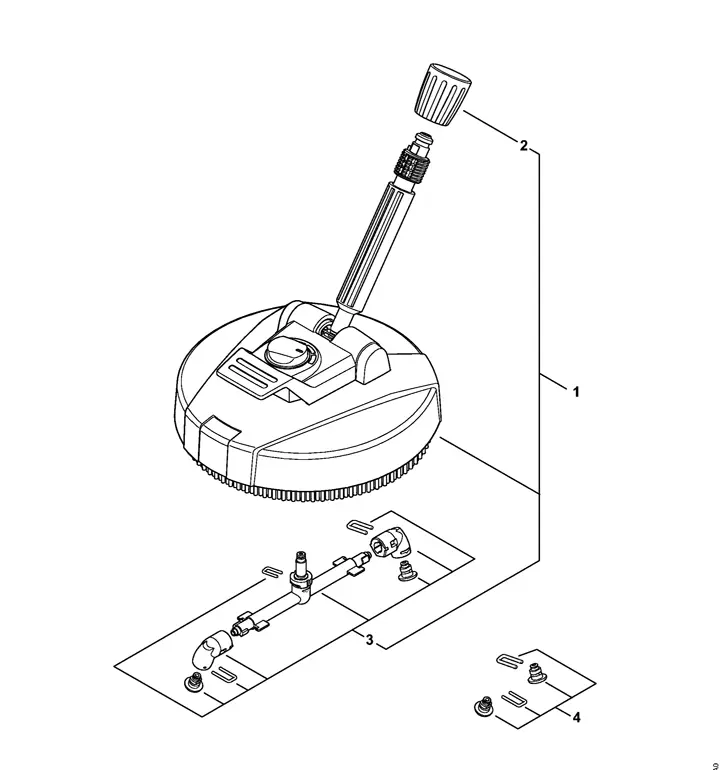

Briggs and Stratton Surface Cleaner Parts Overview

For those seeking effective cleaning solutions, familiarizing oneself with the various accessories can enhance the overall experience. These attachments play a vital role in optimizing cleaning efficiency and performance, making it essential to comprehend their functionality and arrangement.

In this section, we will delve into the key elements of a popular attachment used with power washers. By exploring the design and assembly, users can gain valuable insights into maintenance and troubleshooting, ensuring longevity and optimal operation of the equipment.

Recognizing the individual components and their respective roles allows for informed decisions during repairs or upgrades. Understanding these elements not only improves operational skills but also contributes to achieving the best results in cleaning tasks.

Briggs and Stratton Surface Cleaner Overview

This section provides a comprehensive look at a specific cleaning device designed for efficiency and effectiveness. These tools are essential for maintaining various outdoor surfaces, ensuring they remain in excellent condition while saving time and effort.

Key features of this cleaning apparatus include:

- Design: Engineered for optimal performance, allowing users to tackle large areas quickly.

- Functionality: Capable of removing dirt, grime, and debris with minimal effort, enhancing surface appeal.

- Compatibility: Designed to work seamlessly with various pressure washers, making it a versatile addition to cleaning equipment.

Overall, this cleaning solution is a valuable investment for anyone looking to maintain the aesthetics and durability of outdoor spaces. Its user-friendly design ensures that both professionals and homeowners can benefit from its use.

Essential Components of Surface Cleaners

Understanding the key elements of pressure washing attachments is crucial for efficient operation. Each component plays a specific role in enhancing performance and ensuring effective cleaning results. Familiarity with these vital elements can lead to improved maintenance and prolonged lifespan of the equipment.

| Component | Description |

|---|---|

| Housing | The outer shell that protects internal parts and provides structural integrity. |

| Wheels | Facilitate easy movement across surfaces, enhancing maneuverability. |

| Nozzles | Control the flow and pattern of water, allowing for targeted cleaning. |

| Handle | Provides user control and comfort while operating the cleaning device. |

| Rotating Arm | Enables a spinning action for even coverage and efficient dirt removal. |

