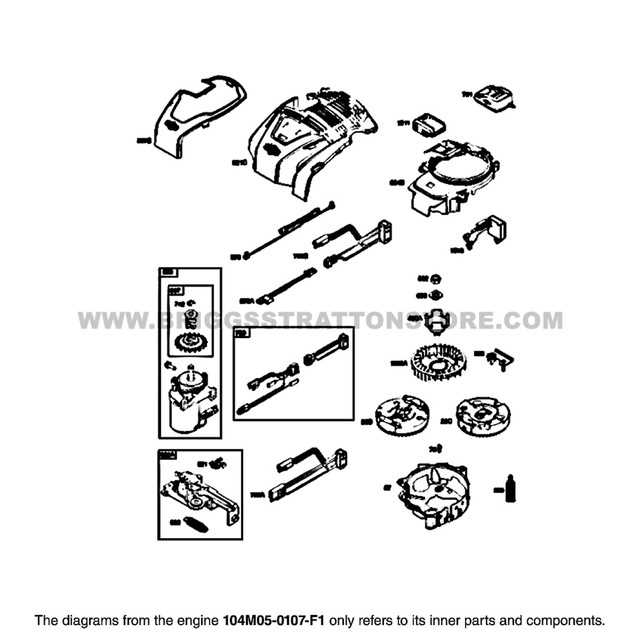

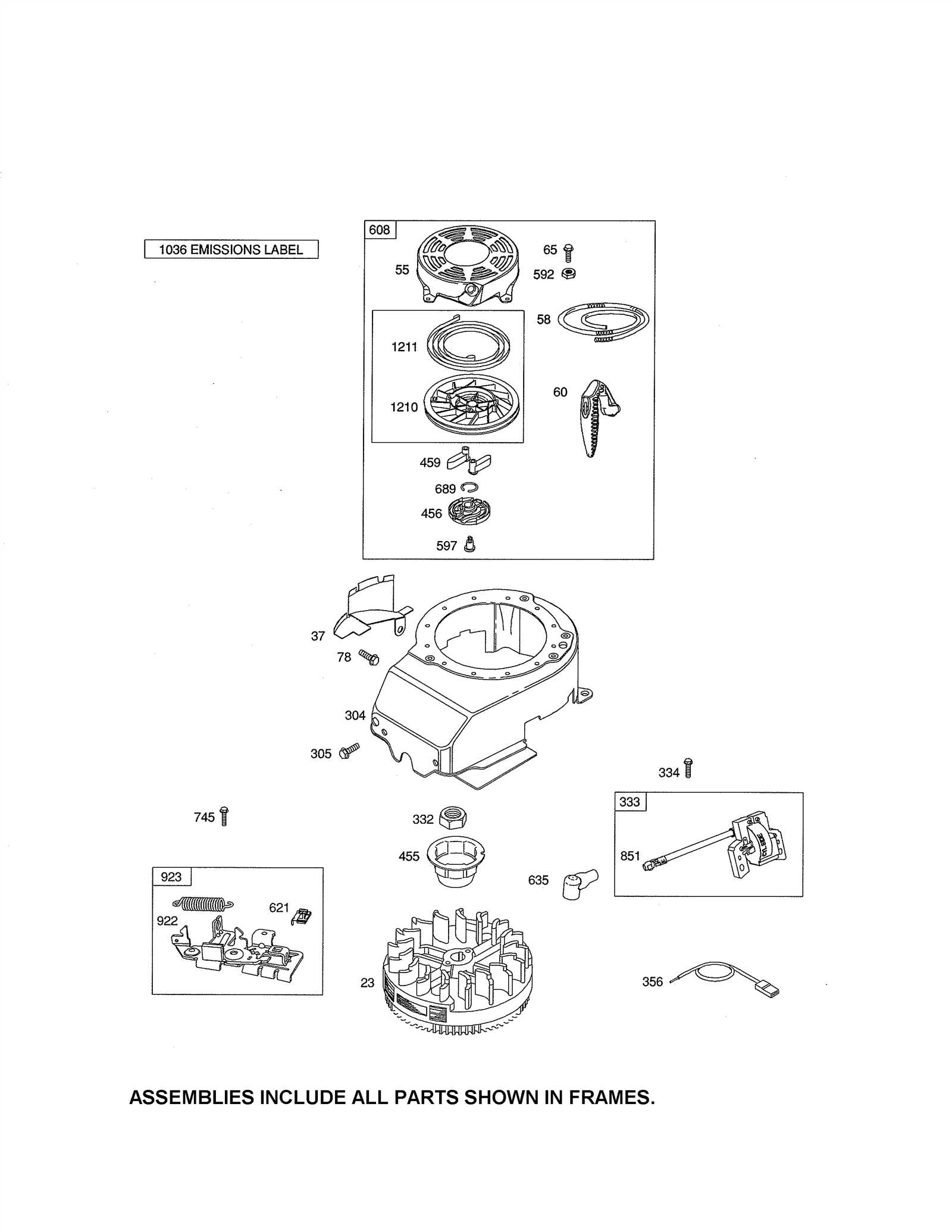

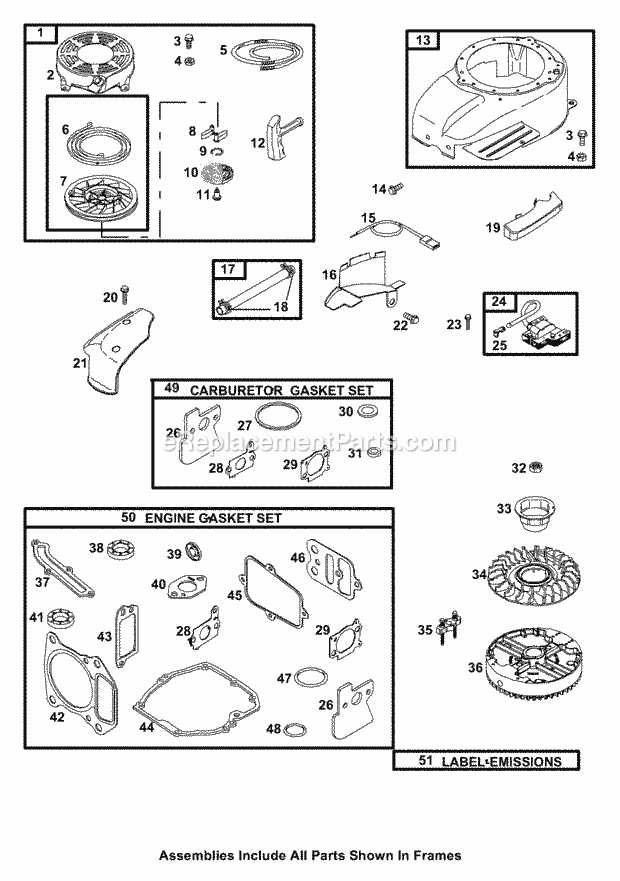

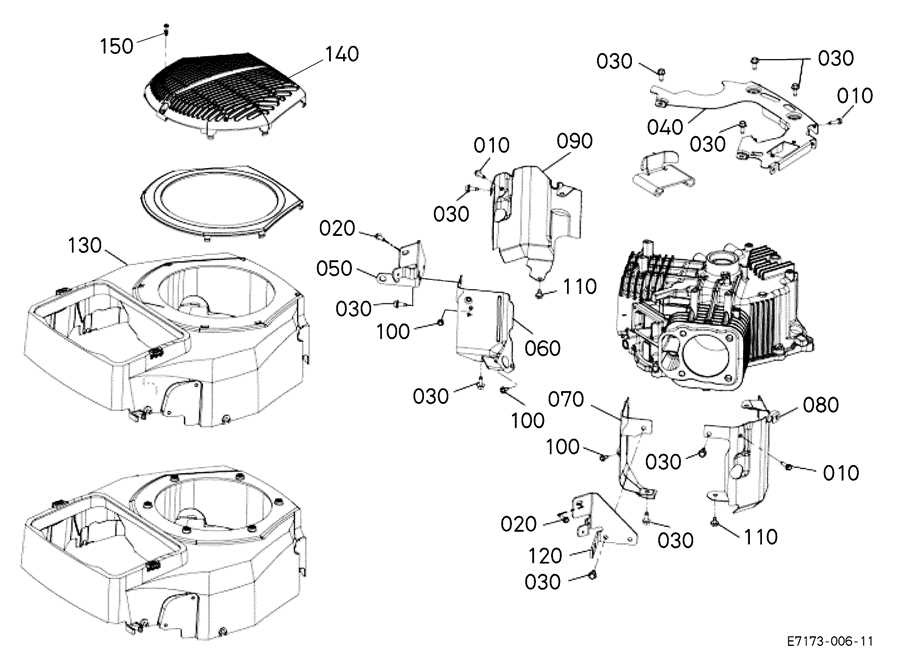

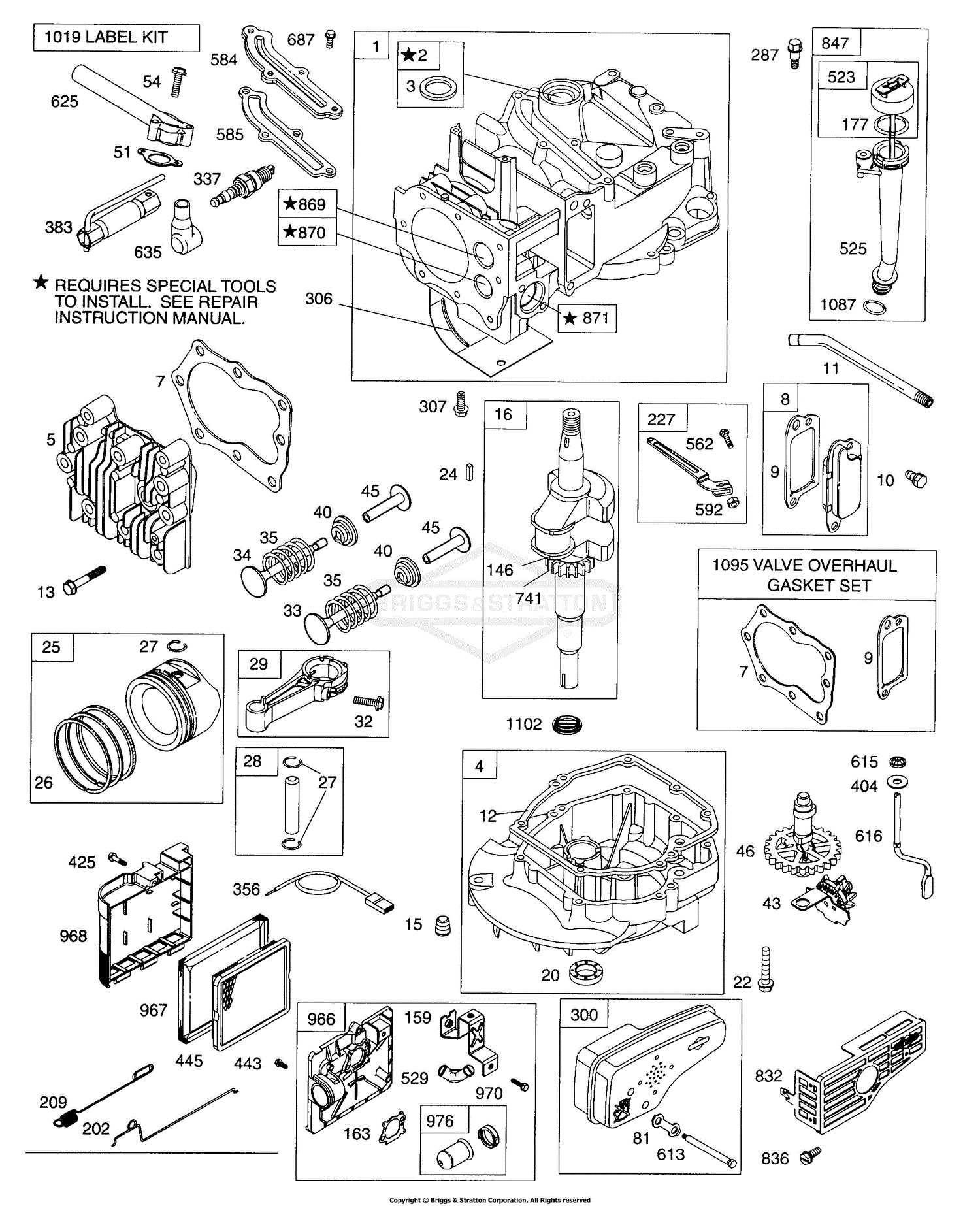

Briggs and Stratton 725EX Parts Diagram Overview

When it comes to maintaining outdoor machinery, comprehending the arrangement of its internal mechanisms is essential. This knowledge helps users identify individual components, ensuring efficient repairs and optimal performance. Having access to a clear visual reference can significantly enhance the understanding of how various elements interact within the engine.

In this section, we will explore the specific arrangement of a well-known engine model. By examining the layout of its components, users can gain valuable insights into their functions and relationships. This understanding not only facilitates troubleshooting but also aids in the proper maintenance of the equipment, allowing for prolonged usability.

Whether you are a seasoned mechanic or a hobbyist, familiarity with the configuration of these internal parts will empower you to tackle repairs confidently. Emphasizing the significance of having a detailed overview, this guide serves as a valuable resource for anyone seeking to enhance their mechanical knowledge.

