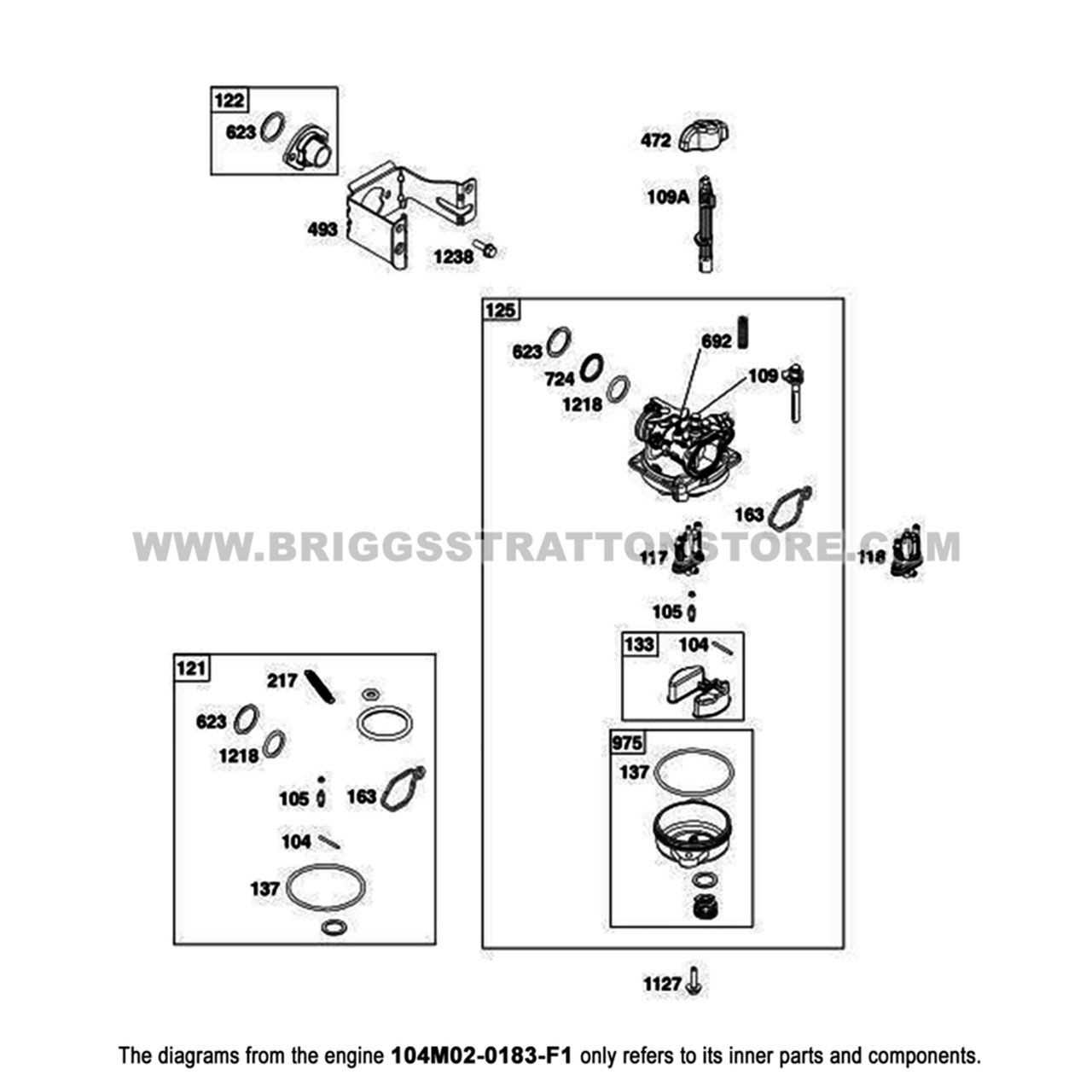

Understanding Briggs and Stratton EXi 625 Parts Diagram

Understanding the layout of engine components is essential for effective maintenance and repairs. This section provides a detailed look at the key elements that ensure optimal performance and longevity of the motor. By familiarizing yourself with the arrangement of various mechanical elements, you can ensure smooth operation and address potential issues early.