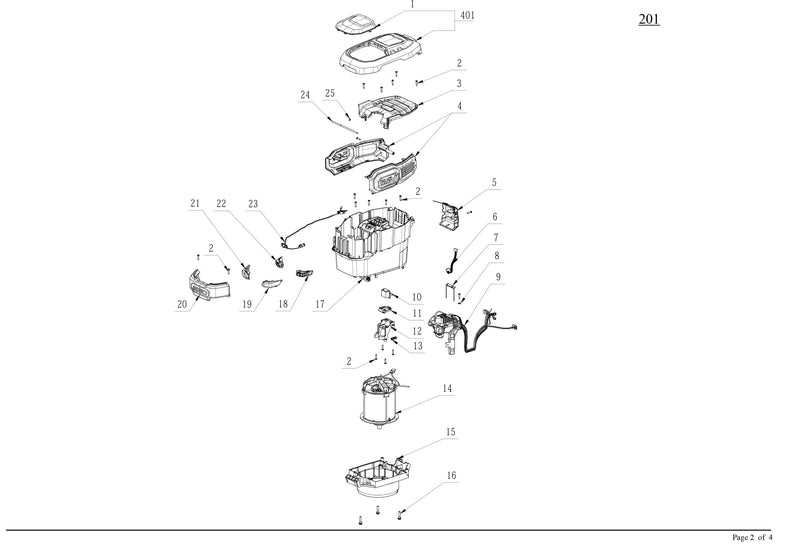

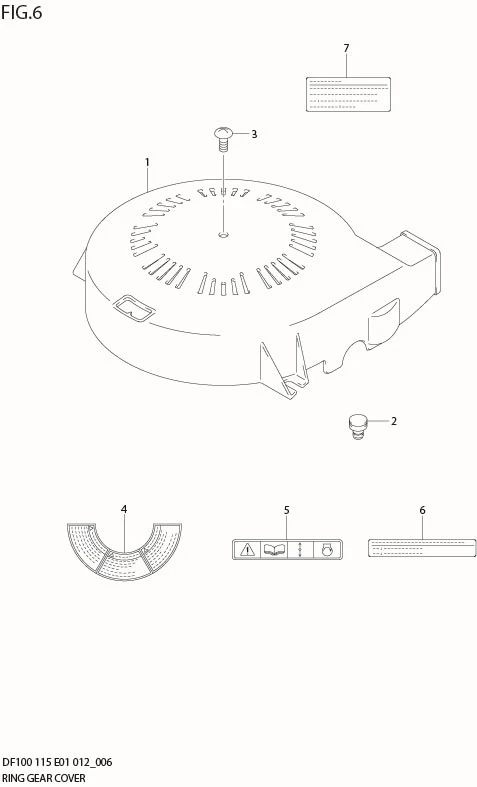

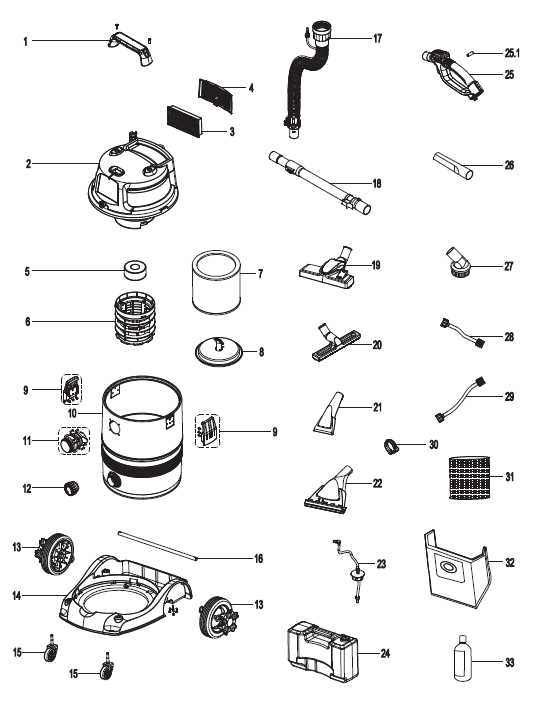

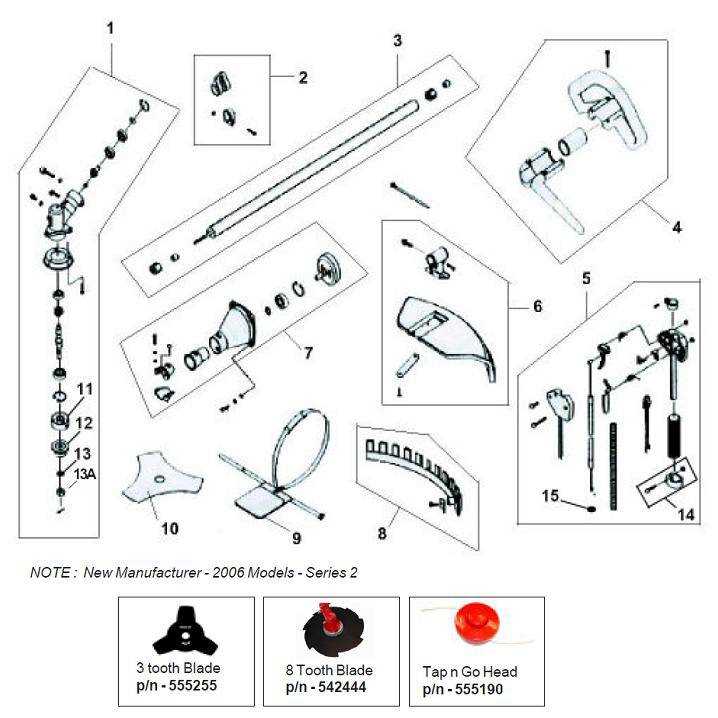

Understanding the Parts Diagram

This section provides an overview of a visual representation that illustrates the components of a cleaning device. Familiarity with this illustration aids in identifying individual elements, understanding their functions, and facilitating maintenance or repair tasks.

Each segment of the illustration is typically labeled with corresponding numbers or letters, which correspond to specific parts. This enhances clarity when referencing the manual or ordering replacements. The diagram is an essential resource for troubleshooting and ensuring the longevity of the device.

| Label | Description |

|---|---|

| 1 | Wheel Assembly |

| 2 | Housing Unit |

| 3 | Brush Mechanism |

| 4 | Water Inlet |

| 5 | Power Supply Connection |

Common Replacement Parts Explained

This section provides insights into essential components that may need to be replaced over time. Understanding these elements can enhance the longevity and efficiency of your equipment, ensuring optimal performance during use. Regular maintenance and timely replacement of these components can prevent larger issues and extend the overall lifespan of the machine.

Key Components to Consider

Several crucial elements are often subject to wear and tear. Recognizing their significance can help in maintaining functionality and preventing operational failures. Here are some of the most commonly replaced components:

| Component | Function | Signs of Wear |

|---|---|---|

| Seals | Prevent leaks and maintain pressure | Leaks or reduced pressure |

| Filters | Trap debris and impurities | Reduced performance or clogs |

| Spray Nozzles | Direct water flow for effective cleaning | Ineffective cleaning or uneven spray |

Maintenance Tips

To ensure the reliability of your equipment, regularly inspect these components for any signs of damage or wear. Timely replacements not only maintain efficiency but also enhance the safety and effectiveness of your machine. Adopting a routine maintenance schedule can significantly impact performance and prolong the lifespan of your equipment.

How to Read Parts Diagrams

Understanding assembly illustrations is essential for effective maintenance and repairs. These visual representations help identify components and their relationships within the system, making it easier to locate and replace specific items.

To interpret these visuals successfully, follow these guidelines:

- Familiarize Yourself with Symbols: Different symbols represent various elements, such as fasteners, connectors, and subassemblies. Knowing these can aid in comprehension.

- Identify the Key: Most illustrations include a legend or key that explains the symbols used. Always refer to this section for clarity.

- Study the Layout: Observe how components are arranged. This layout can reveal how parts interact and the order of assembly.

