Ultimate Guide to Briggs and Stratton Vanguard 18 HP V-Twin Parts Diagram

In the realm of small engines, the significance of comprehending the various elements that contribute to optimal performance cannot be overstated. Each component plays a crucial role in ensuring the machine operates smoothly and efficiently. This exploration aims to illuminate the intricate relationships among these parts, fostering a deeper appreciation for engine mechanics.

By breaking down the essential components, enthusiasts and technicians alike can gain valuable insights into maintenance and repair practices. This knowledge not only enhances the lifespan of the engine but also empowers users to tackle issues with confidence. Engaging with the structure and function of these elements ultimately leads to a more proficient handling of engine-related tasks.

Moreover, understanding the assembly and disassembly processes can significantly aid in troubleshooting. When problems arise, having a clear visual representation of how each piece fits together provides a strategic advantage. This article serves as a guide for those looking to delve into the inner workings of this powerful engine, paving the way for informed decisions and enhanced mechanical skills.

Understanding Vanguard V-Twin Engines

These powerful engines are designed to deliver exceptional performance and reliability, making them ideal for a variety of applications. Their engineering incorporates advanced technology to enhance efficiency and durability, ensuring they can handle demanding tasks with ease.

Key Features

- Robust construction for long-lasting use

- High torque output, suitable for heavy-duty machinery

- Improved fuel efficiency to reduce operational costs

- Quiet operation to minimize noise pollution

Applications

- Commercial lawn care equipment

- Construction machinery

- Generators for reliable power supply

- Utility vehicles for various tasks

Understanding these engines’ unique characteristics helps users choose the right model for their needs, ensuring optimal performance and longevity.

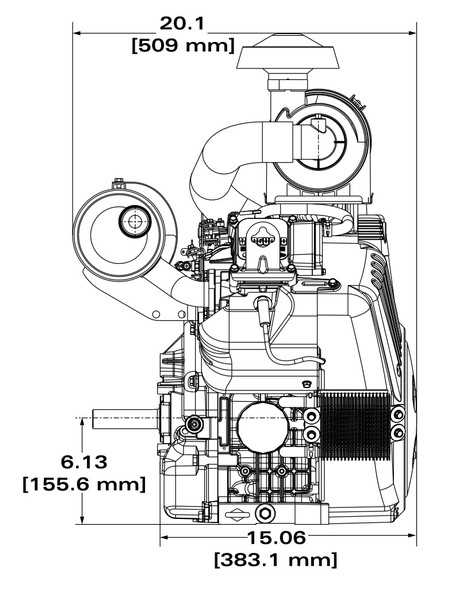

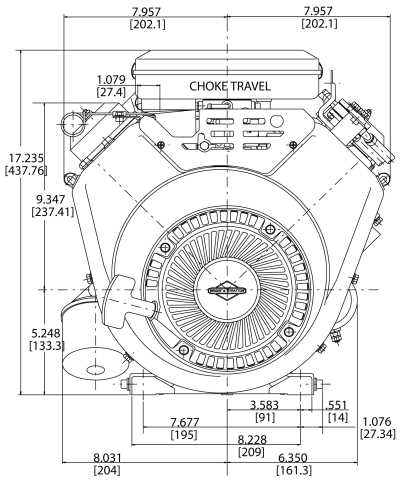

Key Features of 18 HP Model

This engine boasts a range of remarkable characteristics that enhance its performance and reliability. Designed for heavy-duty applications, it delivers efficient power output while maintaining a compact form factor. These features make it a preferred choice for various outdoor equipment and industrial use.

Power and Efficiency

The 18 HP engine is engineered to provide robust power for demanding tasks. Its optimized fuel consumption ensures that users can operate for extended periods without frequent refueling, maximizing productivity.

Durability and Maintenance

Constructed with high-quality materials, this model offers exceptional longevity. Routine maintenance is simplified through accessible components, allowing users to keep the engine in top condition with minimal effort.

