Comprehensive Guide to Briggs and Stratton Push Mower Parts Diagram

The maintenance and operation of outdoor machinery can often be a daunting task for many users. Familiarity with the individual elements of these devices enhances efficiency and ensures longevity. Analyzing the structure of such equipment unveils the significance of each component in the overall functionality.

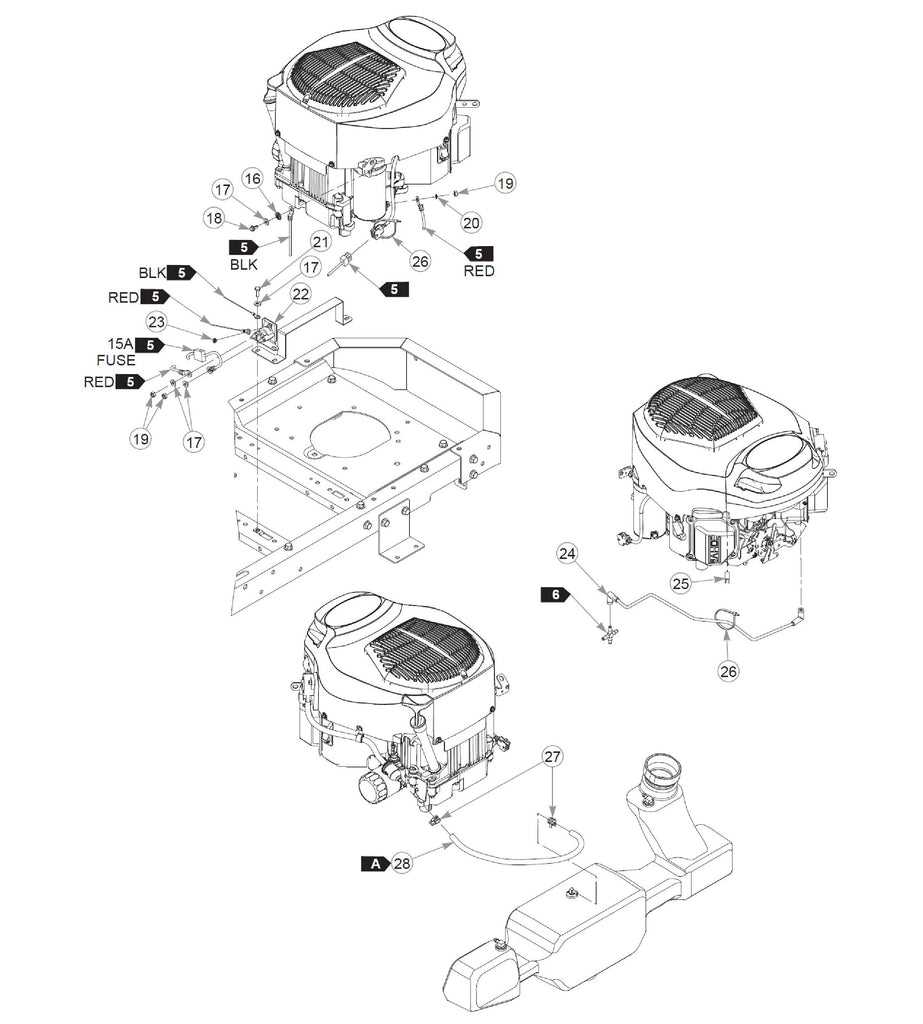

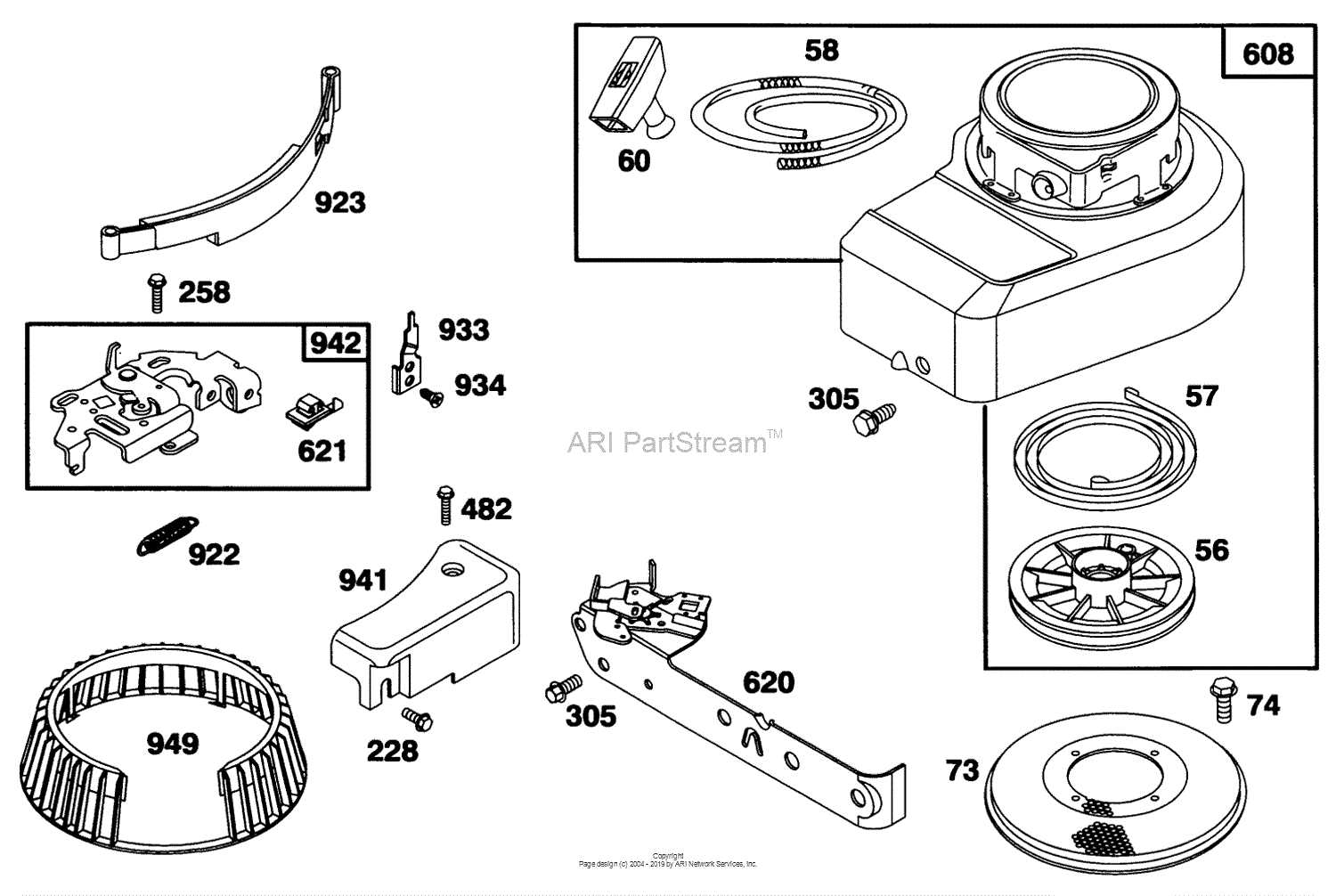

