Understanding the Parts of a Stihl Strimmer Head

The functionality of outdoor cutting tools is largely determined by the various elements that comprise them. Each component plays a crucial role in ensuring the efficiency and performance of these machines. Recognizing the individual functions of each section can significantly enhance both maintenance practices and overall user experience.

When it comes to effective lawn care, a thorough understanding of the intricate mechanisms involved is essential. Different segments interact harmoniously to achieve optimal results, and familiarity with their configurations can help users make informed decisions during repairs or upgrades. By examining these components closely, users can gain insights into improving the longevity and reliability of their equipment.

This section aims to provide a comprehensive overview of the crucial elements that contribute to the effective operation of trimming tools. From the outer casing to the internal mechanisms, each segment is designed with precision to meet specific operational needs. Exploring these elements will empower users to maximize their tools’ potential and maintain them with confidence.

Understanding Strimmer Head Components

The functionality of a grass trimming device relies heavily on the intricate assembly of its various components. Each element plays a vital role in ensuring efficient operation and optimal performance. By grasping the roles of these individual components, users can enhance their understanding of how to maintain and troubleshoot the device effectively.

One key element is the mechanism that facilitates the release of cutting line. This component allows for the seamless dispensing of line, ensuring that users can continue their task without interruption. In addition, the protective cover safeguards the user from debris and contributes to the device’s overall safety features.

Moreover, the attachment system enables quick and easy replacement of the cutting line, which is crucial for maintaining performance. Understanding how these elements work together can help users identify potential issues, leading to more effective upkeep and enhanced longevity of the equipment.

Overall, familiarizing oneself with these essential components not only aids in the effective use of the tool but also empowers users to carry out necessary maintenance and repairs confidently.

Importance of Proper Maintenance

Maintaining outdoor equipment is crucial for ensuring optimal performance and longevity. Regular care not only enhances efficiency but also prevents potential breakdowns, which can lead to costly repairs and replacements. By investing time in upkeep, users can maximize the lifespan of their tools and improve their overall gardening experience.

Enhancing Performance

Proper upkeep significantly boosts the effectiveness of the equipment. When all components are in good condition, the machine operates smoothly, providing better results in cutting and trimming. Neglected tools can lead to decreased performance, making tasks more labor-intensive and time-consuming.

Preventing Damage

Regular inspections and servicing help identify and address minor issues before they escalate into major problems. Timely intervention reduces the risk of damage, ensuring that the equipment remains functional and safe to use. Moreover, consistent maintenance can save users from unexpected interruptions during work, allowing them to focus on their tasks with peace of mind.

Identifying Common Wear Parts

In the context of maintenance and operation of lawn care equipment, understanding the components that are prone to wear is essential for ensuring optimal performance. Regular inspection and timely replacement of these elements can significantly enhance the longevity and efficiency of the device. This section highlights the various types of components that typically exhibit signs of deterioration over time.

Key Components to Monitor

Several elements within the equipment are particularly susceptible to wear due to their frequent exposure to harsh conditions and high levels of use. Keeping an eye on these components can prevent potential malfunctions and improve overall functionality.

