Comprehensive Guide to Briggs and Stratton 550EX Parts Diagram

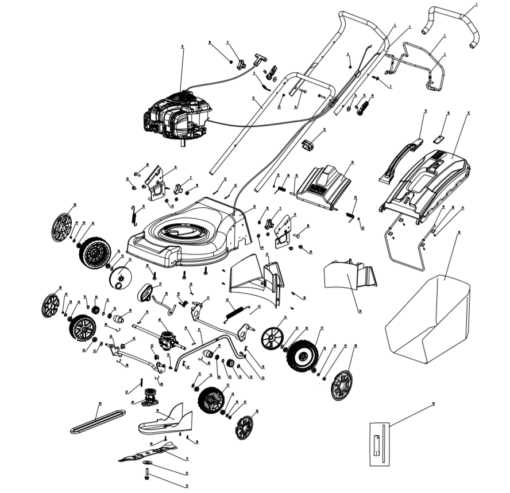

In the realm of small machinery, knowing the layout of essential elements can greatly enhance the maintenance and repair process. Recognizing how various components interact not only facilitates smoother operation but also extends the lifespan of your equipment. This knowledge is invaluable for both amateur enthusiasts and seasoned professionals alike.

Visual aids play a crucial role in this understanding. By studying a comprehensive layout of engine segments, users can identify each piece’s function and its relationship to others. This insight is particularly beneficial when troubleshooting issues or performing routine checks.

Furthermore, having a clear overview of these components enables individuals to source replacements or upgrades effectively. Being equipped with the right information empowers users to make informed decisions, ensuring optimal performance and reliability in their machinery.

Understanding Briggs and Stratton 550EX Engine

The engine discussed here represents a blend of efficiency and reliability, making it a popular choice for various outdoor equipment. Its design focuses on delivering consistent performance while being user-friendly. This section aims to provide insights into the fundamental components and functionalities that contribute to its operation.

Key Features

This power unit is equipped with several distinctive characteristics that enhance its performance. Notably, the advanced air filtration system ensures optimal air intake, promoting combustion efficiency. Additionally, the engine boasts an easy-start mechanism, reducing the effort required to initiate operation. Such features make it ideal for both novice and experienced users.

Maintenance Considerations

Proper upkeep is essential for prolonging the lifespan of this engine. Regular checks of essential elements, such as the fuel system and spark plug, can prevent potential issues. Keeping the exterior clean and ensuring that the cooling system functions effectively also contributes to maintaining peak performance. By adhering to these maintenance practices, users can enjoy a reliable power source for years to come.

Key Components of the 550EX Model

This section highlights the essential elements of the engine model, focusing on the various parts that contribute to its functionality and performance. Understanding these components is crucial for maintenance and troubleshooting.

- Air Filter: Ensures clean air intake, protecting the internal mechanisms from dirt and debris.

- Fuel Tank: Holds the necessary fuel for operation, designed for easy refueling and efficient use.

- Cylinder Head: Houses critical parts like valves and spark plugs, playing a vital role in combustion.

- Crankshaft: Converts linear motion into rotational energy, powering the engine.

- Ignition System: Responsible for starting the engine by generating a spark at the right moment.

Each of these components works in concert to ensure optimal performance, durability, and efficiency. Regular inspection and maintenance of these parts can significantly extend the lifespan of the engine.

- Check the air filter regularly to prevent airflow restrictions.

- Ensure the fuel tank is clean to avoid contamination.

- Inspect the ignition system for reliable starting.

By familiarizing oneself with these key components, users can better understand the operation and maintenance of the engine model.