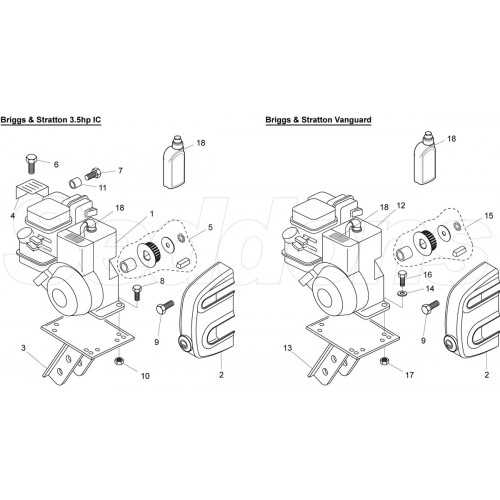

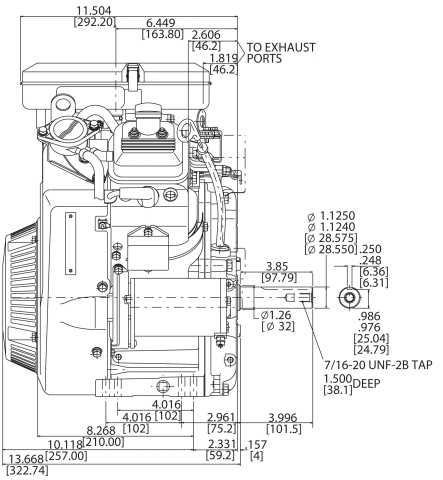

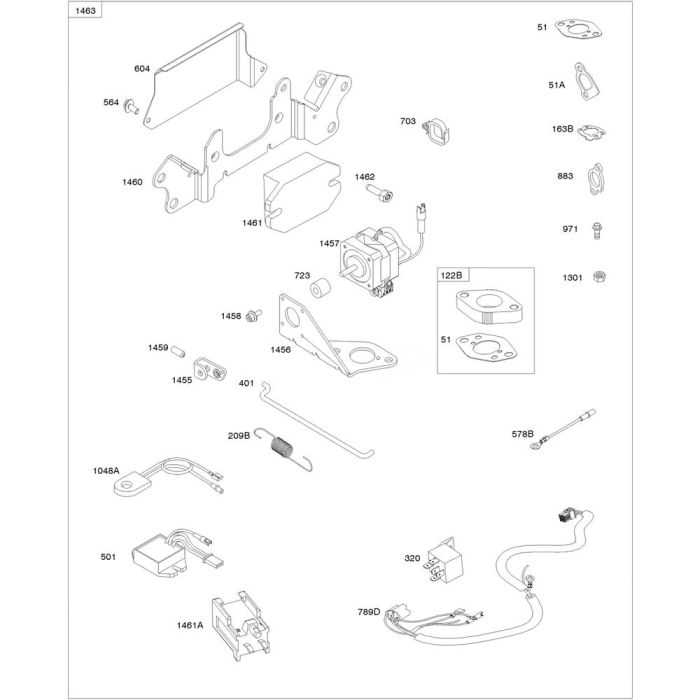

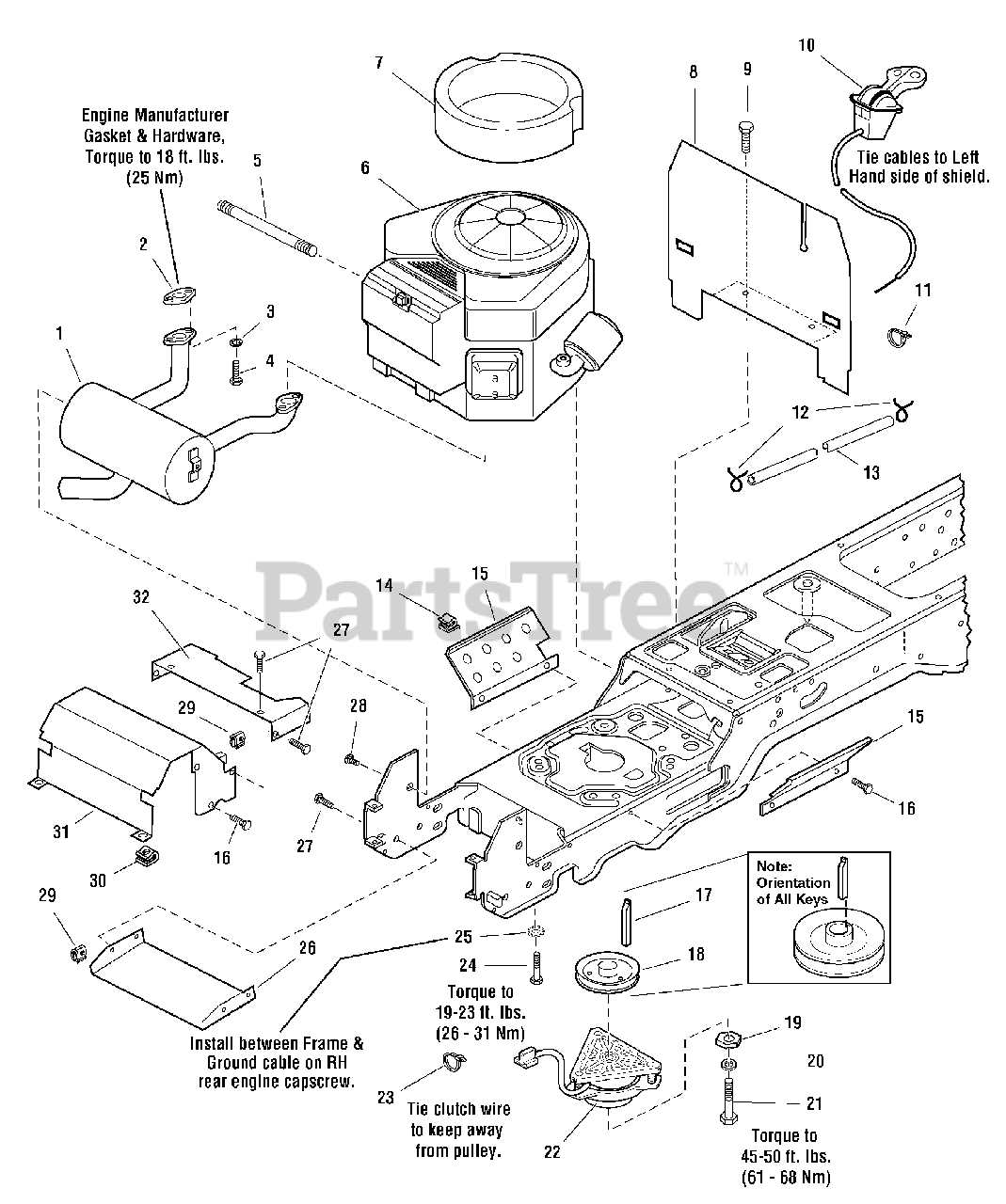

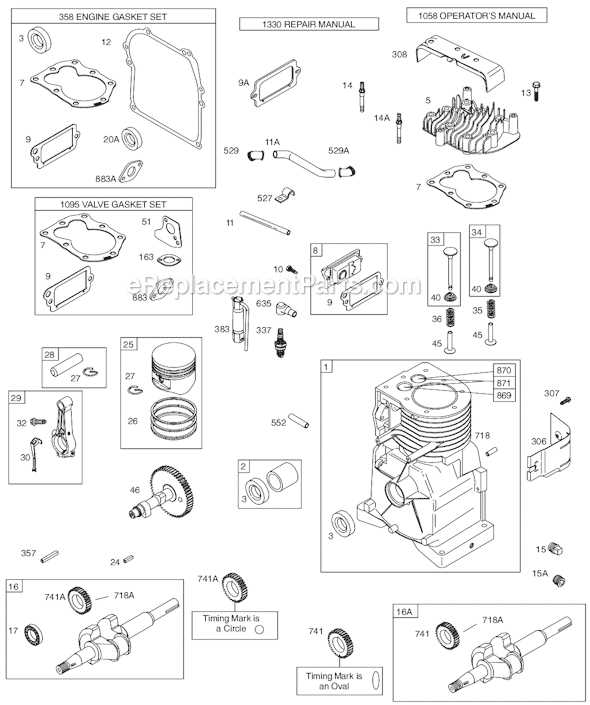

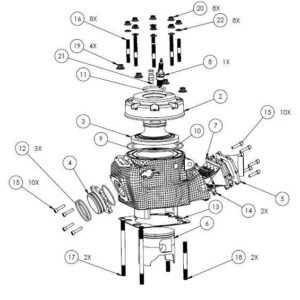

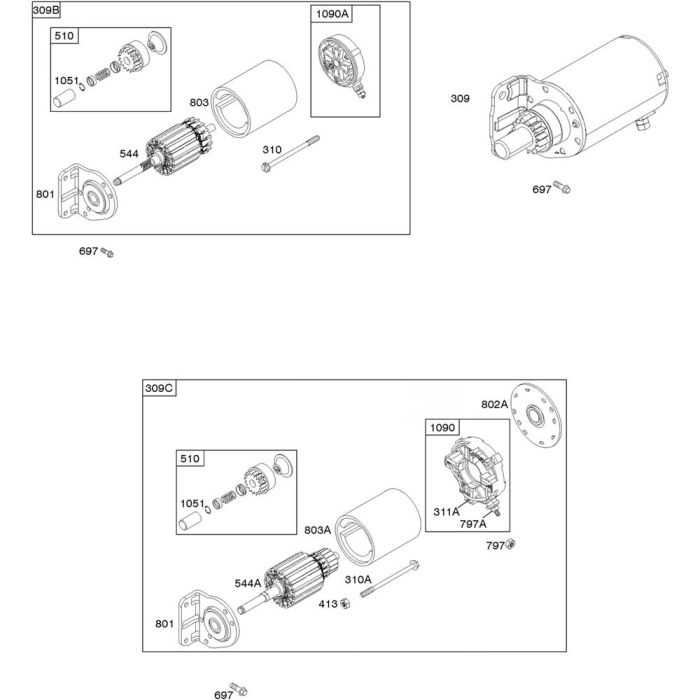

Importance of Parts Diagrams

Visual representations of component layouts play a crucial role in maintenance and repair tasks. They provide clarity, enabling technicians and enthusiasts alike to identify individual elements within complex machinery. Understanding these illustrations can significantly enhance the efficiency of troubleshooting and assembly processes.

Facilitating Troubleshooting

When faced with mechanical issues, a clear visual guide assists in pinpointing the source of the problem. By referring to these graphical depictions, users can quickly locate faulty or worn-out components, thereby streamlining the repair process. This reduces downtime and promotes effective resolution strategies.

Enhancing Assembly Efficiency

Accurate visual aids also improve the assembly of equipment. Knowing where each element fits allows for quicker and more precise construction. This is particularly valuable during reassembly after repairs or when upgrading existing systems. With well-defined visuals, the risk of errors decreases, leading to enhanced performance and longevity of the machinery.

Common Issues with Vanguard Engines

Engines of this type often encounter specific challenges that can affect their performance and longevity. Understanding these common problems is crucial for effective maintenance and timely repairs.

| Issue | Description |

|---|---|

| Overheating | Inadequate cooling can lead to elevated temperatures, resulting in potential damage. |

| Fuel System Problems | Clogs or leaks in the fuel system can cause poor engine performance or stalling. |

| Starting Difficulties | Issues with ignition components may hinder the starting process. |

| Oil Leaks | Worn seals or gaskets can lead to leaks, affecting engine operation. |

