Understanding the Briggs and Stratton Vanguard 14 HP Parts Diagram

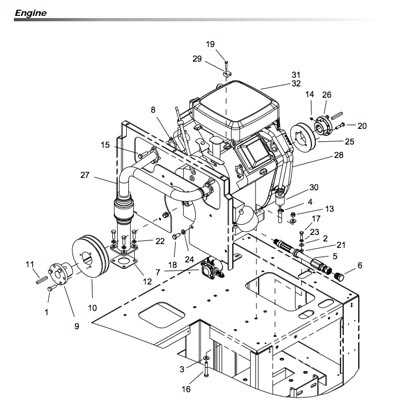

In the realm of small engines, comprehending the intricacies of each component is essential for maintenance and troubleshooting. A well-structured illustration of these elements can serve as a valuable resource for enthusiasts and professionals alike. This section delves into the key features and functionalities of a specific engine model, providing insights into its operational mechanics.

Identifying the various elements within an engine not only aids in effective repairs but also enhances overall efficiency. Each part plays a crucial role, contributing to the smooth functioning of the machine. By exploring the detailed layout of these components, users can gain a clearer understanding of their interactions and importance.

Moreover, having access to a comprehensive overview enables users to make informed decisions regarding maintenance and upgrades. This knowledge fosters a deeper appreciation for the craftsmanship behind engine design and promotes longevity through proactive care.

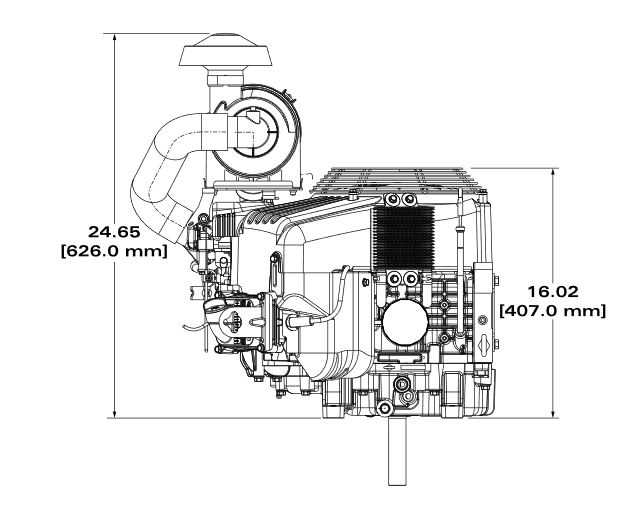

Understanding Vanguard 14 HP Engine Design

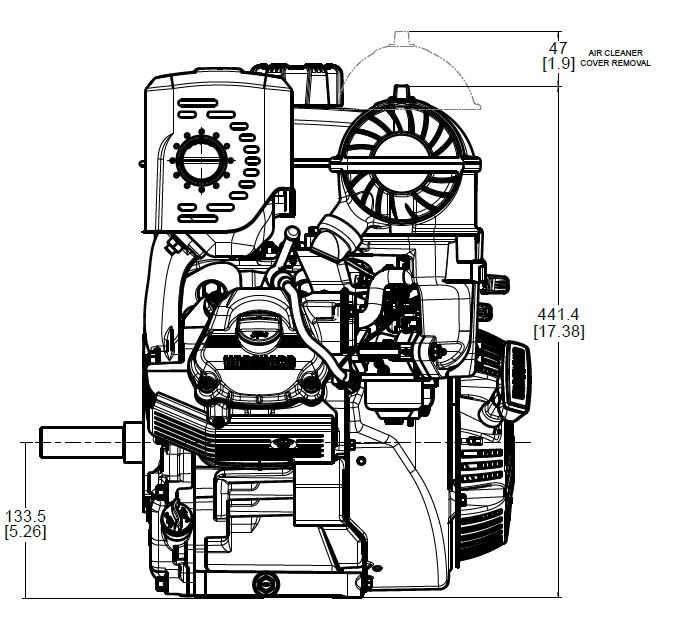

The design of a 14 horsepower engine is a testament to modern engineering, emphasizing reliability and efficiency. This powerful machine integrates various components that work in harmony, ensuring optimal performance for a range of applications. Understanding its structure and function can help users appreciate the intricacies involved in its operation.

Key Components of the Engine

Several essential elements contribute to the effective functioning of the engine. Each part plays a unique role, influencing overall performance and longevity. The following table outlines some of the critical components:

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process, where fuel and air mix and ignite. |

| Piston | Moves up and down within the cylinder, transferring energy to the crankshaft. |

| Crankshaft | Converts linear motion from the piston into rotational motion, powering the engine. |

