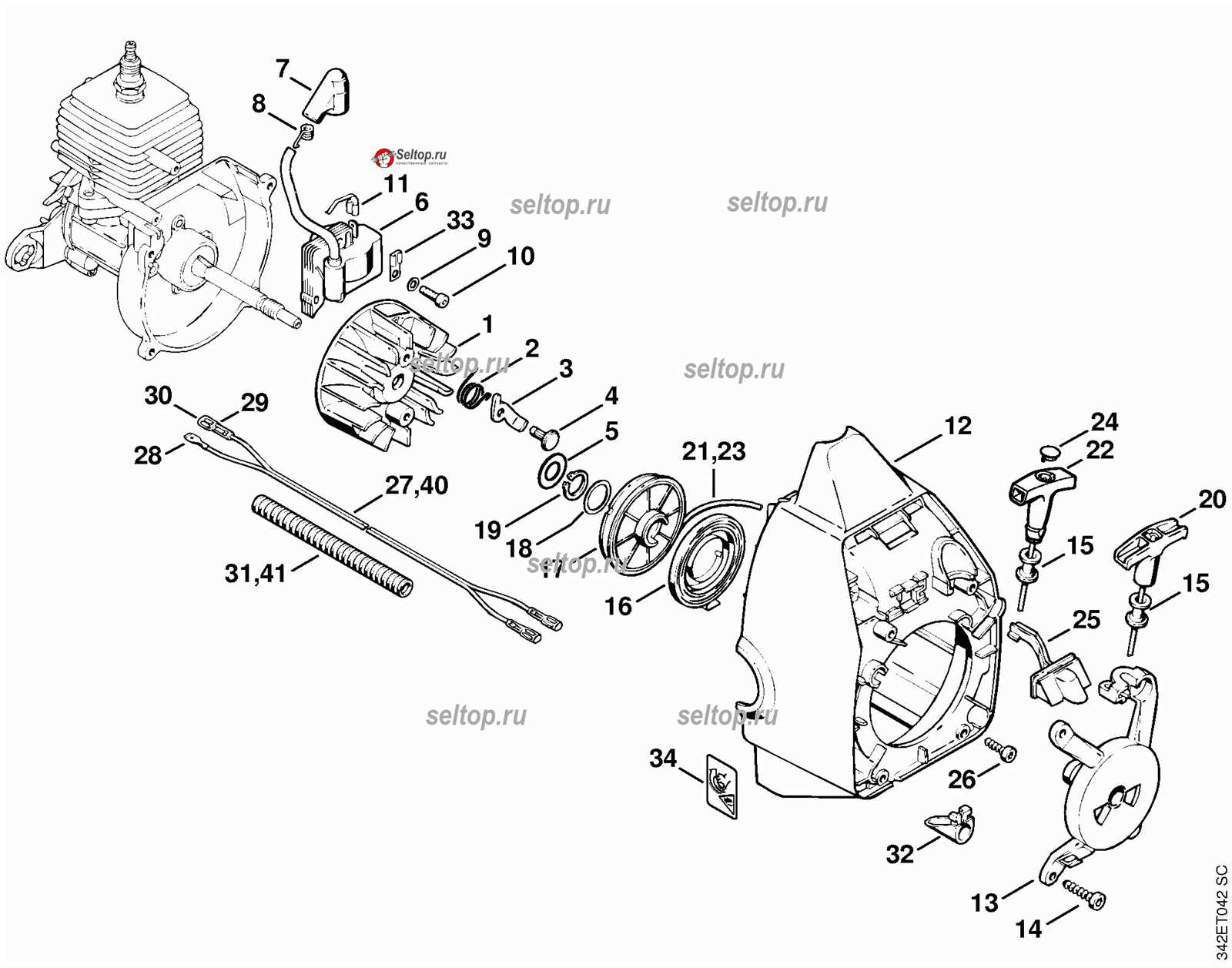

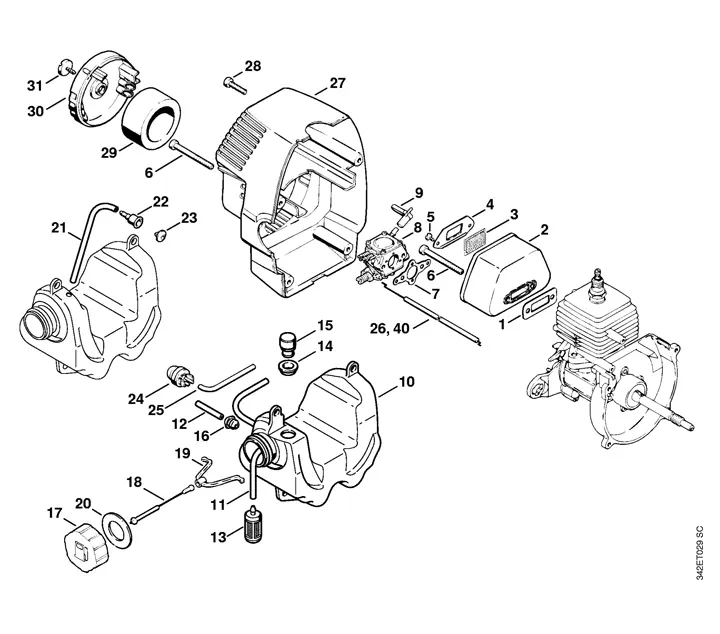

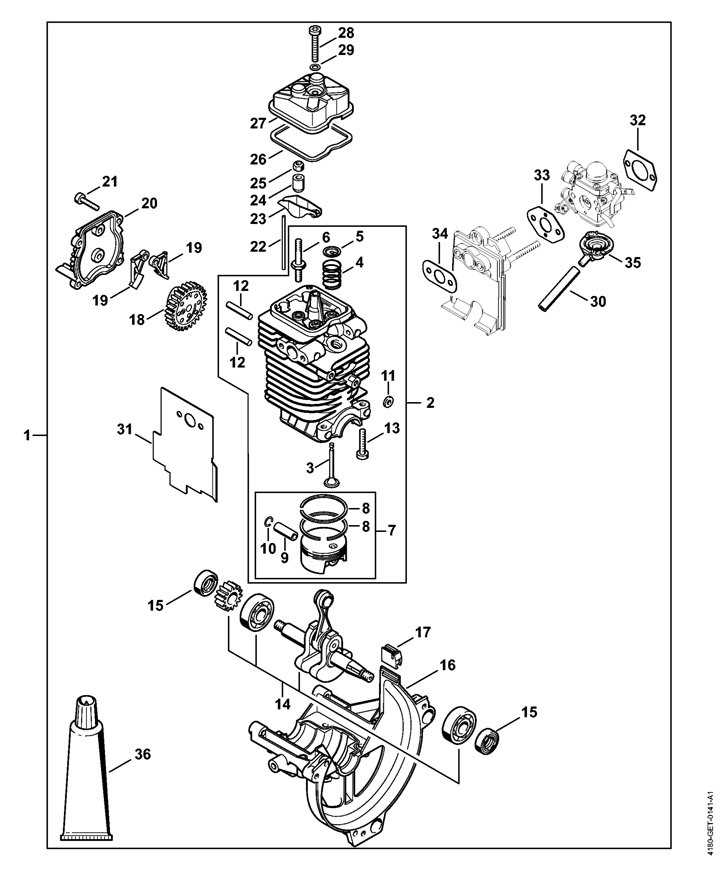

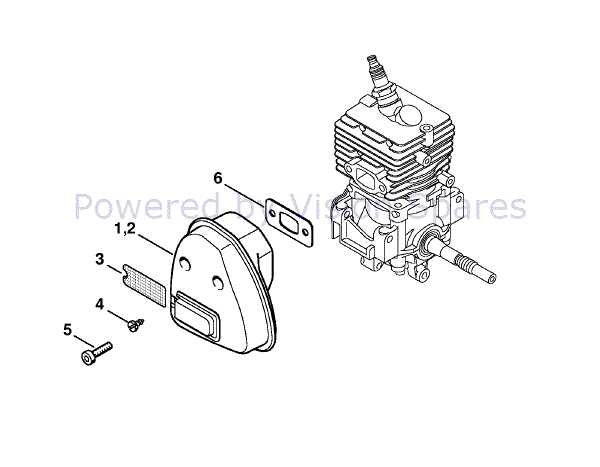

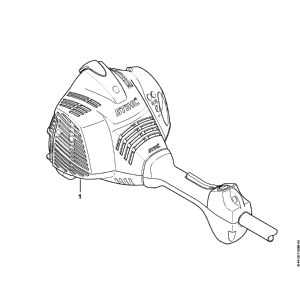

Stihl FS 40 Trimmer Parts Diagram Guide

When maintaining a tool for yard care, it’s important to have a clear overview of the various elements that make up the machine. Knowing how each element interacts ensures better performance and easier repairs. Whether you’re replacing a small piece or simply understanding how the device functions, this knowledge can significantly improve your experience with the equipment.

