Understanding the Subaru Pressure Washer Parts Diagram

When it comes to maintaining and optimizing your outdoor cleaning apparatus, a comprehensive grasp of its various components is essential. This knowledge not only enhances the efficiency of the equipment but also prolongs its lifespan. Familiarity with the internal structure can help in troubleshooting and repairs, ensuring that you get the most out of your investment.

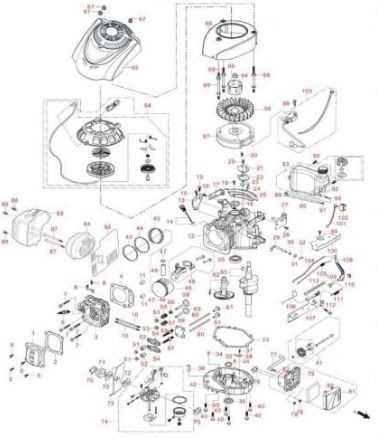

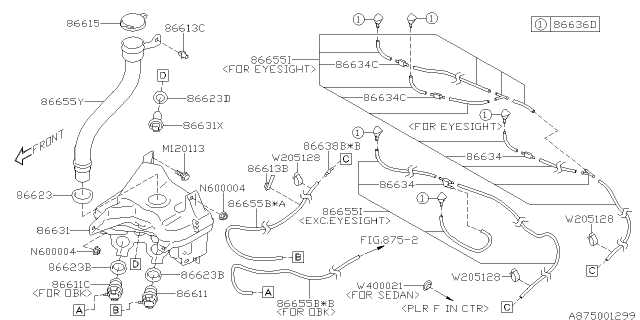

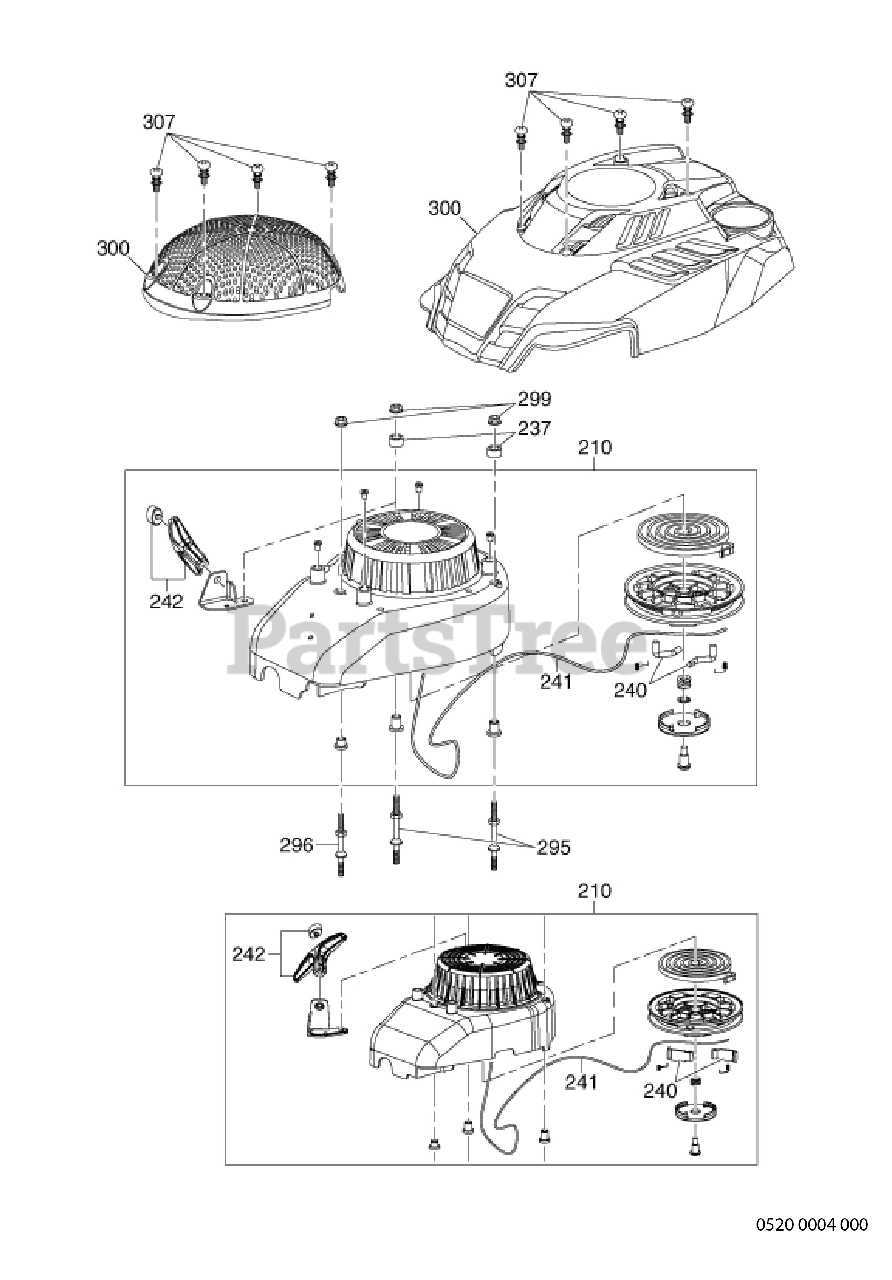

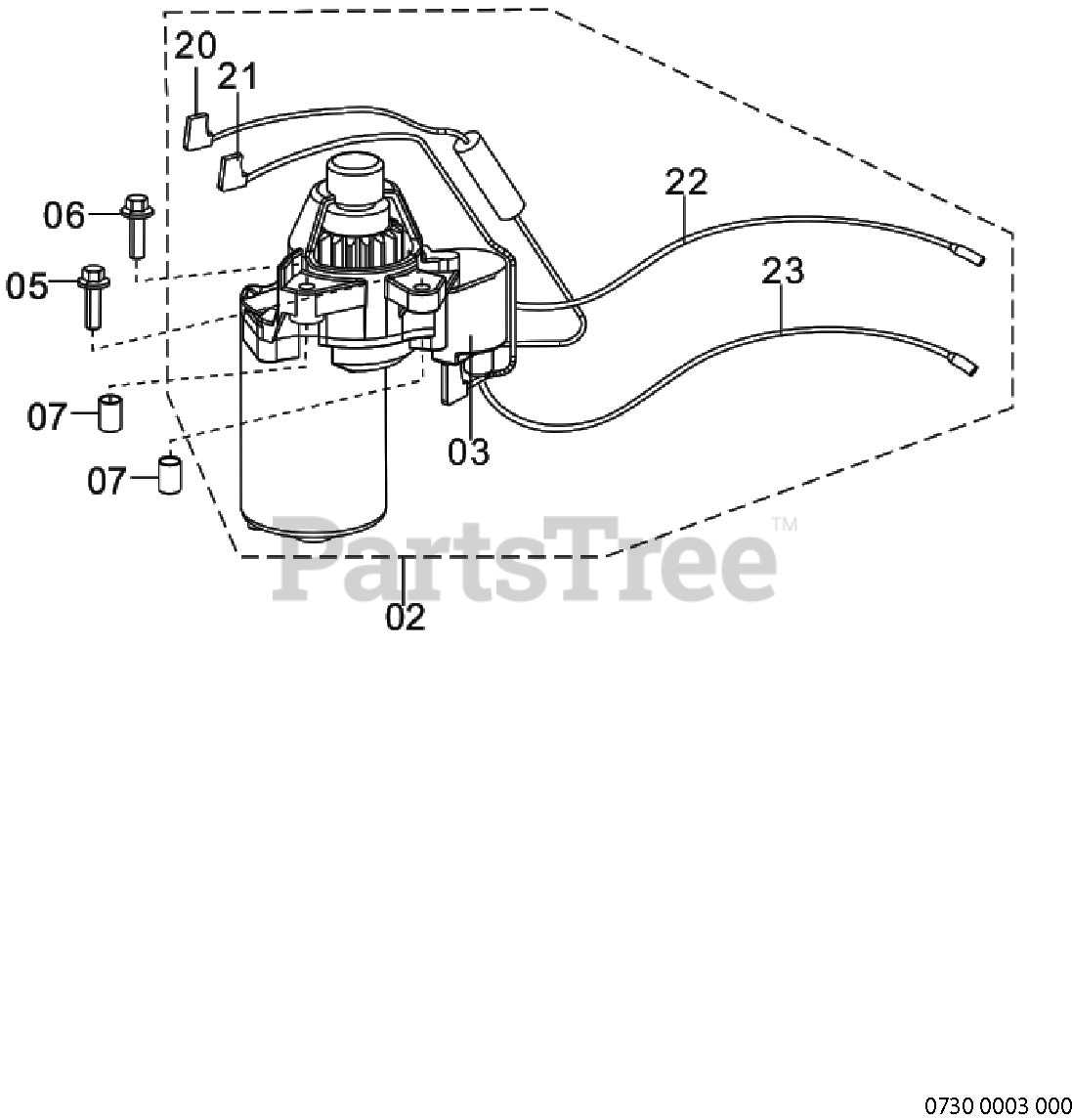

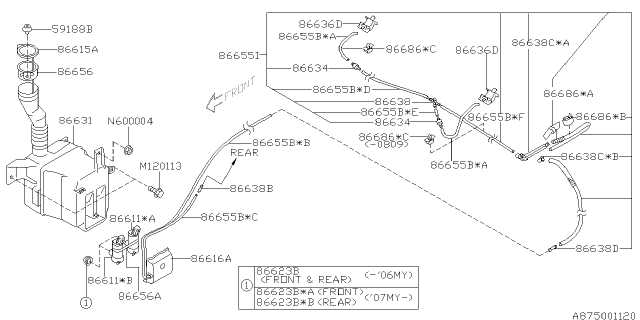

In this section, we will explore a detailed representation of the different elements that make up your cleaning machine. From the motor to the hoses, each component plays a critical role in delivering exceptional performance. By understanding how these parts interact, users can better appreciate the technology behind their cleaning tasks.