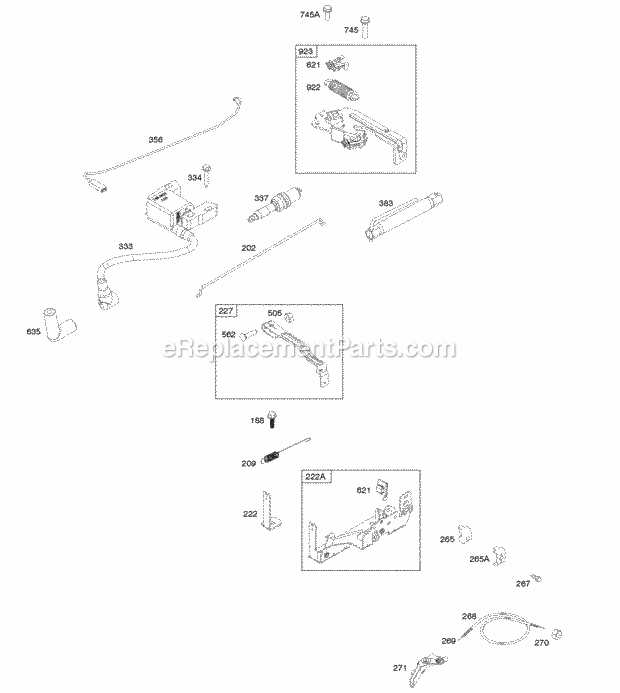

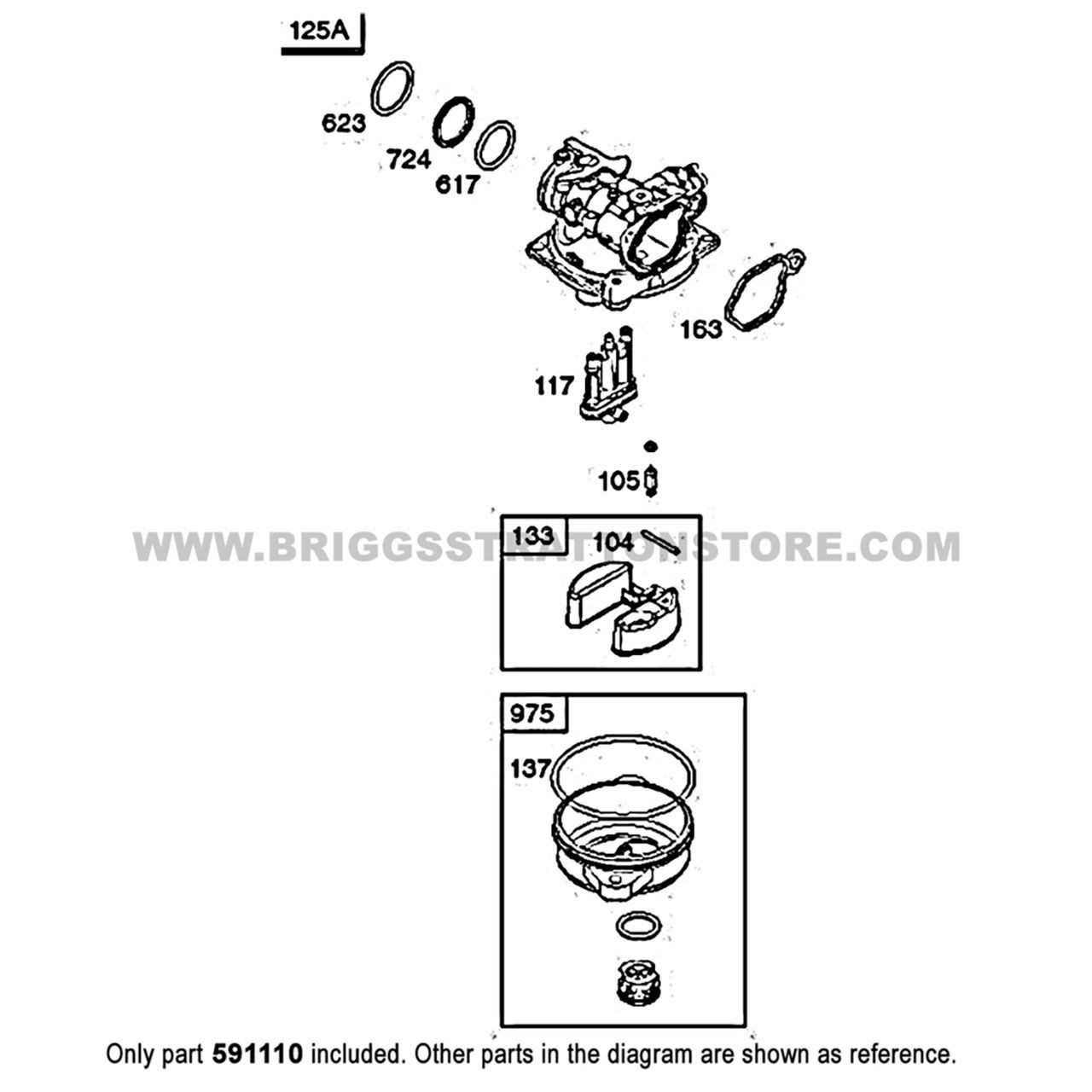

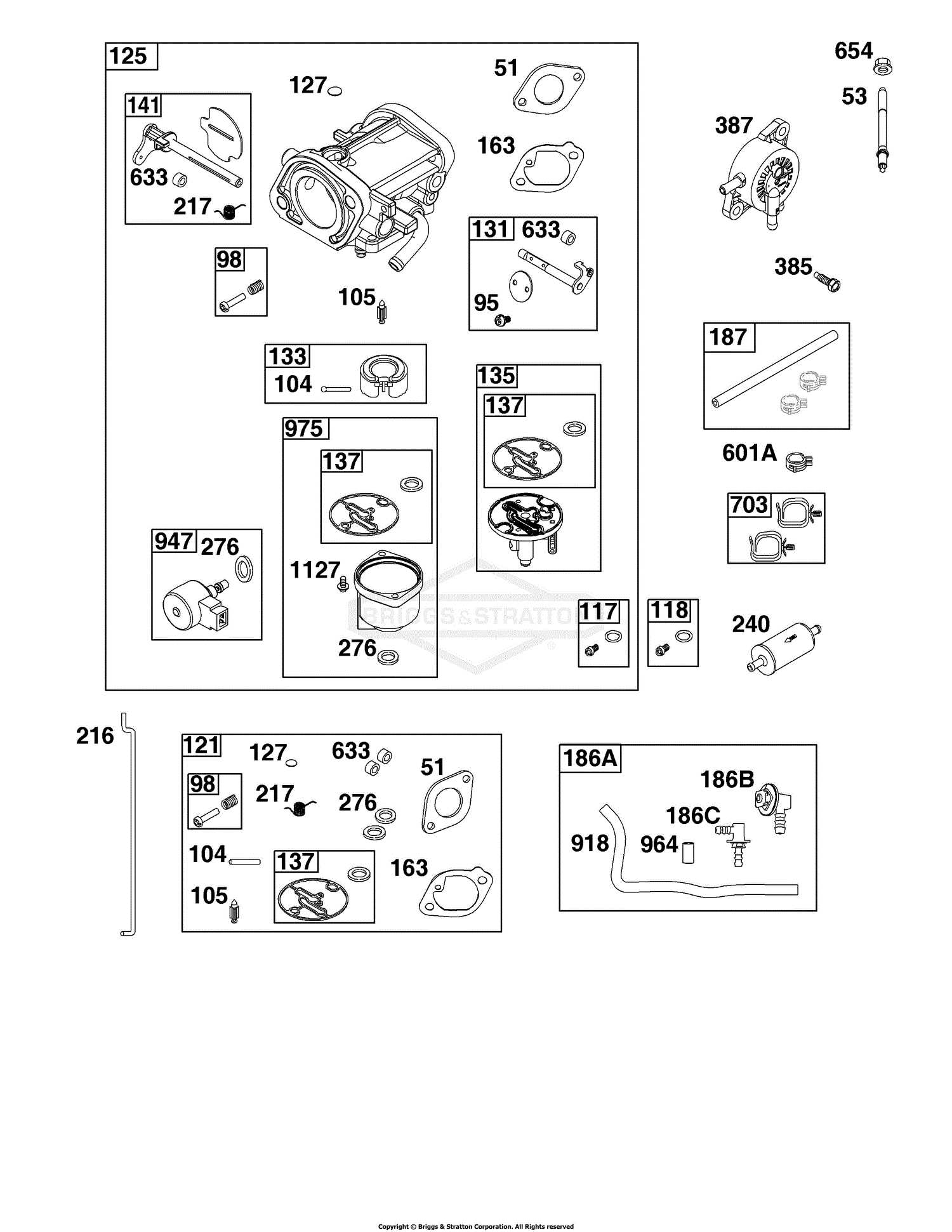

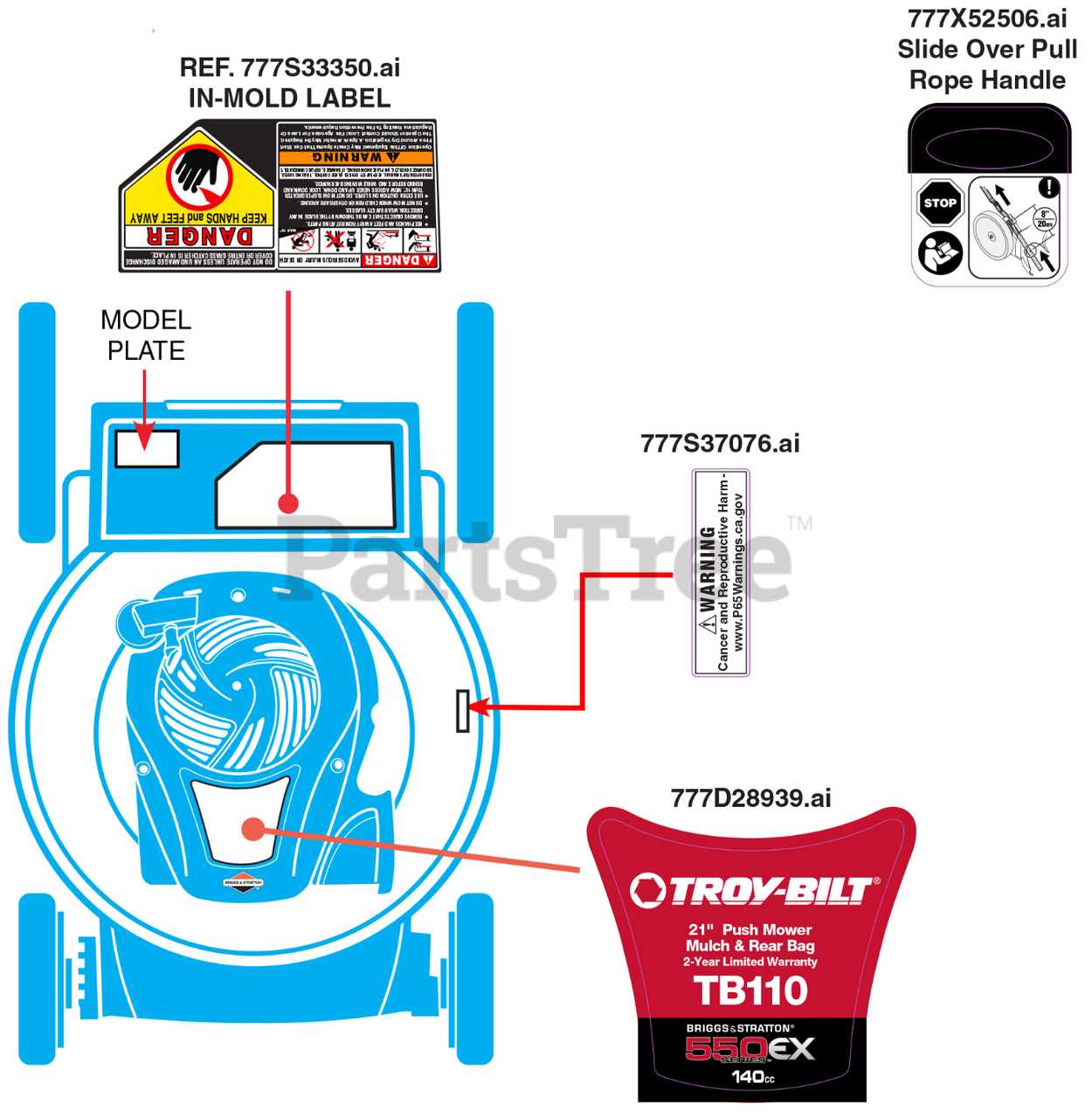

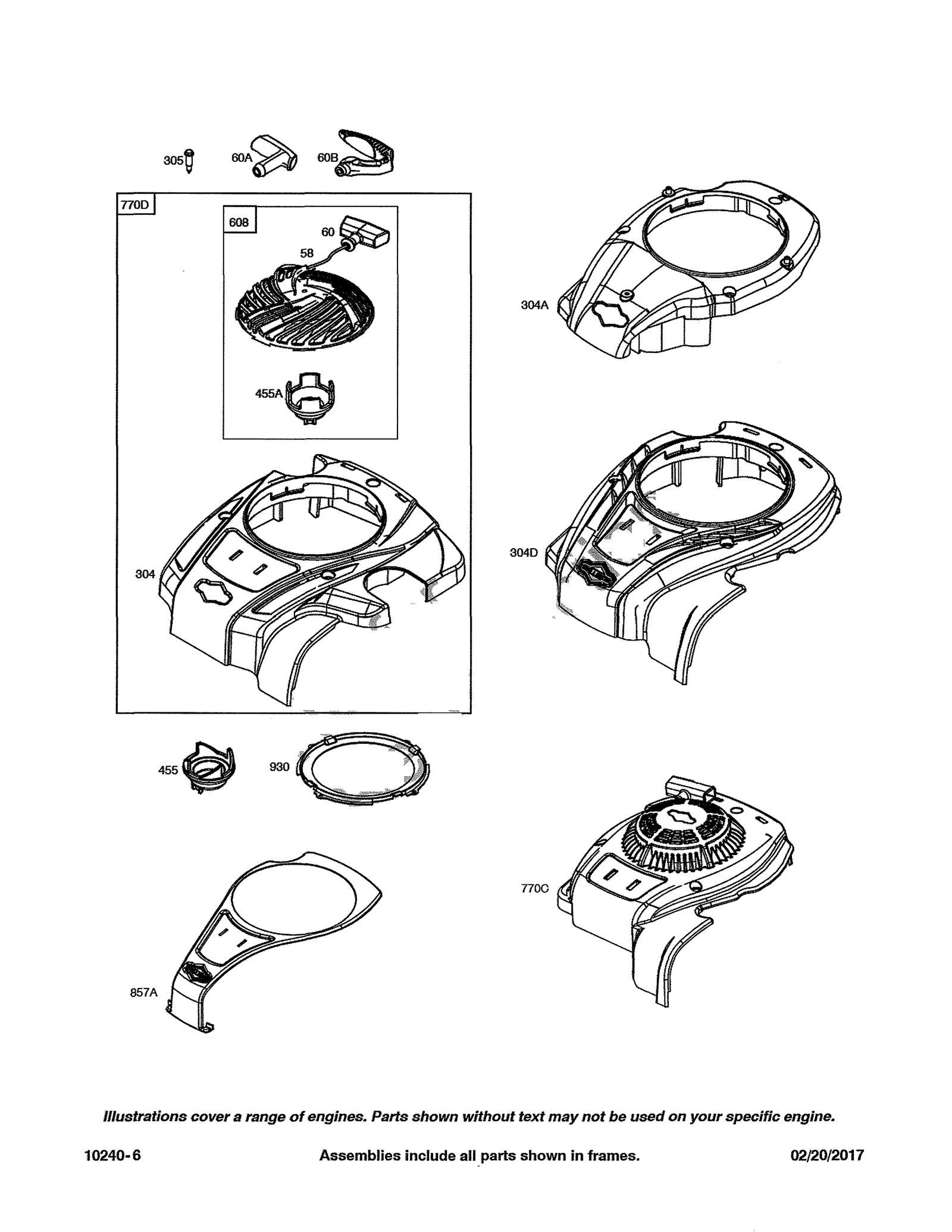

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to assemble or repair equipment. These illustrations serve as a guide, showing the arrangement and relationships of individual elements within a machine. Familiarizing yourself with these visuals is essential for effective maintenance and troubleshooting.

Here are some key tips to help you interpret these visuals:

- Identify Symbols: Different shapes and lines often represent specific items or actions. Familiarize yourself with common symbols used in these illustrations.

- Follow Numbering: Items are typically numbered for easy reference. Make sure to match these numbers with a corresponding list that provides detailed descriptions.

- Group Similar Items: Look for clusters or sections where similar components are grouped together. This can help you understand how various parts interact.

- Orientation Matters: Pay attention to the orientation of the parts. Sometimes, components may appear differently based on their position in the assembly.

