Toro 20056 Parts Diagram Comprehensive Guide

When maintaining outdoor machinery, grasping the intricacies of its various elements is essential for optimal performance. Familiarizing oneself with the intricate relationships between different components can significantly enhance functionality and longevity.

In-depth knowledge of your device’s structure empowers users to identify issues quickly and efficiently. By exploring the arrangement and roles of each section, you can ensure proper care and timely repairs.

Diving into the specifics of these mechanical systems unveils a roadmap to effective troubleshooting. This understanding ultimately leads to improved reliability and efficiency in your equipment’s operation.

Toro 20056 Overview

This section provides a comprehensive understanding of a specific model renowned for its reliability and efficiency in outdoor maintenance tasks. The equipment is designed to meet the needs of both residential and commercial users, offering a blend of advanced features and user-friendly operation.

With a focus on durability and performance, this model stands out due to its innovative design and high-quality components. Users can expect an enhanced experience that simplifies yard care while ensuring optimal results.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine for robust operation. |

| Durability | Built with materials that withstand rigorous use. |

| User-Friendly | Designed for easy handling and operation. |

| Maintenance | Simple upkeep procedures to prolong lifespan. |

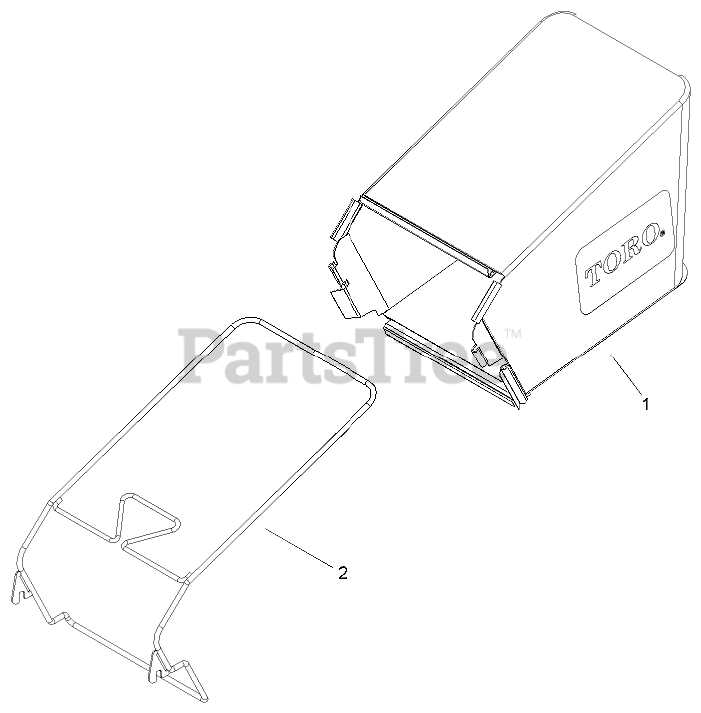

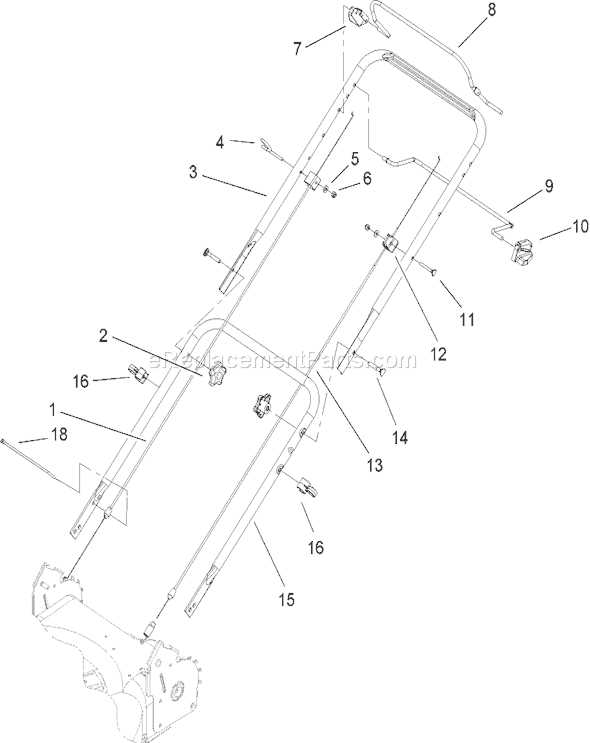

Understanding the Parts Diagram

Comprehending a visual representation of components is essential for effective maintenance and repair of machinery. Such illustrations offer a systematic overview of individual elements, helping users identify and locate each piece efficiently. This section will delve into the significance of these visual aids and provide guidance on how to interpret them effectively.

