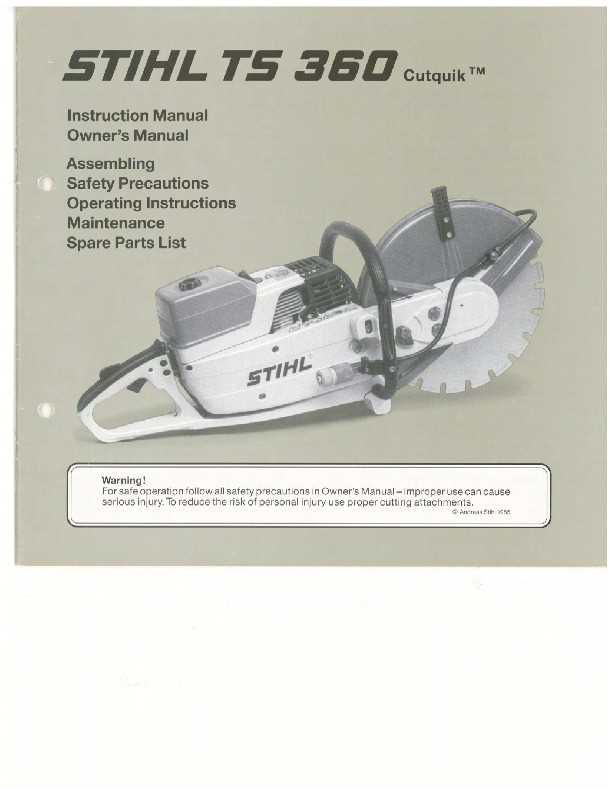

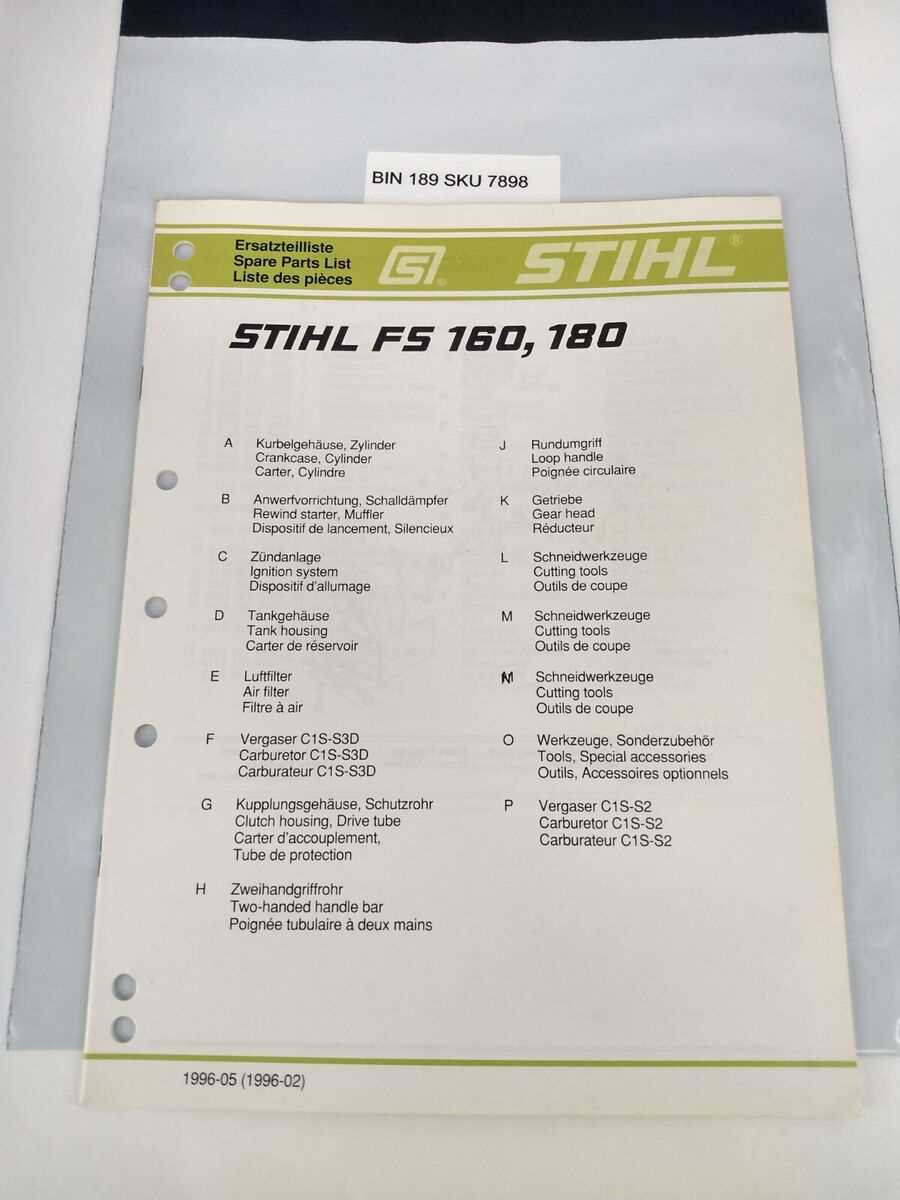

Stihl TS360 Parts Overview

The understanding of a cutting tool’s structure is essential for effective maintenance and repair. Recognizing each component’s role and interaction can enhance operational efficiency and prolong the machine’s lifespan. This section will delve into various sections of the tool, providing clarity on how each part contributes to its overall function.

By exploring the intricate layout of the device, users can identify specific elements that may require attention or replacement. Whether you’re a seasoned technician or a novice user, having a detailed reference can significantly