Toro 22298 Parts Diagram Overview

Exploring the intricacies of machinery can often feel overwhelming, yet gaining insight into its individual elements is crucial for effective maintenance and repair. Each component plays a pivotal role, contributing to the overall functionality and efficiency of the device. By familiarizing oneself with these parts, users can ensure longevity and optimal performance.

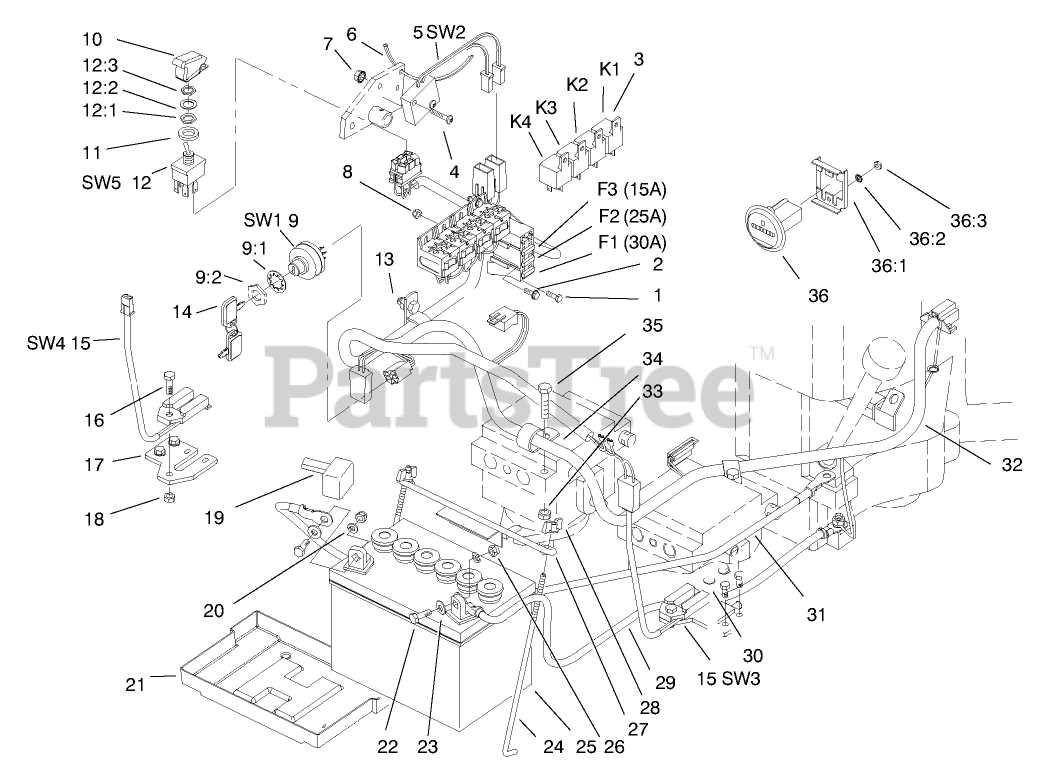

