Comprehensive Guide to Briggs and Stratton 10T502 Parts Diagram

When it comes to maintaining outdoor machinery, having a clear understanding of the individual elements that comprise the engine is essential. This knowledge not only facilitates efficient repairs but also enhances the longevity of your equipment. Each component plays a crucial role in the overall functionality, ensuring optimal performance during operation.

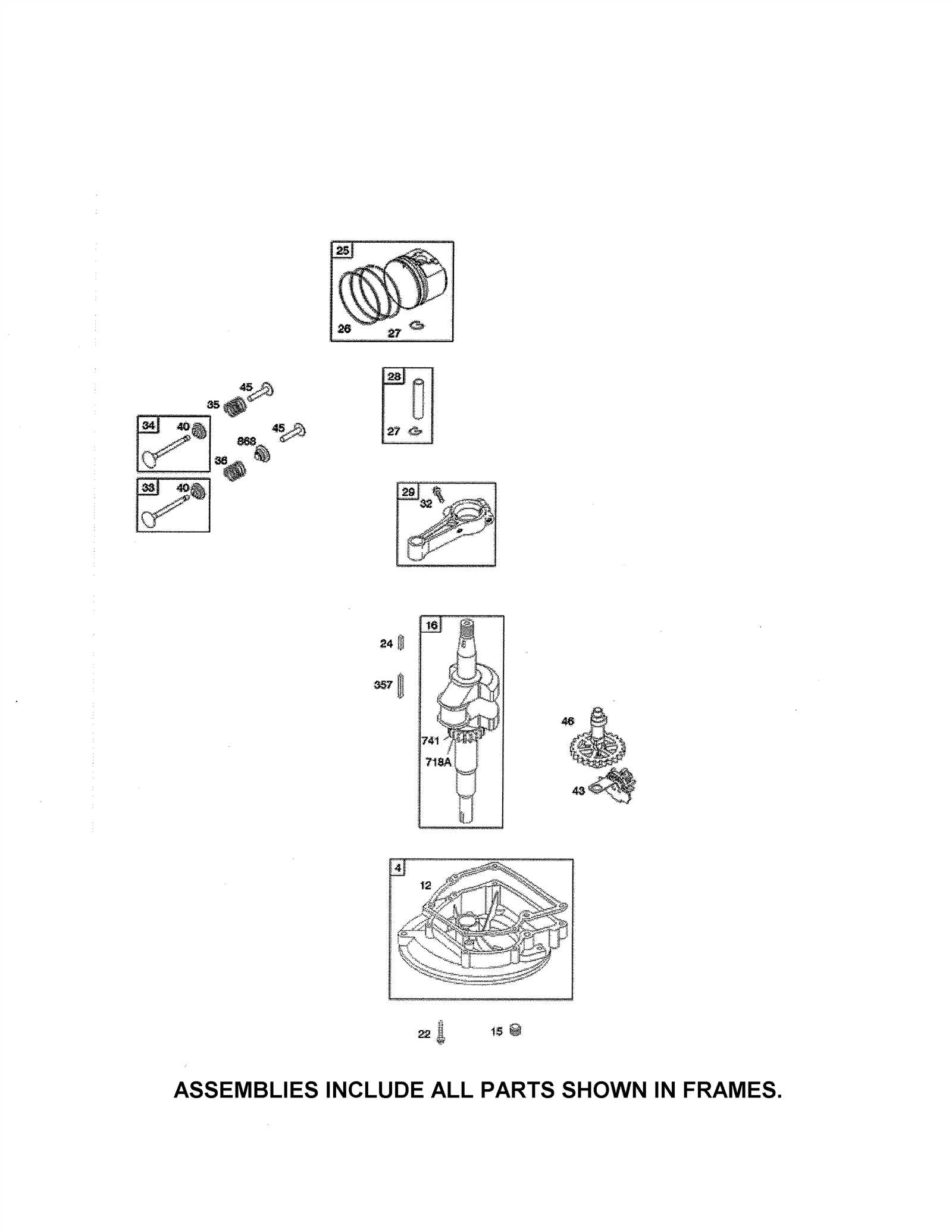

Visual representations serve as invaluable tools for identifying various segments of the engine. They provide clarity, allowing users to pinpoint specific parts quickly and easily. Whether you’re troubleshooting issues or planning routine maintenance, these illustrations offer a roadmap to navigate the intricate assembly.