simplify troubleshooting processes. An organized illustration serves as an invaluable guide in both routine upkeep and complex repairs.

Familiarizing oneself with the arrangement of components fosters confidence and competence in handling the machine. Empowering users with this knowledge not only ensures optimal performance but also encourages a proactive approach to equipment care.

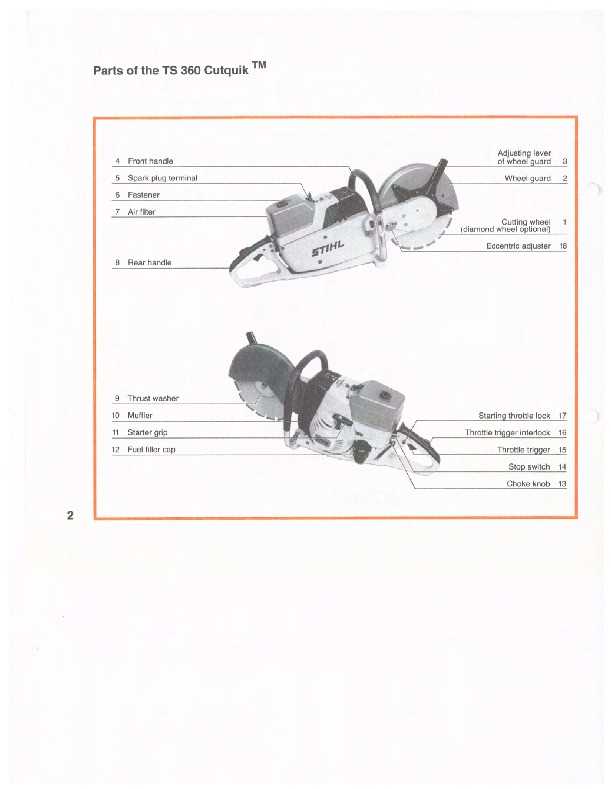

This section outlines the essential elements of a specific cutting tool, focusing on its components and their functions. Understanding each part is crucial for proper maintenance and repair, ensuring optimal performance and longevity of the equipment.

