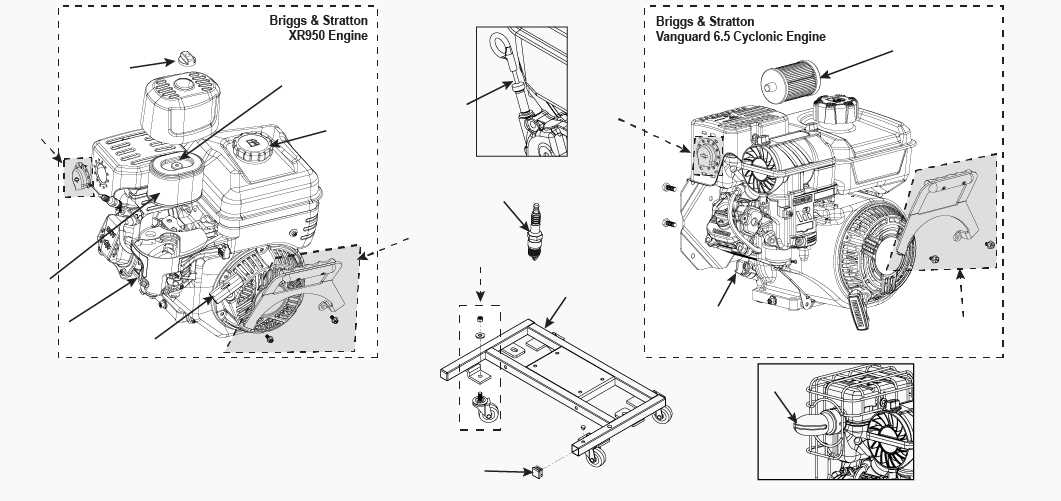

Comprehensive Guide to Briggs and Stratton 6.5 HP Engine Vertical Shaft Parts Diagram

In the realm of small power units, comprehending the intricate assembly of its components is essential for effective maintenance and troubleshooting. Each element plays a crucial role in the overall functionality, ensuring optimal performance during operation.

Familiarity with the various sections allows users to identify potential issues and facilitates timely repairs. A clear illustration serves as a valuable reference, guiding enthusiasts and professionals alike through the complexities of their machinery.

Whether for personal projects or professional applications, a thorough grasp of these mechanical details enhances the user’s capability to manage and service their equipment efficiently. This knowledge ultimately contributes to prolonged lifespan and reliability of the unit.

Understanding Briggs and Stratton Engines

Familiarizing oneself with small power units can greatly enhance the ability to maintain and troubleshoot various outdoor equipment. These compact machines play a crucial role in powering lawnmowers, generators, and numerous other tools, making them essential for both residential and commercial applications.

Key Components of Small Power Units

To fully grasp how these units operate, it’s important to understand their primary elements:

- Fuel System: Supplies the necessary fuel for combustion.

- Ignition System: Initiates the combustion process, enabling the unit to start.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Lubrication System: Ensures smooth operation by reducing friction between moving parts.

Common Applications

These versatile units are employed in a variety of tasks, including:

- Lawn maintenance with mowers and trimmers.

- Power generation for portable and standby units.

- Garden equipment like tillers and blowers.

- Construction tools such as concrete mixers and pressure washers.

Understanding the functionality and components of these small machines is vital for effective maintenance and repair, ensuring longevity and reliability in their performance.

