Understanding the Briggs and Stratton 6hp Parts Diagram for Efficient Repairs

For anyone involved in small engine maintenance or repair, a clear understanding of the components that make up these machines is crucial. Familiarity with how each part functions and interacts with others can significantly enhance your ability to troubleshoot and perform effective repairs.

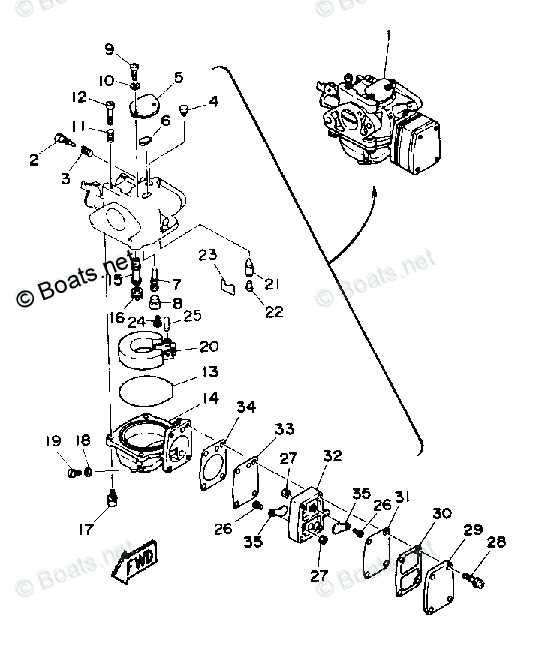

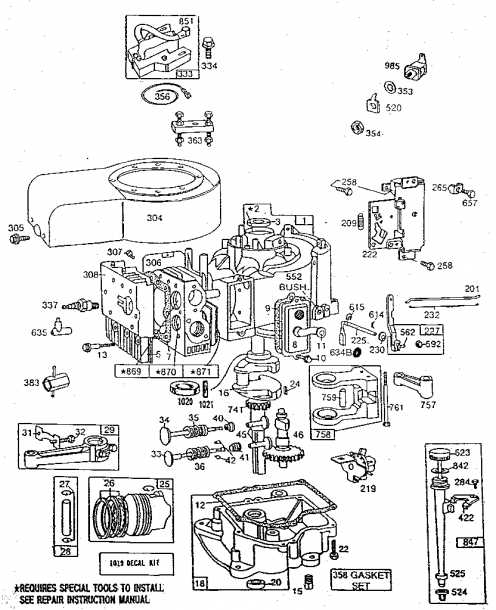

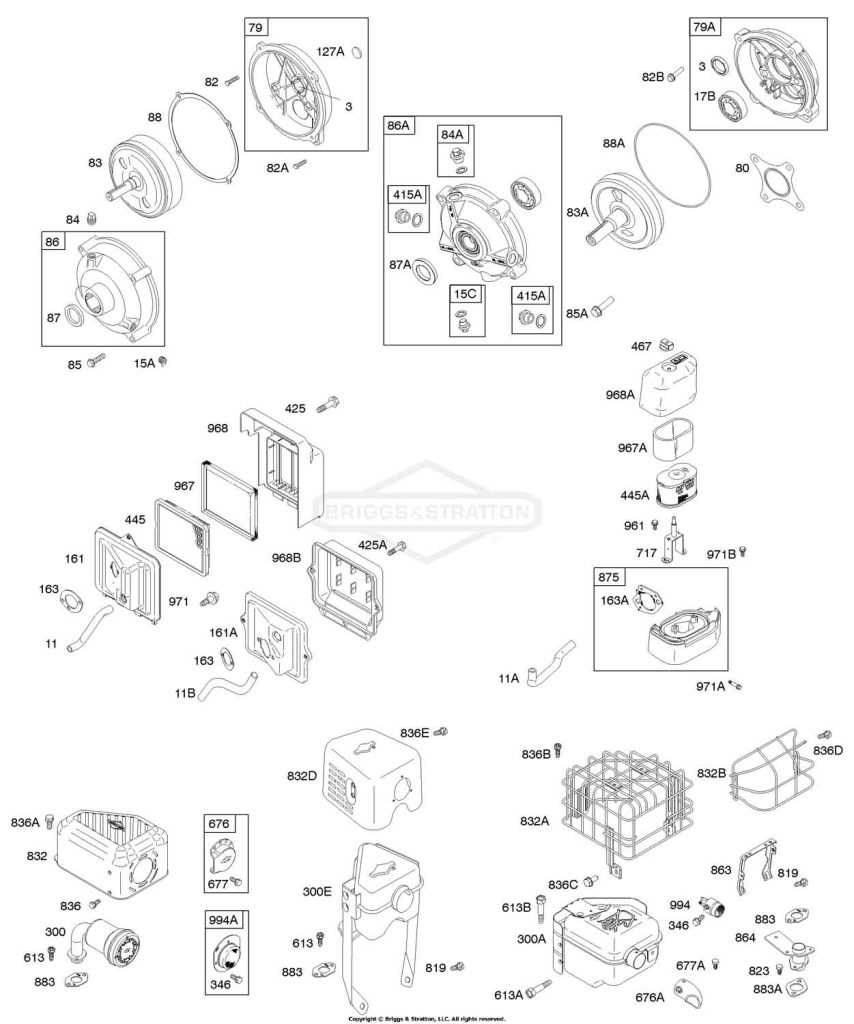

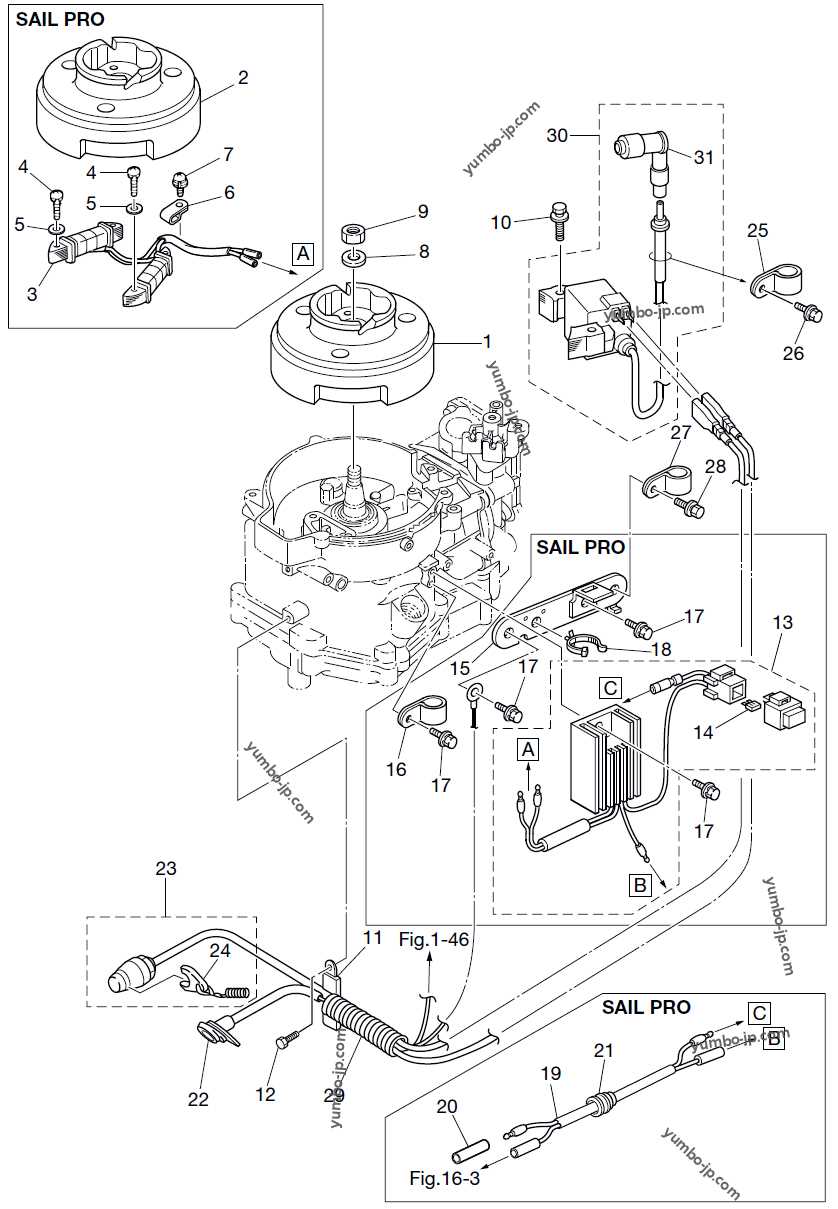

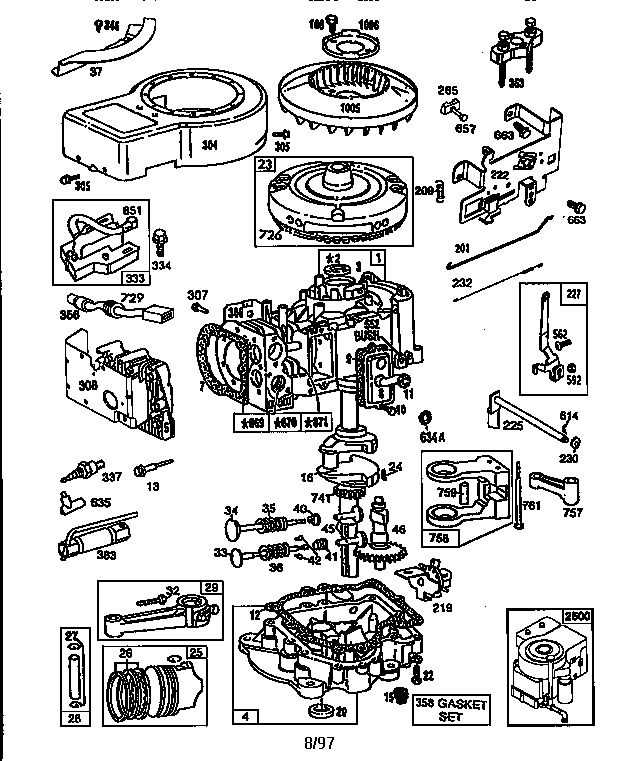

Visual representations of engine components serve as valuable resources, allowing enthusiasts and professionals alike to identify individual elements quickly. These schematics provide insight into assembly and disassembly processes, ensuring that every component is correctly placed and functioning optimally.

Whether you’re seeking to replace a worn-out element or simply aiming to enhance your knowledge, exploring detailed layouts can empower you. This guide will delve into the essential components, offering clarity and direction for those who wish to maintain or restore their engines to peak performance.

Understanding Briggs and Stratton Engines

This section explores the intricacies of small power units known for their reliability and performance in various applications. By examining their components and mechanisms, users can gain insights into their functionality and maintenance.

Key Components

The essential elements of these engines include the fuel system, ignition system, and lubrication. Each part plays a crucial role in ensuring efficient operation and longevity, making it vital for users to familiarize themselves with their functions.

Maintenance Tips

Common Components of 6HP Models

Understanding the fundamental elements of small engine designs is essential for effective maintenance and repair. These engines typically consist of several crucial parts that work together to ensure optimal performance. Each component plays a specific role, contributing to the overall functionality and reliability of the machine.

Key elements include the cylinder, which houses the combustion process, and the piston, responsible for converting fuel energy into mechanical work. The crankshaft acts as the backbone, transmitting power from the piston to the output shaft. Additionally, the carburetor is vital for mixing air and fuel, while the ignition system ensures proper starting and operation.