By examining the layout of the components, users can delve deeper into the mechanics of their machinery. This understanding empowers owners to make informed decisions regarding repairs and upgrades, ultimately leading to improved reliability and efficiency in their outdoor tasks.

Understanding the Briggs and Stratton 10T502

This section delves into the essential aspects of a specific engine model, focusing on its construction, functionality, and maintenance requirements. By examining various components and their roles, one can gain a comprehensive understanding of how this power unit operates effectively in various applications.

Key Features

- Compact design that ensures versatility in usage

- Efficient fuel consumption for prolonged operation

- Durable materials that enhance longevity and reliability

Maintenance Tips

- Regularly check the oil level and replace it as needed.

- Clean or replace the air filter to ensure optimal airflow.

- Inspect the spark plug for wear and replace if necessary.

- Keep the cooling system free from debris to prevent overheating.

By following these maintenance practices, users can ensure their engine remains in peak condition, providing consistent performance over time.

Key Components of the Engine

An internal combustion engine comprises several critical elements that work together to produce power efficiently. Each part plays a vital role in the engine’s operation, contributing to its overall performance and reliability. Understanding these components is essential for effective maintenance and repair.

The crankshaft serves as the heart of the engine, converting linear motion from the pistons into rotational energy. The pistons, housed within the cylinders, move up and down, creating pressure that drives the crankshaft. Meanwhile, the camshaft regulates the timing of the valve openings and closings, ensuring optimal airflow and combustion.

The fuel system, including the carburetor or fuel injector, delivers the right mixture of air and fuel to the combustion chamber. This mixture is ignited by the spark plug, initiating the combustion process. The exhaust system then expels gases produced during combustion, helping to maintain engine efficiency and performance.

Additionally, lubrication is provided by the oil pump, which circulates oil throughout the engine to minimize friction and wear. Cooling is managed by the cooling system, typically utilizing a radiator and water pump to maintain optimal operating temperatures.

Each of these components is essential for the smooth operation of the engine, making knowledge of their functions crucial for anyone involved in engine care and repair.

Importance of a Parts Diagram

Understanding the significance of a visual representation of components is crucial for effective maintenance and repair tasks. These illustrations provide a comprehensive overview of individual elements, allowing users to identify and locate each piece with precision.

Clarity in seeing how parts interact enhances the ability to troubleshoot issues efficiently. A well-organized illustration not only simplifies the identification of components but also serves as a valuable reference during reassembly.

Moreover, these visuals can significantly reduce the risk of errors, ensuring that every element is in its rightful place. This ultimately leads to better performance and longevity of the machinery.

Common Issues with 10T502 Engines

Engines in this category often face several recurring problems that can affect their performance and longevity. Understanding these issues is essential for maintaining optimal functionality and ensuring efficient operation over time.

Frequent Problems

Some of the typical challenges encountered include fuel delivery issues, starting difficulties, and overheating. Each of these can stem from various factors, ranging from worn components to improper maintenance practices.

Maintenance Tips

Regular upkeep is crucial in preventing these common complications. Routine checks and timely replacements can significantly enhance the engine’s reliability and efficiency.

| Issue | Possible Cause | Solution |

|---|---|---|

| Fuel Delivery Problems | Clogged filter or damaged lines | Replace filters and inspect fuel lines |

| Starting Difficulties | Weak battery or faulty spark plug | Test battery and replace spark plugs |

| Overheating | Blocked cooling fins or low oil | Clean cooling areas and check oil levels |

How to Use the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. This guide will help you navigate the schematic, enabling you to identify each element clearly, ensuring you can efficiently source replacements or troubleshoot issues.

Identifying Components

Begin by familiarizing yourself with the layout. Each section is typically labeled, allowing you to pinpoint specific elements. Pay attention to numbers and references, as these will guide you in locating parts within a supplier’s catalog or a repair manual.

Finding Replacement Items

Once you have identified the necessary components, use the corresponding identifiers to search for replacements. This can save time and prevent confusion when ordering. Make sure to verify compatibility with your model to avoid any issues.

| Component | Description | Part Number |

|---|---|---|

| Filter | Air filtration component | 123456 |

| Spark Plug | Ignition component | 789012 |

| Carburetor | Fuel mixing device | 345678 |

Where to Find Replacement Parts

When seeking components for small engines, numerous options are available to ensure optimal performance. Exploring various sources can help users locate the necessary items efficiently, catering to both budgetary needs and quality requirements.