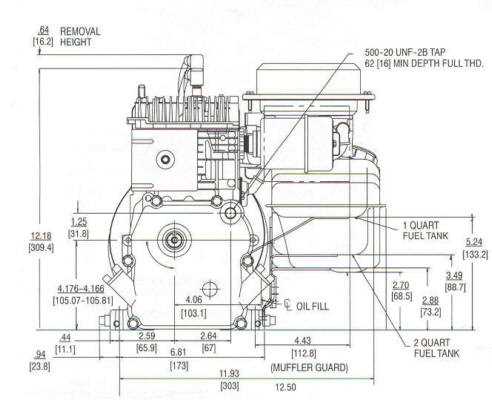

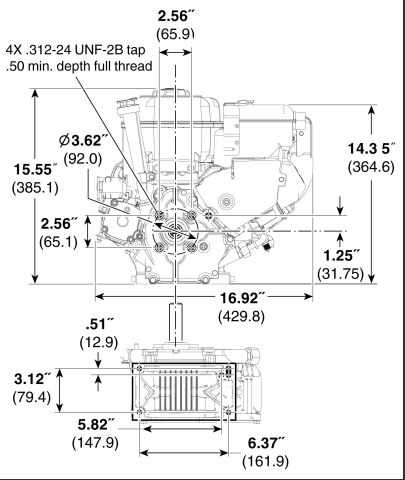

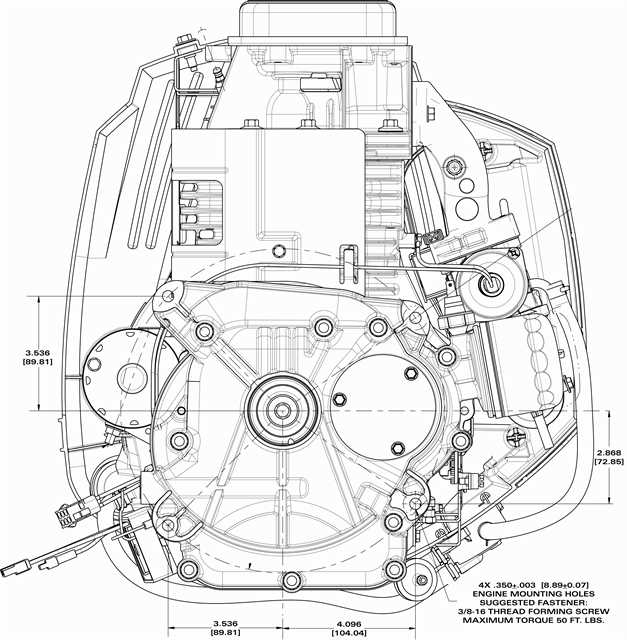

Overview of Vertical Shaft Engines

This section explores a specific category of power sources widely used in various outdoor equipment. These machines feature a unique construction that optimizes their functionality and adaptability for numerous applications, ranging from gardening tools to industrial machinery.

Design and Functionality

The construction of these power units allows for a compact layout, enabling efficient operation in confined spaces. Their orientation facilitates seamless integration with attachments, enhancing their versatility. Additionally, the unique arrangement of components contributes to effective torque delivery, ensuring reliable performance even under demanding conditions.

Applications and Benefits

Such power sources are prevalent in lawn care, construction, and agricultural sectors. Their durability and ease of maintenance make them a preferred choice for both professionals and hobbyists. The ability to perform consistently over extended periods, combined with lower operational costs, further solidifies their reputation in the market.

In summary, this type of machinery represents a vital component in the landscape of power solutions, showcasing innovation and efficiency in design and application.

Key Features of 6.5 HP Engines

This section explores the essential characteristics that make small power units effective for various applications. Understanding these attributes helps users select the right model for their needs.

Performance and Efficiency

High-output motors are designed for optimal performance, providing a balance between power and fuel efficiency. They are ideal for tasks requiring sustained energy without excessive consumption.

Durability and Maintenance

These units are built to withstand rigorous conditions, featuring robust materials that enhance longevity. Regular upkeep is straightforward, ensuring reliable operation over time.

| Feature | Description |

|---|---|

| Power Output | Delivers substantial energy for various tasks. |

| Fuel Efficiency | Optimized to minimize consumption while maximizing performance. |

| Durability | Constructed with strong materials to endure tough environments. |

| Ease of Maintenance | Designed for quick and simple servicing procedures. |

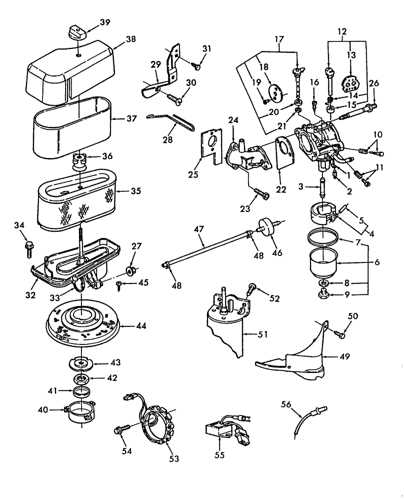

Importance of Engine Diagrams

Understanding mechanical structures is crucial for effective maintenance and repair. Visual representations play a significant role in this process, offering clarity and guidance. They allow users to quickly identify components and their functions, ultimately enhancing troubleshooting efficiency.

Diagrams serve as vital tools in both educational settings and practical applications. They simplify complex information, enabling even novices to grasp intricate details. Additionally, these visual aids foster better communication among technicians and enthusiasts, ensuring everyone is on the same page during discussions.

Furthermore, having a reliable reference reduces the risk of errors during assembly or disassembly. With accurate representations, users can confidently tackle projects, saving time and minimizing frustration. Overall, the value of these visual guides cannot be overstated in the realm of mechanical upkeep.