Whether you are a novice or a seasoned user, having access to a visual guide that illustrates these components can greatly facilitate the process of assembly and disassembly. It allows for a more intuitive understanding of how to maintain and replace specific elements as needed, ensuring optimal operation at all times.

Understanding Subaru Pressure Washers

These cleaning machines are designed for high efficiency and versatility, making them ideal for a variety of tasks. Their robust construction and innovative features ensure reliable performance, catering to both residential and commercial needs. Users can enjoy a seamless experience when tackling dirt, grime, and stubborn stains.

The design incorporates various elements that enhance usability and functionality. Each component plays a crucial role in the overall effectiveness of the equipment, allowing for optimal pressure and flow rates. Familiarizing oneself with these essential components can lead to better maintenance and prolonged longevity.

By examining the mechanisms at work, operators can better appreciate the intricacies involved in achieving outstanding results. A thorough understanding of these machines empowers users to make informed decisions regarding maintenance and troubleshooting, ultimately leading to a more satisfying cleaning experience.

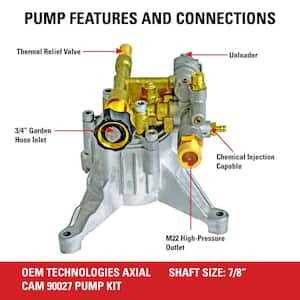

Key Components of Pressure Washers

Understanding the essential elements of a cleaning machine can significantly enhance its efficiency and lifespan. Each component plays a vital role in delivering optimal performance, ensuring thorough cleaning results while maintaining ease of use.

Main Elements

- Motor: Powers the entire unit, converting electrical or fuel energy into mechanical force.

- Pump: Responsible for drawing in water and creating high-pressure output for effective cleaning.

- Trigger Gun: The control mechanism that allows users to start and stop the flow of water easily.

- Nozzles: Attachments that alter the spray pattern, adjusting pressure and coverage according to specific tasks.

- Hose: Transfers water from the unit to the cleaning surface, designed for flexibility and durability.

Additional Features

- Filter: Ensures that debris does not enter the pump, prolonging its lifespan.

- Wheels: Enhance mobility, allowing the unit to be easily moved to various locations.