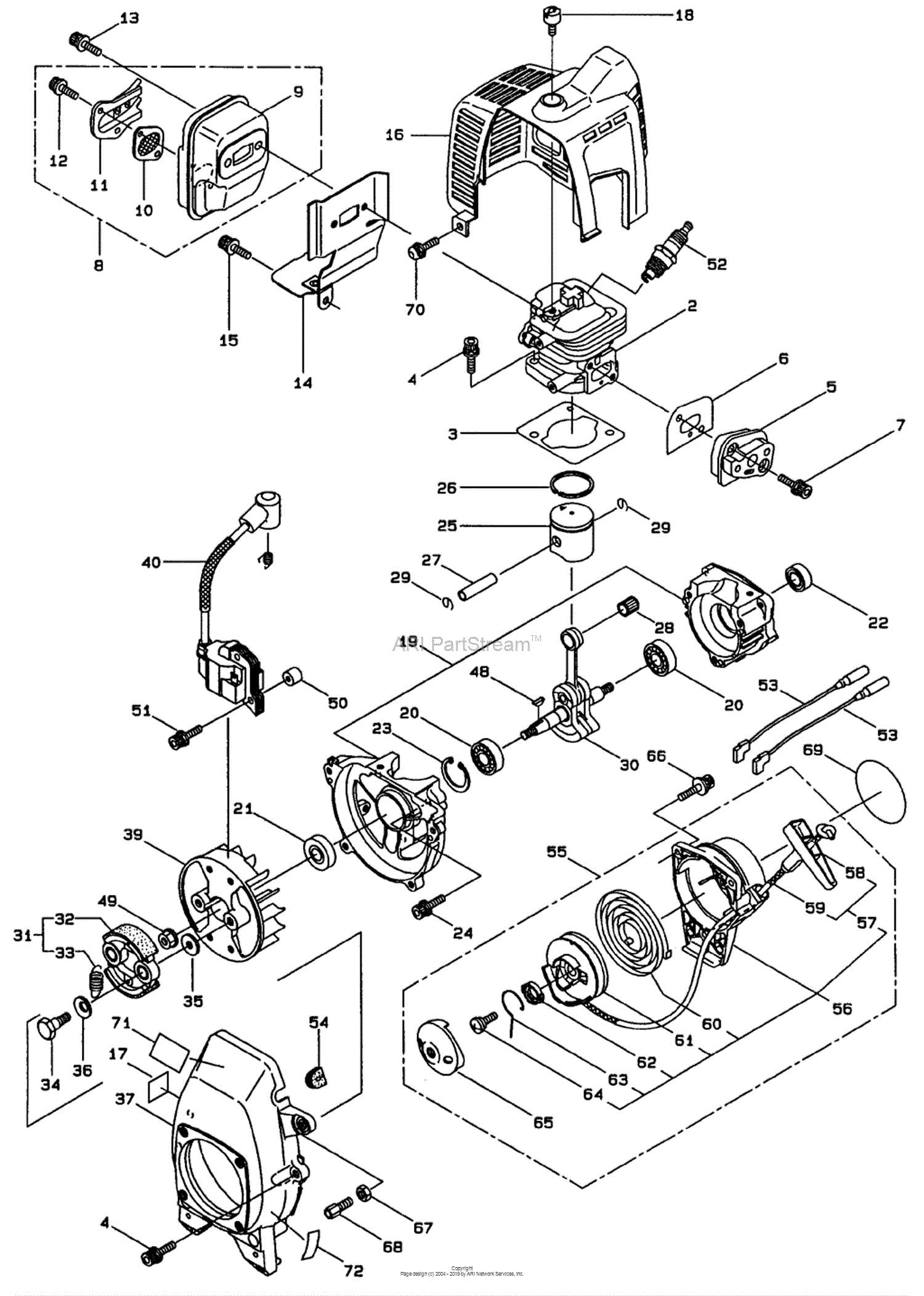

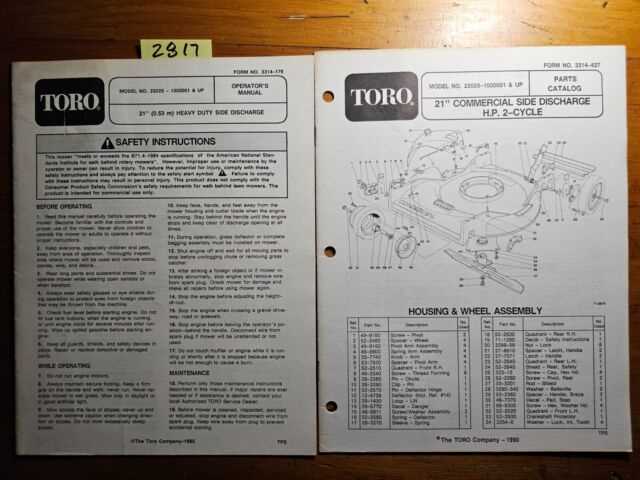

Accessing a visual representation of the various elements within a specific model aids in identifying and understanding the unique features and functions of each segment. Such illustrations serve as valuable resources, particularly when troubleshooting issues or planning upgrades. They provide clarity, making it easier to locate and address specific areas of concern.