The Importance of Visual Representations

Visual aids play a crucial role in various aspects of equipment management:

- Facilitating quick identification of parts.

- Enhancing communication among technicians and operators.

- Streamlining the repair process by providing clarity on assembly and disassembly.

- Supporting troubleshooting efforts by pinpointing problematic components.

How to Read the Visual Representation

To effectively utilize these illustrations, consider the following tips:

- Familiarize yourself with the layout: Understanding the general organization can aid in locating specific elements.

- Identify key labels and symbols: Many diagrams include annotations that clarify the function or type of each component.

- Cross-reference with manuals: Use the accompanying documentation to deepen your understanding of the visual elements.

- Take note of assembly sequences: Some representations provide insight into the order of assembly, which can be critical during repairs.

By mastering these techniques, you can enhance your proficiency in navigating and utilizing component representations effectively.

Common Issues with Toro 20056

Many users encounter recurring challenges with their lawn equipment, impacting performance and reliability. Understanding these frequent concerns can significantly enhance maintenance efforts and prolong the lifespan of the machine.

One prevalent issue is the difficulty in starting the engine, often stemming from fuel problems or electrical faults. Regular checks on the fuel system and battery can mitigate this inconvenience.

Another common challenge involves blade dullness, which can lead to poor cutting efficiency. Timely sharpening or replacement of blades is crucial to maintaining optimal performance.

Additionally, users may face issues with the transmission system, which can affect maneuverability. Ensuring proper lubrication and regular inspections can help address this concern.

Lastly, overheating is a frequent problem, often caused by clogged air filters or debris accumulation. Keeping the machine clean and well-ventilated is essential for preventing overheating.

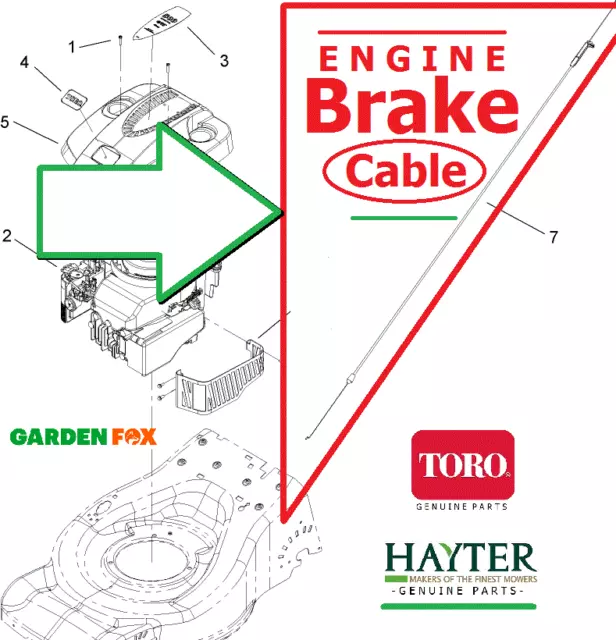

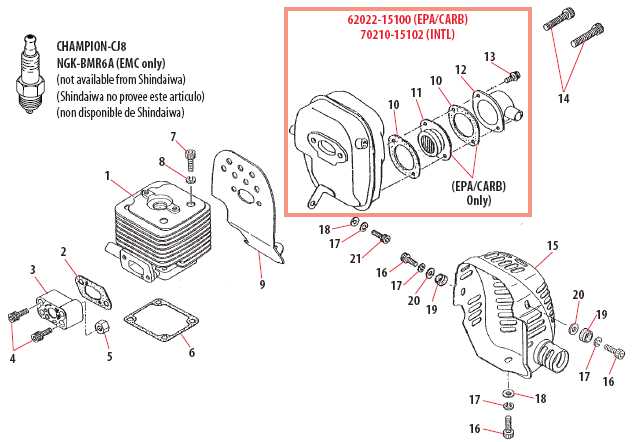

Identifying Replacement Parts

Understanding how to pinpoint components for machinery can significantly enhance maintenance efficiency. By knowing how to locate and recognize essential elements, users can ensure their equipment operates optimally.

To effectively identify components, consider the following steps:

- Consult the user manual for a comprehensive list of parts.

- Examine the equipment for serial numbers or model identifiers.

- Utilize online resources or manufacturer websites for visual references.

Additionally, familiarizing yourself with common terminology can aid in your search:

- Gaskets and seals

- Blades and cutting elements

- Drive belts and chains

- Electrical components and switches

Taking these steps will help ensure you find the ultimate replacements necessary for your machine’s upkeep.