- Follow the Flow: Many diagrams illustrate the sequence in which parts should be assembled or disassembled. Understanding this flow is crucial for effective repairs.

- Cross-Reference with Manuals: Use accompanying manuals for additional information on specifications and installation procedures. They often provide further insights.

By applying these tips, you can effectively utilize assembly illustrations, leading to smoother maintenance processes and enhanced repair accuracy.

Identifying Surface Cleaner Attachments

Understanding the components of a washing device is essential for efficient maintenance and operation. Recognizing the various accessories that enhance performance can significantly impact the effectiveness of the cleaning process. This section focuses on the different attachments that are commonly used with these devices, helping users identify their functions and benefits.

Types of Attachments

Attachments come in various forms, each serving specific purposes to optimize cleaning. Below are some common types:

| Attachment Type | Description |

|---|---|

| Rotary Brush | Utilizes spinning bristles for deep scrubbing, ideal for stubborn dirt. |

| Flat Surface Nozzle | Designed for large areas, providing even pressure for efficient cleaning. |

| Extension Wand | Allows reach to high or hard-to-access areas, enhancing versatility. |

| Detailing Brush | Perfect for intricate surfaces, ensuring thorough cleaning in tight spots. |

Choosing the Right Attachment

Selecting the appropriate accessory is crucial for achieving desired results. Consider the specific tasks at hand and the surfaces being cleaned to make informed choices that enhance overall efficiency and effectiveness.

Maintenance Tips for Surface Cleaners

Proper upkeep is essential for ensuring the longevity and efficiency of cleaning equipment. Regular maintenance helps in identifying potential issues before they escalate and ensures optimal performance. Here are some practical suggestions to enhance the durability and functionality of your cleaning tool.

Routine Checks and Cleaning

Performing regular inspections can significantly prolong the life of your equipment. Make sure to clean the components after each use to remove dirt and debris that can cause wear. Pay close attention to:

| Component | Maintenance Tip |

|---|---|

| Hoses | Check for cracks and leaks; replace if necessary. |

| Nozzles | Clear any blockages to maintain water flow. |

| Wheels | Lubricate regularly to ensure smooth operation. |

Storage Recommendations

When not in use, store your equipment in a clean, dry place. Avoid leaving it outdoors, as exposure to harsh weather can lead to damage. Additionally, consider detaching hoses and other accessories for compact storage and to prevent wear.

Diagnosing Issues with Parts Diagrams

Understanding how components interact is crucial for effective troubleshooting. By analyzing visual representations, users can identify discrepancies and improve their maintenance strategies. This section will guide you through recognizing common issues using these illustrations.

When examining the visual aids, consider the following points:

- Component Placement: Ensure that each element is in its designated location. Misalignment can lead to malfunctions.

- Connection Points: Check all links between parts. Loose or damaged connections can disrupt performance.

- Wear and Tear: Look for signs of damage or excessive wear on visible components. Regular inspection can prevent more serious problems.

- Compatibility: Verify that all components are compatible with each other. Using the wrong parts can lead to operational issues.

By systematically assessing these factors, users can effectively diagnose potential problems and ensure their equipment operates smoothly.

Ordering Replacement Parts Online

Finding suitable components for your equipment has become increasingly convenient with online platforms. Whether you’re looking to replace a broken element or upgrade your current setup, numerous websites offer a wide selection of items to meet your needs. Understanding the ordering process and identifying reliable sources is crucial for a smooth transaction.

Steps to Place an Order

To begin, start by identifying the specific component you need. Gather any necessary information, such as model numbers or product specifications. Once you have this information, navigate to a reputable online retailer that specializes in hardware or accessories for outdoor equipment. Utilize their search function to locate the desired item. After finding the appropriate component, review the product details, including compatibility and pricing. Finally, proceed to checkout and complete your order by providing shipping information and payment details.