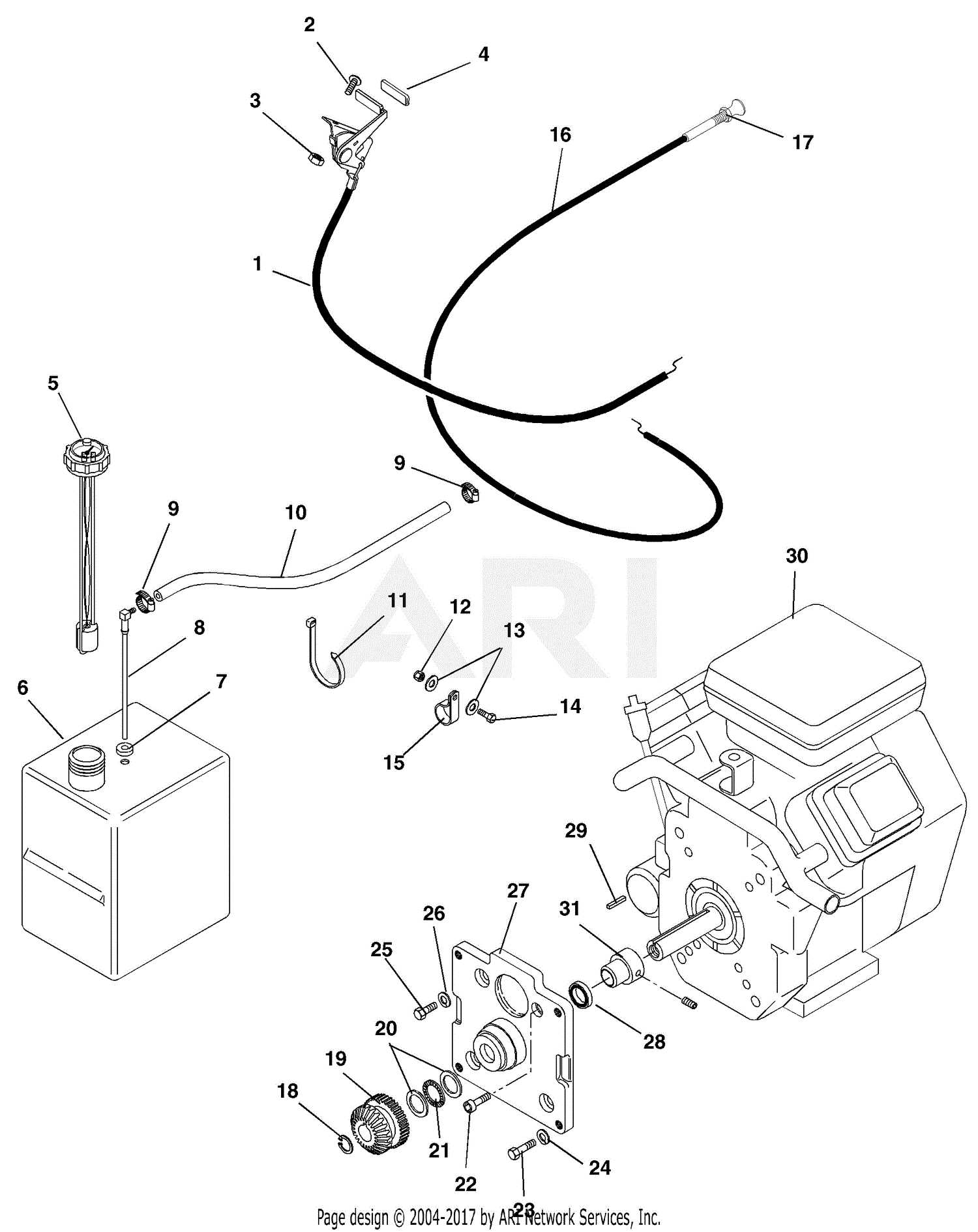

| Fuel System | Delivers the necessary fuel to the combustion chamber for efficient operation. |

| Cooling System | Maintains optimal operating temperature, preventing overheating during use. |

Performance and Efficiency

The thoughtful engineering of the 14 HP unit enhances performance metrics such as torque and fuel efficiency. By optimizing the airflow and combustion process, manufacturers aim to achieve a balance between power output and fuel consumption. This careful design ensures that the engine meets the demands of various tasks, whether in industrial or recreational settings.

Key Features of Briggs and Stratton Engines

This section highlights the essential characteristics that set these power units apart in the market. Known for their reliability and performance, these engines are engineered to meet various operational needs, making them suitable for both residential and commercial applications.

Durability and Longevity

One of the standout aspects of these power sources is their robust construction. Designed with high-quality materials, they can withstand demanding conditions, ensuring a longer lifespan. Regular maintenance further enhances their durability, allowing users to enjoy extended service without frequent replacements.

Versatile Performance

These engines offer exceptional versatility, catering to a range of applications from lawn care to industrial uses. Their ability to adapt to different tasks without sacrificing power makes them a preferred choice among professionals and hobbyists alike. The efficient design ensures optimal fuel consumption, providing effective performance in diverse settings.