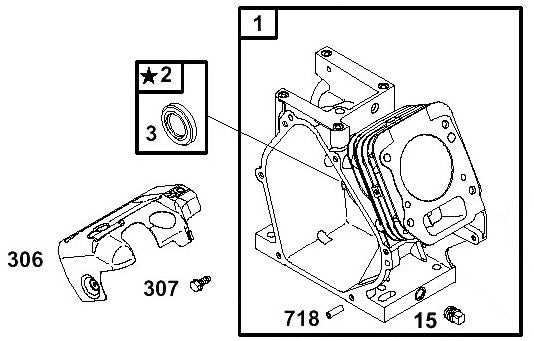

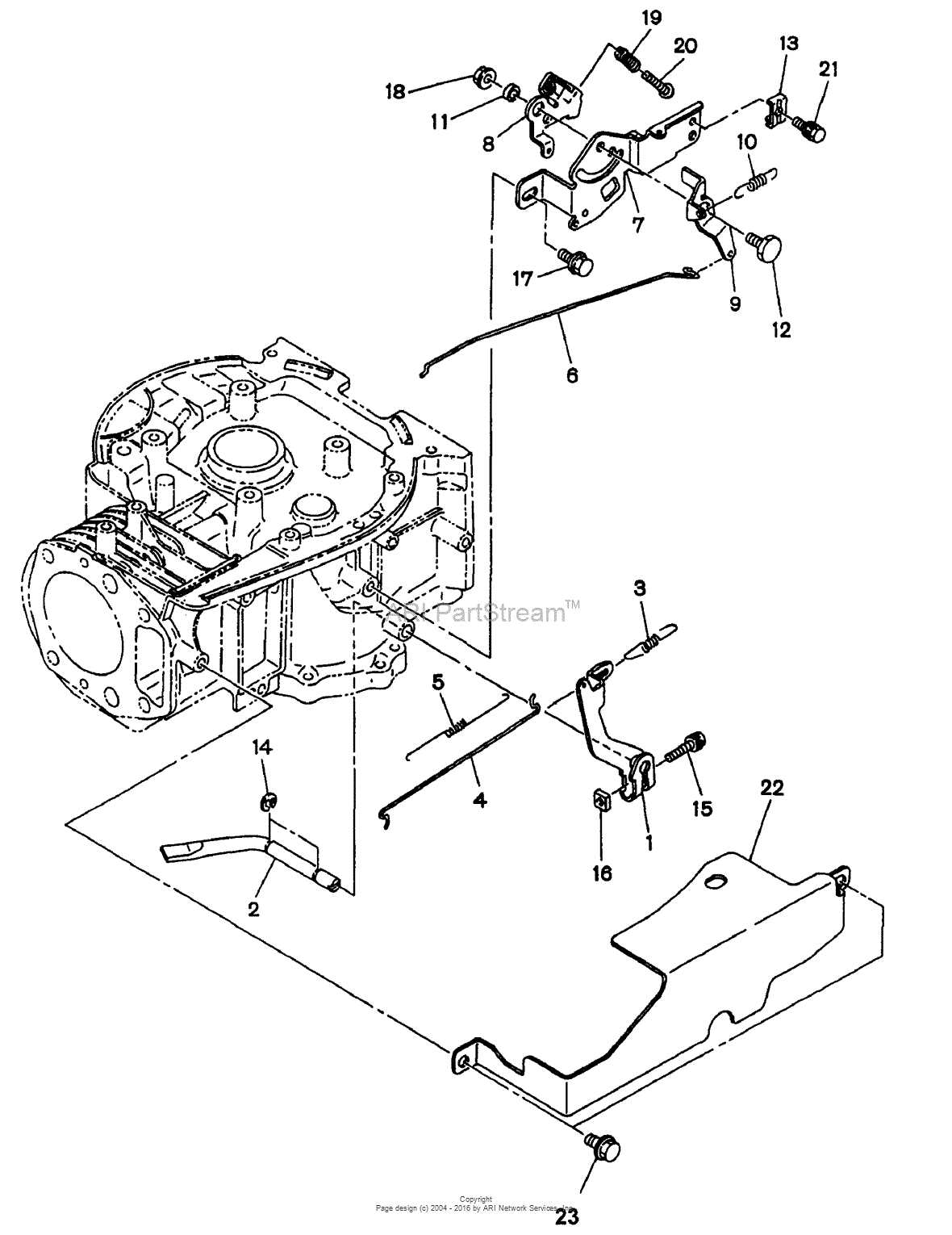

Main Components of the Engine

This section explores the fundamental elements that comprise a typical small power unit. Understanding these components is essential for maintenance, repair, and overall performance enhancement.