Key Components Overview

The primary elements of this cutting device include:

- Engine assembly

- Blade guard

- Fuel tank

- Handle grips

- Throttle trigger

Functionality of Each Element

Each part plays a vital role in the overall operation:

- Engine assembly: Powers the tool, converting fuel into mechanical energy.

- Blade guard: Protects the user from debris and potential injuries during operation.

- Fuel tank: Stores the necessary fuel for engine operation.

- Handle grips: Provide comfort and control while using the device.

- Throttle trigger: Allows the user to adjust the speed of the engine.

Maintenance Tips

Regular maintenance of each component is essential to ensure efficient functioning:

- Check the engine oil level frequently.

- Inspect the blade guard for damage or wear.

- Clean the fuel tank to prevent clogs.

- Examine handle grips for stability and comfort.

- Test the throttle trigger for responsiveness.

Key Features of the TS360 Model

This model stands out in its category due to a combination of innovative design and powerful performance. Its construction allows for exceptional efficiency, making it suitable for a variety of cutting tasks.

Durability and Build Quality

The robust design ensures longevity and reliability, which are crucial for demanding work environments. Key aspects include:

- High-quality materials that withstand heavy use.

- Reinforced components that reduce wear and tear.

- Weather-resistant features for outdoor applications.

Enhanced Performance

This model is engineered for optimal performance, providing users with a range of benefits:

- Powerful engine for efficient cutting.

- Lightweight structure for easy handling.

- Advanced cooling system to prevent overheating.

Identifying Major Assembly Parts

Understanding the key components of a machine is essential for effective maintenance and repair. Familiarity with the main assembly elements allows users to identify issues and carry out necessary replacements or adjustments efficiently. Each component plays a critical role in the overall functionality, and recognizing them can aid in troubleshooting and ensuring optimal performance.

The primary assemblies typically include the power unit, cutting mechanism, and various housing elements. These sections work together harmoniously to facilitate operation. Knowing how to access and inspect these major components can significantly enhance one’s ability to maintain the equipment effectively.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring your equipment operates at its best. Proper maintenance not only prolongs the lifespan of your tools but also enhances their efficiency. Following a structured maintenance routine can prevent potential issues and ensure reliable performance.

Routine Inspection

Conducting regular inspections is crucial to identify wear and tear. Check the following components frequently:

- Blades and cutting edges

- Air filters for clogs

- Fuel lines for leaks

- Fasteners and screws for tightness

Cleaning and Lubrication

Keeping your equipment clean and properly lubricated is vital for optimal functioning. Consider these steps:

- Remove debris after each use.

- Clean air filters regularly to ensure airflow.

- Apply lubricant to moving parts as specified in the manual.

- Store in a dry place to prevent rust.