- Storage: Compartments for accessories and hoses that help keep everything organized.

- Pressure Gauge: Monitors the output force, allowing users to adjust settings for optimal cleaning.

Importance of Quality Parts

Using high-quality components in any machinery is crucial for ensuring optimal performance and longevity. When you invest in superior elements, you not only enhance the efficiency of your equipment but also minimize the risk of malfunctions and costly repairs.

Durability is a key benefit of selecting top-notch materials. Quality components are designed to withstand the rigors of regular use, reducing the likelihood of wear and tear over time. This longevity translates to less frequent replacements, ultimately saving you money in the long run.

Moreover, reliability plays a significant role. When you choose components from reputable manufacturers, you can trust that they will perform consistently under various conditions. This consistency is vital for maintaining workflow and achieving desired results.

Additionally, quality components often come with better warranties and support. Manufacturers who stand behind their products are more likely to offer assistance and resources should issues arise, providing peace of mind to the user.

In summary, investing in high-quality elements is essential for enhancing efficiency, durability, and reliability, ultimately leading to a more satisfying and productive experience.

Common Issues with Subaru Washers

Many users encounter specific challenges when utilizing these cleaning machines. Understanding these common problems can aid in effective maintenance and troubleshooting, ensuring optimal performance and longevity of the device.

Here are some frequent issues and their potential causes:

| Issue | Possible Causes |

|---|---|

| Loss of Pressure | Clogged nozzle, air in the system, worn seals |

| Leakage | Loose connections, damaged hoses, faulty pump |

| No Start | Electrical issues, faulty switch, dead battery |

| Inconsistent Performance | Dirty filters, fluctuating water supply, engine problems |

Addressing these issues promptly can significantly enhance the functionality and efficiency of your cleaning equipment.

How to Read Diagrams Effectively

Understanding visual representations can significantly enhance your ability to work with complex machinery. These illustrations serve as essential guides, providing clarity and insight into the components and their interrelationships. Mastering the art of interpreting these visuals is crucial for both troubleshooting and assembly tasks.

Familiarize Yourself with Symbols

Before diving into the details, take time to learn the common symbols used in these visuals. Each icon or mark conveys specific information about the function or connection of the components. Investing time in understanding these symbols will save you from confusion later on.

Follow the Flow of Information

Pay attention to the layout and direction indicated within the representation. Most illustrations are designed to guide you through a logical sequence, often leading from the input to the output. By following this flow, you can better comprehend how each part interacts within the overall system, making your tasks much more efficient.

Maintenance Tips for Longevity

To ensure your equipment remains efficient and durable over time, regular care and attention are essential. Implementing a consistent maintenance routine can significantly enhance performance and extend the lifespan of your device. This section outlines key practices to keep in mind for optimal upkeep.

First, always inspect your machine before use. Check for any signs of wear or damage, including hoses and connections. Addressing issues early can prevent more significant problems down the line. Additionally, clean all components thoroughly after each session to remove dirt and debris that can cause corrosion or blockages.

Another important aspect is to regularly change fluids and filters as recommended by the manufacturer. Fresh fluids help in maintaining smooth operation and prevent overheating. Furthermore, ensuring that all moving parts are adequately lubricated will reduce friction and enhance performance.

Finally, store your equipment in a dry, sheltered location to protect it from environmental factors. Proper storage not only prevents rust but also keeps components in optimal condition for the next use. By following these guidelines, you can maximize efficiency and prolong the life of your equipment.

Identifying Replacement Parts Easily

Finding the right components for maintenance or repair can often be a daunting task. However, with a systematic approach, you can streamline the process and ensure that you obtain the correct elements swiftly and efficiently. Understanding the layout and function of each component is crucial to achieving this goal.

Steps to Simplify Identification

To facilitate the identification of the necessary components, follow these steps:

- Gather all relevant documentation that provides insight into the equipment.

- Familiarize yourself with the various elements and their functions.

- Utilize online resources or manuals for visual references.