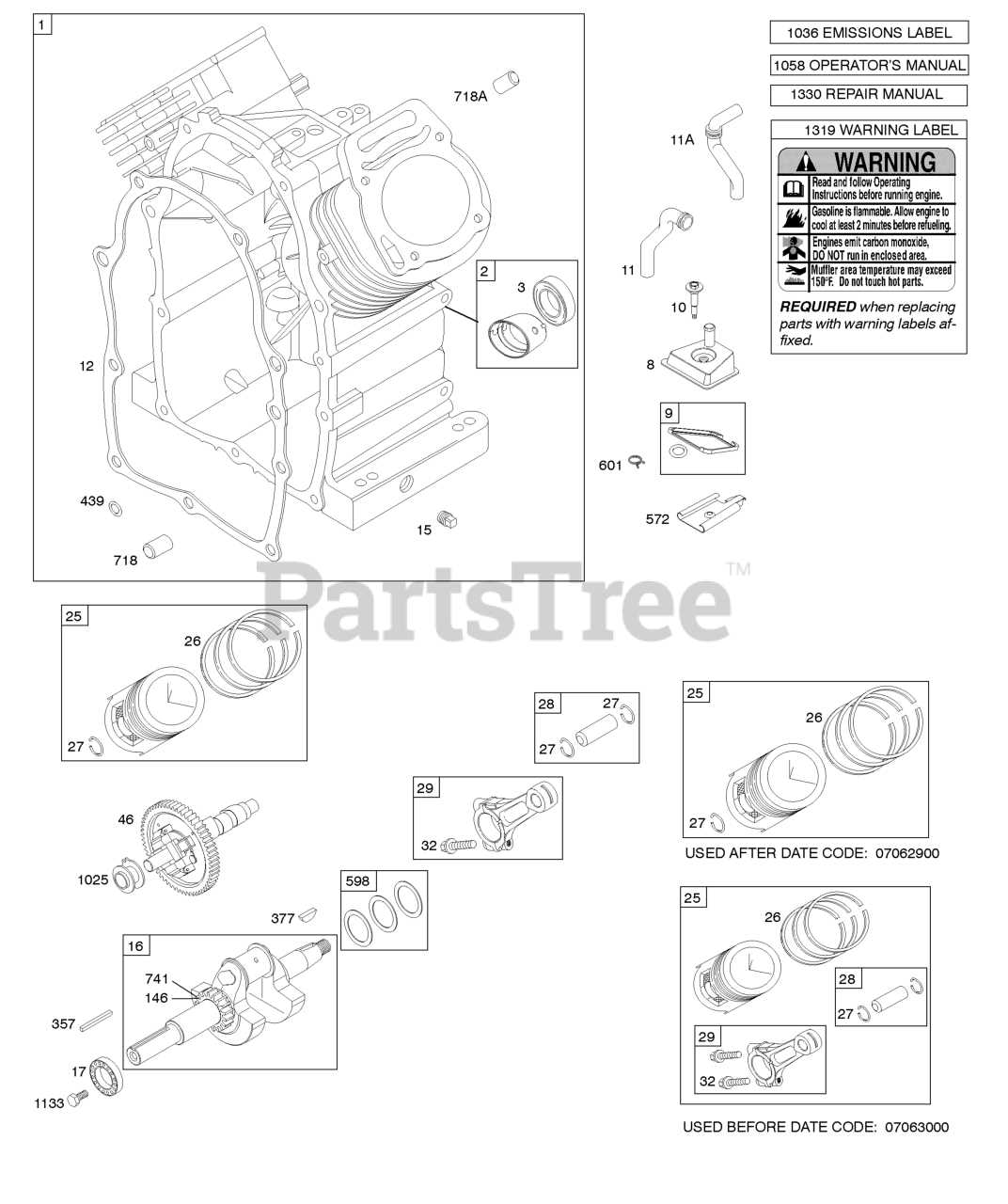

Identifying Essential Components

Understanding the key elements of a small engine is crucial for maintenance and repair. Recognizing each part’s role enhances performance and longevity, allowing for effective troubleshooting.

- Crankshaft: Transmits power from the engine to the drivetrain.

- Piston: Moves within the cylinder to create compression.

- Valves: Control the intake of air and fuel, as well as exhaust release.

- Camshaft: Regulates the timing of valve operations.