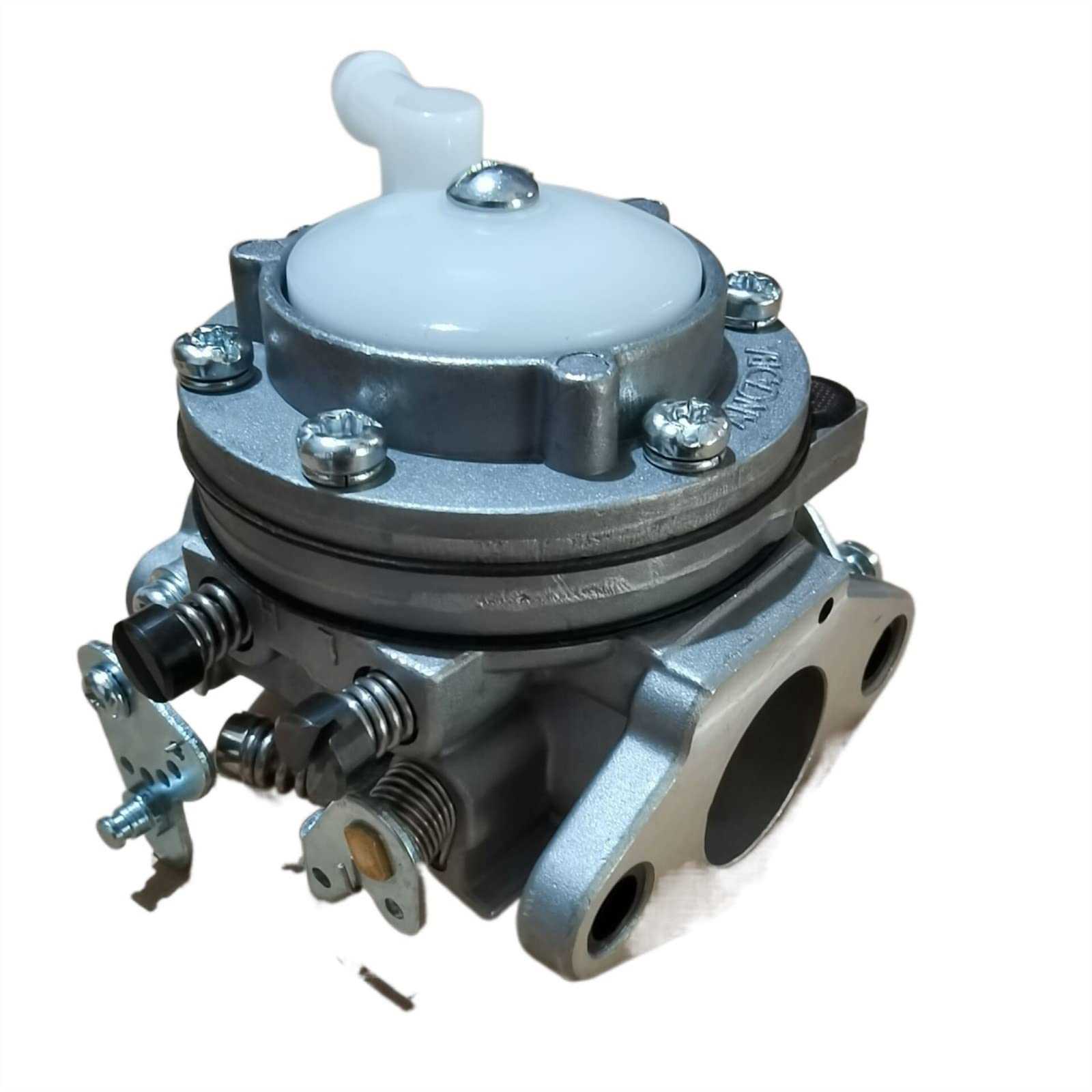

Common Replacement Parts Overview

Understanding the essential components that may require periodic replacement is crucial for maintaining the efficiency of your equipment. Various elements contribute to the overall functionality and performance, ensuring optimal operation over time. Familiarizing yourself with these common items can help streamline repairs and enhance longevity.

Among the frequently replaced components are the cutting blades, which endure significant wear during use. Additionally, air filters play a vital role in maintaining engine performance, as they prevent debris from entering the system. Spark plugs also require regular inspection and replacement to ensure proper ignition and efficient fuel combustion.

Furthermore, fuel lines are susceptible to degradation and may need to be replaced to prevent leaks and maintain fuel delivery efficiency. Finally, it is essential to keep an eye on gaskets and seals, as these elements are crucial for preventing leaks and ensuring the proper functioning of moving parts.