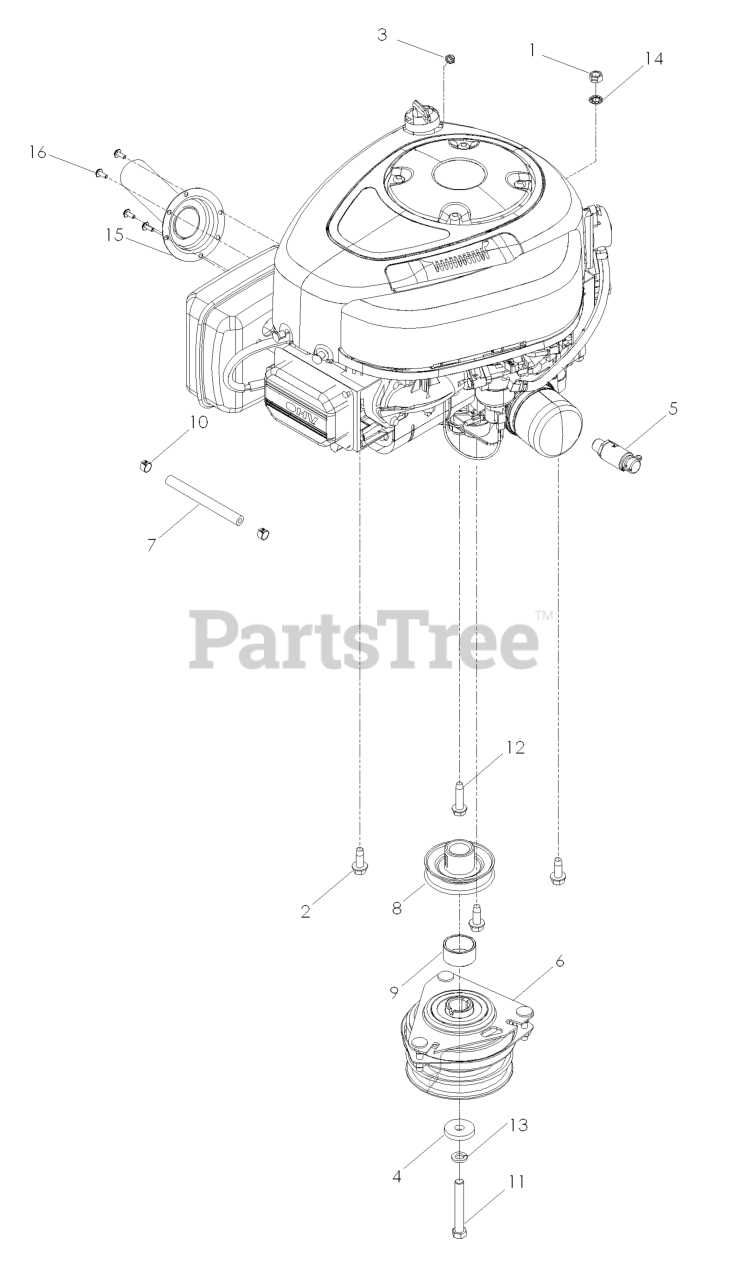

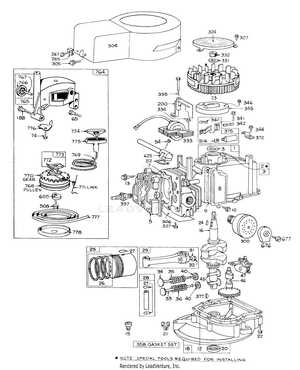

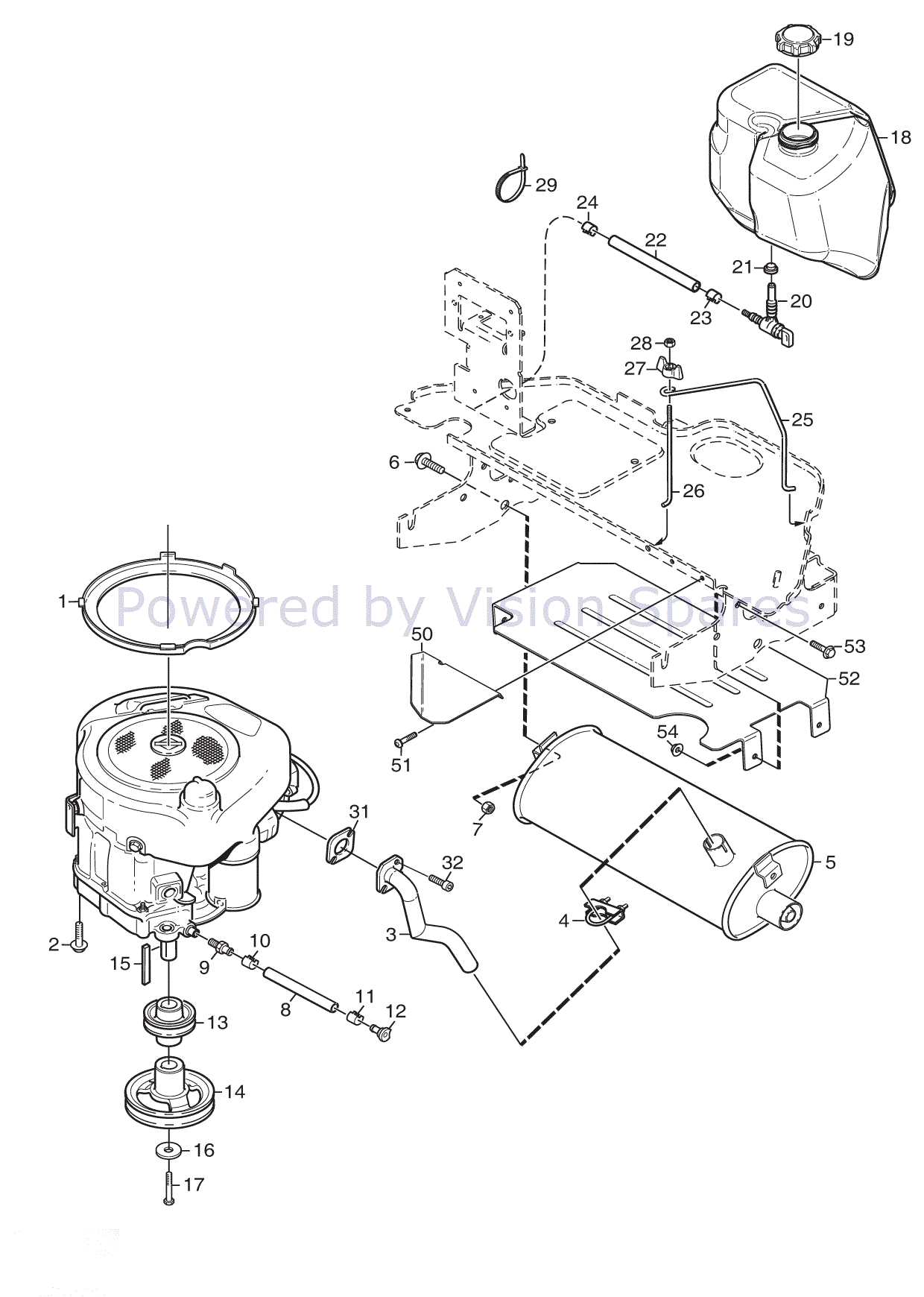

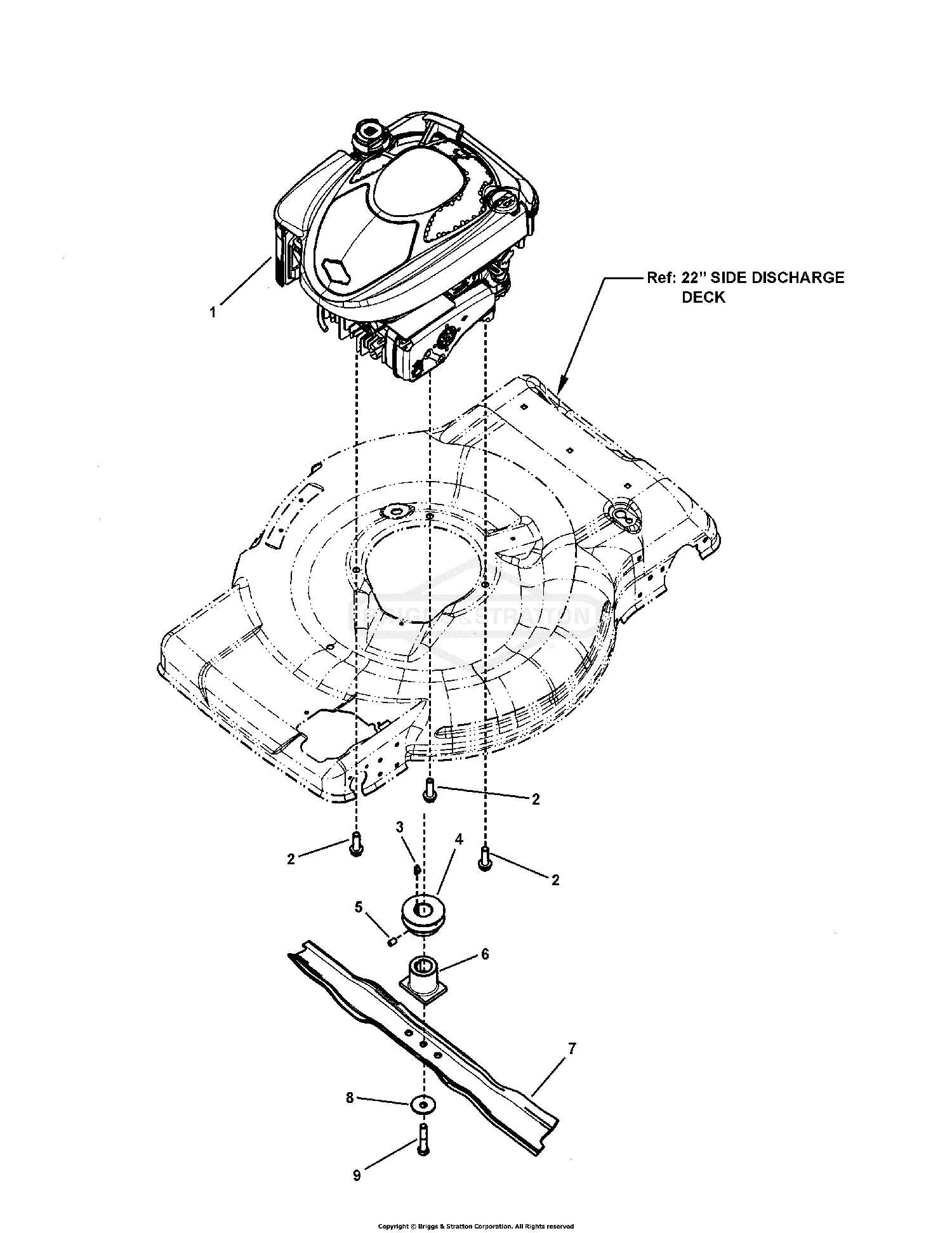

In this section, we will explore a visual representation that elucidates the intricate relationships between various elements. By gaining insight into their arrangement, users can make informed decisions regarding repairs and replacements. This knowledge ultimately empowers owners to maximize the performance of their machines.

Whether you are a seasoned enthusiast or a novice, understanding the intricacies of your equipment will lead to better care and maintenance practices. As we delve into this topic, we will emphasize the importance of knowing how each part contributes to the machine’s operation.

Understanding Briggs and Stratton Mowers

Exploring the intricacies of lawn maintenance machines reveals a world of engineering excellence and reliability. These tools are designed to simplify yard care, providing efficient performance for various outdoor tasks. Familiarity with their components and functionality enhances user experience and extends the lifespan of the equipment.

Key Components

Each machine consists of several essential elements that contribute to its overall efficiency. Understanding these parts allows for better maintenance and troubleshooting.

| Component | Description |

|---|---|

| Engine | Power source driving the machine, available in various sizes. |

| Deck | The housing that supports the cutting mechanism. |

| Blades | Sharp edges responsible for cutting grass to the desired length. |

| Wheels | Facilitate movement across different terrains. |

Maintenance Tips

Regular upkeep ensures optimal functionality. Checking oil levels, sharpening blades, and cleaning debris are crucial steps to prolong the machine’s life and maintain performance.

