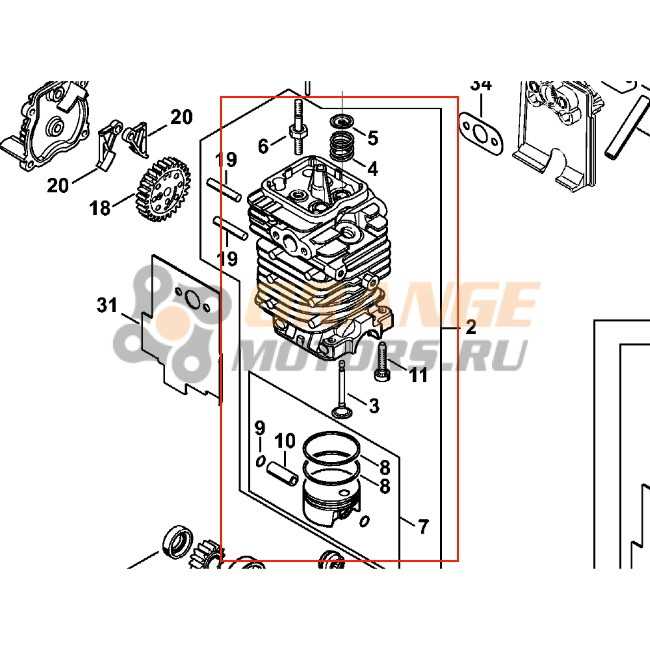

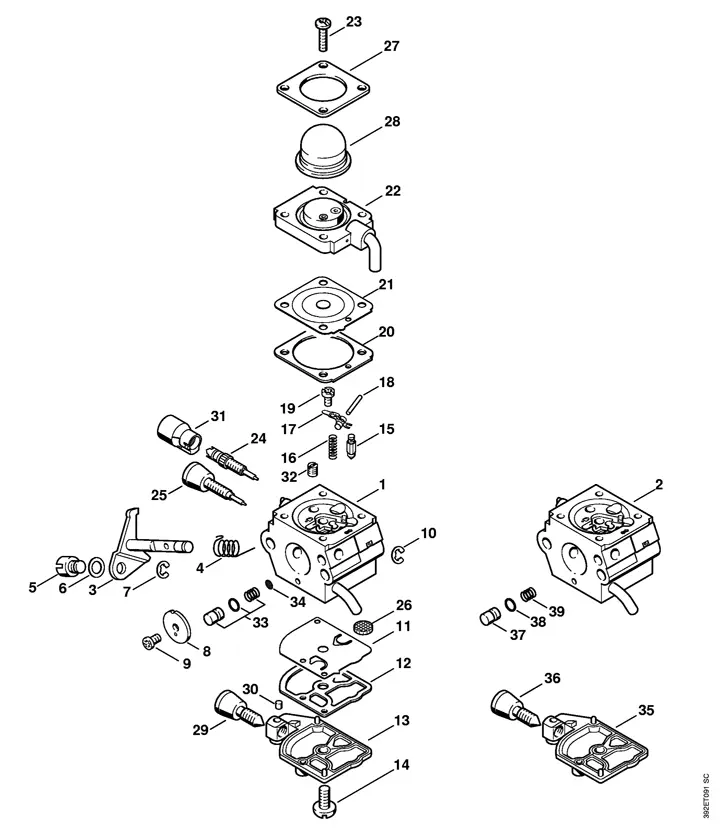

Complete Parts Diagram for Stihl Trimmer FS 75

Maintaining your outdoor machinery is crucial for ensuring its longevity and efficiency. A thorough understanding of the individual elements that make up your equipment can greatly enhance your ability to troubleshoot and perform routine maintenance. Whether you’re dealing with wear and tear or simply looking to optimize performance, knowledge of these components is invaluable.

In this section, we will explore the various pieces that comprise your gardening tool, highlighting their functions and interrelationships. By familiarizing yourself with each element, you’ll be better equipped to identify issues and implement effective solutions.

Additionally, having a clear visualization of these components can simplify the repair process, making it more manageable even for those with limited mechanical experience. This knowledge not only empowers you but also fosters a deeper appreciation for the engineering behind your equipment.

Understanding Stihl FS 75 Trimmer Components

Familiarizing oneself with the various elements of a cutting tool is essential for optimal performance and maintenance. Each component plays a critical role in ensuring the efficiency and effectiveness of the machine. A comprehensive understanding of these parts not only aids in troubleshooting but also enhances the overall user experience.

Power Unit: At the core of the apparatus lies the engine, which generates the necessary power for operation. This component’s performance directly influences the tool’s capability to handle various tasks.

Cutting Mechanism: The blade assembly is crucial for achieving precise cutting. Whether it’s a string or a blade system, understanding its function and maintenance is key to ensuring a clean cut.

Fuel System: The reservoir and associated lines are responsible for delivering fuel to the engine. Proper management of this system is vital to prevent issues such as clogging and ensure smooth operation.