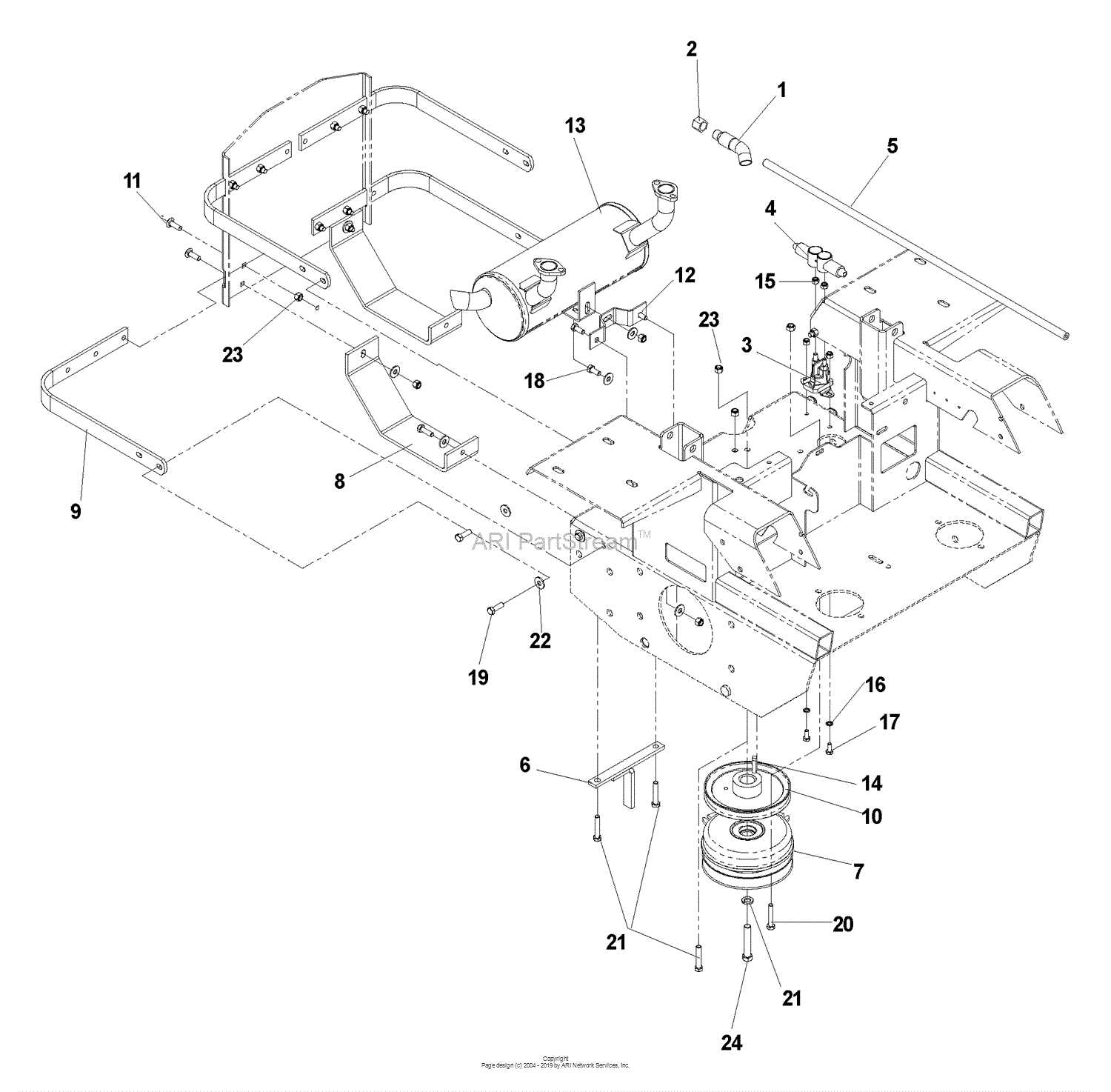

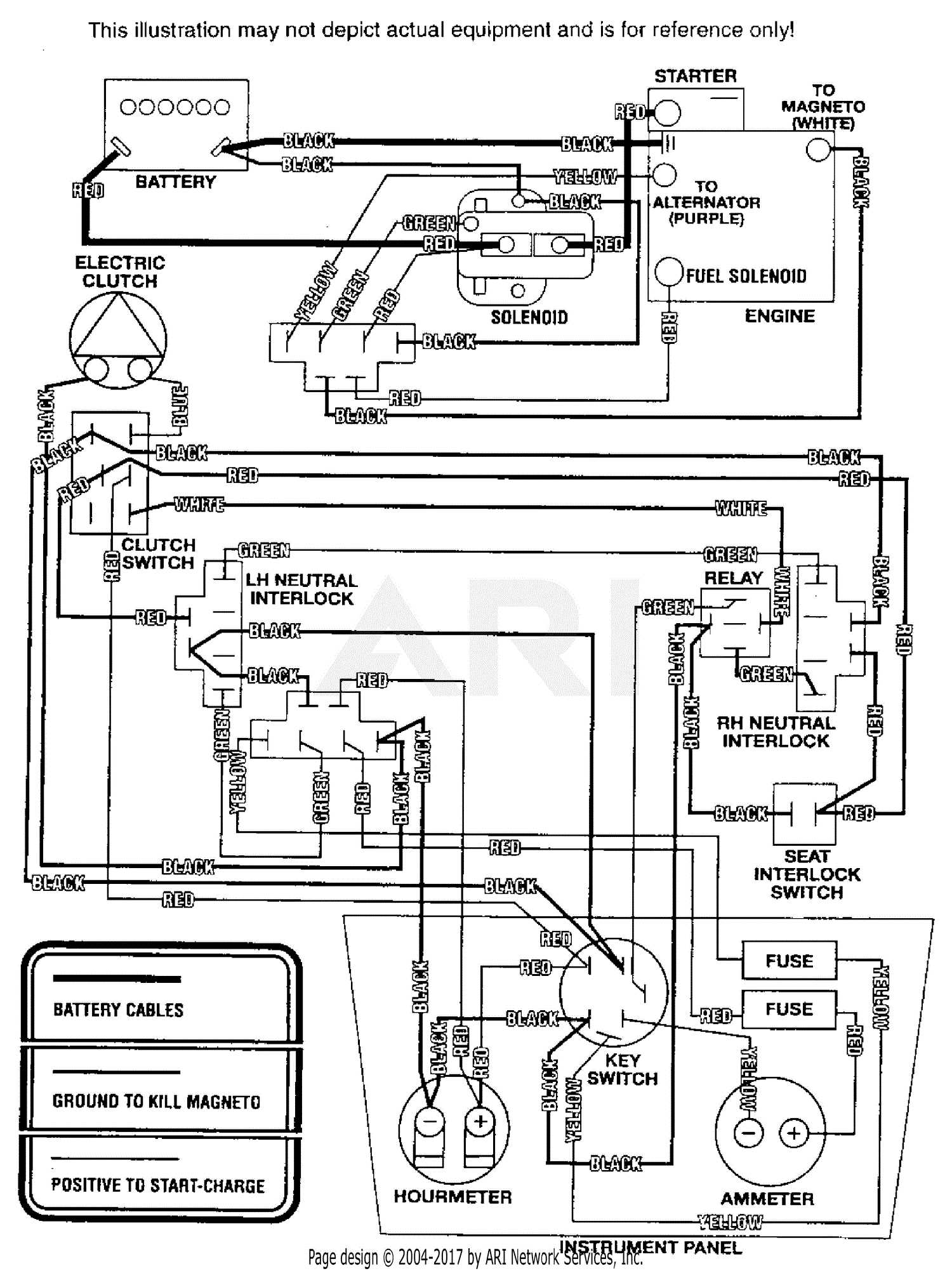

Importance of Parts Diagrams for Maintenance

Understanding the various components of machinery is crucial for effective upkeep. Visual representations that illustrate the arrangement and function of these elements provide invaluable guidance for both novices and experienced users. These tools facilitate a deeper comprehension of how systems operate and where issues may arise.

Accurate identification of individual components is vital for troubleshooting. When a machine malfunctions, having a visual reference enables quick recognition of the specific area that requires attention. This minimizes downtime and ensures efficient repairs.

Moreover, these illustrations serve as educational resources. They help users familiarize themselves with the construction of their equipment, enhancing their ability to perform maintenance tasks confidently. Knowing where each element is located can also prevent misdiagnosis and unnecessary disassembly.

Additionally, clear representations foster better communication between users and service professionals. When discussing repairs or replacements, having a visual aid simplifies explanations and reduces misunderstandings, leading to more effective solutions.

In summary, visual aids that detail the various components of equipment are essential for successful maintenance. They not only streamline the repair process but also empower users with knowledge and improve collaboration with service experts.

Common Issues with Vanguard 14 HP Engines

Understanding the typical problems encountered with small power units is essential for effective maintenance and longevity. Various challenges can arise, impacting performance, reliability, and overall functionality. Recognizing these issues early can save time and resources in the long run.

Fuel System Challenges

One prevalent issue involves the fuel delivery system. Clogged filters or fuel lines can restrict flow, leading to inadequate performance. Additionally, using stale fuel can cause significant complications, resulting in hard starting or stalling. Regularly inspecting and replacing filters, along with ensuring fresh fuel, can mitigate these concerns.

