Understanding the Components of the Toro 1128 OXE

When dealing with a powerful machine designed to handle demanding winter conditions, having a clear overview of its inner workings is crucial. Each element plays a specific role in ensuring the equipment functions smoothly during harsh weather, allowing for efficient and reliable operation. This section aims to provide an insightful look into the connections and structure that keep this winter powerhouse running at its best.

We will explore the intricate assembly of key mechanical and functional components, highlighting their purpose and interaction within the system. By gaining a better understanding of how these elements work together, you can ensure proper maintenance and timely repairs, extending the longevity of your machine and optimizing its performance in the toughest environments.

Whether you are looking to perform regular upkeep or solve a specific issue, having a comprehensive guide to these important components will help you navigate the complexities with ease. This knowledge allows you to approach any challenge with confidence, ensuring your machine is always ready

Understanding the Layout of Your Equipment

Having a clear grasp of how your machine is structured can greatly enhance both its maintenance and performance. By familiarizing yourself with the layout, you can identify key areas that may require attention over time, ensuring optimal functionality.

- Examine the primary components and their placements.

- Identify crucial areas that may require frequent servicing.

- Understand how different sections interact to support overall efficiency.

A proper understanding of the arrangement allows for easier troubleshooting and smoother operation. This insight is essential for keeping your device in top shape, reducing downtime and prolonging its lifespan.

Key Components of the Snow Blower

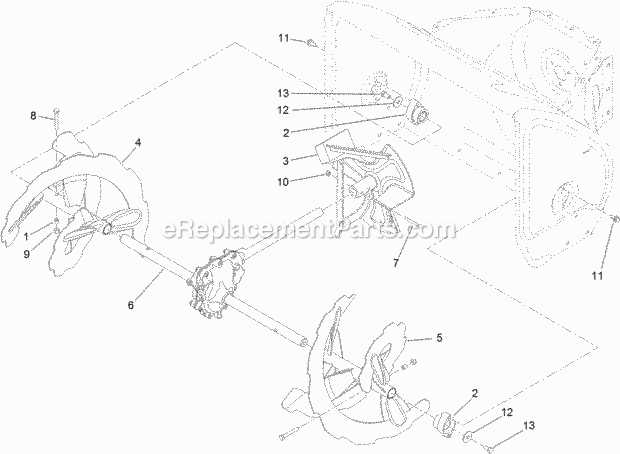

A well-engineered snow clearing machine consists of various interconnected elements that work together to ensure efficient operation. Each part plays a critical role in ensuring the device can move snow effectively, offering users a reliable and powerful tool for winter maintenance.

Core Elements

The heart of this machine lies in its engine, responsible for generating the necessary power to drive the equipment. The cutting blades at the front are designed

Exploring the Function of Major Parts

Understanding the role of key components within complex machinery is essential for ensuring smooth operation and timely maintenance. By focusing on how each element contributes to the overall performance, we gain valuable insights into potential issues and effective upkeep strategies.

One critical component is the power source, responsible for generating the necessary force to drive the entire system. Without its proper functioning, the machine cannot perform its intended tasks. Additionally, the transmission mechanism plays a pivotal role in distributing power to various sections, ensuring synchronized movement and operation.

The steering system, designed for precise control, allows for accurate maneuverability, which is especially crucial when working in tight spaces or challenging conditions. Equally important is the braking system, which guarantees safety by providing reliable stopping power when needed.

Finally, the housing structure protects internal

How to Identify Critical Elements

Understanding how to recognize the most vital components is essential for effective maintenance and troubleshooting. By focusing on key areas of functionality, you can ensure that each essential piece operates as intended, minimizing the risk of breakdowns or malfunctions. This section will guide you through the process of spotting crucial areas within a mechanical assembly, highlighting where attention should be directed.

Key Features to Look For

When inspecting any mechanical system, certain elements play a more significant role in ensuring smooth performance. These include power delivery components, control systems, and areas that experience the most wear and tear. Identifying these can help prioritize maintenance tasks and prevent future issues.

Organizing Your Inspection

Dividing the system into functional zones allows for a more systematic approach to identifying important

Maintaining Efficiency Through Regular Checks

Ensuring the smooth operation of your equipment requires periodic inspections and attention to detail. Regular assessments help identify any potential issues before they become costly repairs. By maintaining a consistent routine, you can prolong the lifespan of your machine and keep it running at optimal performance levels.