Other significant components include the fuel tank, which stores the necessary energy source, and the cooling system, crucial for maintaining optimal operating temperatures. The air filter plays a role in protecting internal mechanisms by preventing dust and debris from entering the engine. Understanding these fundamental parts is crucial for anyone looking to maintain or repair small engines effectively.

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone looking to repair or maintain small engines. These illustrations provide a clear representation of components and their relationships, allowing users to identify necessary elements easily. Grasping how to interpret these visuals can significantly streamline the troubleshooting and replacement processes.

1. Familiarize Yourself with Symbols: Each illustration employs standardized symbols and notations. Take time to learn what each icon represents, as this knowledge will facilitate quicker identification of individual components.

2. Follow the Layout: Typically, these schematics are organized systematically. Starting from the engine’s core, components are arranged in a logical manner, often moving outward. Recognizing this flow will help in understanding how parts connect and function together.

3. Reference the Legend: Most illustrations include a legend that explains the symbols and numbers used. Consult this key to clarify any uncertainties you may encounter while analyzing the graphic.

4. Identify Connection Points: Pay close attention to how components are linked. Understanding these connection points is crucial for successful assembly or disassembly, ensuring that each piece fits properly in the overall structure.

5. Take Notes: As you study the schematic, jot down notes regarding specific parts you may need to replace. This will help create a checklist for your repair process, making it more efficient and organized.

Importance of Regular Maintenance

Consistent upkeep is crucial for ensuring the longevity and efficiency of machinery. By adhering to a regular service schedule, owners can prevent minor issues from escalating into significant problems, ultimately enhancing performance and reliability.

Benefits of Routine Care

- Increases equipment lifespan

- Enhances operational efficiency

- Reduces repair costs

- Improves safety for users

Key Maintenance Tasks

- Regularly check and change fluids

- Inspect air filters and replace if necessary

- Examine spark plugs and clean or replace

- Keep components clean and free from debris

Identifying Genuine Replacement Parts

Ensuring the longevity and efficiency of your engine requires careful selection of components. Using authentic components not only enhances performance but also maintains warranty coverage and safety. Recognizing genuine items can be challenging amidst a plethora of alternatives available in the market.

Key Indicators of Authenticity

- Brand Markings: Look for official logos and trademarks on the item.

- Quality of Materials: Genuine components are typically crafted from high-grade materials, ensuring durability.

- Packaging: Authentic items often come in branded packaging with detailed information about the product.

- Manufacturer’s Documentation: Reliable parts usually include manuals or documentation that verify their origin.

Where to Purchase

- Authorized Dealers: Always opt for recognized sellers with a reputation for quality.

- Official Websites: Purchasing directly from the manufacturer’s site guarantees authenticity.

- Reputable Retailers: Look for established retailers known for offering genuine items.

By being vigilant and informed, you can effectively distinguish authentic components from substandard alternatives, ensuring optimal performance for your machinery.

Common Issues with 6HP Engines

Small engines often encounter a variety of challenges that can affect their performance and longevity. Understanding these common problems can help in maintaining optimal functionality and ensuring a longer lifespan.

Typical Problems

- Fuel contamination leading to poor combustion

- Overheating caused by inadequate cooling

- Starting difficulties due to battery issues

- Vibration and noise from loose components

Preventative Measures

- Regularly check and replace fuel filters.

- Inspect cooling fins and clean as needed.

- Maintain battery charge and connections.

- Tighten all bolts and screws periodically.

Tools Needed for Repairs

Effective maintenance requires the right set of instruments to ensure smooth operation and longevity. Utilizing the appropriate tools not only facilitates repairs but also enhances overall efficiency. Here’s a comprehensive list of essential implements that will aid in your servicing tasks.

- Wrenches: A set of various sizes, including adjustable wrenches, is crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for removing and securing screws.