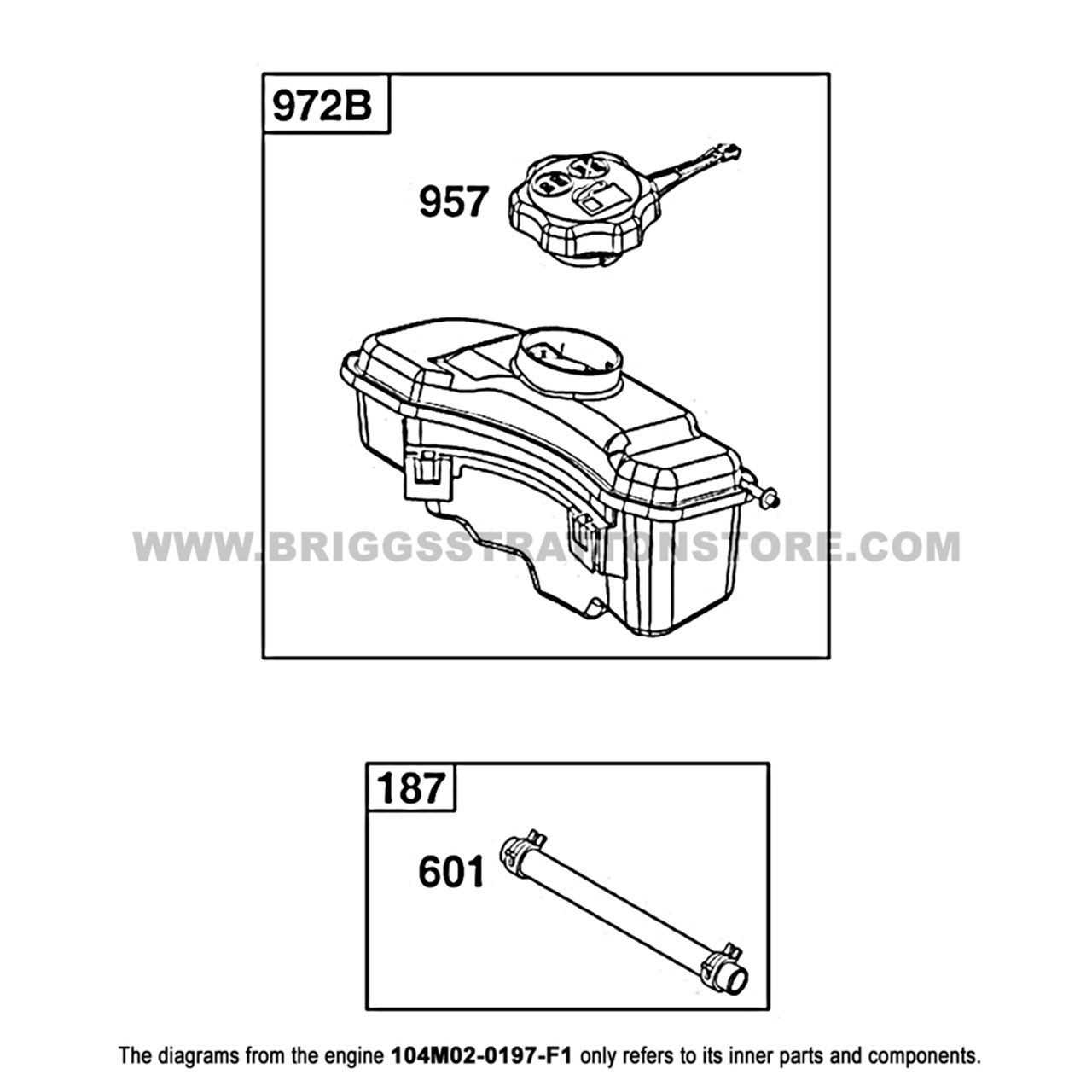

Each mechanism plays a crucial role in the overall function, and knowing where everything is positioned allows for easier troubleshooting. From fuel systems to cooling mechanisms, recognizing the layout enables users to efficiently carry out necessary adjustments or replacements without confusion.