- Inspect critical connections to ensure they are secure and free from wear.

- Check for any signs of leaks or unusual noises that could indicate underlying problems.

- Regularly clean components that are prone to accumulating dirt or debris, as buildup can affect functionality.

- Monitor fluid levels and ensure they are within the recommended range for smooth operation.

By incorporating these steps into your maintenance routine, you can ensure that your machine continues to function efficiently, minimizing downtime and extending its overall longevity.

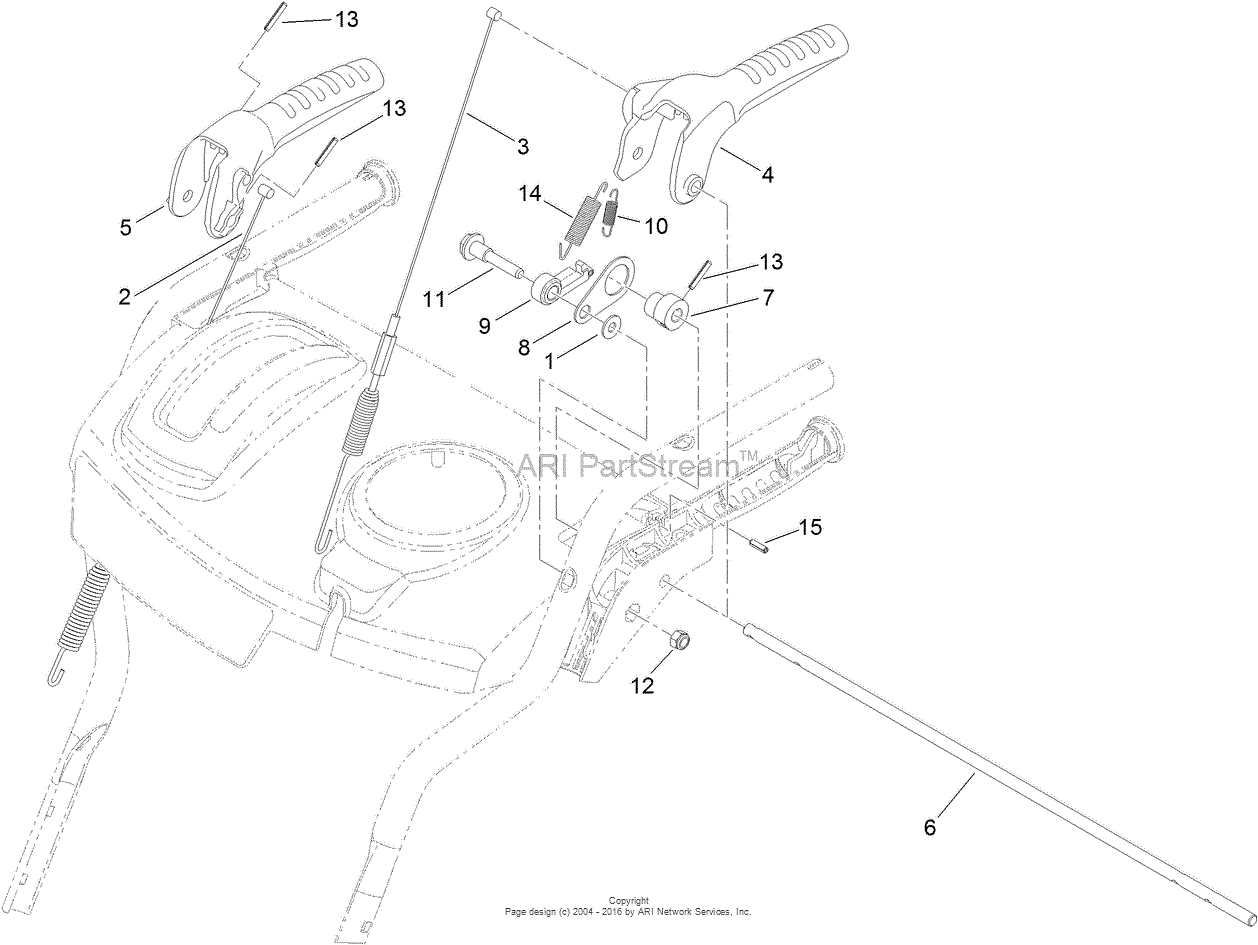

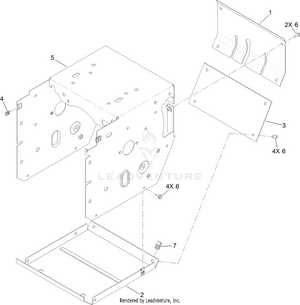

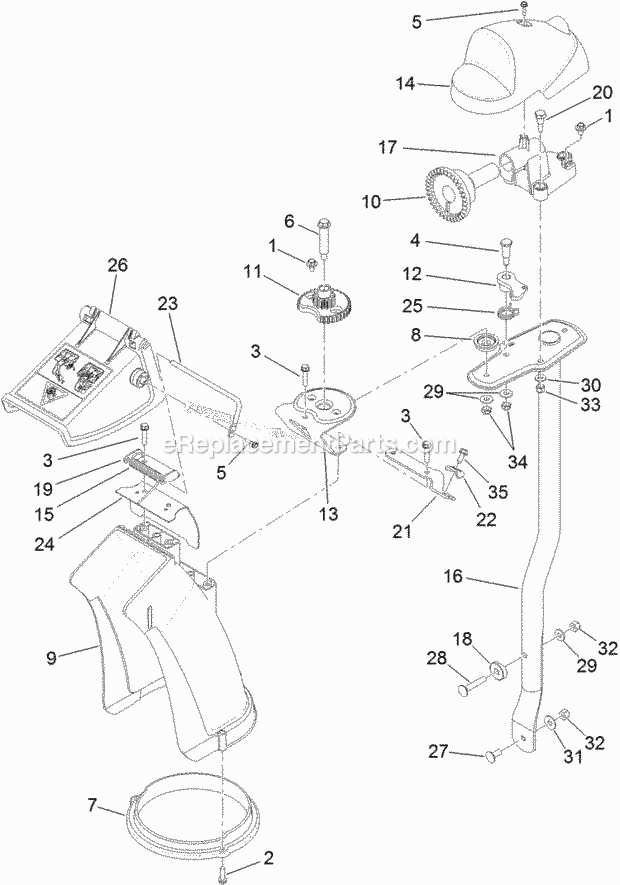

Visual Breakdown of the Machine’s Structure

This section provides an insightful overview of the components that make up the machine, emphasizing their arrangement and functionality. Understanding these elements is crucial for anyone looking to maintain or enhance their operational efficiency.

Key features include:

- Engine Assembly: The powerhouse of the machine, responsible for generating the necessary energy to perform various tasks.

- Transmission System: This mechanism transfers power from the engine to the wheels, ensuring smooth movement and control.

- Chassis Framework: The sturdy base that supports all other components, providing stability and durability.

- Control Mechanisms: These parts enable the operator to guide and manipulate the machine effectively.

- Attachment Points: Locations designed for adding various tools and implements, increasing the versatility of the equipment.

Each of these sections plays a vital role in the overall functionality, and understanding their interactions can significantly enhance the user experience.