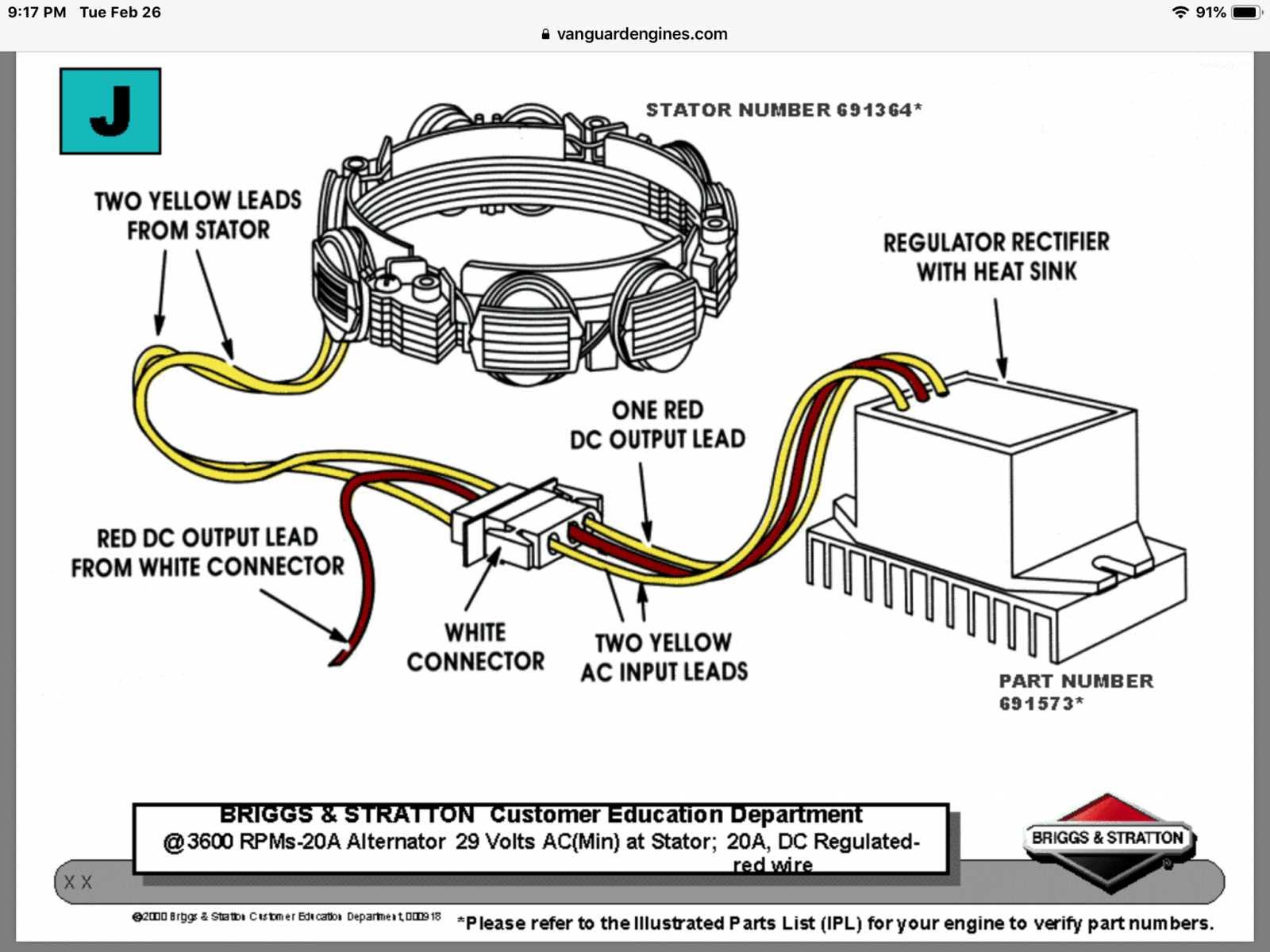

Electrical System Failures

The electrical components of these engines can also be a source of difficulty. Faulty spark plugs or defective ignition coils can hinder starting or cause rough running. Periodic checks and timely replacements of these components are vital to maintaining optimal operation.

