s Needs

Before making a decision, it’s essential to analyze your machine’s specific requirements. Knowing which elements need replacement and their purpose will help narrow down your options. Take note of the model and any relevant technical information that can guide your choice.

Focus on Quality and Durability

Opting for high-quality materials ensures that the selected components will not only fit properly but also withstand demanding conditions. Prioritize durability and performance over cost to avoid frequent replacements, which may lead to higher expenses over time.

Understanding the Assembly of Stihl Machines

The process of putting together complex outdoor equipment involves a deep understanding of how each component works in harmony. Each element has a specific role in ensuring smooth operation, and recognizing how these elements interact is essential for proper maintenance and longevity. This section will explore the key principles behind the construction, offering insights into the structure and organization of such machinery.

Key Elements of Construction

Each machine is composed of several key components that work together to ensure efficiency. From mechanical systems that drive the operation to smaller mechanisms that provide stability, every part is crucial. Understanding how these components are connected helps in the assembly process and makes maintenance more straightforward.

Ensuring Proper Fit and Alignment

A crucial aspect of the assembly is ensuring that each part is correctly aligned with its neighboring components. This not only enhances the equipment’s overall performance but also minimizes wear and tear. Ensuring precise alignment and secure fitting during the build phase contributes to longer operational life and reduced need for repairs.

Commonly Replaced Parts for Stihl Tools

In the world of outdoor equipment, regular maintenance is essential for ensuring optimal performance. Over time, certain components are more likely to wear out and require attention. Understanding which elements frequently need replacing can help users keep their tools in prime condition.

Here are some components that are commonly swapped out in outdoor machinery:

- Filters: Air and fuel filters play a crucial role in maintaining the efficiency of your equipment. Regular replacement helps prevent engine damage.

- Blades: Cutting tools often experience wear, making blade replacement essential for achieving clean cuts.

- Chains: For devices such as chainsaws, chain replacement is a routine task to ensure safe and effective operation.

- Spark plugs: These components are vital for engine ignition and may need replacement to maintain reliable starting.

- Fuel lines: Over time, fuel lines can become brittle or clogged, requiring replacement to ensure proper fuel delivery.

Regular inspection and timely replacement of these components can significantly extend the lifespan of your outdoor tools and enhance their performance.

Exploring Different Models and Their Features

Understanding the variety of available models is essential for selecting the right equipment for your needs. Each variant offers distinct characteristics that cater to various applications, ensuring optimal performance and efficiency. This section delves into the key features that differentiate these models and highlights their unique advantages.

Key Characteristics

- Engine Power: Varies across models, impacting performance in demanding tasks.

- Weight: Lightweight designs facilitate maneuverability, while heavier options provide stability.

- Fuel Efficiency: Different models showcase varying levels of fuel consumption, affecting long-term operational costs.

- Cutting Width: Wider cutting widths allow for faster completion of tasks, ideal for larger areas.

Popular Variants

- Model A

- Features a high-powered engine for intensive usage.

- Compact design suitable for residential tasks.

- Model B

- Balanced weight for enhanced stability during operation.

- Designed for extended use with superior fuel efficiency.

- Model C

- Offers advanced safety features to protect users.

- Equipped with ergonomic handles for comfortable handling.

Why Using Genuine Stihl Parts Matters

Utilizing authentic components for your outdoor equipment is crucial for ensuring optimal performance and longevity. These specialized items are designed to fit perfectly and function seamlessly, maintaining the integrity of your tools. When you choose genuine replacements, you invest in quality that can significantly enhance your machinery’s efficiency and reliability.

Benefits of Authentic Components

- Optimal Performance: Genuine components are engineered to work together with your machinery, providing superior performance compared to generic alternatives.

- Durability: Authentic items are made from high-quality materials, ensuring they withstand wear and tear over time.

- Safety: Using the right components reduces the risk of malfunctions that could lead to accidents or equipment failure.

- Warranty Protection: Many manufacturers require the use of authentic components to keep warranties valid, protecting your investment.

Long-Term Cost Efficiency

While the initial investment in genuine components may be higher, the long-term savings are undeniable. These high-quality items reduce the likelihood of breakdowns and costly repairs, ultimately providing better value over time.

By choosing authentic replacements, you ensure your equipment runs at its best, contributing to a more productive and enjoyable experience.

Troubleshooting Common Issues with Stihl Tools

When working with outdoor equipment, encountering difficulties is not uncommon. Identifying and resolving these problems can enhance the longevity and performance of your devices. This section will guide you through common challenges and effective solutions.

Here are some typical issues you might face:

- Engine Won’t Start:

- Check fuel levels and ensure that it is fresh.

- Inspect the spark plug for damage or wear.

- Examine the ignition system for any faults.