- Cylinder: The core area where combustion occurs, driving the piston.

- Piston: A moving part that converts the energy from combustion into mechanical work.

- Crankshaft: This component translates the linear motion of the piston into rotational motion, ultimately powering the output.

- Valves: Essential for regulating the intake of fuel and air, as well as the expulsion of exhaust gases.

- Fuel System: Comprises the fuel tank, lines, and carburetor, crucial for delivering the right mixture to the combustion chamber.

- Ignition System: Responsible for generating the spark needed to ignite the air-fuel mixture.

- Cooling System: Maintains optimal operating temperatures, preventing overheating through air or liquid cooling methods.

- Lubrication System: Ensures smooth operation by reducing friction between moving parts, prolonging the unit’s lifespan.

Each of these elements plays a significant role in the overall functionality of the system, contributing to its efficiency and reliability.

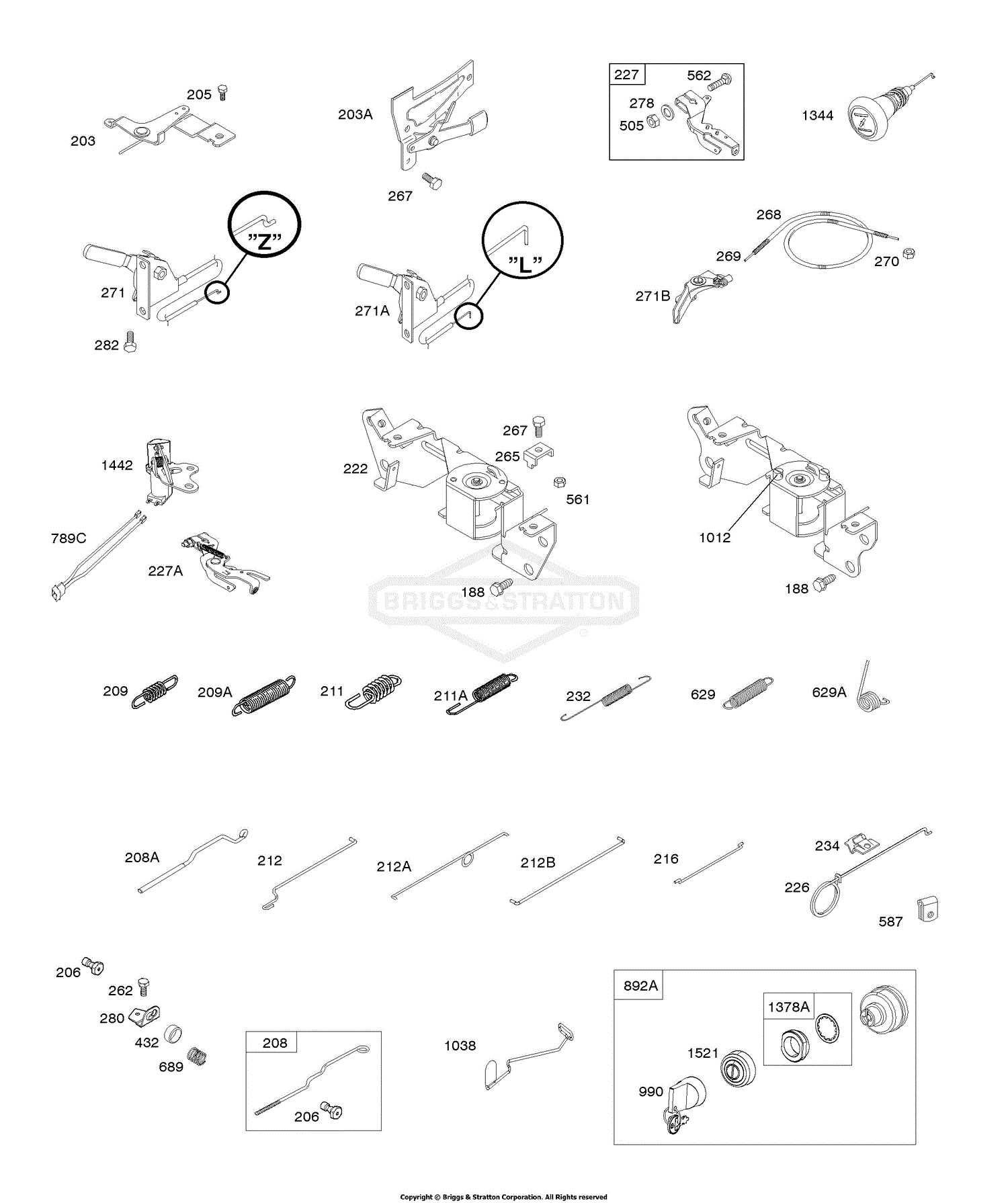

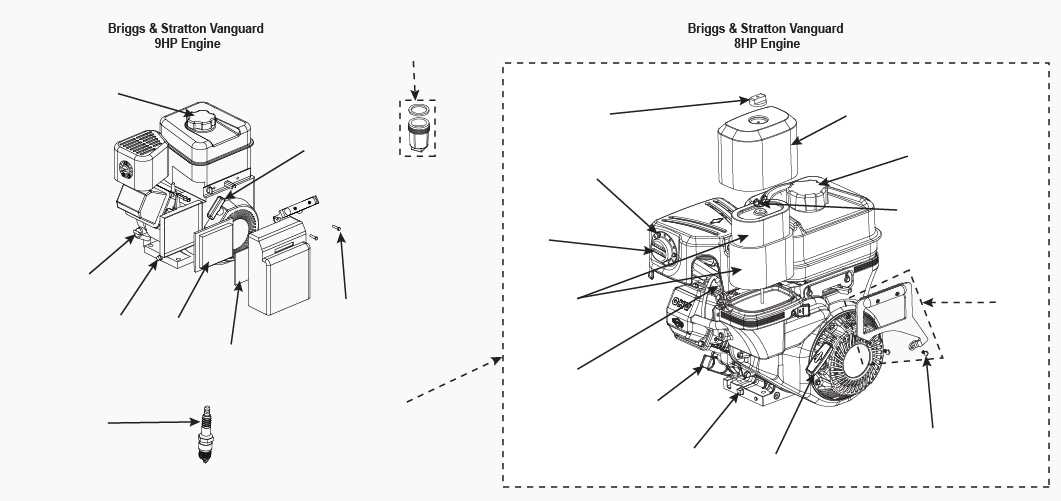

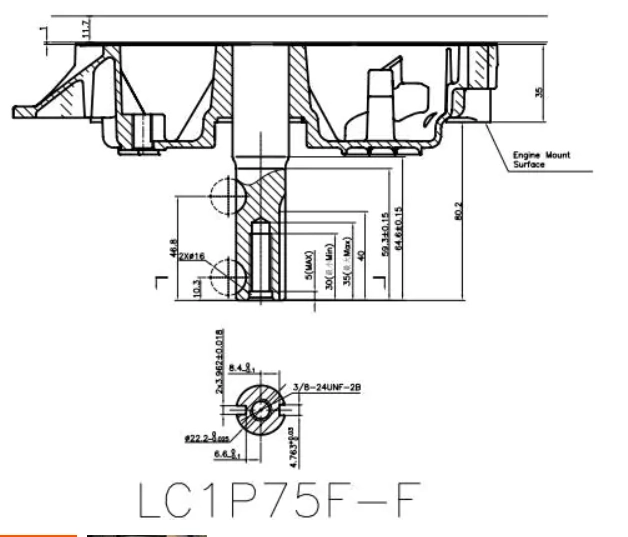

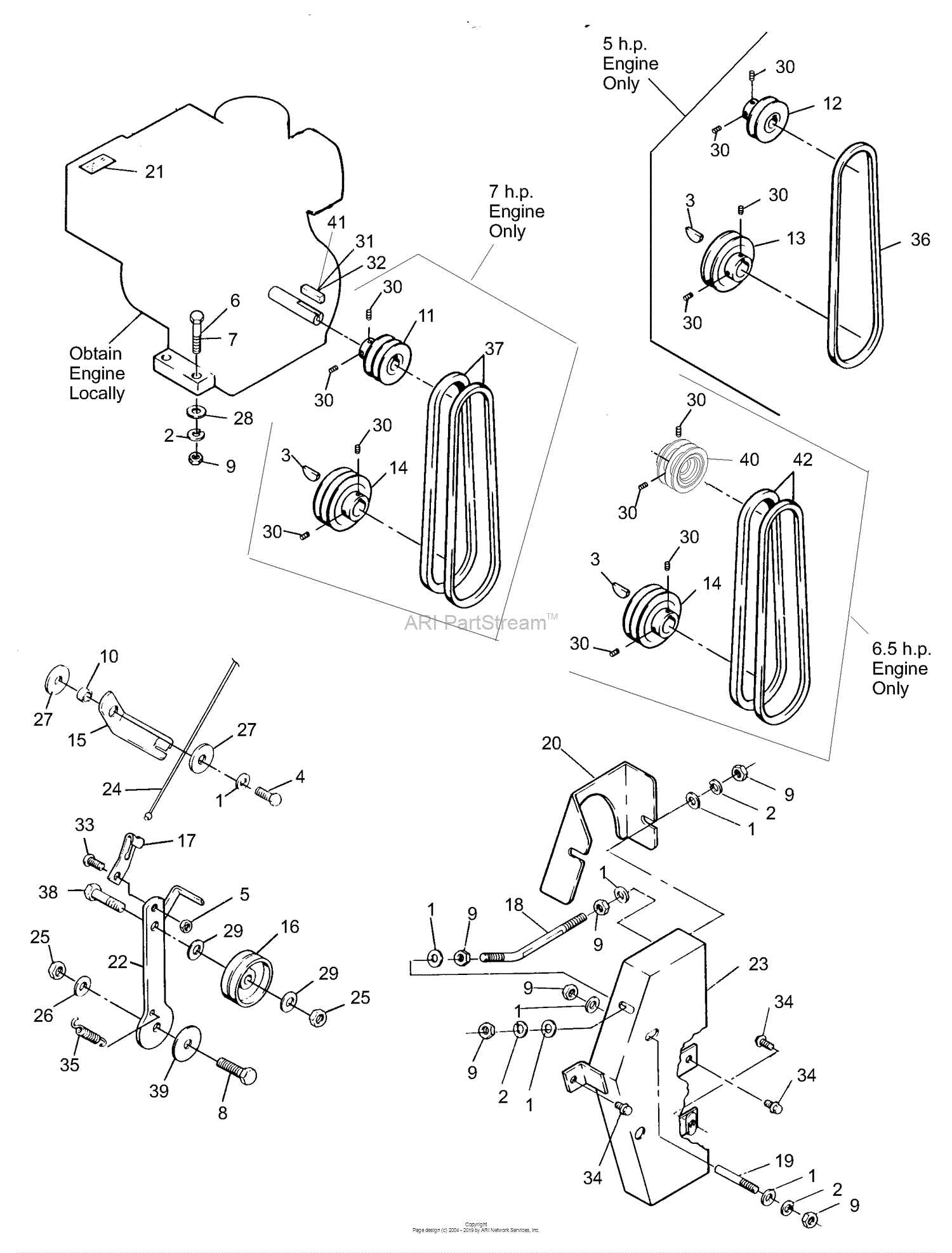