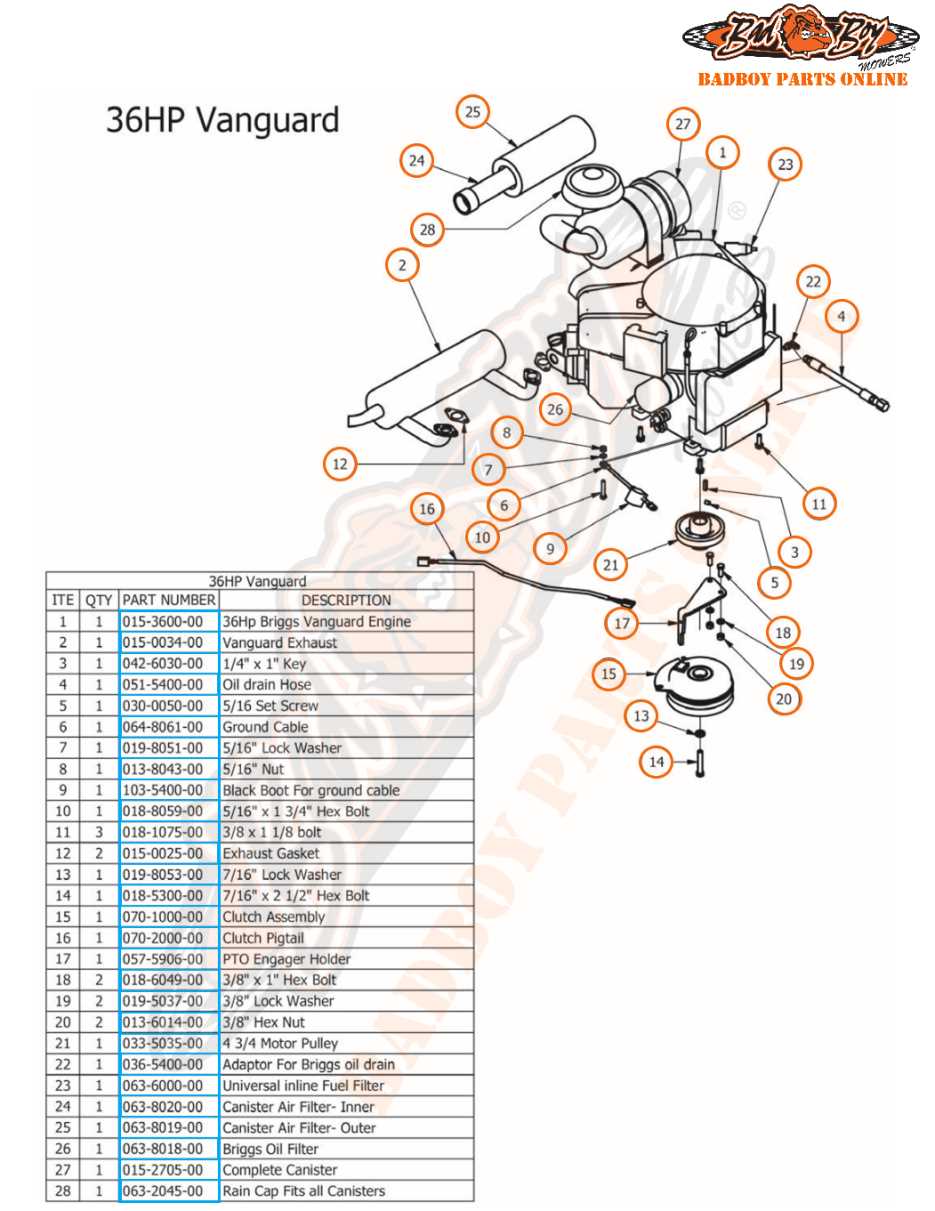

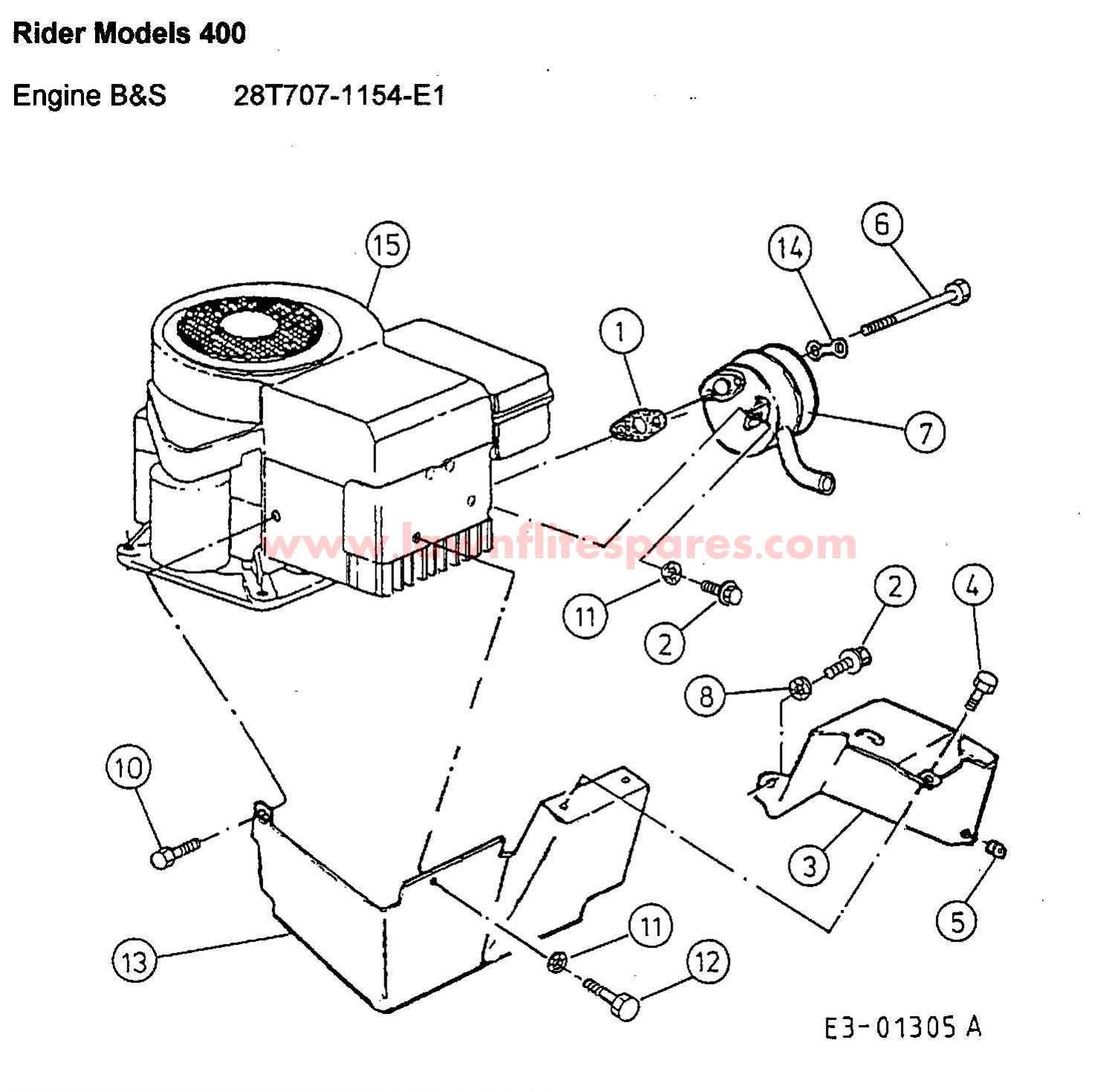

Identifying Parts for Easy Replacement

Recognizing components within machinery is essential for efficient maintenance and repair. By familiarizing oneself with each element, users can swiftly identify what needs to be replaced, ensuring smooth operation and longevity of the equipment. This process not only minimizes downtime but also enhances overall performance.