- Check for Notes: Annotations may provide additional information, such as assembly tips or warnings. Be sure to read these closely.

By following these guidelines, you’ll improve your comprehension of visual component representations, enabling more efficient repairs and maintenance tasks.

Common Replacement Parts Explained

Understanding the essential components of small engines can significantly enhance their performance and longevity. Familiarizing oneself with frequently needed replacements can help ensure smooth operation and prevent unexpected breakdowns. Each element plays a vital role in the overall functionality, and recognizing their purposes is crucial for effective maintenance.

One of the most commonly replaced items is the air filter. This component keeps dirt and debris from entering the engine, which can cause wear and reduce efficiency. Regular replacement of the air filter ensures that the engine breathes properly, leading to improved performance and fuel economy.

The spark plug is another critical element that often requires attention. It ignites the fuel-air mixture, enabling the engine to run. Over time, spark plugs can wear out or become fouled, leading to starting issues or poor performance. Regular inspection and timely replacement can keep the engine running smoothly.

Fuel filters are essential for maintaining clean fuel flow to the engine. Contaminants in the fuel can lead to clogging and decreased performance. Replacing the fuel filter periodically helps protect the engine from potential damage and ensures optimal fuel delivery.

Finally, the oil filter is crucial for keeping the engine lubricated and free of contaminants. Regular oil changes and filter replacements are necessary to maintain engine health, ensuring that all moving parts operate smoothly and efficiently.

Maintenance Tips for Optimal Performance

Ensuring that your outdoor power equipment operates at its best involves regular care and attention. Proper maintenance not only enhances performance but also extends the lifespan of the machinery. Here are some essential practices to keep your engine running smoothly.

Routine Checks

- Inspect air filters regularly; clean or replace them as needed to ensure proper airflow.

- Check oil levels frequently; change the oil according to the manufacturer’s recommendations to maintain engine health.

- Examine spark plugs for wear; replace them if they show signs of damage or fouling.

Seasonal Preparations

- Before the start of each season, ensure that fuel is fresh; old fuel can lead to starting issues and poor performance.

- Clean the exterior of the unit to remove dirt and debris that can affect operation.

- Inspect all belts and hoses for signs of wear; replace any components that are cracked or frayed.

By following these maintenance tips, you can help ensure that your equipment runs efficiently and effectively, reducing the likelihood of breakdowns and costly repairs.

Identifying Engine Issues Through Diagrams

Understanding the inner workings of a small engine can be crucial for diagnosing and resolving performance issues. Utilizing visual representations of engine components allows users to pinpoint areas that may require attention. This method not only simplifies the troubleshooting process but also enhances the overall efficiency of maintenance.

Diagrams serve as valuable tools in identifying common problems. Here are some key advantages of using these visual aids:

- Clarity: Visual aids provide a clear picture of each component’s location and function.

- Easy Reference: Users can quickly refer to diagrams to locate parts without extensive manuals.

- Efficient Troubleshooting: Identifying faulty components becomes faster and more straightforward.

To effectively use these representations, consider the following steps:

- Start by examining the overall layout to familiarize yourself with the engine’s structure.

- Identify specific sections related to the symptoms you observe, such as overheating or lack of power.

- Trace connections and components that may be linked to the issue at hand.

By following this approach, users can enhance their understanding of engine mechanics and tackle issues more confidently. Utilizing visual tools not only simplifies the repair process but also empowers individuals to maintain their equipment effectively.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential for ensuring optimal performance and longevity. Genuine items not only guarantee compatibility but also enhance the reliability of your machinery. Whether you’re a professional or a DIY enthusiast, knowing where to source these elements can save you time and prevent future issues.

Authorized Retailers

One of the most reliable sources for authentic components is through authorized retailers. These establishments are officially recognized by manufacturers and typically stock a wide range of original items. Always check the retailer’s credentials to ensure you are purchasing genuine products.

Manufacturer’s Website

The official website of the manufacturer often features a dedicated section for components. Here, you can browse the available selection and find detailed information on each item. Purchasing directly from the source ensures that you receive the right parts designed specifically for your equipment.