To ensure optimal performance, regular inspections and maintenance of these components are recommended. Key maintenance practices include:

- Routine checks of fluid levels and filters.

- Inspections for wear and tear on moving parts.

- Regular cleaning to prevent debris buildup.

- Calibration of control systems for precision operation.

By comprehending the structure and functionality of each part, users can effectively troubleshoot issues and optimize performance.

Common Wear and Tear Items

When maintaining outdoor machinery, it’s crucial to recognize components that frequently experience degradation due to regular use. These items can significantly affect performance and efficiency, making it essential to monitor their condition closely.

Frequently Replaced Components

Among the most common items that may require replacement are belts and blades. Over time, these parts can wear down from constant friction and cutting action. Regular inspections can help identify signs of wear, allowing for timely replacements to ensure optimal functionality.

Maintenance Tips

Additionally, filters and spark plugs are critical elements that often need attention. Clogged filters can restrict airflow, impacting engine performance, while worn spark plugs can lead to starting issues. Regular cleaning and timely replacements of these components can enhance the longevity and reliability of your equipment.

Proper Assembly of Replacement Parts

Ensuring the correct installation of new components is crucial for optimal functionality and longevity. Following a systematic approach can greatly enhance the efficiency of the assembly process, minimizing the risk of errors and maximizing performance.

Essential Steps for Assembly

- Gather all necessary tools and components before starting the assembly.

