Comprehensive Guide to Subaru Engine Parts Diagram

Every automobile comprises a complex assembly of elements that work in harmony to ensure optimal performance and reliability. Grasping the intricacies of these components can enhance your understanding of how your vehicle operates and assist in maintaining its longevity. By delving into the various segments and their functions, one can gain valuable insights into the mechanics at play.

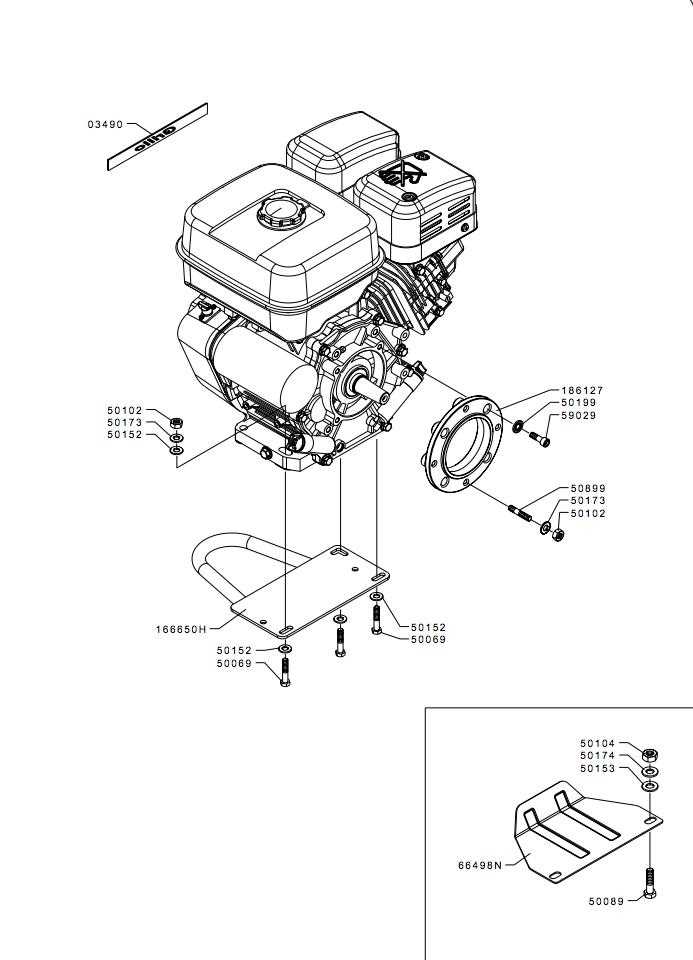

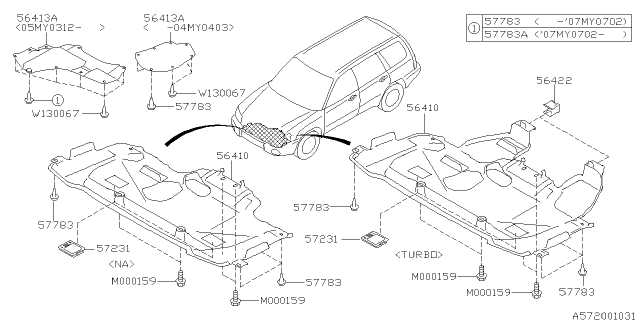

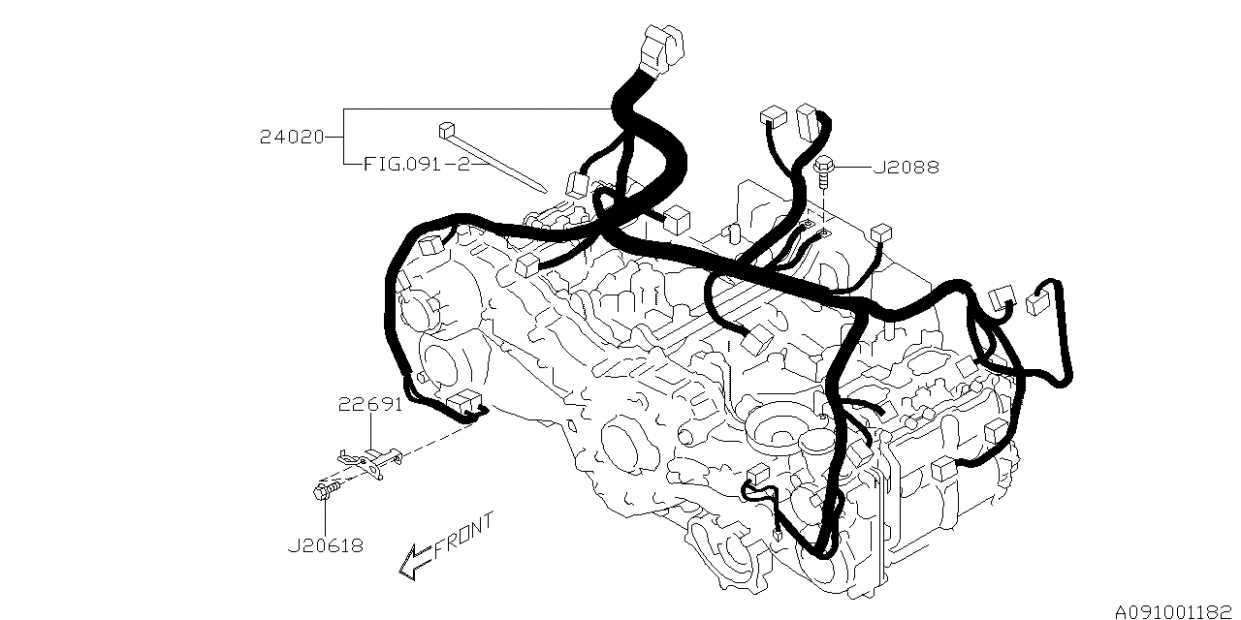