Control Features: The handle and throttle control provide the user with the ability to manage speed and direction effectively. Familiarity with these controls enhances safety and efficiency during use.

Safety Mechanisms: Various built-in features are designed to protect the operator. Recognizing these mechanisms is essential for safe operation and helps in preventing accidents.

By understanding these fundamental components, users can maintain their equipment better, troubleshoot problems more effectively, and enhance their overall experience when operating the machine.

Key Parts of the FS 75 Model

The FS 75 model comprises several essential components that contribute to its functionality and efficiency. Understanding these elements is crucial for effective maintenance and optimal performance. Each section plays a significant role in the overall operation, ensuring that the device meets the demands of various tasks.

Engine and Fuel System

The engine serves as the powerhouse of the unit, providing the necessary energy for operation. Coupled with the fuel system, it ensures a steady supply of energy, enabling the equipment to perform consistently. Proper care and regular checks of these components enhance durability and reliability during use.

Cutting Mechanism

The cutting assembly is designed to deliver precise results, facilitating efficient trimming and clearing. Its design allows for easy adjustments and replacements, ensuring that users can maintain optimal cutting performance. Familiarity with this mechanism is vital for achieving the best results in various applications.

Importance of Accurate Parts Diagrams

Precision in technical illustrations plays a crucial role in the maintenance and repair of machinery. These visual representations provide a clear understanding of the components and their interrelations, ensuring that users can identify the necessary elements for replacement or adjustment effectively.

Enhanced Understanding

Accurate visual guides foster a deeper comprehension of the equipment’s structure. By presenting each component in detail, users can easily grasp how individual pieces function together, leading to more informed decisions during repairs and maintenance tasks.

Streamlined Repairs

When users have access to precise illustrations, the process of fixing or servicing machinery becomes significantly more efficient. Reduced confusion translates into less downtime, as individuals can quickly locate and replace faulty components without extensive trial and error. This not only saves time but also minimizes the risk of errors that can occur when relying on memory or vague instructions.

How to Identify Each Component

Understanding the various elements of your garden tool is crucial for effective maintenance and repair. Each part plays a significant role in the overall functionality, and recognizing them can enhance your operational efficiency and prolong the life of the equipment.

1. Engine Assembly: The core of any device, the engine is responsible for providing the necessary power. Look for the fuel inlet and spark plug to identify this component. The engine’s casing typically houses various moving parts, which should be examined for wear and tear.

2. Cutting Head: This essential section is where the cutting action occurs. It usually includes a spool for the line and may have blades depending on the model. Check for the line’s thickness and the mechanism for ease of replacement.

3. Shaft: The long rod connecting the engine to the cutting head is the shaft. Inspect it for bends or damages, which could affect performance. The shaft may also have a flexible coupling to absorb vibrations.

4. Handle: The handle provides control and comfort during use. Identify it by its ergonomic shape and any features designed to reduce fatigue. Ensure it is secure and free of cracks.

5. Gearbox: This component translates the engine’s power to the cutting head. It can often be found near the base of the shaft. Listen for unusual noises when operating, which might indicate issues within this assembly.

By familiarizing yourself with these elements, you can more effectively troubleshoot and maintain your equipment, ensuring optimal performance for all your landscaping tasks.

Common Issues with Stihl Trimmers

Many users encounter a range of challenges when operating these powerful garden tools. Understanding the typical problems can help in maintaining performance and extending the lifespan of the equipment. Here are some frequent issues that can arise, along with potential solutions.

Engine Problems

One of the most common complaints involves engine performance. Users may experience difficulty starting the machine, inconsistent running, or stalling during operation. These issues can often be traced back to fuel quality, spark plug condition, or air filter blockage. Regular maintenance, including checking and replacing these components, can significantly improve reliability.

Cutting Mechanism Failures

The cutting mechanism can also present difficulties, such as lines tangling or wearing out too quickly. Improper installation of the cutting line or using the wrong type can lead to these frustrations. Ensuring the correct technique during line replacement and selecting the appropriate materials will enhance cutting efficiency and reduce downtime.

Benefits of Using Genuine Parts

Opting for authentic components in your equipment ensures optimal performance and longevity. These items are designed specifically for compatibility, enhancing efficiency and reducing the risk of malfunctions. By choosing genuine replacements, users invest in the reliability of their machinery, ensuring that it operates at its best for an extended period.

Enhanced Performance

Original components provide precise fit and function, resulting in superior performance. They undergo rigorous testing to meet strict quality standards, ensuring that your machinery runs smoothly and efficiently. This attention to detail translates to improved power and reduced operational issues.

Long-Term Savings

While it may be tempting to opt for cheaper alternatives, genuine components often prove to be more economical over time. They are less likely to wear out prematurely or cause damage to other parts, which can lead to costly repairs. Investing in authentic items ultimately safeguards your investment and minimizes maintenance expenses.

Maintenance Tips for Your Trimmer

Regular upkeep is essential for ensuring the longevity and efficiency of your gardening tool. By following a few simple practices, you can keep your equipment in optimal condition, enhancing its performance and extending its lifespan.