In this guide, you’ll gain insight into the positioning of the most important elements of a motor system. It offers a clear reference for anyone looking to maintain or improve the operational efficiency of their machinery.

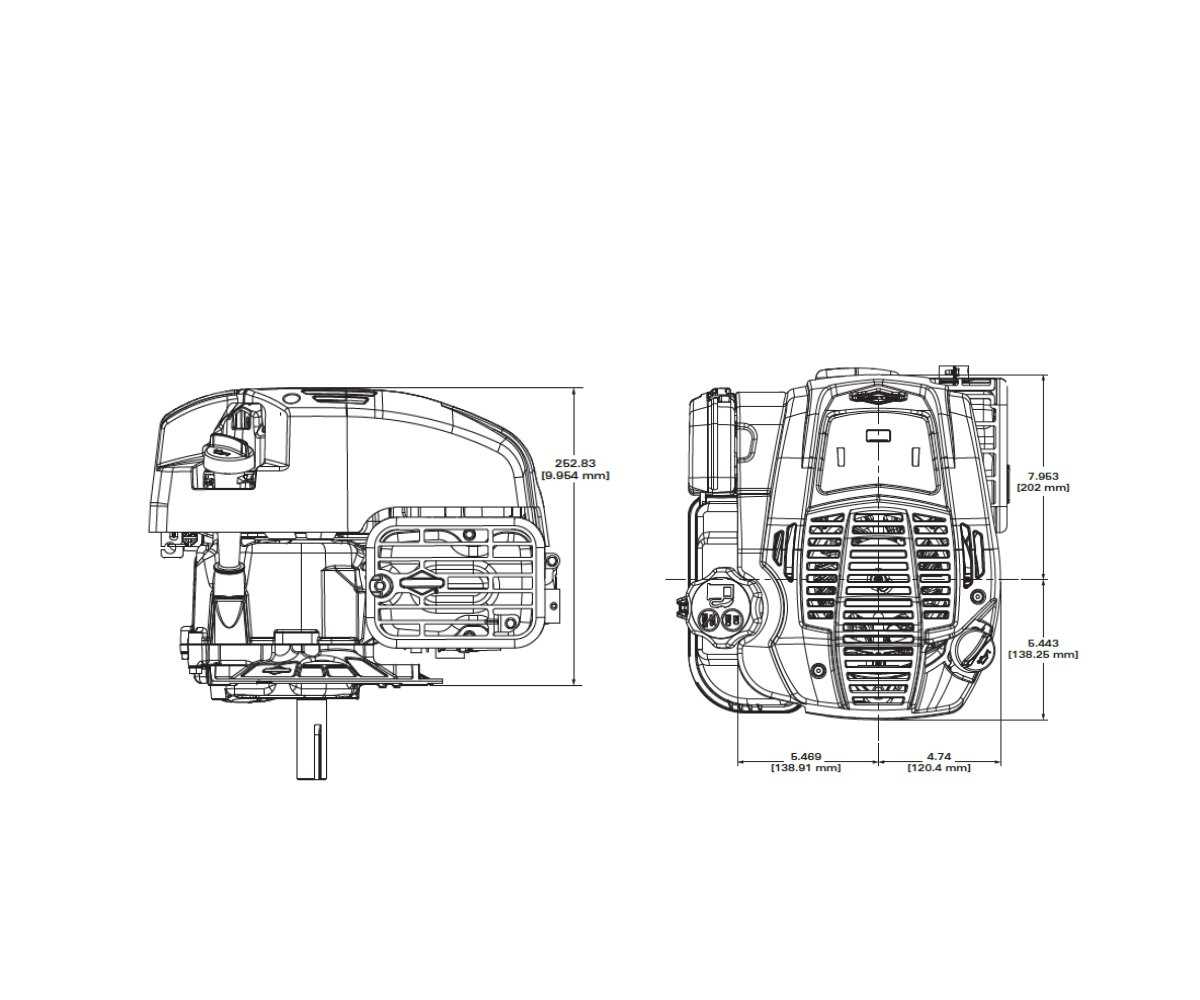

Overview of Briggs and Stratton EXi 625 Engine

The model under discussion is a reliable and efficient small motor used in a variety of outdoor power equipment. It is designed to provide consistent performance, making it ideal for maintaining both residential and commercial landscapes. With an emphasis on easy maintenance and fuel efficiency, this engine stands out for its ability to combine power with a compact, user-friendly design.