By breaking down the device into its individual components, users can gain a better grasp of the structure and internal workings. This understanding not only helps with regular upkeep but also makes the process of troubleshooting more efficient when issues arise.

Detailed layouts and representations of these systems offer valuable insights into the assembly and design. Such guides are essential for anyone looking to maintain or repair their equipment with greater accuracy and confidence.

Comprehensive Guide to Stihl FS 40 Parts

When maintaining or repairing your garden tool, it’s important to understand the essential components that keep it running smoothly. This guide will provide detailed information on the main elements and how they work together to ensure your equipment performs efficiently. Regular upkeep and knowledge of each section can help prevent major issues and extend the lifespan of your machine.

Key Components Overview

Each piece of the system plays a crucial role in the overall operation. From the

Essential Components of the FS 40 Trimmer

The FS 40 model is designed with several key elements that work together to ensure optimal performance and durability. These components are carefully engineered to offer efficiency, ease of use, and reliable function over time. Understanding the function and arrangement of these parts can help in maintaining and improving the overall efficiency of the tool.

Engine Unit: The power source, which drives the entire system, ensures smooth and continuous operation. It’s built to provide consistent energy output, necessary for powering all other sections.

Cutting Mechanism: This part is responsible for performing the core task, using sharp, rotating edges to manage and trim various materials. It’s

How to Identify Key FS 40 Parts

Understanding the essential components of your FS 40 model is crucial for maintaining optimal performance. Familiarizing yourself with the various elements can help you spot wear and tear, ensuring timely replacements and smooth operation. By recognizing these main elements, you’ll also be better equipped to handle basic maintenance tasks.

Focusing on the Main Engine Components

The engine is the heart of your device, and its core elements are vital for smooth operation. Key areas to check include the housing and mechanisms responsible for power generation. Regular inspection of these components can prevent breakdowns and extend the lifespan of your equipment.

Checking Essential External Elements

The external features are equally important, contributing to both functionality and safety. Pay attention to the handles, guard, and other visible structures that ensure proper control and protection during use. Proper upkeep of these parts will maintain both efficiency and user safety.

Maintaining Your FS 40 for Longevity

Ensuring the extended life of your FS 40 requires consistent care and attention to detail. Regular upkeep not only helps avoid unexpected malfunctions but also maximizes performance during use. A well-maintained tool will serve you reliably for years, making your outdoor tasks more efficient and less time-consuming.

Regular Cleaning

To keep your equipment in top shape, cleaning it after each use is essential. Dirt and debris can accumulate and cause wear over time, leading to more frequent repairs. By keeping the device free from buildup, you help prevent unnecessary damage.

Inspecting Components

Checking key components regularly is crucial for longevity. Make sure moving parts are properly lubricated, and inspect for signs of wear or damage. Replacing worn elements before they fail can save you time and money in the

Replacing Worn Out Parts Efficiently

Maintaining optimal performance of your equipment requires timely replacement of any components that show signs of wear. Ensuring that each element functions correctly not only extends the life of the device but also prevents potential malfunctions. Taking proactive steps can minimize downtime and avoid more significant repairs.

Identifying the right moment to swap out a worn component is essential for keeping everything running smoothly. Regular inspections help detect early signs of damage, making it easier to address issues before they escalate. Look for visible deterioration, unusual vibrations, or decreased efficiency as clear indicators.

Once a faulty piece is identified, quick action ensures minimal disruption to operations. Having a well-organized process for replacing defective items, including keeping essential spares on hand, is crucial for maintaining continuous performance. This practice avoids delays and keeps the equipment in top shape.

Understanding the FS 40 Engine Assembly

The FS 40 engine is designed with precision to ensure optimal performance and longevity. By exploring its internal components, we can gain insights into how each element contributes to the smooth operation of the machine. Understanding the mechanics behind the assembly will help users maintain and troubleshoot their equipment more effectively.