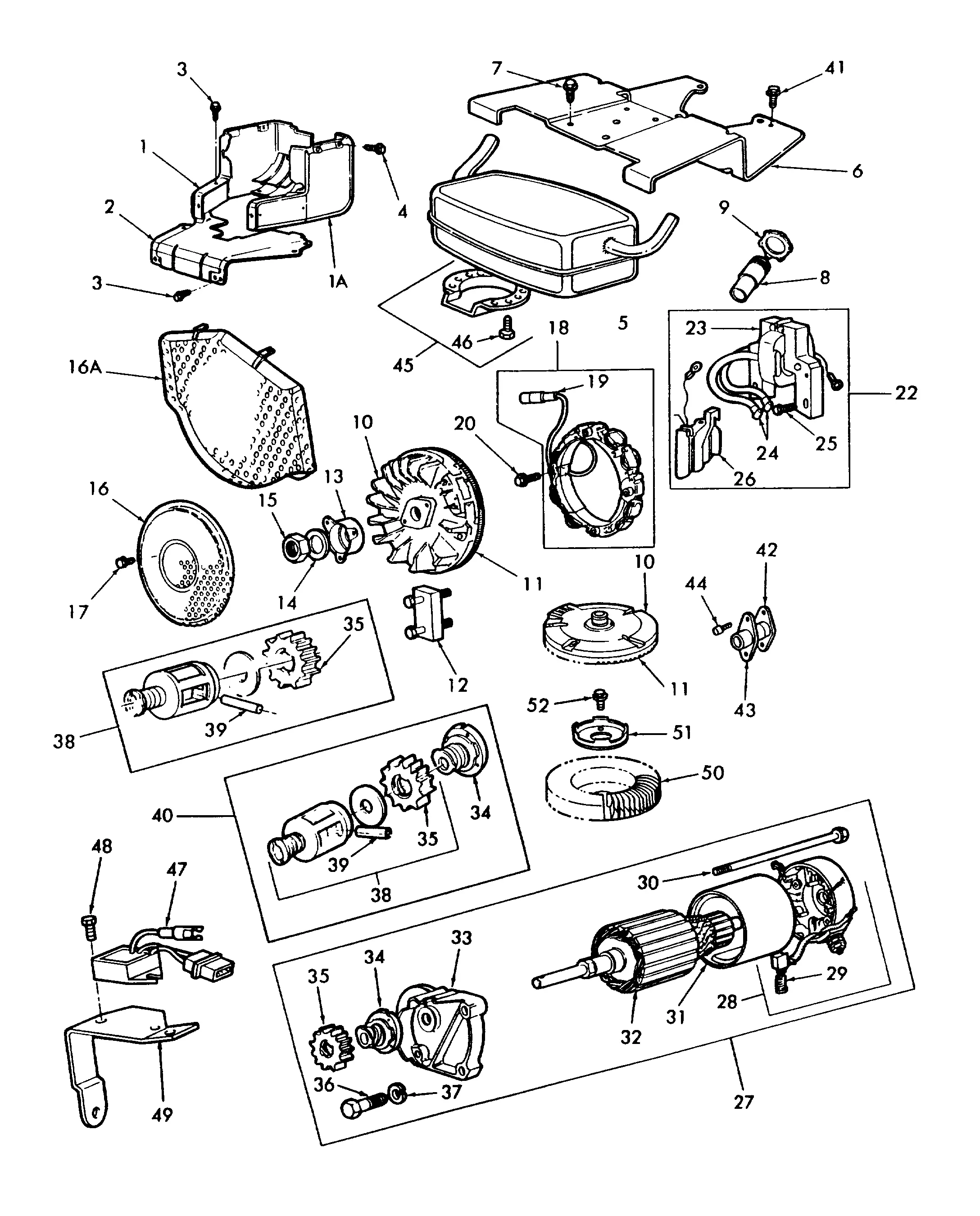

- Fuel System: Delivers the necessary fuel mixture for combustion.

- Ignition System: Initiates combustion through spark generation.

By familiarizing yourself with these components, you can delve deeper into diagnostics and repairs, ultimately improving overall functionality.

Maintenance Tips for Longevity

Regular upkeep is essential for enhancing the lifespan of your engine. By following a systematic approach to care, you can ensure optimal performance and reliability over time.

- Check Oil Levels: Regularly monitor and change the lubricant to keep the engine running smoothly.