- Clean After Use: Remove any grass clippings, dirt, or debris from the equipment after each session. This prevents buildup that can cause rust and deterioration.

- Check the Blades: Inspect the cutting elements for any signs of wear or damage. Sharpen or replace them as needed to ensure clean cuts.

- Inspect the Fuel System: Ensure that the fuel is fresh and that there are no leaks in the system. Stale fuel can cause performance issues.

- Examine Cables and Hoses: Regularly check all cables and hoses for fraying or cracks. Replace any damaged components to prevent malfunctions.

- Lubricate Moving Parts: Use appropriate lubricants on moving components to reduce friction and wear. Follow the manufacturer’s recommendations for specific products.

- Store Properly: When not in use, store the equipment in a dry, cool place. Consider covering it to protect against dust and moisture.

Implementing these practices will help maintain your gardening tool’s efficiency, ensuring it remains reliable for all your outdoor projects.

Where to Find Replacement Parts

When it comes to maintaining your outdoor equipment, sourcing high-quality components is essential for optimal performance. Numerous avenues exist for acquiring necessary items, ensuring that you can keep your machine in top shape without undue hassle.

Authorized Dealers

One of the most reliable options is to visit authorized retailers. These establishments typically carry a comprehensive selection of original components, ensuring compatibility and reliability. Additionally, staff members are often well-versed in the products and can provide valuable assistance in selecting the right items for your needs.

Online Marketplaces

Another convenient avenue is the use of online platforms. Websites specializing in equipment supply often feature extensive catalogs of various components. Here, you can compare prices, read reviews, and even find hard-to-locate items. Make sure to check seller ratings and product descriptions carefully to ensure quality.

In summary, whether you choose a local dealer or an online source, being informed about your options will help you find the right components efficiently. Investing time in research can lead to better performance and longevity for your equipment.

Using Diagrams for Assembly Guidance

Visual representations play a crucial role in simplifying the assembly process of complex equipment. These illustrations provide clarity and enhance understanding, making it easier to identify components and their respective placements. By following a structured visual guide, users can effectively reduce assembly time and minimize errors.

One of the key benefits of utilizing these visuals is the ability to break down intricate mechanisms into manageable sections. This not only aids in comprehension but also ensures that each part is assembled correctly, enhancing the overall functionality and durability of the equipment.

| Component | Description |

|---|---|

| Housing | The outer shell that encases the inner workings. |

| Engine | The power source that drives the mechanism. |

| Attachment | Various tools or accessories that can be fitted. |

| Handle | The part used for gripping and maneuvering the unit. |

Incorporating these illustrative guides not only facilitates a smoother assembly process but also empowers users with confidence, ensuring they can tackle the task with ease. Ultimately, leveraging such resources can lead to more efficient operations and prolonged lifespan of the equipment.

Safety Precautions During Repairs

When undertaking maintenance tasks on any equipment, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, allowing for a smoother and more effective repair process.

Here are essential safety measures to consider:

- Wear Personal Protective Equipment (PPE):

- Safety goggles to protect your eyes from debris.

- Gloves to shield your hands from sharp objects and chemicals.

- Ear protection to minimize noise exposure.

- Sturdy footwear to protect your feet from heavy tools and falling parts.

- Ensure a Clean Workspace:

- Remove clutter to prevent tripping hazards.

- Keep tools organized for easy access.

- Maintain good lighting to see clearly.

- Disconnect Power Sources:

- Always unplug the device or remove batteries before starting repairs.

- Ensure any residual power is discharged to avoid electric shocks.

- Read Manuals and Instructions:

- Familiarize yourself with the equipment’s manual for specific safety guidelines.

- Understand the assembly and disassembly process before starting.

- Work with a Partner:

- Having someone nearby can be crucial in case of an emergency.

- A partner can assist with holding parts or tools, making the process safer.

By following these precautions, you can help ensure a safer environment while performing necessary repairs, reducing the risk of injury and enhancing efficiency.

Frequently Asked Questions About FS 75

This section addresses common inquiries regarding the FS 75 model, providing clarity on its operation, maintenance, and troubleshooting. Understanding these aspects can enhance user experience and prolong the equipment’s lifespan.

| Question | Answer |

|---|---|

| What type of fuel should I use? | It is recommended to use a mixture of gasoline and oil, typically in a 50:1 ratio, to ensure optimal performance. |

| How often should I replace the cutting line? | The cutting line should be replaced when it becomes frayed or too short, usually after several hours of use, depending on the conditions. |

| What maintenance is required? | Regularly clean the air filter, check the spark plug, and inspect the fuel lines to keep the equipment running smoothly. |

| How do I troubleshoot starting issues? | Check the fuel level, ensure the spark plug is in good condition, and verify that the air filter is clean. These factors often affect starting. |

| Is it safe to use in wet conditions? | It is advisable to avoid using the equipment in wet conditions to prevent accidents and damage to the motor. |