In conclusion, prioritizing genuine items is crucial for maintaining the efficiency and safety of your machinery. Utilizing authorized retailers and official websites are two of the best strategies to find the components you need.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your small engine, ensuring it operates efficiently and reliably. By following the outlined procedures, you can troubleshoot common issues, replace necessary components, and perform maintenance tasks effectively. This guide is designed for both novice and experienced users, simplifying the repair process into manageable steps.

Identifying the Issue

Begin by assessing the symptoms your engine is displaying. Common problems include difficulty starting, irregular operation, or reduced power. Carefully listen for unusual sounds and observe any visible leaks. Document your findings, as this information will be crucial when determining the necessary actions to take.

Gathering Tools and Components

Once you’ve identified the problem, collect the required tools and replacement parts. Essential tools may include wrenches, screwdrivers, and pliers. Ensure you have access to high-quality replacement components that match your engine’s specifications. A well-organized workspace will facilitate the repair process and improve efficiency.

Comparing 550EX with Other Models

When evaluating small engine options, it is essential to consider various models available on the market. This section highlights key differences and similarities among different engines, focusing on performance, efficiency, and user experience.

Performance Features

- Power Output: Different engines vary in horsepower, impacting their suitability for various tasks.

- Torque Levels: Higher torque can enhance performance in demanding conditions, making certain models more effective for heavy-duty use.

- Speed Variability: Some engines offer adjustable speed settings, allowing for greater control over operation.

Efficiency and Maintenance

- Fuel Consumption: Compare the efficiency ratings, as some engines are designed to use fuel more sparingly.

- Maintenance Requirements: Look into the frequency and complexity of required maintenance to ensure ease of use.

- Durability: Assess build quality and material, as this can significantly affect the longevity of the engine.

Understanding these aspects allows users to make informed choices when selecting the most suitable engine for their needs.

Tools Needed for DIY Repairs

Undertaking home repairs can be both rewarding and practical. Having the right equipment on hand is crucial for ensuring tasks are completed efficiently and effectively. This section outlines the essential tools that can facilitate various repair projects, helping you achieve professional results.

Essential Hand Tools

When it comes to basic maintenance, a selection of hand tools is indispensable. Wrenches and screwdrivers in various sizes are fundamental for loosening and tightening components. Pliers are also useful for gripping, twisting, and cutting, making them a versatile addition to any toolkit. Furthermore, a good quality hammer can assist in driving nails and fitting parts securely.

Power Tools for Enhanced Efficiency

In addition to hand tools, incorporating power tools can significantly speed up the repair process. A reliable drill is essential for creating holes or driving screws, while a saw can be invaluable for cutting materials to size. Lastly, an air compressor can provide the power needed for various pneumatic tools, further enhancing your ability to tackle larger projects with ease.

Frequently Asked Questions on 550EX

This section addresses common inquiries related to the specific engine model. It aims to provide clarity on maintenance, performance, and troubleshooting aspects for users seeking reliable information.

Maintenance Tips

Regular upkeep is crucial for optimal functioning. Here are some essential practices:

| Task | Frequency |

|---|---|

| Oil Change | Every 50 hours of use |

| Air Filter Cleaning | Every 25 hours of use |

| Spark Plug Replacement | Every 100 hours of use |

Troubleshooting Common Issues

If you encounter problems, consider the following solutions:

| Issue | Possible Solution |

|---|---|

| Engine Won’t Start | Check fuel level and spark plug condition |

| Loss of Power | Inspect air filter and clean or replace if necessary |

| Unusual Noises | Examine for loose components or foreign objects |

Benefits of Using Original Components

Utilizing authentic parts for machinery maintenance ensures optimal performance and longevity. These components are specifically designed to fit and function seamlessly with your equipment, resulting in enhanced efficiency and reliability.

- Quality Assurance: Original items are manufactured under strict quality control standards, ensuring durability and performance.

- Perfect Fit: These components are tailored to match the specifications of your equipment, reducing the risk of misalignment and operational issues.

- Warranty Protection: Using genuine parts often helps maintain warranty coverage, protecting your investment.

- Improved Performance: Authentic components are engineered to work harmoniously with other parts, leading to better overall functionality.

- Safety: Original parts are designed with safety in mind, reducing the likelihood of accidents or malfunctions during operation.

Incorporating these genuine components ultimately leads to a more efficient and reliable machine, making it a worthwhile investment for any operator.