- Clean Air Filters: Ensure air intake is unobstructed to promote efficiency and prevent overheating.

- Inspect Fuel System: Regularly check for leaks and keep fuel lines clear to maintain proper operation.

- Tighten Bolts: Periodically inspect and secure all fasteners to avoid vibrations and potential damage.

- Replace Spark Plugs: Changing spark plugs at recommended intervals can enhance combustion and efficiency.

Implementing these practices will ultimately lead to a more reliable and durable engine.

Replacement Parts Availability

Finding suitable components for your engine is crucial for maintaining its performance and longevity. Availability of these items ensures that you can quickly address any issues that arise, keeping your machinery running smoothly.

Sources for Components

Various retailers, both online and brick-and-mortar, offer a wide selection of replacements. Manufacturers often provide direct access to essential elements, while aftermarket suppliers may deliver cost-effective alternatives.

Quality Considerations

When selecting new components, prioritize quality over price. Genuine items may be more expensive, but they guarantee optimal performance. Aftermarket options can be appealing, yet thorough research is essential to ensure compatibility and reliability.

Choosing Quality Aftermarket Options

Selecting high-grade alternatives for engine components can significantly enhance performance and longevity. It’s crucial to ensure that these substitutes meet stringent standards to avoid potential issues that may arise from inferior products.

Benefits of Quality Alternatives

Investing in reliable options can lead to improved efficiency, better durability, and enhanced performance. Moreover, reputable brands often provide warranties that protect your investment.

Key Factors to Consider

When evaluating substitutes, consider compatibility, material quality, and manufacturer reputation. Researching customer reviews can also provide valuable insights into the effectiveness of these alternatives.

| Factor | Importance |

|---|---|

| Compatibility | Ensures proper fit and function |

| Material Quality | Affects durability and performance |

| Manufacturer Reputation | Indicates reliability and support |

Benefits of Regular Inspections

Conducting consistent evaluations of machinery is essential for maintaining optimal performance and longevity. These checks help identify potential issues before they escalate, ensuring reliability and efficiency in operations.

Early Problem Detection

Proactive measures through regular inspections allow for the early identification of wear and tear, reducing the risk of unexpected breakdowns. This not only saves time but also minimizes repair costs.

Enhanced Performance

Routine assessments can lead to improved functionality and efficiency, ensuring that equipment operates at its ultimate capacity. Keeping components in check enhances overall productivity and extends the lifespan of the machinery.

Tools Needed for Repairs

When tackling mechanical fixes, having the right instruments at your disposal is essential for a smooth process. Proper equipment not only enhances efficiency but also ensures safety and accuracy during maintenance tasks.

Essential Tools include wrenches, sockets, and screwdrivers, which are crucial for loosening or tightening components. Additionally, specialized tools such as torque wrenches and feeler gauges may be necessary for precise adjustments.

Safety Gear is also vital; gloves and goggles protect against debris and injuries, while a sturdy workbench provides a stable surface for repairs. Investing in quality tools will ultimately lead to successful maintenance outcomes.

Exploring Engine Performance Upgrades

Enhancing the efficiency and power of small engines is an exciting journey for enthusiasts seeking to maximize performance. By delving into various modifications, users can achieve the ultimate balance of speed, torque, and reliability. This section explores options that can elevate the engine’s capabilities while ensuring optimal functionality.

Air Intake Improvements: Upgrading the air intake system can significantly boost airflow, leading to better combustion and increased power output. Consider high-flow filters or custom intakes that allow for a smoother air path.

Exhaust System Enhancements: A performance exhaust can reduce back pressure, allowing exhaust gases to exit more efficiently. This change can enhance throttle response and overall engine performance.

Tuning and Calibration: Adjusting fuel mapping and ignition timing can unlock additional power potential. Specialized tuning software or professional services can tailor these settings to your specific modifications.

Performance Components: Replacing stock components with high-performance alternatives, such as pistons, camshafts, or valves, can lead to significant gains in horsepower. Always ensure compatibility with the existing engine setup.

By implementing these enhancements, engine enthusiasts can achieve remarkable improvements, leading to a more exhilarating experience on the road or field.