How to Read the Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. This guide will help you decipher the intricacies of such illustrations, enabling you to identify each element and its function within the system. By grasping the layout and notations, you can enhance your troubleshooting skills and streamline your repair processes.

Key Elements to Look For

When examining the illustration, pay attention to various symbols and labels. Each component will typically be represented by a distinct shape or icon, accompanied by numerical identifiers. Familiarizing yourself with these symbols is crucial for accurate interpretation.

| Symbol | Description |

|---|---|

| Circle | Indicates a connector or junction point. |

| Square | Represents a functional component, such as a motor or pump. |

| Arrow | Shows the direction of flow or movement. |

| Dashed Line | Denotes a hidden or internal connection. |

Interpreting Connections and Functions

Beyond recognizing individual components, it’s important to understand how they interact with one another. The lines connecting different shapes illustrate the relationships and pathways of operation. Pay special attention to how each part is linked, as this will guide you in troubleshooting and replacing any faulty sections effectively.

Where to Purchase Components

Finding the right components for your equipment can significantly enhance its performance and longevity. Numerous avenues exist for sourcing these essential items, each with its unique advantages and considerations.

Online Retailers

Numerous online platforms offer a wide selection of parts. Websites like Amazon and eBay provide user reviews and competitive pricing, making them convenient options. Additionally, specialized sites dedicated to outdoor equipment often have detailed catalogs to help you find what you need.

Local Dealers and Service Centers

Visiting local dealers can be beneficial for personalized service and immediate availability. These establishments often carry genuine items and can offer expert advice, ensuring you select the correct components for optimal functionality.

Maintenance Tips for Toro 20056

Regular upkeep is essential for optimal performance and longevity of your equipment. By following a few simple guidelines, you can ensure that your machine operates smoothly and efficiently throughout its lifespan.

- Inspect and clean air filters regularly to prevent clogging and maintain airflow.

- Check and replace spark plugs as needed to ensure reliable ignition.

- Lubricate moving parts to reduce friction and wear.

- Examine belts and cables for signs of wear and replace them if necessary.

- Keep the exterior clean to avoid rust and corrosion.

Additionally, always refer to the manufacturer’s recommendations for specific maintenance schedules and procedures to achieve the ultimate performance.

Diagram vs. Actual Equipment

Understanding the distinction between visual representations and physical machinery is essential for effective maintenance and repair. Visual guides often serve as a roadmap, providing a clear layout of components and their relationships, while the actual equipment reflects the tangible realities of assembly and functionality.

Visual Representations

Illustrated schematics are valuable tools that simplify complex information. They highlight individual elements, enabling users to identify parts easily and understand their interconnections.

Real-World Applications

In contrast, the physical equipment may exhibit variations due to manufacturing tolerances or design updates. This discrepancy can lead to challenges when attempting to match a visual guide with the actual setup.

| Aspect | Visual Representation | Physical Equipment |

|---|---|---|

| Detail | Clear and simplified | Complex and nuanced |

| Accuracy | Subject to interpretation | Reflects true condition |

| Usage | Reference for repairs | Operational and functional |

Advantages of Using Original Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. These items are specifically designed to meet the precise specifications of the equipment, resulting in enhanced reliability and efficiency.

Quality Assurance

Original items undergo rigorous testing, ensuring they meet high standards. This commitment to quality translates into fewer breakdowns and reduced maintenance costs over time.

Compatibility and Performance

By choosing genuine components, users can rest assured of perfect compatibility with their machines. This leads to superior performance, minimizing the risk of issues that often arise from using inferior alternatives.

DIY Repair Considerations

When embarking on a self-repair journey, it’s crucial to evaluate several factors that can significantly influence the outcome. Understanding the complexities involved in fixing machinery can save time and money while also ensuring safety and efficiency. Knowledge about components, proper tools, and troubleshooting methods is essential for a successful repair experience.

Essential Tools and Materials

Gathering the right tools and materials is vital before starting any repair task. A well-equipped workspace allows for a smoother process, minimizing the likelihood of errors.

| Tool/Material | Purpose |

|---|---|

| Wrench Set | Loosening and tightening bolts |

| Screwdrivers | Adjusting screws in various components |

| Pliers | Gripping and manipulating small parts |

| Safety Gear | Protecting yourself during repairs |

Troubleshooting Tips

Effective troubleshooting is the cornerstone of any repair project. Start by identifying symptoms and gathering information to isolate the issue accurately. This approach leads to informed decisions and efficient solutions.