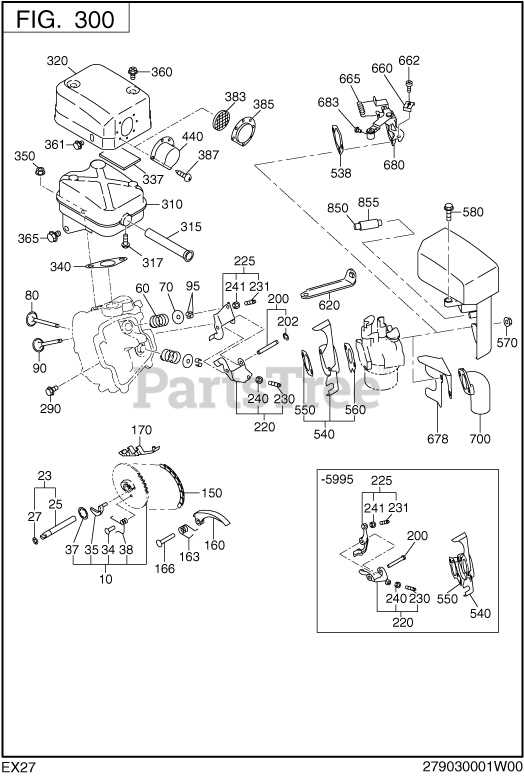

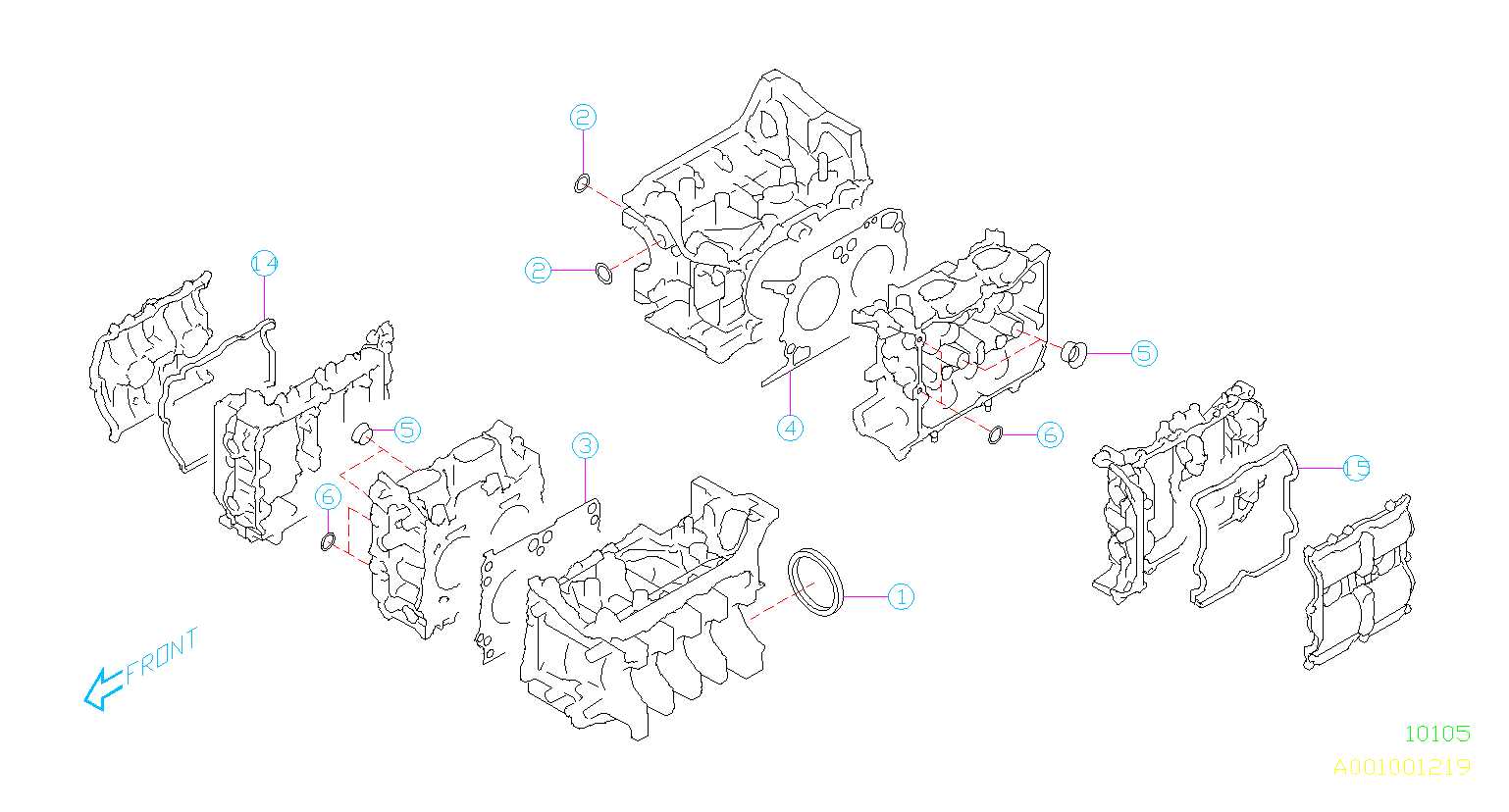

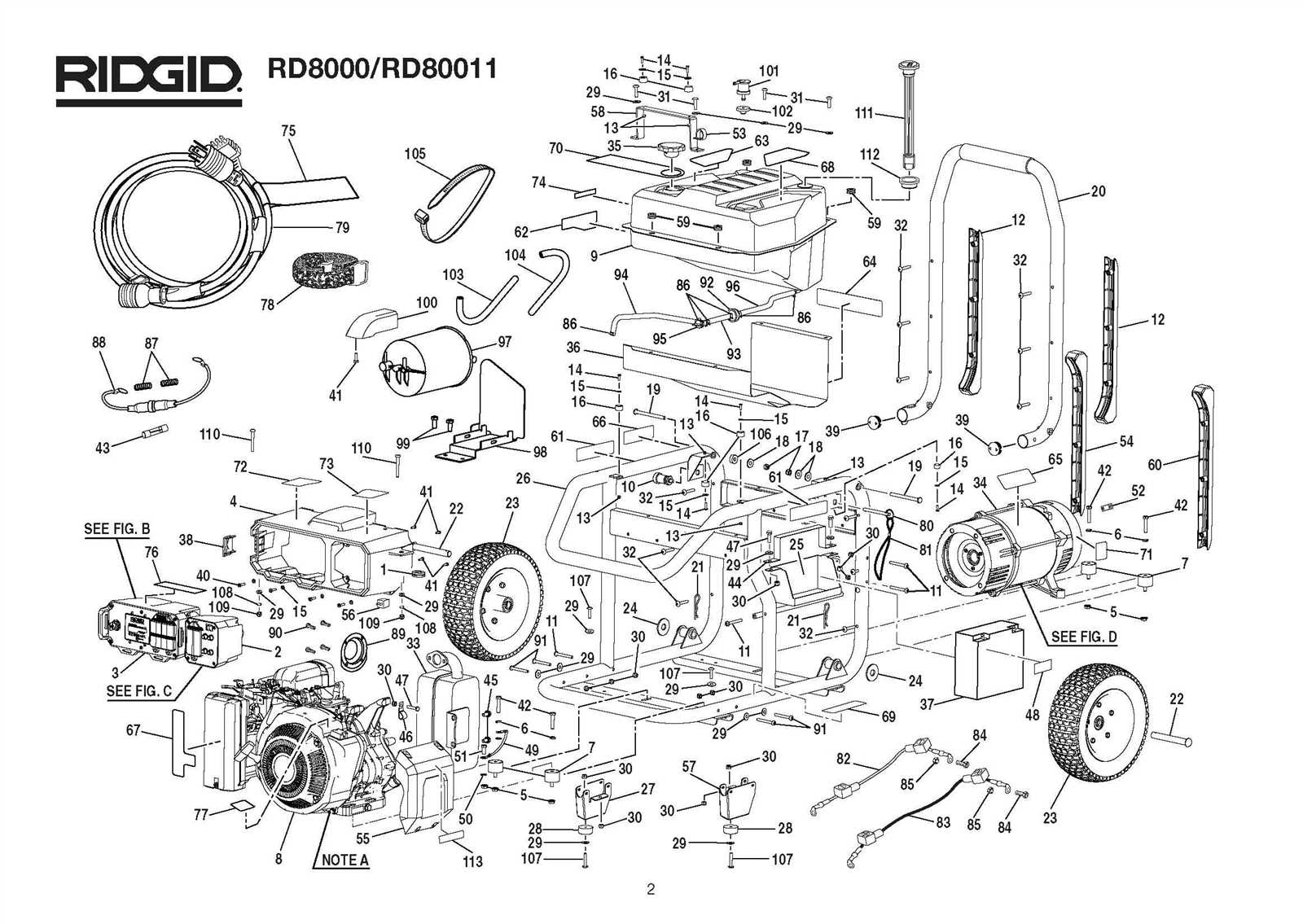

Visual representations serve as crucial tools for enthusiasts and mechanics alike, providing clarity and context to the various structures involved. By examining these illustrations, one can easily identify the roles of individual elements and their relationships within the larger system. This understanding can lead to more informed decisions regarding repairs and upgrades.

Additionally, a comprehensive overview of these intricate structures can aid in troubleshooting potential issues. When a challenge arises, recognizing the specific components involved is vital in diagnosing problems effectively. By familiarizing yourself with the essential features, you empower yourself to tackle maintenance tasks with confidence and precision.

Understanding Subaru Engine Components

Exploring the intricacies of a power unit reveals a complex interplay of various elements that contribute to its functionality and performance. Each component plays a crucial role, working in harmony to ensure optimal operation. A thorough comprehension of these elements enhances the appreciation for automotive engineering and the efficiency of transportation systems.

Among the most vital constituents are those responsible for energy generation, which convert fuel into motion. Additionally, there are mechanisms for controlling air intake and exhaust, which are essential for maintaining the proper balance of combustion. Furthermore, the cooling system is paramount in regulating temperatures, ensuring that the unit operates within safe limits.