Ensuring Quality and Compatibility

Before finalizing your purchase, it’s essential to verify that the item is compatible with your device. Read customer reviews and product descriptions to ensure you’re selecting a high-quality component. If you have questions, consider reaching out to customer service for clarification. This diligence can help prevent issues and ensure your equipment runs smoothly after the replacement.

Benefits of Using Genuine Parts

Utilizing authentic components for your machinery can significantly enhance its performance and longevity. These items are designed specifically for your equipment, ensuring a perfect fit and optimal function. Choosing genuine options over generic alternatives can lead to a more reliable and efficient operation.

Some key advantages include:

- Enhanced Reliability: Authentic components are manufactured to the highest standards, reducing the risk of failures.

- Improved Performance: Genuine parts work seamlessly with your equipment, providing better overall efficiency.

- Longer Lifespan: High-quality materials and precise engineering result in durability, prolonging the life of your machinery.

- Warranty Protection: Using original components often maintains warranty coverage, offering peace of mind.

- Optimal Safety: Authentic parts are designed with safety in mind, minimizing the chances of accidents during operation.

In summary, investing in genuine components is crucial for maintaining the integrity and performance of your equipment. The benefits they provide far outweigh the initial cost, ensuring a worthwhile investment for the future.

Tools Needed for Surface Cleaner Repair

When it comes to maintaining and fixing your cleaning equipment, having the right tools is essential. Using appropriate instruments not only simplifies the process but also ensures that repairs are carried out effectively. Below are the necessary tools that will aid in the repair tasks.

Essential Instruments

- Wrench Set: A variety of wrenches is crucial for loosening and tightening bolts.

- Screwdriver Set: Both flathead and Phillips screwdrivers are needed for different types of screws.

- Socket Set: Useful for reaching tight spaces and providing better leverage.

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

Additional Accessories

- Safety Goggles: Protects your eyes from debris while working.

- Gloves: Keeps hands safe and clean during the repair process.

- Shop Vacuum: Helps to clean up any mess created during repairs.

- Work Light: Provides adequate lighting for better visibility in dark areas.

Step-by-Step Repair Instructions

Follow these detailed guidelines to effectively troubleshoot and fix common issues with your cleaning apparatus. This section provides a structured approach to ensure a successful repair process.

-

Preparation:

- Gather necessary tools such as screwdrivers, wrenches, and replacement components.

- Ensure you have a clean workspace to facilitate organization.

- Disconnect the equipment from its power source for safety.

-

Inspection:

- Examine the unit for visible signs of wear or damage.

- Check hoses and connections for leaks or blockages.

- Identify any unusual noises during operation that may indicate issues.

-

Disassembly:

- Carefully remove any panels or covers using appropriate tools.

- Document the order of disassembly to aid reassembly later.

- Store screws and small parts in labeled containers.

-

Component Replacement:

- Replace damaged or worn parts with new ones, ensuring compatibility.

- Follow manufacturer guidelines for installing new components.

- Reconnect any hoses or electrical connections securely.

-

Reassembly:

- Reattach panels and covers in the reverse order of disassembly.

- Ensure all screws are tightened properly to prevent any loose fittings.

-

Testing:

- Reconnect the equipment to its power source.

- Conduct a brief test to confirm that repairs were successful.

- Monitor the unit for any further issues during operation.

By following these steps, you can efficiently restore your cleaning equipment to optimal performance.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components used in cleaning equipment. Understanding these elements is crucial for maintenance and effective operation. Here, we provide insights into the most frequently asked questions to help users make informed decisions.

What should I consider when purchasing replacements? It’s essential to ensure compatibility with your specific model. Checking the dimensions and specifications is critical to avoid any issues during installation.

How can I identify which component needs replacement? If you notice decreased performance or unusual sounds, it may indicate that a part requires attention. Referencing your user manual can guide you in diagnosing potential issues.

Where can I find genuine components? Authorized retailers or official websites often provide authentic replacements. It’s advisable to avoid third-party sellers unless they are reputable to ensure quality.

How often should components be inspected? Regular inspections, ideally before each use, can help in identifying wear and tear. This proactive approach can prevent larger issues down the line.