How to Read Parts Diagrams

Understanding assembly illustrations is crucial for effective maintenance and repairs. These visual guides provide essential information on components, their arrangement, and how to replace them efficiently. Knowing how to interpret these images can save time and ensure accuracy during disassembly and reassembly.

Here are some key tips for reading these illustrations:

- Familiarize Yourself with Symbols: Different symbols represent various elements. Recognizing these can help in identifying parts quickly.

- Check the Legend: Most illustrations include a legend that explains the symbols used. Refer to this before starting.

- Follow the Numbering: Components are often numbered. Following this sequence can clarify the assembly order.

- Pay Attention to Orientation: Some components may have specific orientations. Ensure you understand how each part fits together.

- Look for Exploded Views: These views show parts separated by distance, making it easier to see how they connect.

By applying these strategies, you can effectively navigate through any assembly guide, making your repair tasks more manageable.

Common Issues with 6.5 HP Engines

Small power units often encounter various problems that can affect their performance and longevity. Understanding these issues is crucial for effective maintenance and repair, ensuring optimal operation and reducing downtime.

Frequent Problems

| Issue | Description |

|---|---|

| Fuel Delivery | Inadequate fuel flow can lead to starting difficulties and inconsistent performance. |

| Overheating | Excessive heat may arise from insufficient lubrication or blocked cooling fins. |

| Inefficient Spark | A weak ignition spark can result in misfires or failure to start altogether. |

Maintenance Tips

Regular checks on fuel quality, air filters, and spark plugs can significantly enhance reliability. Keeping the machine clean and well-lubricated will also help prevent common malfunctions.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your machinery. Regular care ensures optimal performance and prevents unexpected failures, ultimately saving time and money.

- Check oil levels frequently and replace as needed to keep components lubricated.

- Clean air filters regularly to ensure efficient airflow and prevent overheating.