Local hardware stores often stock essential items, providing immediate access for quick repairs. Online retailers offer a vast selection, allowing users to compare prices and find specific components easily. Manufacturer websites may also provide direct purchasing options, ensuring authenticity.

Additionally, specialized forums and community groups can be invaluable for recommendations and advice on sourcing hard-to-find components. Utilizing these resources can simplify the process of maintaining and restoring equipment to peak condition.

Step-by-Step Repair Guide

This section provides a comprehensive approach to tackling common issues with small engine units. Following a structured method can help identify problems, replace faulty components, and ensure smooth operation. With the right tools and a bit of patience, anyone can perform repairs effectively.

Identifying the Problem

Begin by observing the symptoms of the malfunction. Listen for unusual noises, check for leaks, and assess the performance. Make a note of any irregularities, as this information will guide the troubleshooting process. Familiarize yourself with the engine’s components to better understand where the issue might lie.

Gathering Necessary Tools

Before starting the repair, collect all required tools and replacement items. Common tools include wrenches, screwdrivers, pliers, and specialized equipment as needed. Ensure that replacement components match the specifications of your engine. Having everything ready will streamline the repair process and minimize downtime.

Following these steps will help ensure a thorough and efficient repair, leading to optimal performance and longevity of your equipment.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of any small engine. Regular attention to key components can prevent breakdowns and ensure optimal performance over time. Following a few simple guidelines can greatly enhance reliability and efficiency.

| Task | Frequency | Notes |

|---|---|---|

| Check oil level | Every use | Maintain optimal oil level to ensure proper lubrication. |

| Change oil | Every 50 hours | Use recommended oil type for best results. |

| Inspect air filter | Every month | Clean or replace as needed to ensure airflow. |

| Sharpen blades | Every season | Keep blades sharp for effective cutting. |

| Clean spark plug | Every season | Check for wear and replace if necessary. |

| Check fuel system | Before storage | Use fresh fuel and consider adding stabilizer. |

Following these maintenance practices will not only enhance performance but also save time and money in the long run. Consistent care leads to a reliable machine ready for any task.

Tools Required for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right equipment is essential for achieving efficient and effective results. Utilizing the appropriate tools not only simplifies the repair process but also ensures that the equipment remains in optimal condition.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are indispensable for most repair tasks. A socket set is particularly useful for reaching various fasteners, while a reliable torque wrench helps in applying the correct amount of force to bolts, preventing damage.

Specialized Equipment

In addition to standard tools, certain specialized items may be required for more complex repairs. For instance, a fuel line cutter can facilitate the replacement of fuel lines without unnecessary spillage, while a spark plug socket is essential for accessing and replacing the ignition components efficiently.

Upgrading Your Engine Components

Enhancing the performance of your power unit can lead to significant improvements in efficiency and longevity. By focusing on various components, you can optimize functionality and achieve better results in your tasks.

Consider the following areas for potential upgrades:

- Air Intake: Upgrading the air filter or intake system can increase airflow, leading to improved combustion and performance.

- Fuel System: Installing a higher quality fuel filter or optimizing the carburetor can enhance fuel delivery, resulting in better efficiency.

- Exhaust: An upgraded exhaust system can reduce back pressure, allowing for more efficient expulsion of gases and improved engine sound.

- Ignition System: Replacing the spark plug or ignition coil can improve starting reliability and enhance power output.

When selecting components, it is essential to consider compatibility and the specific requirements of your engine. Researching available options and consulting with experts can lead to informed decisions that yield the best outcomes.

In conclusion, investing in quality upgrades not only improves performance but also contributes to the overall lifespan of your machinery. Make thoughtful choices to ensure your engine operates at its best.

Customer Reviews and Experiences

This section focuses on the insights and feedback from users regarding their interactions with a well-known small engine model. Customer opinions provide valuable perspectives on performance, reliability, and overall satisfaction, which can guide potential buyers in their decision-making process.

Positive Feedback

Many users express high satisfaction with the engine’s efficiency and ease of use. Customers often highlight its robust construction, which contributes to longevity and minimal maintenance. One user noted that the power output was more than adequate for their needs, making tasks such as lawn care and yard work effortless.

Challenges Faced

While most reviews are favorable, some customers have encountered challenges. Issues such as starting difficulties or parts compatibility can arise, leading to frustration. However, many users appreciate the availability of replacement components, which helps mitigate these concerns. Overall, the community support and resources available enhance the ownership experience.