Key elements of the engine structure include the cylinder, piston, and crankshaft. These core components work in harmony, converting fuel into mechanical power. The alignment and quality of each part are crucial for achieving efficient combustion and reducing wear over time.

Furthermore, the fuel system plays a vital role in delivering the right mixture to the engine, ensuring consistent performance. Familiarizing oneself with the layout of these components can significantly enhance repair and maintenance skills, preventing unexpected breakdowns.

Trimmer Head: Troubleshooting and Repair Tips

Proper maintenance of your cutting tool’s head ensures efficient operation and longevity. When performance issues arise, identifying and addressing common problems quickly can prevent further damage and downtime. Here, we cover frequent challenges users face and practical solutions for keeping your device in top shape.

Common Issues and Their Causes

Several issues may arise during regular use, such as uneven cutting or unexpected vibrations. These problems often stem from wear and tear, improper assembly, or debris buildup. Identifying the root cause early on will make repairs more manageable and extend the overall lifespan of the tool.

Simple Fixes to Keep Your Tool Running Smoothly

Cleaning

Air Filter and Its Importance for Performance

The air filter plays a critical role in maintaining the efficiency of any engine-driven equipment. By preventing dust, debris, and other particles from entering the engine, it helps to ensure that the motor operates smoothly and effectively. Without proper filtration, these contaminants could cause internal damage, leading to a significant reduction in power and longevity.

Maintaining a clean air filter is essential for optimal engine performance. A clogged or dirty filter restricts airflow, which can negatively affect fuel combustion and reduce overall efficiency. Regular inspections and replacements are necessary to avoid potential issues and keep the engine running at its best.

In conclusion, the air filter is not just a minor component but a key factor in ensuring peak performance and extending the lifespan of the machine. Prioritizing

Choosing the Right Replacement Parts for FS 40

Ensuring your equipment operates efficiently requires selecting the appropriate components for replacement. When it’s time to repair or maintain your device, it’s crucial to identify compatible and high-quality elements to avoid performance issues. Using the correct replacements can improve longevity and functionality, making your equipment work like new.

Key Considerations for Selecting Replacement Components

Before purchasing any replacement, evaluate the following factors:

- Compatibility: Verify that the components fit your specific model.

- Quality: Opt for high-grade materials to guarantee durability and longevity.

- Performance: Choose items that will restore or enhance the device’s efficiency.

Where to Find Reliable Replacement Options

Reliable suppliers and manufacturers provide a wide range of replacement options. It’s important to select reputable sources to ensure you receive genuine, long-lasting products. Many retailers offer online catalogs, allowing you to compare and select the best options for your needs.

How to Assemble FS 40 After Repairs

Once you have completed the necessary maintenance or fixes, it’s time to reassemble the equipment to ensure it functions properly. The process involves carefully reattaching all components to restore the machine’s optimal performance. Start by reviewing the steps to make sure all parts are in place, and that no detail is overlooked. Proper assembly ensures safety and efficiency during use.

Step-by-Step Assembly

Begin by reconnecting the main body components, ensuring that all fittings are secured tightly. Pay close attention to the alignment of the internal mechanisms, as improper placement can lead to malfunction or uneven operation. Once the central parts are in position, proceed with attaching the remaining sections, making sure each component clicks into place without forcing it.

Final Check

After all parts are in place, conduct a thorough inspection. Look for any loose connections or misaligned sections. Double-check that all parts are fastened correctly, and make sure no tools or materials are left behind. When you’re satisfied with the assembly, perform a test run to confirm the equipment works as expected.

Common Issues with

Many users encounter similar problems when working with handheld garden tools. These issues can arise from various factors, including wear and tear, improper maintenance, or incorrect usage. Identifying and addressing these common malfunctions ensures smoother operation and longer service life of the equipment.

- Difficulty starting the engine: Often caused by a clogged fuel filter, spark plug issues, or improper fuel mix.

- Unusual vibrations: This may indicate loose components or damaged parts that need tightening or replacement.

- Loss of power: Can be due to air filter blockages, worn-out parts, or fuel system problems.

- Excessive noise: This is typically linked to loose parts or excessive friction between moving components.

- Problems with the cutting mechanism: May arise from dull blades or improperly adjusted cutting angles.