Common Component Types

Familiarizing yourself with common types of components can help in quickly locating the right items. The following table outlines some typical types and their descriptions:

| Component Type | Description |

|---|---|

| Motor | Drives the overall function, providing power to the system. |

| Hoses | Transport fluid, connecting various sections together. |

| Filters | Remove impurities from the fluid, ensuring optimal performance. |

| Nozzles | Direct the flow, allowing for various spraying patterns. |

By following these guidelines and utilizing available resources, you can efficiently identify and procure the components you need for your equipment.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right instruments is essential for achieving efficient and effective results. Proper tools not only facilitate the repair process but also ensure safety and precision. A well-prepared toolkit can make all the difference in handling various tasks, from minor adjustments to more complex restorations.

For any repair project, a combination of basic hand tools and specialized instruments is often required. Commonly needed items include screwdrivers of different sizes, wrenches, pliers, and a sturdy set of sockets. These essentials provide the versatility needed for most tasks. Additionally, having a multimeter can be invaluable for diagnosing electrical issues, while a torque wrench ensures components are tightened to the correct specifications.

Moreover, safety equipment should not be overlooked. Gloves, goggles, and a face mask protect against potential hazards during the repair process. Investing in quality tools and safety gear can lead to more efficient repairs and longer-lasting results.

Where to Buy Subaru Parts

Finding quality components for your vehicle can be a daunting task, especially when seeking reliable sources. Numerous options are available, ranging from authorized dealers to online marketplaces, each with its own advantages. Understanding where to look can significantly enhance your shopping experience and ensure you acquire the right items for your needs.

Authorized Dealers

Purchasing from official retailers offers several benefits:

- Guaranteed authenticity of the items

- Access to expert advice and support

- Potential for warranty coverage on new components

Online Marketplaces

For convenience and variety, consider exploring digital platforms. They often provide:

- A wide selection of options

- Competitive pricing and discounts

- Customer reviews to guide your decisions

Be sure to verify the credibility of the sellers to ensure the quality of your purchases. With the right approach, you can confidently locate the necessary items to maintain or upgrade your vehicle effectively.

Aftermarket vs. Original Components

The choice between replacement items from manufacturers and those produced by third parties can significantly impact performance and longevity. Each option presents distinct advantages and disadvantages, making it crucial for users to weigh their preferences and requirements before making a decision.

Advantages of Original Components

Original components are designed specifically for the equipment, ensuring compatibility and optimal performance. They typically undergo rigorous testing and quality control, which can lead to enhanced reliability and a longer lifespan. Moreover, using these items may help maintain warranty coverage, providing peace of mind for the user.

Benefits of Aftermarket Items

Aftermarket options often come at a lower price point and can provide a broader selection of features and enhancements. Many manufacturers focus on improving performance and efficiency, offering users the opportunity to customize their equipment. Additionally, accessibility is usually better, as these items are widely available in various retail outlets.