Another significant aspect is the lubrication system, which minimizes friction and wear among moving elements, extending the longevity of the assembly. Each piece, from the smallest bolts to the largest assemblies, contributes to the overall performance and reliability, highlighting the importance of regular maintenance and awareness of potential issues.

Understanding these various elements not only fosters a deeper knowledge of vehicle mechanics but also empowers enthusiasts and owners alike to make informed decisions regarding repairs and upgrades. Delving into the specifics of each component ultimately enhances the driving experience and ensures that vehicles remain in peak condition.

Importance of Engine Parts Diagrams

Understanding the layout and functionality of crucial components within a vehicle is essential for effective maintenance and repairs. Visual representations serve as valuable tools, providing clarity and enhancing comprehension for both professionals and enthusiasts alike. These illustrations play a significant role in identifying, locating, and comprehending the interaction of various elements within the power unit.

Benefits of Visual Representations

- Enhanced Clarity: Visual aids simplify complex arrangements, making it easier to grasp the structure and function of individual components.

- Efficient Troubleshooting: With a clear view of the assembly, diagnosing issues becomes more straightforward, saving time and effort.

- Accurate Repairs: Detailed visuals ensure that replacements and adjustments are made correctly, reducing the risk of errors.

- Learning Resource: These illustrations serve as educational tools, helping newcomers understand the intricacies of mechanical systems.

Practical Applications

- Facilitating routine maintenance checks.

- Aiding in the assembly and disassembly of components.

- Providing reference for modifications and upgrades.

- Supporting effective communication between technicians and clients.

In summary, having access to clear and informative visual references significantly enhances the understanding and management of a vehicle’s intricate systems, leading to better performance and longevity.

Common Subaru Engine Types Explained

Understanding various powertrain configurations is crucial for enthusiasts and mechanics alike. Different designs offer unique performance characteristics, fuel efficiencies, and driving experiences. This overview will delve into the most prevalent configurations found in compact vehicles, highlighting their attributes and applications.

Boxer Configuration

The boxer layout features horizontally opposed cylinders, promoting a low center of gravity and balanced weight distribution. This design enhances stability and handling, making it a popular choice for sporty models. Additionally, the engine’s compact form allows for better airflow, contributing to overall efficiency.

Turbocharged Variants

Turbocharged systems significantly boost performance by forcing more air into the combustion chamber, resulting in increased power without a substantial increase in size. These variants often deliver impressive torque at lower RPMs, providing an exhilarating driving experience, particularly in challenging conditions. Ultimately, this setup is favored for its blend of power and efficiency.

Key Elements in Engine Diagrams

Understanding the intricate layout of mechanical systems requires a focus on essential components. These elements are vital for comprehending how various sections interact and function cohesively.

- Components: Fundamental units that perform specific tasks.

- Connections: Linkages that illustrate how units interact.

- Labels: Clear identifiers that enhance comprehension of each element.

- Flow Paths: Directions indicating movement or transmission of forces.

By analyzing these key aspects, one can delve deeper into the overall functionality and ultimate efficiency of the system.

Visualizing Engine Assembly Process

The assembly process of mechanical systems involves a meticulous arrangement of components that must work in harmony to achieve optimal performance. Understanding this intricate workflow is essential for both enthusiasts and professionals. By visualizing each stage, one can appreciate the engineering behind the seamless functionality.

Step-by-Step Breakdown

Beginning with the foundational elements, the journey starts with the core structures. As each piece is added, attention to detail is critical. Careful alignment and precise fitting ensure that every unit contributes to the overall efficacy.

Importance of Organization

Maintaining an organized workspace is vital throughout this undertaking. Clarity in arrangement not only streamlines the process but also minimizes errors. A systematic approach enables a smooth transition from one stage to another, culminating in a robust assembly.

Identifying Essential Subaru Engine Parts

Understanding the crucial components of a vehicle’s power unit is vital for maintenance and performance. Each element plays a significant role in ensuring smooth operation and longevity. Familiarity with these components not only aids in troubleshooting but also enhances overall vehicle knowledge.

One key component is the cylinder head, which houses valves and facilitates air and fuel intake. Another important element is the crankshaft, responsible for converting linear motion into rotational force. Additionally, the timing belt ensures synchronization between moving parts, preventing potential damage.