Key Components to Focus On

Understanding the main elements that typically require attention can simplify the replacement process. Here are some critical components to consider:

| Component | Function |

|---|---|

| Engine Block | Houses all engine parts and maintains structure. |

| Carburetor | Mixes air and fuel for combustion. |

| Fuel Tank | Stores fuel for engine operation. |

| Ignition Coil | Generates spark for engine start. |

| Air Filter | Prevents dirt and debris from entering the engine. |

Tips for Successful Identification

To enhance your ability to identify components, consider these strategies:

- Consult the user manual for a detailed list of components.

- Utilize online resources, including forums and instructional videos.

- Take notes or photos of each element for future reference.

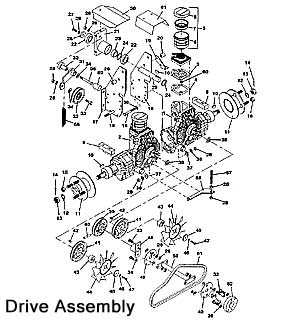

Tools Required for Engine Repair

Proper maintenance and repair of small engines necessitate a specific set of instruments. Having the right tools on hand not only facilitates the repair process but also ensures safety and efficiency. Understanding which instruments are essential can make a significant difference in the outcome of your work.

Essential Hand Tools include screwdrivers, wrenches, and pliers. These basic tools are crucial for disassembling and reassembling engine components. A reliable socket set is also indispensable for tightening or loosening various bolts.

Specialized Equipment may be required depending on the complexity of the repair. A torque wrench is vital for applying the correct amount of force to bolts, preventing damage. Additionally, a multimeter can help diagnose electrical issues, ensuring all systems are functioning properly.

Cleaning Supplies should not be overlooked. Engine parts often accumulate dirt and grime, so having brushes, rags, and appropriate solvents will help maintain cleanliness during repairs. This is essential for optimal performance and longevity.

Safety Gear is equally important. Wearing gloves, goggles, and masks protects against potential hazards while working on engines. Always prioritize personal safety to prevent injuries during maintenance tasks.

By equipping yourself with the necessary tools and safety measures, you can effectively tackle engine repairs with confidence and precision.

Step-by-Step Guide to Troubleshooting

Troubleshooting engine issues can seem daunting, but with a systematic approach, it becomes manageable. This guide will walk you through identifying common problems, isolating their causes, and implementing effective solutions.

-

Gather Necessary Tools: Before starting, ensure you have the following items on hand:

- Wrench set

- Screwdrivers (flathead and Phillips)

- Multimeter

- Clean rags

- Safety goggles

-

Inspect Fuel System: Begin by checking the fuel supply.

- Ensure there is adequate fuel in the tank.

- Examine the fuel lines for cracks or blockages.

- Verify that the fuel filter is clean.

-

Check Electrical Components: Electrical issues can often cause performance problems.

- Inspect the battery for charge and connections.

- Examine wiring for signs of wear or damage.

- Test the ignition system using a multimeter.

-

Assess Air Intake: A clear air supply is crucial for optimal operation.

- Inspect the air filter for dirt and debris.

- Ensure the intake system is free from obstructions.

-

Evaluate Engine Performance: If the engine is running poorly, listen for unusual sounds.

- Check for any abnormal vibrations.

- Observe exhaust for excessive smoke.

-

Conduct a Final Test: After making adjustments, it’s essential to test the engine.

- Start the engine and monitor its operation.

- Look for any signs of leaks or strange noises.

By following these steps, you can effectively troubleshoot issues and enhance the performance of your engine. Always prioritize safety and consult a professional if uncertain about any procedures.

Finding Original Vanguard Replacement Parts

Locating authentic components for machinery can significantly enhance performance and longevity. Ensuring that you use the correct pieces designed for your specific engine model helps maintain optimal functionality and efficiency. This section will guide you through the process of sourcing genuine replacements that fit your needs.