Key Features

One of the main highlights of this motor is its ability to run smoothly with minimal upkeep. The innovative design reduces the need for regular oil changes, providing a hassle-free experience for users. The engine is also built with advanced technologies to optimize fuel usage, ensuring longer run times and lower emissions.

Performance and Durability

This small engine is known for its robust build, designed to withstand harsh conditions and prolonged use. Whether powering a lawn mower or other equipment, it delivers consistent torque and horsepower. The long-lasting components are built to resist wear and tear, contributing to its reputation for durability.

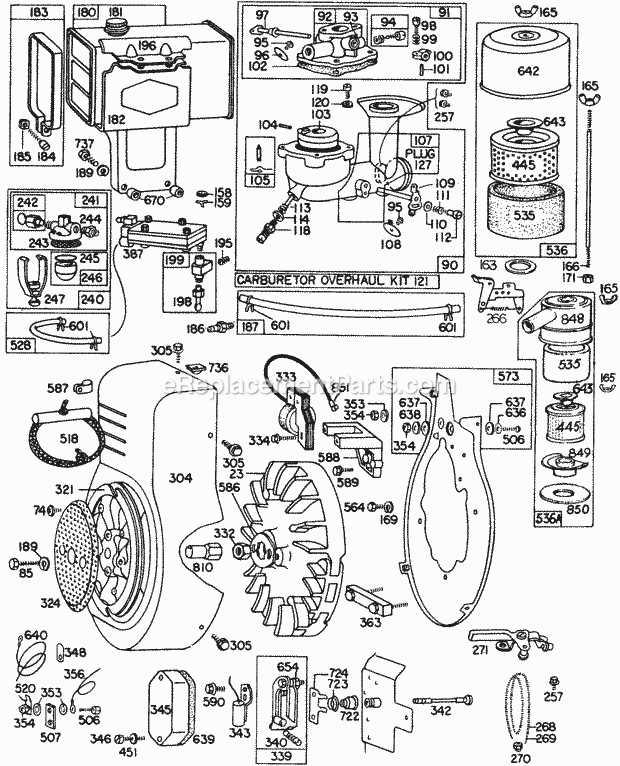

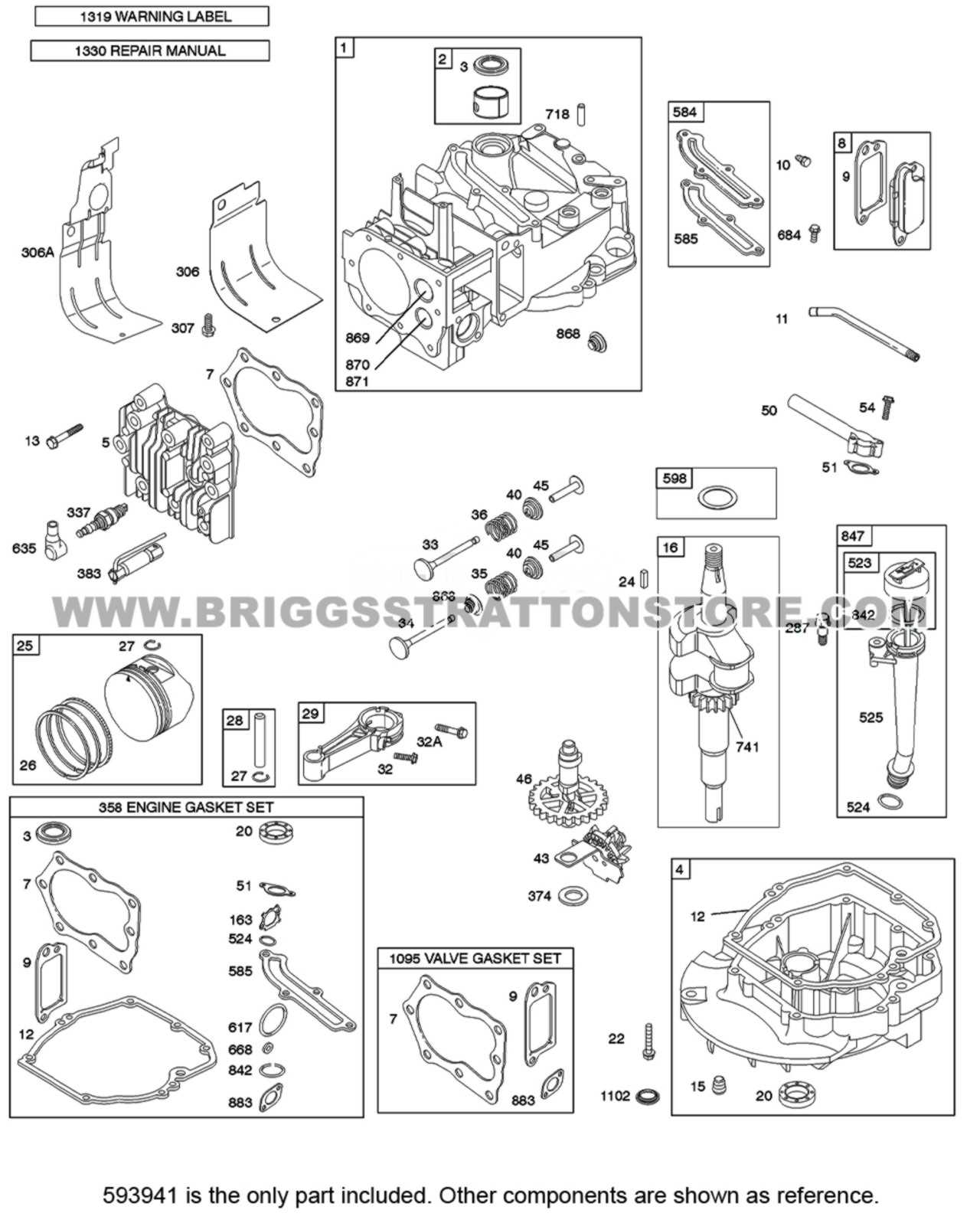

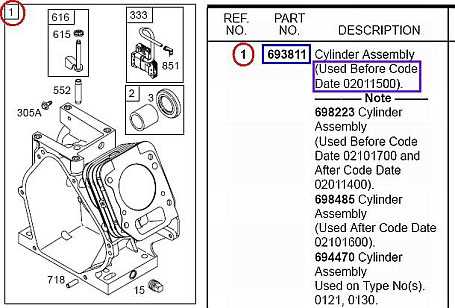

Main Components and Their Functions

This section focuses on the primary elements that make up a small engine system, explaining the role each component plays in the overall functionality. Understanding the core elements will help in maintaining and troubleshooting the engine efficiently.

Key Engine Elements

The engine consists of several essential parts that work together to convert fuel into mechanical power. Below are the critical components:

| Component | Function | |

|---|---|---|

| Cylinder | Houses the piston and provides the space for combustion to occur. | |

| Piston | Moves up and down within the cylinder, transferring the energy from combustion to the crankshaft. | |

| Crankshaft | Converts the linear motion of the piston into rotational energy that powers the engine. | |

| Carburetor | Mixes air and fuel in the correct ratio to ensure proper combustion. | |

| Air Filter | Prevents dirt and debris from entering the engine, ensuring clean air for combustion. |

| Component | Description |

|---|---|

| Float | Regulates the fuel level in the chamber to ensure consistent flow. |

| Needle Valve | Controls fuel entry based on the float’s position. |

| Jets | Mix fuel with air before it enters the combustion chamber. |

| Gasket | Prevents fuel leaks and ensures a tight seal. |

Cleaning Techniques

Regular cleaning is vital for maintaining efficiency. Here are some recommended steps:

- Disassemble the fuel mixing device carefully.