Other notable components include the oil pump, which circulates lubricant, and the fuel injectors, essential for delivering the right mixture into the combustion chamber. Recognizing these essential elements can lead to informed decisions regarding repairs and enhancements.

Functionality of Each Engine Component

Understanding the role of each mechanical element within a power unit is essential for optimal performance and maintenance. Each component plays a specific part in the overall operation, contributing to efficiency, power generation, and reliability.

The following list outlines key components and their respective functions:

- Piston: Converts the energy from combustion into mechanical movement, driving the crankshaft.

- Crankshaft: Transforms the linear motion of the pistons into rotational motion, enabling the transmission of power.

- Camshaft: Regulates the timing of valve openings and closings, ensuring proper airflow and fuel intake.

- Valves: Control the entry of air-fuel mixture and the exit of exhaust gases, directly impacting performance.

- Connecting Rod: Links the piston to the crankshaft, transmitting force and enabling movement.

- Oil Pump: Circulates lubricant throughout the system, reducing friction and preventing wear.

- Fuel Injector: Precisely delivers fuel into the combustion chamber, optimizing the fuel-air mixture for efficiency.

- Intake Manifold: Distributes the air-fuel mixture evenly to each cylinder, ensuring balanced combustion.

- Exhaust Manifold: Collects exhaust gases from multiple cylinders and directs them to the exhaust system.

Each of these elements works in unison, ensuring that the system operates smoothly and efficiently, ultimately affecting the vehicle’s overall performance and longevity.

Comparative Analysis of Engine Designs

This section explores the nuances of various mechanical configurations, emphasizing their distinct characteristics and operational efficiencies. By examining the fundamental principles and variations in design, we can uncover how each structure influences performance, durability, and overall functionality.

Diverse arrangements, such as inline, V-type, and flat configurations, present unique advantages and challenges. For instance, V-type setups often provide compactness while enhancing power output, whereas inline designs are celebrated for their simplicity and ease of maintenance.

In addition to structural variations, the choice of materials and manufacturing techniques plays a critical role in performance outcomes. Lightweight alloys and advanced composites can significantly affect weight distribution and thermal management, ultimately influencing efficiency and longevity.

Moreover, the integration of modern technologies, such as variable valve timing and turbocharging, showcases the continuous evolution within these frameworks. Understanding these developments is essential for making informed decisions regarding application suitability and performance enhancement.

Maintenance Tips for Engine Parts

Regular upkeep is essential for ensuring the longevity and performance of any mechanical system. Proper care not only enhances efficiency but also prevents unexpected failures that can lead to costly repairs. Adopting a systematic approach to maintenance can significantly extend the lifespan of crucial components.

One of the most important practices is to conduct routine inspections. Check for any signs of wear or damage, such as cracks, leaks, or corrosion. Addressing these issues early can prevent more severe problems later on. Additionally, keep all connection points clean and free from debris to promote optimal functionality.

Another key aspect is timely replacement of consumable items. Filters, seals, and lubricants should be changed according to the manufacturer’s recommendations to ensure that everything operates smoothly. Using high-quality replacements can further enhance performance and reliability.

Furthermore, monitoring performance metrics can provide valuable insights into the condition of the system. Keeping track of any unusual noises, vibrations, or changes in efficiency can help identify potential issues before they escalate. Regularly updating your knowledge about advancements in technology can also aid in maintaining peak performance.

Lastly, ensure that all components are properly lubricated. Adequate lubrication minimizes friction, reducing wear and tear. Always use the recommended types of lubricants for specific applications, and consider consulting a professional if unsure about any maintenance procedure.

How to Read Engine Diagrams

Understanding technical illustrations is crucial for anyone involved in automotive maintenance or repair. These visuals provide a comprehensive representation of various components and their interconnections, helping you to identify and troubleshoot issues effectively. Mastering the art of interpreting these schematics can greatly enhance your ability to work on any vehicle.

Key Elements to Look For

- Symbols: Familiarize yourself with common symbols that represent different components, such as pistons, valves, and crankshafts.