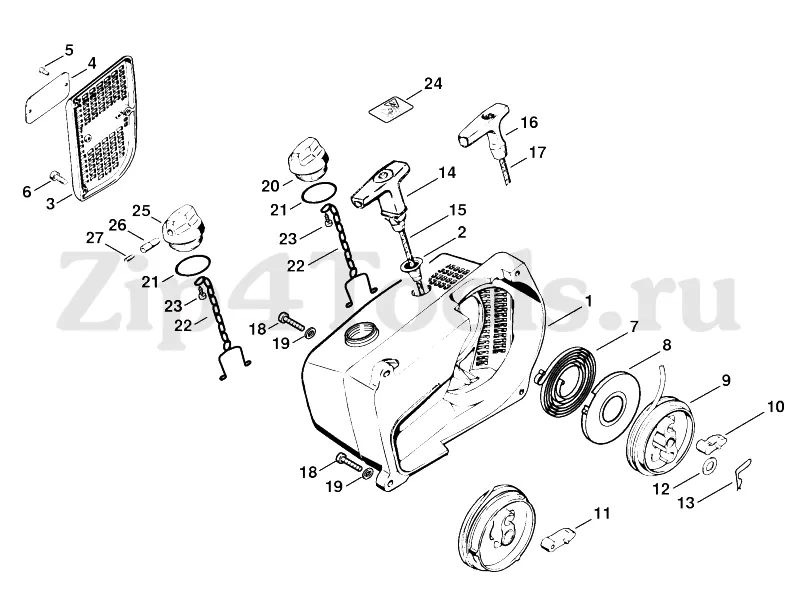

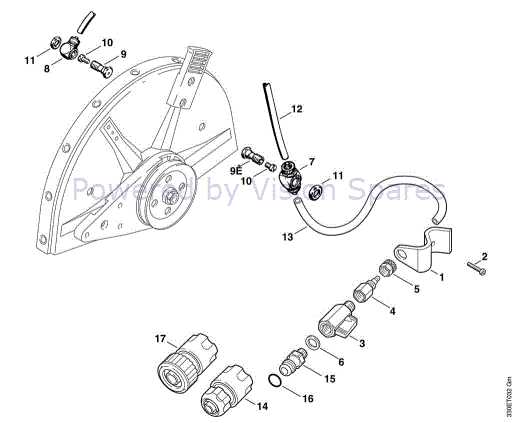

How to Interpret Parts Diagrams

Understanding assembly illustrations is crucial for efficient repairs and maintenance. These visual guides provide a detailed overview of components and their relationships within a machine. By grasping the layout and symbols used, users can accurately identify necessary items and comprehend their arrangement.

To start, familiarize yourself with the various sections of the illustration. Typically, the drawing will display components in a logical sequence, often reflecting their physical arrangement in the machine. Take note of any labels or numbers associated with each part, as these will assist in locating replacements or related resources.

Additionally, it’s important to understand the symbols used in these visuals. Commonly, circles may represent attachment points, while arrows can indicate movement or orientation. Paying attention to these details can enhance your understanding and streamline the repair process.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and accessories related to various machinery. Understanding these aspects can significantly enhance the efficiency and longevity of your equipment.

What should I consider when purchasing components?

When selecting new elements for your machine, it’s crucial to evaluate compatibility, quality, and the manufacturer’s specifications. Always opt for reliable sources to ensure you receive genuine items that meet the necessary standards.

How can I identify the right components for my machine?

To accurately determine which elements are suitable, refer to the user manual or the manufacturer’s website. Many manufacturers provide detailed information, including model numbers and specifications that facilitate the identification process.

| Component | Description |

|---|---|

| Blade | Essential for cutting, available in various sizes and materials. |

| Filter | Helps to keep the engine clean by trapping dust and debris. |

| Fuel Tank | Stores fuel needed for operation, ensuring efficient performance. |

| Spark Plug | Ignites the fuel-air mixture, crucial for starting the engine. |

Where to Find Authentic Components

Locating genuine replacements for your equipment can significantly enhance its performance and longevity. It is essential to source high-quality items to ensure optimal functioning and reliability of your machinery. Below are some recommended avenues for acquiring authentic components.