Identifying Authentic Components

When searching for original components, it is crucial to understand how to distinguish them from aftermarket options. Genuine items often come with specific markings or part numbers. Always check the manufacturer’s specifications to ensure compatibility. Here are some tips to help you identify genuine components:

| Tip | Description |

|---|---|

| Verify Part Numbers | Always cross-reference the part number with the manufacturer’s catalog. |

| Check Quality | Authentic components typically have a superior build quality compared to generic versions. |

| Authorized Dealers | Purchase from certified retailers to ensure you are getting genuine items. |

Where to Purchase Genuine Components

There are several reliable sources for acquiring authentic components. Local dealers often stock a wide variety, while online platforms may offer convenience and competitive pricing. Be sure to review customer feedback to gauge the reliability of the seller. Some recommended sources include:

| Source | Description |

|---|---|

| Official Retailers | These vendors offer the latest genuine components and often have knowledgeable staff. |

| Online Marketplaces | Websites specializing in machinery often provide a vast selection of original items. |

Comparing Vanguard with Other Engine Models

When evaluating different power units, it’s essential to consider various attributes that influence performance, durability, and efficiency. This analysis will focus on comparing a specific engine series with other popular models in the market, highlighting key differences and advantages.

Performance Characteristics

One of the primary aspects to examine is the output power and torque. Here’s how the engine in question stands against competitors:

- Power Output: Many units in the same category offer similar horsepower ratings, but some may deliver superior torque at lower RPMs.

- Fuel Efficiency: Comparative studies often reveal varying fuel consumption rates, which can significantly impact long-term operating costs.

- Cooling Systems: Different models employ various cooling mechanisms, affecting their ability to handle extended use under heavy loads.

Durability and Maintenance

Durability is critical for heavy-duty applications. A comparison of longevity and maintenance needs can highlight important distinctions:

- Construction Quality: Some engines are built with more robust materials, enhancing their resistance to wear and tear.

- Maintenance Intervals: Frequency of service checks can vary significantly, influencing overall user convenience.

- Availability of Replacement Components: The ease of sourcing parts can impact repair times and costs.

By analyzing these factors, users can make informed decisions tailored to their specific requirements, ensuring they select the most suitable engine for their applications.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the long-term performance and reliability of your engine. Implementing a consistent maintenance routine can significantly extend its lifespan and enhance efficiency. Here are some practical suggestions to keep your equipment running smoothly.

Regular Inspection

- Check oil levels frequently and change the oil as recommended.

- Inspect air filters for dirt and replace them when necessary.

- Examine fuel lines and connections for leaks or wear.

Cleaning Practices

- Clean the exterior of the engine to prevent dirt buildup.

- Remove debris from cooling fins to ensure proper airflow.

- Wipe down the carburetor to avoid blockages that could hinder performance.

By following these maintenance tips, you can help ensure your engine operates efficiently for years to come.

Upgrades to Enhance Engine Performance

Improving engine efficiency can significantly boost power output and operational reliability. Several modifications can be made to enhance overall performance, ensuring that the engine runs smoothly under various conditions. By focusing on key components and systems, users can achieve remarkable improvements in both speed and fuel efficiency.

Air Intake Modifications

Upgrading the air intake system is one of the most effective ways to increase engine performance. Installing a high-flow air filter allows for better airflow, which can improve combustion efficiency. Additionally, replacing the factory intake manifold with a performance-oriented version can enhance airflow dynamics, contributing to greater power generation.

Exhaust System Enhancements

Optimizing the exhaust system is equally crucial for maximizing performance. A performance exhaust system reduces back pressure, allowing exhaust gases to exit more freely. This not only helps in improving horsepower but also enhances the engine’s sound. Investing in a quality header can further facilitate this process by improving exhaust flow and thermal efficiency.

Resources for Engine Enthusiasts

For those passionate about small machinery, finding quality materials and support is essential. Numerous platforms offer a wealth of information, ranging from repair manuals to troubleshooting guides. These resources can significantly enhance your understanding and maintenance skills, enabling you to tackle various projects with confidence.

Below is a table highlighting some valuable resources for engine aficionados:

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Community-driven discussions where enthusiasts share tips and experiences. | Engine Forum |

| Repair Manuals | Comprehensive guides providing step-by-step repair instructions. | Manuals Online |

| Video Tutorials | Visual guides covering various maintenance and repair tasks. | YouTube |

| Parts Suppliers | Retailers specializing in replacement components and accessories. | Parts Shop |

| Technical Blogs | Expert-written articles offering insights and detailed explanations. | Engine Blog |

Utilizing these resources can lead to improved knowledge and efficiency, ultimately enhancing your engine maintenance journey.

Community Forums and Support Networks

Engaging with online communities can significantly enhance your understanding and troubleshooting skills regarding small engines. These platforms serve as invaluable resources for enthusiasts and professionals alike, offering a space to share experiences, seek advice, and discover solutions to common challenges.

Many forums feature sections dedicated to specific models, where users can exchange tips on maintenance, repairs, and upgrades. By participating in these discussions, you can gain insights from others who have encountered similar issues. The collective knowledge of these networks often leads to quicker resolutions and improved performance.

In addition to forums, social media groups and dedicated websites provide ample opportunities for interaction. Users can post questions, share their success stories, and even upload instructional videos, fostering a collaborative learning environment. Engaging with these networks not only builds a sense of community but also equips you with the tools necessary for effective problem-solving.

Remember, connecting with others who share your passion can make your journey much more enjoyable. Whether you’re a novice or a seasoned expert, tapping into these resources can help you navigate the complexities of engine care with confidence.