- Use a carburetor cleaner to remove deposits and grime.

- Inspect and replace any damaged components.

- Reassemble the device, ensuring all seals are secure.

Implementing these practices will promote reliable engine operation and prevent performance issues, ultimately ensuring longevity and efficiency.

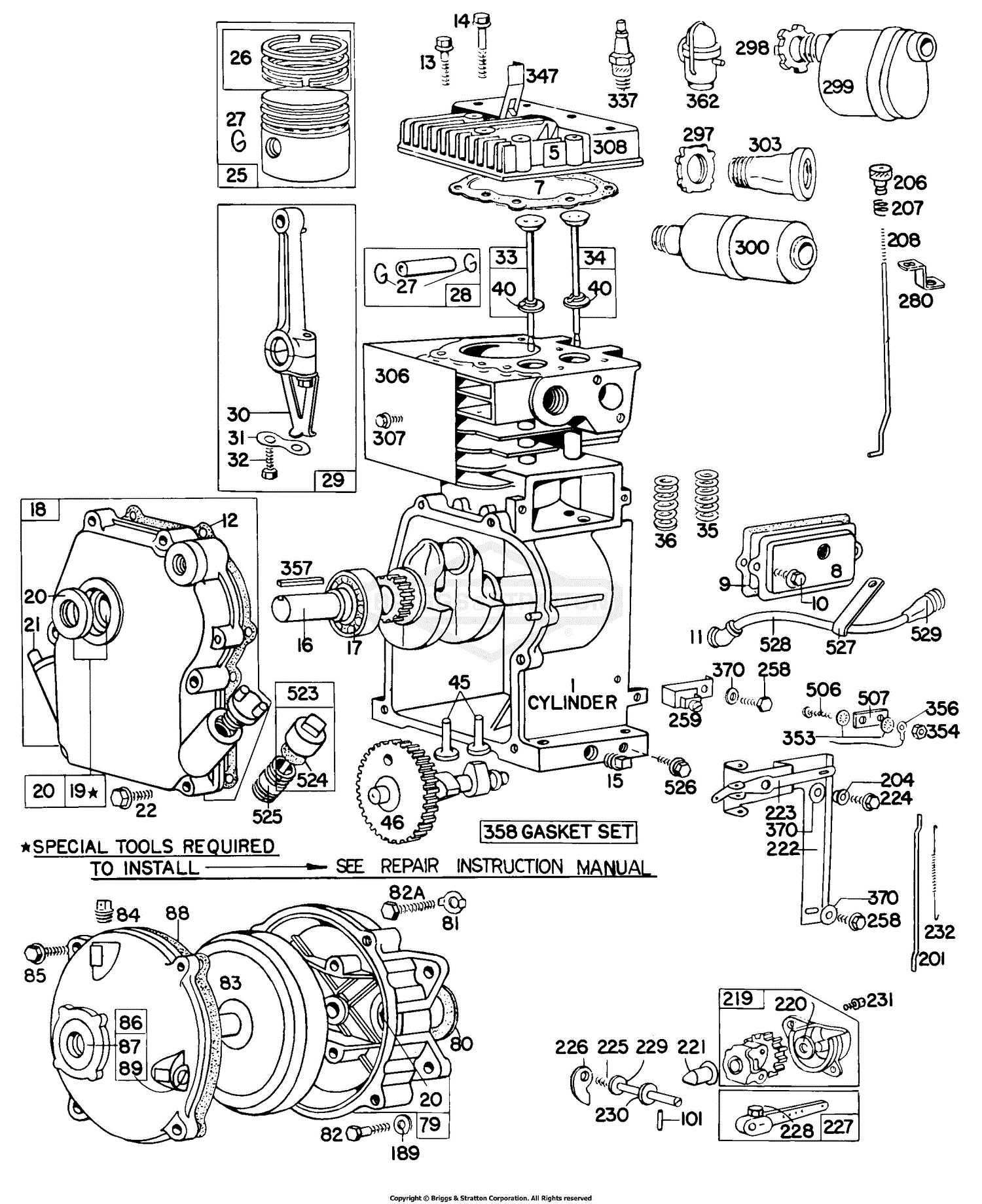

Crankshaft and Piston Details

The crankshaft and piston assembly plays a crucial role in the functionality of small engines. This essential mechanism transforms linear motion into rotational energy, driving the overall operation of the unit. Understanding the characteristics and specifications of these components is vital for maintenance and performance enhancement.

Crankshaft: The crankshaft is a key element that converts the up-and-down motion of the piston into rotational motion. Typically crafted from high-strength materials, it ensures durability and efficiency. The design features several critical points, including journals and counterweights, which balance the engine and minimize vibrations during operation.

Piston: The piston is a cylindrical component that moves within the engine’s cylinder, creating pressure that drives the crankshaft. Made from lightweight alloys, the piston is designed to withstand extreme temperatures and pressures. It often includes features such as piston rings, which enhance sealing and reduce oil consumption, thereby improving the overall efficiency of the engine.

Conclusion: Together, the crankshaft and piston form a fundamental assembly in small engines, contributing significantly to their performance and reliability. Proper knowledge of these components aids in effective troubleshooting and repair processes.

Valve Mechanism and Timing Overview

The valve system is a crucial component in the functioning of any internal combustion engine, governing the intake and exhaust processes. This mechanism ensures that the air-fuel mixture enters the combustion chamber at the right time while allowing exhaust gases to exit efficiently. Proper timing of these operations is essential for optimal performance and fuel efficiency.

Understanding the timing of the valve operation is vital, as it directly affects the engine’s efficiency and power output. The synchronization of the opening and closing of valves with the movement of the piston is achieved through a carefully designed arrangement. This alignment allows for precise control over the combustion cycle, enhancing overall performance.