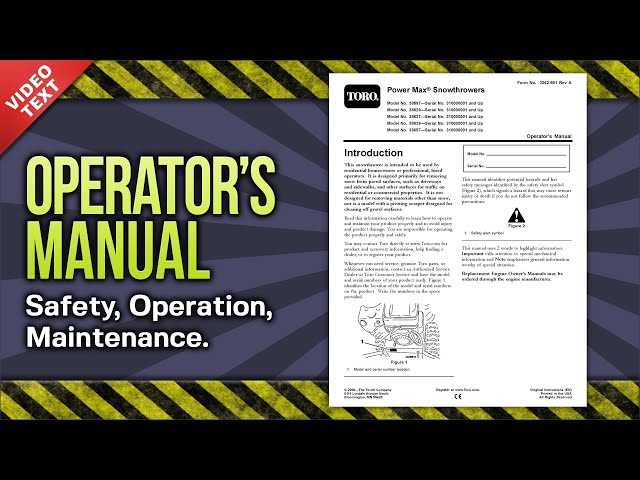

- Refer to the provided guidelines to familiarize yourself with the required procedures.

- Carefully inspect each replacement item for any damage or defects prior to installation.

- Follow a step-by-step approach, ensuring that each piece is secured in place as intended.

- Double-check connections to ensure they are tight and correctly positioned.

Common Mistakes to Avoid

- Neglecting to clean the area before starting, which can lead to debris contamination.

- Forgetting to test the functionality of components after assembly.

- Over-tightening screws or bolts, which can cause damage to the new items.

- Ignoring any signs of wear in surrounding parts that may need attention.

By adhering to these practices, individuals can ensure that the new components are properly integrated, leading to enhanced performance and reliability.

Ensuring Longevity with Correct Installation

Proper installation is crucial for maximizing the lifespan of any mechanical device. When components are assembled correctly, the likelihood of malfunctions and wear diminishes significantly. Attention to detail during the installation process can prevent costly repairs and enhance overall performance, ensuring that the equipment operates smoothly for years to come.

Importance of Following Guidelines

Adhering to manufacturer guidelines is essential for achieving optimal functionality. Each device comes with specific instructions that outline the necessary steps for installation. Ignoring these guidelines can lead to improper assembly, resulting in decreased efficiency or even complete failure. Therefore, carefully reviewing and following these recommendations can make a substantial difference in the longevity of the machinery.

Regular Maintenance Checks

In addition to correct installation, routine maintenance plays a vital role in preserving the integrity of the equipment. Regular inspections allow for the early detection of potential issues, enabling timely interventions. By keeping components clean and addressing any signs of wear promptly, users can extend the operational life and reliability of their machinery, ensuring it continues to perform at its best.

Tools Needed for Effective Repairs

To achieve successful maintenance and restoration of outdoor equipment, having the right set of tools is essential. A well-equipped toolkit not only simplifies the repair process but also enhances efficiency and precision. Selecting appropriate instruments can significantly reduce the time and effort required to tackle various tasks.

Begin with basic hand tools such as screwdrivers, wrenches, and pliers, which are fundamental for disassembly and reassembly. Additionally, incorporating specialized tools tailored for specific components can greatly aid in addressing unique challenges. For instance, a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications, preventing potential damage.

Don’t overlook the importance of safety gear, including gloves and goggles, to protect yourself during repairs. Furthermore, having a reliable work surface and proper lighting can facilitate a smoother workflow. By equipping yourself with the right tools and protective equipment, you set the stage for effective and efficient repairs, leading to prolonged equipment life and optimal performance.

Finding Compatible Components for Your Model

When it comes to maintaining and repairing your machinery, identifying suitable elements that match your specific version is crucial. Whether you’re upgrading parts or replacing worn-out components, understanding compatibility ensures optimal performance and longevity. This section will guide you through the process of locating the right elements for your equipment.

Understanding Compatibility Factors

Several factors influence the compatibility of components, including size, functionality, and specifications. It’s essential to consult manuals or reputable online resources to gather information about your model’s requirements. Additionally, cross-referencing with similar models can provide insights into interchangeable parts that may enhance your equipment’s efficiency.

Where to Find Reliable Resources

To locate compatible elements, consider visiting specialized retailers or trusted online platforms. Many manufacturers offer detailed catalogs and tools for identifying parts specific to your machinery. Engaging with online forums and communities can also yield valuable recommendations and firsthand experiences from other users, helping you make informed decisions.