Essential Components of Push Mowers

Understanding the key elements that contribute to the functionality of lawn maintenance devices is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance, durability, and ease of use.

Main Functional Elements

- Engine: Powers the entire mechanism.

- Deck: Houses the cutting blade and ensures stability.

- Blade: Responsible for cutting grass efficiently.

- Wheels: Provide mobility and maneuverability.

- Handle: Allows for control and navigation during use.

Supportive Features

- Chassis: Framework that supports various components.

- Fuel System: Supplies necessary energy to the engine.

- Air Filter: Ensures optimal airflow to the engine.

- Bagging System: Collects clippings for a tidy lawn.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair. These illustrations provide a clear overview, helping users identify individual elements and their interconnections within machinery.

Key Elements to Focus On

When examining these visuals, pay attention to the labels, which often indicate specific items. Additionally, note the numbering system, as it correlates to the list of components, enhancing clarity.

Tips for Effective Interpretation

Start by familiarizing yourself with the layout. Break down the image into sections to avoid feeling overwhelmed. Refer to the accompanying list for detailed descriptions of each item.

| Component | Description |

|---|---|

| Blade | The cutting element responsible for trimming grass. |

| Engine | Powers the entire system, ensuring optimal functionality. |

| Deck | Holds all components together, providing stability. |

Common Parts and Their Functions

This section explores various components typically found in lawn care equipment, highlighting their roles and importance in maintaining functionality and efficiency.

- Engine: The heart of the equipment, responsible for generating power.

- Blade: Essential for cutting grass, the sharpness and design impact performance.

- Deck: The casing that houses the blade, protecting users and ensuring stability.

- Handle: Provides control and maneuverability, often adjustable for user comfort.

- Wheels: Facilitate movement, with size and tread affecting terrain navigation.

Understanding these essential components can help users maintain their equipment more effectively.

Identifying Replacement Parts Easily

Understanding how to recognize the necessary components for your lawn equipment is crucial for maintaining its performance. A clear grasp of the different elements involved can simplify the process of finding suitable substitutes, ultimately ensuring your machine runs smoothly and efficiently.

Utilizing Visual Guides

One of the most effective methods for identifying components is through the use of visual aids. Diagrams or images that depict the various sections of the machinery can provide a clearer perspective on what to look for. By comparing your device with these resources, you can easily spot worn or damaged items that need to be replaced.

Consulting Manufacturer Resources

Manufacturers often provide comprehensive resources that detail their equipment. These resources can include catalogs, manuals, and online databases. Referencing these materials not only helps in identifying the correct components but also ensures compatibility with your specific model, minimizing the risk of purchasing incorrect items.

Maintenance Tips for Lawn Mowers

Regular upkeep is essential for ensuring the longevity and efficiency of your grass-cutting equipment. By following a few simple practices, you can keep your machine in top shape, enhancing its performance and extending its lifespan. This guide outlines key maintenance strategies to help you achieve optimal results.

Routine Checks

- Inspect the blades regularly for signs of wear and tear.

- Ensure the air filter is clean and free from debris.

- Examine the fuel system for leaks or blockages.

- Check the oil level and quality, changing it as needed.

Seasonal Maintenance

- Sharpen the cutting blades at the beginning of each season.

- Clean the undercarriage to remove grass clippings and dirt.

- Store the unit in a dry place during the off-season.

- Inspect belts and cables for any signs of fraying or damage.

By following these maintenance tips, you can ensure your equipment remains efficient, reliable, and ready for any lawn care task.

Where to Buy Genuine Parts

Finding authentic components for your outdoor equipment is essential for maintaining performance and longevity. Quality replacements ensure your machine operates smoothly and efficiently, minimizing the risk of breakdowns and enhancing overall durability.

One of the best options for sourcing original components is through authorized dealers. These retailers specialize in genuine merchandise and often provide additional support, including expert advice on installation and maintenance. Visiting a local dealer can also foster a sense of community and trust, as you engage with knowledgeable staff who understand your specific needs.