Components involved in the valve mechanism include camshafts, lifters, and rocker arms. Each of these parts plays a specific role in facilitating the movement of the valves. Regular inspection and maintenance of these components are important to prevent issues such as misalignment or wear that can lead to decreased engine performance.

In summary, the valve mechanism and its timing are fundamental to the efficient operation of an engine. A well-functioning system not only improves power delivery but also contributes to the longevity of the engine itself.

Cooling System Components

The cooling mechanism is crucial for maintaining optimal operating temperatures in small engines. A well-functioning system ensures the engine runs efficiently, preventing overheating and prolonging its lifespan. This section delves into the essential elements that constitute the cooling assembly, highlighting their functions and interconnections.

Key Elements

Several vital components work in unison to regulate engine temperature. These parts include the cooling fins, air intake, and cooling shroud, each contributing to effective heat dissipation.

Functionality Overview

Understanding how each component operates can aid in diagnosing potential issues within the cooling assembly. Proper maintenance of these elements is essential for the reliable performance of the engine.

| Component | Description |

|---|---|

| Cooling Fins | Metal extensions that increase surface area for heat dissipation. |

| Air Intake | Channel that directs airflow to enhance cooling efficiency. |

| Cooling Shroud | Casing that directs airflow over the engine components. |

Common Wear and Tear Areas

In any mechanical system, certain components are more prone to deterioration due to regular use and environmental factors. Identifying these areas can help in proactive maintenance, ensuring optimal performance and longevity of the equipment. Understanding the common sections that experience wear can aid in planning timely replacements or repairs.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Cylinder Head | Cracks, warping, or loss of compression | Inspect regularly and replace if necessary |

| Piston Rings | Excessive oil consumption, loss of power | Check for wear and replace as needed |

| Fuel Lines | Cracks, leaks, or hardening | Inspect for integrity and replace if damaged |

| Air Filter | Clogging or excessive dirt accumulation | Clean or replace to maintain airflow |

| Blade | Dullness, chips, or breaks | Sharpen regularly or replace if severely damaged |