Moreover, a detailed examination of these illustrations reveals the interconnectivity of components, highlighting how they work together harmoniously. This understanding empowers operators to tackle maintenance tasks with confidence, reducing the risk of errors and enhancing the overall user experience.

Parts Overview

This section provides a comprehensive look at the various components associated with the model in question. Understanding each element is crucial for effective maintenance and troubleshooting, ensuring optimal performance and longevity.

Key Components

Essential elements include the engine, transmission, and cutting mechanisms, which work together to deliver superior functionality. Each component plays a vital role, and recognizing their individual contributions helps users appreciate the overall design and efficiency.

Maintenance Considerations

Regular upkeep of these integral parts is necessary to prevent wear and tear. Attention to detail, such as checking for wear indicators and replacing worn elements promptly, can significantly enhance the machine’s performance. Always consult the specific guidelines to ensure proper care.

Importance of Parts Diagrams

Understanding the components of machinery is essential for efficient maintenance and repair. Visual representations of these elements provide a clear overview, making it easier to identify individual pieces and their functions. This clarity not only aids in troubleshooting but also streamlines the assembly process.

One of the key benefits of having a visual reference is the ability to quickly locate specific items when they need replacement. This reduces downtime and minimizes frustration during repair tasks. Additionally, it enhances communication among team members, as everyone can refer to the same illustration when discussing issues or solutions.

Furthermore, these visuals can serve as educational tools for those new to the machinery. They foster a deeper understanding of how different components interact, contributing to a more comprehensive knowledge base. This can lead to improved operational efficiency and a greater appreciation for the intricacies of the equipment.

In summary, visual guides are invaluable resources in the world of machinery, promoting effective repairs, facilitating teamwork, and enhancing learning opportunities for users at all levels.

Key Components of the 22298 Model

In this section, we explore the essential elements that constitute the framework of the 22298 unit. Understanding these core components provides insight into its operational structure and functionality.

Engine Assembly

The heart of the device, the engine assembly drives the performance and power delivery of the machine. It comprises intricate mechanisms that convert fuel into mechanical energy, enabling the unit to perform its designated tasks efficiently.

Transmission System

An integral part of the 22298 setup, the transmission system facilitates the transfer of power from the engine to the wheels or cutting blades. This system ensures smooth operation and optimal control over various terrains and conditions.

How to Access Parts Diagram

Finding detailed illustrations and breakdowns of components is essential for anyone looking to repair or maintain their equipment effectively. Accessing these resources can streamline your tasks and enhance your understanding of how various pieces fit together. Here’s a guide to help you locate these valuable reference materials.

Online Resources

One of the most convenient ways to obtain component schematics is through online platforms. Many manufacturers provide digital catalogs on their official websites. Simply navigate to the support or resources section and enter the model number of your equipment. This search should yield a variety of useful documents, including comprehensive charts and visuals that outline each part’s function and placement.

Local Dealerships and Repair Shops

If online searches do not yield satisfactory results, consider reaching out to local dealerships or authorized repair facilities. These establishments often have access to printed manuals and can assist you in finding the information you need. Additionally, they may offer expert advice on common issues related to specific models, enhancing your repair experience.

Identifying Specific Parts Easily

Locating individual components in a complex assembly can often be a challenging task. A systematic approach helps streamline the identification process, ensuring efficiency and accuracy. Utilizing visual aids can significantly enhance understanding and assist in pinpointing the necessary elements without confusion.

To facilitate this process, consider the following strategies:

| Strategy | Description |

|---|---|

| Visual Reference | Employ detailed illustrations that label each section clearly, allowing for quick identification of items. |

| Color Coding | Utilize different colors for various categories of elements, making it easier to distinguish among them at a glance. |

| Numbering System | Incorporate a sequential numbering scheme to correspond with a list of components, ensuring no part is overlooked. |

| Descriptive Labels | Add clear, concise labels to each section, which helps in quickly finding specific items during assembly or maintenance. |

By implementing these techniques, the process of finding individual elements becomes more manageable, allowing users to focus on the task at hand with greater confidence.

Common Issues with Toro 22298

When it comes to equipment maintenance, certain challenges frequently arise that can hinder performance and efficiency. Understanding these typical problems is essential for users to ensure their devices operate smoothly and reliably over time. Addressing these issues promptly can prevent further complications and extend the lifespan of the machinery.