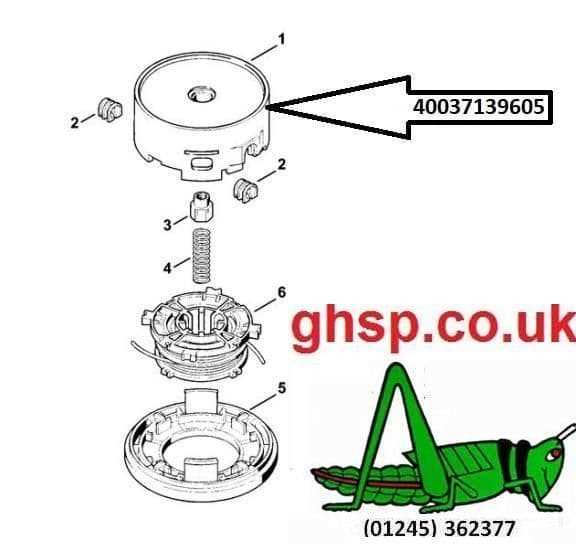

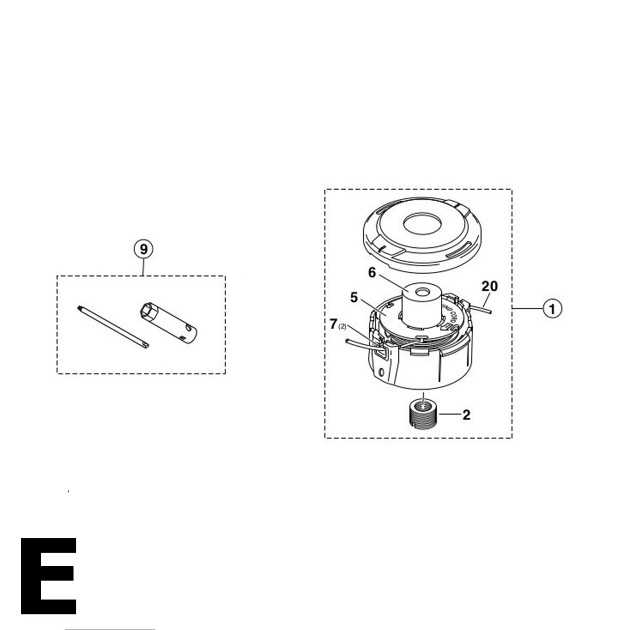

| Component | Description | Signs of Wear |

|---|---|---|

| Line | The flexible filament that cuts through vegetation. | Fraying, thinning, or breaking. |

| Spool | Holds and feeds the cutting line. | Cracking or deformation. |

| Casing | Encloses the internal mechanisms. | Cracks, chips, or signs of wear. |

| Spring | Assists in line retraction and tension. | Loss of tension or breaks. |

| Cap | Secures the spool in place. | Loose fit or damage. |

Maintenance Tips

Regular maintenance of these components is crucial. Periodic checks can help identify wear before it leads to performance issues. Always replace worn-out elements promptly to maintain the efficiency of the equipment.

How to Replace Strimmer Parts

Replacing components of a trimming tool is essential for maintaining its performance and extending its lifespan. Regular checks can help identify worn or damaged elements that need attention. This section outlines the steps to efficiently swap out various elements, ensuring your device operates optimally.

1. Gather Necessary Tools: Before beginning, ensure you have all required tools handy. Common items include screwdrivers, wrenches, and replacement components. Having everything within reach simplifies the process and saves time.

2. Disconnect the Power Source: Prior to making any modifications, disconnect the power supply or remove the battery. This step is crucial for safety, preventing accidental activation during the replacement process.

3. Remove the Old Component: Locate the part needing replacement. Carefully unscrew or detach it according to the manufacturer’s guidelines. Take your time to avoid damaging surrounding elements or the main device.

4. Install the New Element: Align the new component properly and secure it in place. Ensure it fits snugly without excessive force. Following the instructions provided can help avoid common installation errors.

5. Reconnect and Test: Once the new element is installed, reconnect the power source. Perform a test run to verify that the tool functions correctly. Listen for any unusual sounds and ensure everything operates smoothly.

Following these steps will help maintain the efficiency of your trimming tool, allowing for optimal performance during use. Regular maintenance and timely replacements can significantly enhance your device’s effectiveness.

Choosing the Right Replacement Parts

When it comes to maintaining garden equipment, selecting the appropriate components is essential for ensuring optimal performance and longevity. Understanding the different elements that make up your tool can help you make informed choices and avoid compatibility issues. This section will guide you through the process of finding the best replacements to keep your equipment running smoothly.

Identifying Compatibility

One of the most crucial steps in the replacement process is ensuring that the new components are compatible with your device. Always consult the manufacturer’s specifications to determine the correct dimensions and fitting types. Utilizing parts that are not designed for your model can lead to decreased efficiency or even damage.

Quality vs. Price

While it may be tempting to opt for the cheapest options available, investing in high-quality replacements can save you money in the long run. Premium components are often made from durable materials and are designed to withstand the rigors of frequent use. Consider balancing cost with quality to ensure you achieve the best value for your investment.

Tools Needed for Repair Tasks

Effective maintenance and repair require specific instruments to ensure efficiency and precision. Having the right tools not only simplifies the process but also enhances the quality of the work. This section outlines essential equipment necessary for undertaking repair projects involving outdoor power devices.

Essential Hand Tools

Hand tools are fundamental for any repair task, providing the necessary leverage and control. Below is a list of crucial hand tools that you may need:

| Tool | Purpose |

|---|---|

| Screwdriver Set | To tighten or loosen screws of various sizes. |

| Wrench Set | For gripping, turning, and loosening nuts and bolts. |

| Pliers | To hold, twist, or cut wire and other materials. |

| Socket Set | For efficiently removing and installing nuts and bolts. |

Power Tools and Safety Equipment

In addition to hand tools, power tools can greatly expedite the repair process. Safety equipment is equally important to protect the user during repairs. Below are recommended items:

| Tool/Equipment | Purpose |

|---|---|

| Drill | For making holes or driving screws with ease. |

| Safety Glasses | To protect eyes from debris and hazardous materials. |

| Gloves | To safeguard hands from sharp objects and chemicals. |

| Workbench | To provide a stable and organized workspace. |

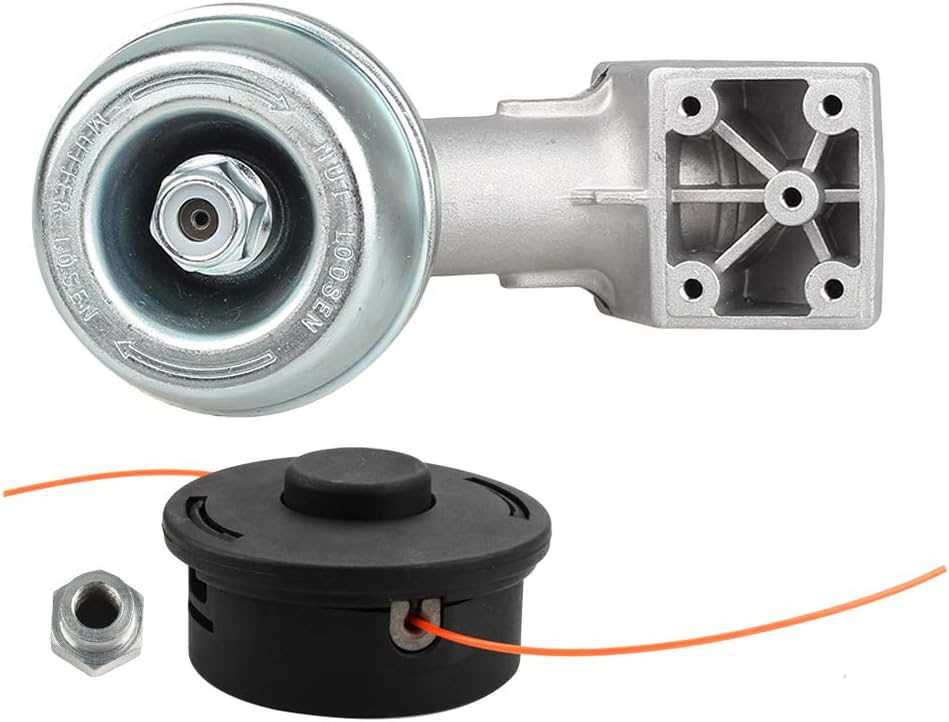

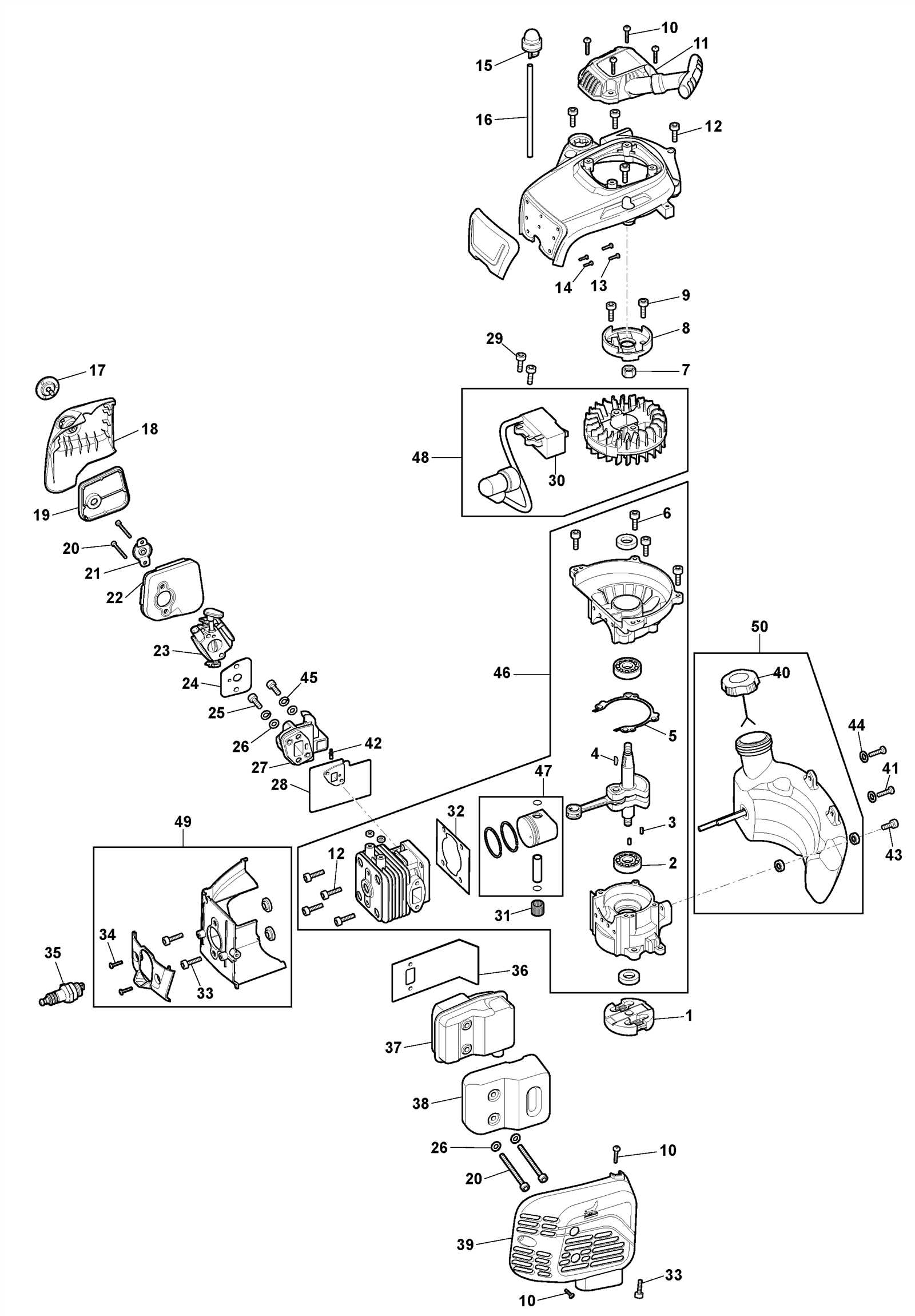