Another reliable avenue is online marketplaces dedicated to outdoor equipment. Many reputable websites offer extensive catalogs of authentic items, complete with detailed descriptions and customer reviews. Shopping online allows for easy price comparisons and the convenience of home delivery.

Manufacturer websites are also an excellent source for purchasing genuine components. They often feature up-to-date inventories and exclusive items not available elsewhere. Moreover, buying directly from the source ensures you receive high-quality products tailored for your specific model.

Finally, don’t overlook local repair shops. Many technicians maintain a stock of genuine components and can provide personalized service. Building a relationship with a local expert can prove invaluable for future maintenance and repairs.

Tools Needed for DIY Repairs

Undertaking home maintenance can be a rewarding experience, especially when equipped with the right instruments. Having the essential tools at your disposal not only simplifies the repair process but also enhances efficiency and safety. Whether you’re a novice or an experienced handyman, the proper equipment is crucial for successful outcomes.

Basic Hand Tools

Start with fundamental implements such as screwdrivers, wrenches, and pliers. These hand tools are versatile and can tackle various tasks. Investing in a quality set ensures durability and reliability for numerous projects.

Power Tools

For more extensive repairs, consider adding power tools to your collection. Drills, saws, and grinders can significantly reduce effort and time. Always prioritize safety by using protective gear while operating these machines.

Common Issues and Solutions

This section explores frequent challenges encountered with lawn maintenance equipment and provides effective solutions to enhance performance and longevity. Identifying these common problems can save time and improve the overall efficiency of your device.

One prevalent issue is engine starting difficulties, often caused by a clogged fuel filter or stale gasoline. To resolve this, ensure the fuel is fresh and replace the filter if necessary.

Another common problem is uneven cutting. This can result from dull blades or improper height settings. Regularly sharpening the blades and adjusting the height can ensure a consistent cut.

Overheating is also a frequent concern, typically due to low oil levels or debris obstructing airflow. Regularly check the oil level and clean the cooling fins to maintain optimal operating temperatures.

Finally, frequent stalling may occur due to a blocked air filter or issues with the spark plug. Cleaning or replacing these components can significantly improve performance and reliability.

Safety Precautions During Repairs

Ensuring personal safety during maintenance tasks is essential to prevent accidents and injuries. Proper precautions can make a significant difference in creating a secure environment while working on equipment.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and appropriate clothing to shield against potential hazards. |

| Disconnect Power Source | Before beginning any repairs, ensure that the equipment is completely disconnected from its power supply. |

| Use Proper Tools | Utilize the correct tools for the job to avoid damage and ensure efficiency. |

| Work in a Well-Lit Area | Ensure that the workspace is adequately illuminated to see clearly and minimize mistakes. |

| Read the Manual | Familiarize yourself with the manufacturer’s instructions and safety guidelines specific to the equipment. |

Enhancing Mower Performance with Upgrades

Improving the efficiency and effectiveness of your lawn equipment can lead to a more satisfying gardening experience. By exploring various enhancements, users can unlock the full potential of their machinery, resulting in superior cutting performance and longevity.

Key Upgrades to Consider

Engine Enhancements: Upgrading the engine or its components can significantly boost power and reliability. Consider investing in a high-performance air filter or an improved spark plug for better combustion and efficiency.

Maintenance Tips for Optimal Functionality

Regular maintenance plays a crucial role in ensuring your equipment runs smoothly. Keep blades sharp and clean, check tire pressure, and replace worn-out components promptly to maintain peak performance.

FAQs About Push Mower Parts

This section addresses common inquiries regarding components of lawn care equipment, providing clarity for users seeking to maintain or repair their machines. Understanding the essential elements can enhance performance and longevity.

What are the most common components that need replacement?

Typically, users may find themselves replacing blades, air filters, spark plugs, and drive belts. Regular checks can prevent malfunctions and ensure optimal functionality.

How can I identify the correct components for my machine?

Referencing the user manual or manufacturer’s specifications is crucial. Online resources and diagrams can also assist in accurately pinpointing the required items for your specific model.