Various challenges can arise with small engines of this model, impacting their performance and longevity. Identifying and addressing these concerns early can enhance efficiency and reduce downtime.

Performance Decline

One frequent issue is a noticeable drop in power output. This can be caused by several factors, including fuel delivery problems, air filter obstructions, or ignition system failures. Regular maintenance checks can help mitigate these issues.

Starting Difficulties

Starting problems are another common complaint among users. These difficulties can stem from battery issues, a faulty starter motor, or carburetor malfunctions. Troubleshooting these areas can often lead to a quick resolution.

| Issue | Possible Cause | Solution |

|---|---|---|

| Power Loss | Clogged air filter | Replace air filter |

| Starting Problems | Weak battery | Recharge or replace battery |

| Overheating | Insufficient oil | Add oil and check levels |

Parts Replacement Guidelines

This section provides essential instructions for the substitution of various components within small engines. Properly replacing these elements is crucial for maintaining optimal performance and extending the life of the equipment. Understanding the process can help ensure that replacements are carried out efficiently and effectively.

Preparation Steps

Before beginning the replacement process, gather the necessary tools and new components. Ensure the equipment is turned off and disconnected from any power source. Familiarize yourself with the specific requirements for the engine to ensure you have the correct items on hand.

Replacement Procedure

Follow these steps for a successful replacement:

| Step | Description |

|---|---|

| 1 | Remove the existing component carefully, ensuring not to damage surrounding parts. |

| 2 | Inspect the area for any debris or damage that may affect the new installation. |

| 3 | Install the new component, following the manufacturer’s guidelines for placement and torque specifications. |

| 4 | Test the engine to ensure proper functionality after the replacement. |

Tools Required for Repairs

When undertaking maintenance or fixing machinery, having the right equipment is essential for ensuring efficiency and effectiveness. Proper tools not only facilitate the repair process but also enhance safety, helping to avoid potential injuries. Familiarity with the necessary implements can greatly simplify tasks and lead to a successful outcome.

Essential Tools

The following list includes some fundamental instruments commonly needed for repair work:

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening or tightening nuts and bolts. |

| Wrench | Helps in gripping and turning fasteners securely. |

| Phillips Screwdriver | Ideal for driving screws with a cross-shaped socket. |

| Flathead Screwdriver | Useful for screws with a straight, flat socket. |

| Pliers | Assist in gripping, twisting, and cutting materials. |

Additional Recommendations

Beyond the basics, certain tasks may require specialized tools. For example, a torque wrench is crucial for ensuring fasteners are tightened to the manufacturer’s specifications. Additionally, having a multimeter on hand can aid in diagnosing electrical issues. Always assess the requirements of your specific project to ensure you are fully equipped.