- Lines and Arrows: Pay attention to lines and arrows that indicate connections, flow of fluids, or the direction of movement.

- Labels: Look for labels that provide additional information about each part, including specifications and part numbers.

Steps to Decipher the Illustration

- Start by reviewing the legend or key if available; it explains the symbols used in the representation.

- Identify the main components, noting their positions and relationships to one another.

- Trace the connections and pathways, ensuring you understand how each part interacts with others.

- Refer to a repair manual or online resources for further clarification on specific components or systems.

By practicing these techniques, you will improve your proficiency in reading and understanding complex technical illustrations, making maintenance and repairs more manageable.

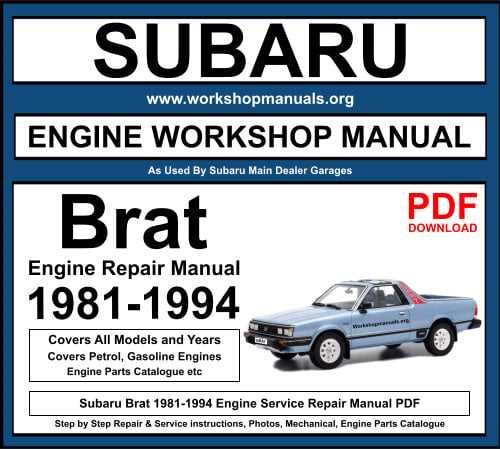

Resources for Subaru Engine Information

This section offers a collection of valuable tools and references for those seeking knowledge about mechanical components and their configurations. Whether you’re an enthusiast or a professional, these resources can help you understand the intricate details of various systems.

Online Resources

- Official manufacturer websites

- Specialized automotive forums

- Online repair guides and manuals

- Video tutorials on platforms like YouTube

Printed Materials

- Service manuals

- Automotive reference books

- Technical bulletins

Common Issues with Engine Parts

Understanding the frequent problems associated with internal components is essential for maintaining optimal performance. Many issues arise due to wear and tear, improper installation, or manufacturing defects. Identifying these challenges early can prevent more significant complications down the line.

One prevalent concern involves overheating, which can result from inadequate cooling or blocked passages. This can lead to severe damage if not addressed promptly. Additionally, oil leaks are common, often caused by worn seals or gaskets, resulting in decreased lubrication and potential failure.

Another issue is abnormal noises, such as knocking or rattling, which can indicate misalignment or loose connections. Regular inspections are crucial for spotting these signs before they escalate. Lastly, electrical failures can disrupt functionality, often stemming from corroded connectors or frayed wires, highlighting the importance of routine maintenance.

Future Trends in Engine Technology

The automotive industry is on the brink of a significant transformation, driven by innovations that promise to enhance performance, efficiency, and sustainability. As manufacturers and researchers explore new possibilities, the focus is shifting towards integrating advanced materials, electrification, and intelligent systems to redefine propulsion methods.

One of the most prominent trends is the increasing adoption of hybrid and fully electric propulsion systems. These technologies not only reduce carbon emissions but also improve overall efficiency, making vehicles more environmentally friendly. Additionally, advancements in battery technology are enabling longer ranges and faster charging times, further supporting the shift away from traditional fuel sources.

Moreover, the integration of smart technologies is revolutionizing the way propulsion systems operate. From real-time data analytics to predictive maintenance, these innovations are enhancing performance and reliability. The development of autonomous vehicles also plays a crucial role, as it necessitates more sophisticated control systems that can adapt to various driving conditions.

| Trend | Description |

|---|---|

| Electrification | Increased use of hybrid and electric powertrains to reduce emissions. |

| Smart Technology | Integration of AI and data analytics for improved performance and maintenance. |

| Advanced Materials | Utilization of lightweight and durable materials to enhance efficiency. |

| Autonomous Systems | Development of self-driving technologies requiring innovative control mechanisms. |

As these trends continue to evolve, the automotive landscape will witness a shift towards more sustainable, efficient, and technologically advanced solutions, shaping the future of transportation for generations to come.