- Inspect spark plugs for wear and replace them to maintain ignition efficiency.

- Examine fuel lines for leaks or blockages, ensuring a steady fuel supply.

- Keep the exterior clean to prevent dirt buildup, which can hinder performance.

Following these guidelines will help you delve deeper into the mechanics, leading to enhanced functionality and longevity of your equipment.

Replacement Parts Availability

Access to suitable components is crucial for maintaining optimal performance and longevity of outdoor machinery. Whether you’re looking for essential spares or specific accessories, the market offers a wide range of options to meet diverse needs. Knowing where to find quality replacements can save time and ensure that your equipment runs smoothly.

Sources for Replacement Components

There are several reliable sources where you can obtain replacement components for your machinery. These include authorized dealers, online marketplaces, and specialty stores. Each source has its advantages, such as availability, pricing, and customer support.

Quality Considerations

When selecting replacements, it is important to consider the quality and compatibility of the items. Using genuine or high-quality aftermarket components can significantly impact the performance and durability of your machinery.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Guaranteed compatibility, expert advice | Potentially higher prices |

| Online Marketplaces | Wide selection, competitive pricing | Variable quality, check reviews |

| Specialty Stores | Expertise in specific equipment | Limited stock |

Safety Precautions During Repair

When undertaking maintenance or repair tasks, prioritizing safety is essential to prevent accidents and injuries. Proper precautions create a secure working environment, ensuring that both the technician and the equipment remain safe throughout the process.

Always wear appropriate personal protective equipment (PPE), such as safety goggles, gloves, and sturdy footwear. These items help shield against potential hazards, including sharp objects and hot surfaces. Additionally, ensure that the workspace is well-ventilated and free of clutter, reducing the risk of slips, trips, and falls.

Before starting any work, disconnect the power source to avoid accidental activation. Allow the machinery to cool down if it has been running recently. Familiarize yourself with the specific components and their functions, as understanding the assembly will enhance both efficiency and safety during the repair process.

Utilize the correct tools and equipment designed for the specific task at hand. Using improper tools can lead to mistakes and increase the likelihood of injury. If you encounter unfamiliar parts or procedures, consult the relevant manuals or seek advice from experienced individuals to ensure the job is performed correctly.

Finally, maintain a focused mindset while working. Avoid distractions and take regular breaks to prevent fatigue, which can impair judgment and reaction times. Following these guidelines will contribute to a safer and more effective repair experience.

Upgrades for Enhanced Performance

Improving the functionality of your machinery can significantly elevate its efficiency and longevity. By integrating various enhancements, users can achieve superior output, smoother operation, and increased reliability. These upgrades can range from minor tweaks to substantial modifications, all aimed at optimizing performance.

Fuel System Enhancements: Upgrading the fuel delivery components can lead to better combustion and power output. Consider installing a high-performance carburetor to maximize airflow and fuel mixing.

Exhaust Modifications: A more efficient exhaust system can reduce back pressure, allowing for improved engine breathing. This can enhance overall power and efficiency, leading to a noticeable performance boost.

Air Intake Improvements: Replacing the stock air filter with a high-flow variant can increase the volume of air entering the combustion chamber, resulting in better power delivery and efficiency.

Ignition System Upgrades: Upgrading the ignition components, such as spark plugs and coils, can lead to more reliable starts and improved throttle response, ultimately enhancing the overall performance of the system.

By carefully selecting and implementing these modifications, users can delve into a realm of enhanced operational capabilities, ensuring that their equipment reaches its ultimate potential.