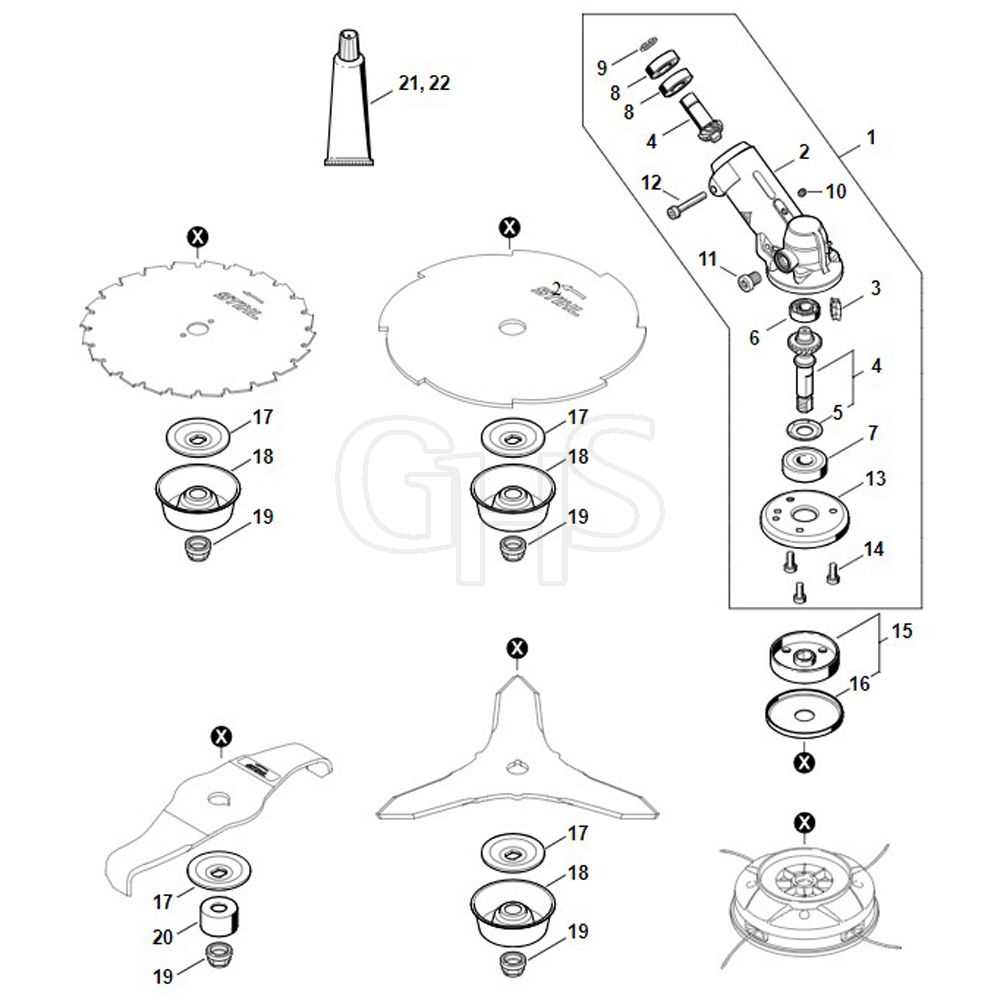

Strimmer Head Assembly Process

Assembling the trimming tool’s cutting mechanism involves several essential steps to ensure optimal performance and durability. This process is crucial for maintaining the equipment’s efficiency and prolonging its lifespan. By understanding the components and their arrangement, users can confidently undertake the assembly task with precision.