Authorized Dealers

Visiting an authorized dealer is one of the best ways to secure original components. These suppliers are officially recognized and provide assurance of authenticity. They often have a comprehensive range of products and knowledgeable staff who can assist you in finding the right items for your needs.

Online Marketplaces

Many online platforms specialize in selling genuine replacement items. When utilizing these websites, it’s crucial to check for seller ratings and reviews to ensure you are purchasing from a reputable source. Look for guarantees of authenticity and return policies for peace of mind.

| Source Type | Benefits | Considerations |

|---|---|---|

| Authorized Dealers | Guaranteed authenticity, expert advice | May have higher prices |

| Online Marketplaces | Convenient, wide selection | Need to verify seller reputation |

| Manufacturer’s Website | Direct access to genuine components | Limited availability for some items |

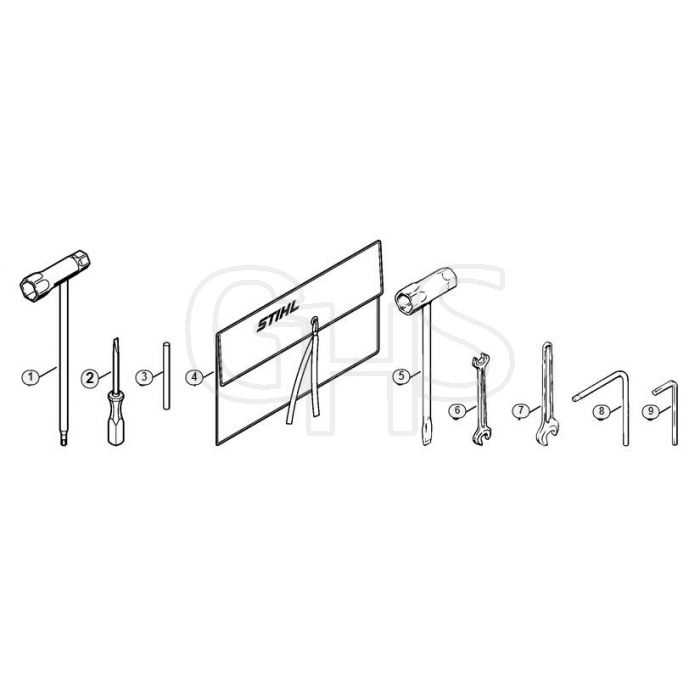

Tools Required for Assembly and Repair

Having the right tools is essential for effective assembly and maintenance of any machinery. Proper equipment not only ensures efficiency but also enhances safety during the repair process. Familiarity with the necessary tools can significantly simplify tasks and lead to successful outcomes.

To begin with, a set of screwdrivers with varying head types is crucial for loosening or tightening screws. Wrenches in different sizes will also be required for adjusting bolts and nuts securely. Additionally, pliers can be invaluable for gripping and manipulating small components. A sturdy workbench will provide a reliable surface for assembly tasks.

Moreover, it is advisable to have a torque wrench on hand to ensure that fasteners are tightened to the manufacturer’s specifications. A safety knife may be needed for cutting materials or removing packaging. Lastly, organization tools, such as trays or bins, can help keep components sorted and easily accessible throughout the assembly or repair process.

Safety Guidelines for Using Parts

When working with machinery components, adhering to safety protocols is essential for preventing accidents and ensuring optimal performance. Proper understanding of each element’s function and installation procedures minimizes risks associated with equipment use.

Before handling any components, wear appropriate personal protective equipment such as gloves and safety goggles. Inspect all items for damage or wear before installation; replacing defective pieces is crucial to maintaining functionality. Follow the manufacturer’s instructions for assembly and disassembly to avoid errors that could lead to operational hazards.

Ensure the workspace is clean and well-lit, reducing the likelihood of accidents. Additionally, familiarize yourself with emergency procedures and keep first aid supplies accessible. Regular maintenance and checks of tools and components enhance safety and prolong the lifespan of the machinery.