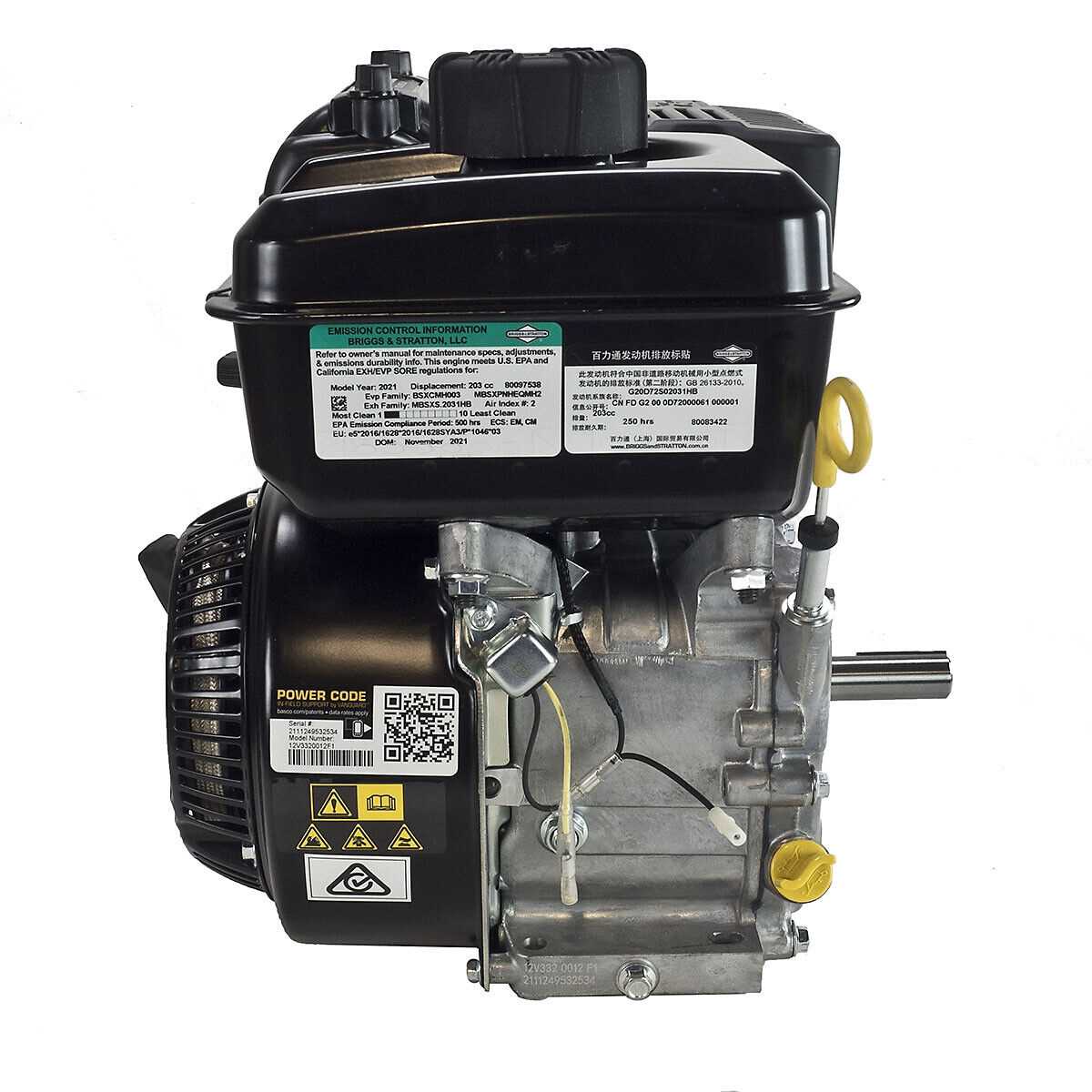

Comparison with Other Engine Models

This section explores the distinctions between a particular power unit and similar models available in the market. By analyzing various specifications, performance metrics, and design features, we aim to provide a comprehensive understanding of how this unit stands out or aligns with its competitors.

When examining power output, many comparable units offer similar horsepower ratings. However, variations in torque delivery and efficiency can significantly impact operational effectiveness. Some alternatives may excel in fuel consumption or durability, making them more suitable for specific applications.

Additionally, design aspects such as weight, size, and mounting configuration can influence user experience. Certain models feature more compact designs, allowing for easier integration into smaller machinery, while others may prioritize robust construction for heavy-duty tasks.

Maintenance requirements also vary across different brands and models. Some power units may offer easier access to components for servicing, while others might necessitate more complex procedures. Understanding these differences can aid users in selecting the most appropriate option for their needs.

Finally, pricing structures play a crucial role in the decision-making process. While some alternatives might present a lower initial cost, factors like long-term reliability and potential repair expenses should also be considered to determine overall value.

Resources for Troubleshooting Assistance

Accessing reliable support materials is essential for effectively diagnosing and resolving mechanical issues. These resources can guide users through various challenges, providing step-by-step instructions and insights for efficient problem-solving.

Online Forums and Communities

- Reddit: Join specialized subreddits for discussions and tips.

- Facebook Groups: Engage with communities dedicated to small machinery.

- Dedicated Websites: Explore forums focused on equipment repairs and modifications.

Instructional Videos

- YouTube: Find tutorials that illustrate common fixes and maintenance tips.

- Manufacturer Channels: Check official video guides for specific models.

Utilizing these resources can enhance your troubleshooting experience, ultimately leading to a successful resolution of issues encountered.