Components Overview

The following table outlines the various elements involved in the assembly, including their functions and descriptions.

| Component | Function | Description |

|---|---|---|

| Spindle | Holds the cutting line | A central shaft that supports the cutting line or blades. |

| Cover | Protects internal parts | An outer casing that shields the inner components from debris. |

| Line Feed Mechanism | Automatically dispenses cutting line | Ensures a continuous supply of line during operation. |

| Fasteners | Secures components | Various bolts and screws that hold the assembly together. |

Assembly Steps

Follow these steps to properly assemble the cutting mechanism:

- Begin by securing the spindle in place, ensuring it is firmly attached.

- Attach the cover over the spindle, aligning it correctly to protect the internal components.

- Integrate the line feed mechanism, ensuring it functions smoothly for uninterrupted cutting.

- Finally, use the fasteners to secure all components, checking for tightness and stability.

Best Practices for Efficient Use

Achieving optimal performance with your cutting equipment requires understanding key techniques and maintenance strategies. By following a few essential guidelines, you can enhance productivity, reduce wear, and ensure longevity of the tool.

Regular maintenance is crucial for smooth operation. Keeping the equipment clean and checking for any signs of damage can prevent unexpected issues. Additionally, using the right type of cutting line can significantly impact effectiveness. Below are some best practices to consider:

| Practice | Description |

|---|---|

| Maintain Sharpness | Ensure the cutting elements are sharp for efficient trimming and reduced strain on the engine. |

| Adjust Cutting Height | Set the cutting height appropriately to avoid scalping and promote healthy growth of the surrounding vegetation. |

| Utilize Proper Technique | Employ a sweeping motion for better coverage and to minimize the workload on the machine. |

| Inspect Regularly | Check for any loose components or signs of wear after each use to catch problems early. |

| Use Appropriate Fuel | Select the right fuel mix to enhance performance and prevent engine damage. |

By implementing these strategies, users can maximize the efficiency of their equipment while ensuring a clean and well-maintained working environment.

Frequently Asked Questions

This section addresses common inquiries regarding the various components associated with garden trimming equipment. Here, you will find useful insights to enhance your understanding and optimize your experience with these tools.

What maintenance is required for my trimming tool?

Regular upkeep involves cleaning the equipment, checking for wear on the components, and ensuring proper lubrication. It is essential to follow the manufacturer’s recommendations for best practices.

How do I know when to replace a specific component?

Signs that a component may need replacement include unusual noises during operation, difficulty in achieving desired results, or visible damage. Regular inspections will help identify issues before they escalate.

Can I use different types of cutting lines with my equipment?

Yes, various cutting lines are available, each designed for specific tasks. It is crucial to select the appropriate line for the type of vegetation you are trimming to ensure efficiency and safety.

Is it possible to upgrade components for better performance?

Many users choose to enhance their equipment with upgraded parts that offer improved durability and cutting efficiency. Ensure that any upgrades are compatible with your existing model.

What safety precautions should I take while using trimming tools?

Always wear protective gear such as gloves, goggles, and long pants. Be mindful of your surroundings and ensure that bystanders are at a safe distance during operation.

Resources for Further Learning

To deepen your understanding of maintenance and assembly related to gardening tools, a variety of resources are available. These materials can provide valuable insights, technical specifications, and practical tips for enhancing your skills and knowledge.

Consider exploring the following types of resources:

- Instruction Manuals: Detailed guides often accompany tools, offering step-by-step instructions for usage, maintenance, and troubleshooting.

- Online Forums: Communities where enthusiasts and professionals share experiences, tips, and solutions to common issues can be highly beneficial.

- Video Tutorials: Platforms like YouTube feature countless videos demonstrating techniques and offering visual explanations for various tasks.

- Workshops and Classes: Local hardware stores or gardening centers may offer hands-on workshops that cover practical aspects of tool management.

- Books and Guides: Literature focused on gardening equipment and maintenance can provide in-depth knowledge and best practices.

Engaging with these resources can significantly enhance your expertise and confidence in managing your gardening tools effectively.