- Socket Set: A complete socket set allows for easier access to nuts and bolts in tight spaces.

- Pliers: Needle-nose and standard pliers are helpful for gripping and twisting wires or small components.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

- Fuel Line Wrenches: Designed specifically for working with fuel systems, these tools simplify tasks without damaging components.

- Cleaning Brushes: Various brushes are essential for removing dirt and debris from parts, ensuring optimal performance.

Having these tools on hand will streamline your repair process, making it more effective and less time-consuming. Proper preparation is key to successful maintenance and repair work.

Step-by-Step Repair Guide

This section provides a comprehensive approach to effectively addressing common issues in small engines. By following a systematic method, you can ensure that every step is completed thoroughly, minimizing the risk of further complications. Whether you are a seasoned mechanic or a beginner, this guide will assist you in successfully performing maintenance and repairs.

Essential Tools and Safety Precautions

Before beginning any repair work, it is crucial to gather the necessary tools and take appropriate safety measures. Here is a list of tools you will need:

| Tool | Purpose |

|---|---|

| Socket Wrench Set | Tightening and loosening bolts |

| Screwdriver Set | Removing screws and fasteners |

| Clean Rags | Wiping surfaces and parts |

| Safety Goggles | Protecting eyes from debris |

| Gloves | Protecting hands during repairs |

Step-by-Step Process

Follow these steps to ensure a smooth repair:

- Disconnect the power source to prevent any accidents.

- Remove the outer casing to access the engine components.

- Inspect each part for wear or damage, making a note of any necessary replacements.

- Carefully clean all components to remove dirt and debris.

- Replace any faulty parts using the appropriate tools.

- Reassemble the unit, ensuring all fasteners are securely tightened.

- Reconnect the power source and test the engine for proper operation.

Upgrading Your Engine Performance

Enhancing the efficiency of your engine can lead to improved power output, better fuel economy, and a more enjoyable driving experience. By focusing on specific components and modifications, enthusiasts can unlock the potential of their machines, ensuring optimal performance and longevity.

Key Modifications to Consider

There are several upgrades that can significantly impact engine performance. From improving airflow to optimizing fuel delivery, each change contributes to a more robust system.

| Modification | Benefit |

|---|---|

| High-Performance Carburetor | Increased fuel atomization for better combustion |

| Exhaust Upgrade | Improved exhaust flow for enhanced power |

| Air Filter Replacement | Better airflow resulting in higher efficiency |

Final Thoughts

By carefully selecting and implementing these upgrades, you can take your engine’s capabilities to the next level, ensuring a more powerful and efficient performance overall.

Where to Buy Replacement Parts

Finding high-quality components for small engines can be essential for maintaining performance and reliability. Various sources provide options for acquiring necessary items, catering to different preferences and budgets.

Online Retailers

- Specialty websites offer a wide range of components.

- Major e-commerce platforms often feature customer reviews to aid decision-making.

- Manufacturer’s official sites can provide authenticity guarantees.

Local Stores

- Automotive supply shops typically carry essential components.

- Home improvement centers often stock common engine parts.

- Independent repair shops may provide personalized assistance and advice.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures superior quality and performance in machinery. These elements are specifically designed to fit and function perfectly with your equipment, promoting longevity and reliability. The investment in authentic replacements can ultimately lead to enhanced efficiency and reduced maintenance issues.

Quality Assurance

Original components undergo rigorous testing and quality checks, guaranteeing that they meet strict industry standards. This assurance translates to better performance and lower risk of failures, ultimately saving time and money.

Compatibility

OEM components are engineered to match the specifications of the original design. This perfect alignment minimizes the chances of malfunction, ensuring that your machinery operates as intended.

| Benefit | Description |

|---|---|

| Reliability | Engineered to prevent premature failures. |

| Performance | Optimized for maximum efficiency and effectiveness. |

| Warranty | Often backed by a manufacturer’s guarantee. |