Identifying Genuine Parts

Ensuring the authenticity of components is crucial for maintaining the optimal performance and longevity of your equipment. Recognizing original elements can help prevent potential issues caused by counterfeit or substandard substitutes. This section provides insights into how to distinguish authentic elements from imitations.

Key Features to Look For

When assessing the authenticity of components, several characteristics can serve as indicators. Here are the main aspects to consider:

| Feature | Description |

|---|---|

| Brand Markings | Original components often have specific logos or markings that indicate their authenticity. |

| Packaging Quality | Genuine items are typically packaged securely, with clear labeling and product information. |

| Material Quality | Original elements are made from high-quality materials, which can be felt and observed upon inspection. |

Where to Purchase Authentic Components

Acquiring genuine components is essential for ensuring the reliability of your machinery. It is recommended to purchase from authorized dealers or reputable suppliers known for selling original items. Online platforms can also be a viable option, provided they have a trustworthy reputation and customer reviews confirming the authenticity of their offerings.

Exploring Upgrade Options

When considering enhancements for your engine, it’s essential to assess various components that can improve performance and efficiency. Upgrading specific elements can lead to noticeable gains in power, reliability, and overall functionality. This section will delve into potential modifications that can elevate your machine’s capabilities.

One common approach is to replace standard components with higher-quality alternatives. This can include improving air intake systems, fuel delivery mechanisms, and exhaust systems. Each of these upgrades plays a vital role in optimizing engine performance.

| Component | Upgrade Option | Benefits |

|---|---|---|

| Air Filter | High-Flow Air Filter | Increased airflow and enhanced combustion |

| Spark Plug | Performance Spark Plug | Improved ignition efficiency and responsiveness |

| Exhaust System | Performance Muffler | Reduced back pressure and better sound |

| Carburetor | Upgraded Carburetor | Enhanced fuel atomization and power delivery |

Ultimately, carefully selecting upgrades can lead to a more robust and efficient engine. By investing in quality enhancements, you ensure better performance and longevity for your equipment.

Wiring Diagram for 725EX

This section provides a comprehensive overview of the electrical connections essential for optimal operation of the specified engine model. Understanding the arrangement of wires and their respective functions is crucial for effective troubleshooting and maintenance. Proper wiring ensures that the engine performs reliably and efficiently.

Below is a simplified representation of the electrical layout, detailing the connections between various components:

| Component | Connection Type | Notes |

|---|---|---|

| Starter Motor | Positive Terminal | Connects to battery positive |

| Ignition Coil | Power Supply | Receives voltage from the ignition switch |

| Magneto | Ground | Ensures proper grounding for spark generation |

| Fuel Shutoff Valve | Signal Wire | Controls fuel flow based on electrical signals |

Following this guide will aid in maintaining the electrical integrity of the engine, leading to enhanced performance and longevity.

Finding a Parts Supplier

Locating a reliable source for components is essential for maintaining the functionality of your equipment. With numerous options available, it is crucial to identify suppliers that offer quality materials and services tailored to your needs.

Considerations for Choosing a Supplier

- Reputation: Research the supplier’s history and customer feedback.

- Quality: Ensure the components meet industry standards for durability and performance.

- Availability: Confirm that the supplier has a consistent stock of the items you require.

- Pricing: Compare prices among different suppliers to ensure you receive fair rates.

- Support: Check if they provide assistance in identifying the correct components for your needs.

Where to Search

- Online marketplaces that specialize in machinery and equipment.

- Local hardware stores with dedicated sections for machinery components.

- Manufacturer websites that may offer direct sales or recommended suppliers.

- Forums and communities where enthusiasts share their experiences and recommendations.

Frequently Asked Questions About 725EX

This section aims to address common inquiries regarding the specific engine model, offering insights and guidance to enhance understanding and troubleshooting.

Common Questions

- What are the recommended maintenance practices for this engine?

- How often should oil changes be performed?

- What type of fuel is best suited for optimal performance?

- Where can I find replacement components?

Troubleshooting Tips

- Check the spark plug for wear and replace if necessary.

- Ensure the air filter is clean and unobstructed.

- Inspect fuel lines for leaks or blockages.

- Verify that all electrical connections are secure.