- Overheating:

- Verify that air intake is not blocked by debris.

- Ensure that the cooling fins are clean and unobstructed.

- Check the fuel mixture and adjust if necessary.

- Poor Cutting Performance:

- Inspect the cutting blade for dullness or damage.

- Ensure that the correct chain tension is maintained.

- Examine the chain lubrication system for clogs.

- Excessive Vibration:

- Check for loose screws or components.

- Inspect the blade for any imbalances.

- Ensure that the equipment is properly assembled.

By understanding these common issues and their solutions, you can keep your equipment in top condition and ensure optimal performance for all your outdoor tasks.

Best Practices for Stihl Equipment Repairs

Maintaining and restoring outdoor machinery requires a thoughtful approach to ensure longevity and optimal performance. Implementing effective techniques can significantly enhance the repair process, allowing for smoother operations and reduced downtime. Whether you are a seasoned technician or a DIY enthusiast, understanding the essentials of equipment restoration is crucial.

Thorough Preparation

Before starting any repair work, gather all necessary tools and materials. This includes the appropriate manuals, which provide valuable insights into the equipment’s structure and functioning. A clean workspace is essential, as it minimizes the risk of losing components and helps maintain focus during the repair.

Regular Maintenance and Inspection

Performing routine checks on your equipment can prevent unexpected failures. Regularly inspect critical components for wear and tear, and address issues promptly. Keeping a detailed log of maintenance activities helps track performance and identify patterns that may require attention. This proactive approach not only prolongs the life of your machinery but also enhances its efficiency.

Comparing Original and Aftermarket Parts

When it comes to maintaining equipment, the choice between authentic components and those produced by alternative manufacturers can significantly influence performance and durability. Understanding the differences can help users make informed decisions based on their needs and budgets.

Authentic components are typically made by the original manufacturer and are designed to meet specific quality and performance standards. On the other hand, alternative options are produced by third-party companies and may vary in quality and compatibility. Here are some key factors to consider:

- Quality: Authentic components often undergo rigorous testing to ensure reliability, while alternative options may not consistently meet the same standards.

- Cost: Alternative components are frequently more affordable, which can be appealing for those on a budget.

- Compatibility: Authentic components are guaranteed to fit and function with specific equipment, while alternative options may require adjustments or may not perform as expected.

- Warranty: Authentic components typically come with a warranty, providing peace of mind. Alternative options may have limited or no warranty coverage.

- Availability: Authentic components might be more difficult to source, especially for older equipment, while alternatives are often readily available.

Ultimately, the decision should be based on individual priorities, whether that be performance, budget, or convenience. Weighing the pros and cons of each choice can lead to more effective maintenance and enhanced equipment longevity.

Where to Find Reliable Stihl Parts

Locating trustworthy components for your outdoor equipment can be challenging, yet it is essential for maintaining performance and longevity. Reliable sources not only provide quality items but also ensure that you receive the correct specifications for your machinery.

Authorized Dealers: One of the most dependable options is to visit authorized retailers. These establishments offer genuine items that are specifically designed for your equipment, ensuring optimal functionality.

Online Marketplaces: The internet is a valuable resource for finding components. Numerous websites specialize in outdoor equipment and carry a wide range of selections. Look for platforms with positive reviews and reliable customer service to ensure a smooth purchasing experience.

Local Repair Shops: Local service centers can be a great source of assistance. Many of these businesses have access to quality components and can offer advice on installation and compatibility.

Manufacturer’s Website: Exploring the official website of the manufacturer can provide insights into the available items and direct you to verified sellers. This option ensures that you are receiving the most accurate information regarding compatibility and availability.

By considering these sources, you can confidently procure the necessary components to keep your outdoor tools running smoothly.

Maintaining Peak Performance with Proper Parts

Ensuring optimal functionality of your equipment requires a keen focus on high-quality components. The longevity and efficiency of your tools are directly influenced by the parts you choose, making it essential to understand their role in overall performance.

Regular maintenance is critical for sustaining the effectiveness of your machinery. Here are some key strategies to consider:

- Utilize original components that meet manufacturer specifications.

- Inspect and replace worn or damaged elements promptly.

- Keep your tools clean and free from debris to avoid unnecessary wear.

By adhering to these guidelines, you can enhance the reliability and longevity of your equipment, ensuring it remains in top condition for years to come.

In addition to regular upkeep, being aware of the specific requirements for your tools can significantly impact their performance. Consider the following:

- Research the correct specifications for components suited to your machinery.

- Consult resources or professionals for expert advice on part compatibility.

- Stay informed about any updates or improvements in technology that may enhance your equipment.

Implementing these practices will help you maintain peak performance and get the most out of your tools, allowing you to tackle tasks efficiently and effectively.