| Feature | Original Components | Aftermarket Options |

|---|---|---|

| Compatibility | High | Variable |

| Price | Higher | Lower |

| Quality Assurance | Strict Standards | Variable Quality |

| Warranty | Maintained | Risk of Voiding |

| Innovation | Limited | Often Advanced |

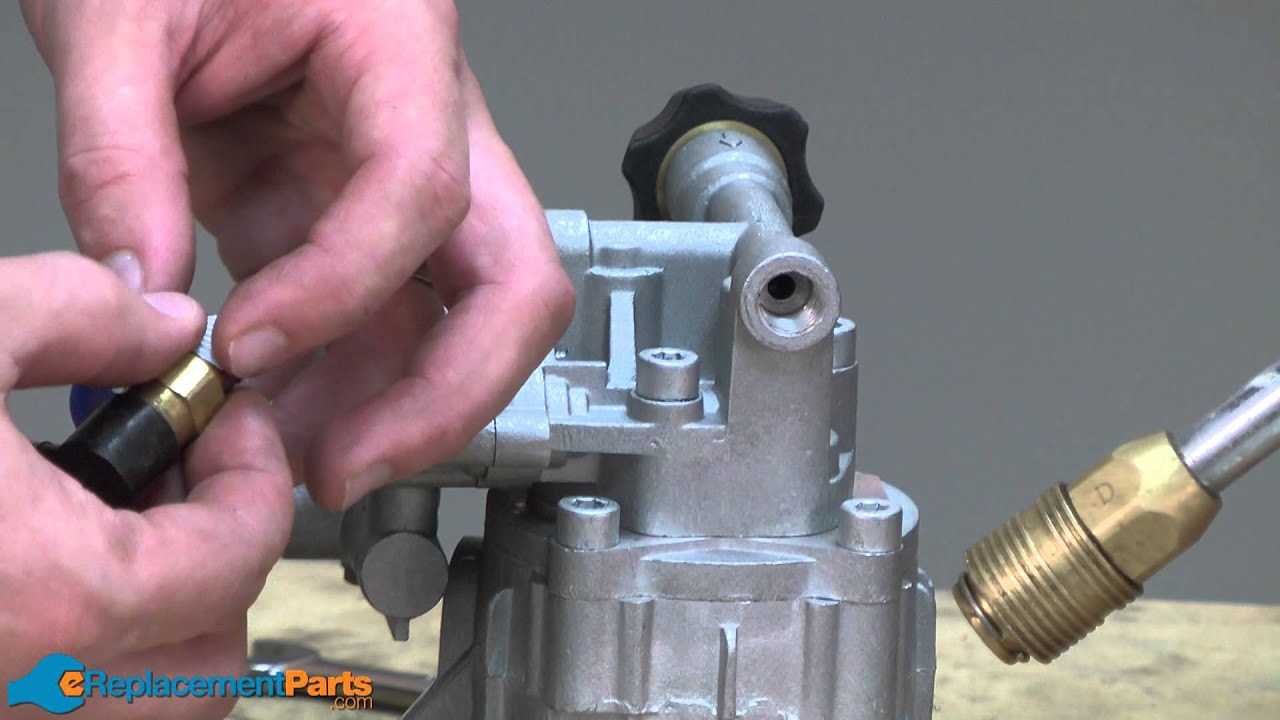

Assembling Your Pressure Washer

When it comes to constructing your cleaning device, a systematic approach ensures efficiency and reliability. Understanding the components and their arrangement is crucial for optimal performance. This section will guide you through the necessary steps to successfully bring your equipment together.

Gathering Your Components

Start by collecting all essential elements required for assembly. Refer to the user manual to confirm you have everything, including hoses, nozzles, and connectors. Organizing these items will simplify the process and help you avoid unnecessary delays.

Step-by-Step Assembly Process

Begin by attaching the base and handle, ensuring they are securely fastened. Next, connect the water intake and the spray mechanism. Double-check all connections to prevent leaks during operation. Finally, test the device to confirm everything is functioning properly before use.

Troubleshooting Common Problems

Encountering issues with your cleaning equipment can be frustrating, but many problems are easily fixable with a bit of investigation. By understanding typical symptoms and their underlying causes, users can efficiently restore functionality without unnecessary delays.

If the device fails to start, check the power source and connections. Ensure the switch is engaged, and inspect the fuse or circuit breaker. A lack of pressure may indicate a blockage in the hose or a malfunctioning pump, while irregular flow could suggest air in the system or a damaged seal.

Listen for unusual sounds during operation, which can hint at internal wear or loose components. If leaking occurs, examine all connections and seals for integrity. Addressing these common issues promptly can enhance the longevity and effectiveness of your cleaning equipment.

Upgrades for Enhanced Performance

Enhancing the functionality of your cleaning equipment can significantly improve its efficiency and longevity. By focusing on key modifications, you can ensure that your device operates at its ultimate capacity, tackling even the toughest tasks with ease.

| Upgrade | Description | Benefits |

|---|---|---|

| High-Pressure Nozzle | Switching to a high-performance nozzle can increase the intensity of the spray. | Improved cleaning power for stubborn stains. |

| Durable Hose | Upgrading to a reinforced hose reduces wear and tear. | Increased flexibility and reduced risk of leaks. |

| Enhanced Motor | Installing a more robust motor boosts overall output. | Faster cleaning with consistent performance. |

| Advanced Filter | A better filtration system prevents debris from entering the system. | Longer lifespan and reduced maintenance needs. |