Frequent Problems Encountered

Users often report a range of malfunctions that can disrupt the normal functioning of their devices. These can include issues related to power, mechanical failures, and difficulties with operational components.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Starting Difficulties | Faulty ignition system, low battery charge | Check battery connections, inspect ignition components |

| Uneven Cutting | Dull blades, improper height adjustment | Sharpen or replace blades, adjust cutting height |

| Excessive Vibration | Loose components, imbalanced parts | Tighten loose screws, inspect and balance parts |

Preventative Measures

To mitigate these common challenges, regular maintenance and inspections are crucial. Establishing a routine that includes checking key components and performing necessary repairs can significantly reduce the likelihood of encountering these issues in the first place.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment involves regular care and attention. By implementing a few simple practices, you can enhance performance and reduce the likelihood of unexpected breakdowns. Proper upkeep not only preserves functionality but also maximizes efficiency, allowing you to enjoy the benefits of your investment for years to come.

1. Regular Cleaning: Keep your machinery free from debris and buildup. Dirt and grass clippings can cause overheating and mechanical issues. Use a brush or compressed air to remove any residue after each use.

2. Scheduled Inspections: Conduct periodic checks of key components. Look for signs of wear or damage, such as cracks or loose fittings. Early detection can prevent costly repairs down the line.

3. Lubrication: Regularly apply lubricant to moving parts to ensure smooth operation. This reduces friction and helps avoid premature wear, enhancing the overall efficiency of your unit.

4. Proper Storage: Store your equipment in a dry, sheltered place to protect it from the elements. Covering it can also shield it from dust and moisture, which can lead to rust and corrosion.

5. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and procedures outlined in the user manual. These guidelines are tailored to optimize the performance and longevity of your equipment.

By integrating these practices into your routine, you can significantly enhance the durability and efficiency of your machinery, ensuring it remains a reliable asset for your tasks.

Replacing Worn-Out Components

Maintaining the efficiency and functionality of your equipment often requires the replacement of aging or damaged elements. Identifying when these parts need to be swapped out is crucial for prolonging the lifespan of the machine and ensuring optimal performance.

Here are some signs that components may need replacement:

- Decreased performance or power output.

- Unusual noises during operation.

- Visible wear or damage on parts.

- Frequent breakdowns or malfunctions.

When it comes time to replace components, follow these essential steps:

- Gather necessary tools and replacement items.

- Refer to the user manual for guidance on the replacement process.

- Ensure the equipment is powered off and disconnected before starting work.

- Carefully remove the worn components, taking note of how they are installed.

- Install the new parts, ensuring they fit securely and correctly.

- Test the equipment to confirm proper functionality.

By proactively replacing worn-out elements, you can enhance the reliability and efficiency of your machinery, ultimately leading to better results in your tasks.

Where to Buy Replacement Parts

Finding the right components for your equipment can be a daunting task. However, knowing where to look can simplify the process significantly. Whether you need a specific item for maintenance or an upgrade, various sources can provide the necessary solutions to keep your machinery running smoothly.

Online Retailers

One of the most convenient ways to acquire the required items is through online platforms. Many websites specialize in offering a wide range of equipment components, often with user-friendly search features to help you locate exactly what you need. Here are some popular online options:

| Website | Description |

|---|---|

| Amazon | A vast marketplace with numerous sellers offering various components, often with customer reviews for guidance. |

| eBay | A great platform for both new and used items, allowing for bidding or immediate purchases. |

| Specialty Stores | Many online retailers focus solely on specific types of equipment, providing expertise and detailed product information. |

Local Suppliers

For those who prefer a hands-on approach, visiting local suppliers can be beneficial. Many communities have dedicated stores that specialize in equipment maintenance. Visiting these shops allows you to consult with knowledgeable staff who can assist in finding the perfect match for your needs.

Benefits of Genuine Toro Parts

Utilizing authentic components ensures optimal performance and longevity for your equipment. High-quality replacements are specifically designed to fit seamlessly and function effectively, minimizing the risk of malfunctions or failures.

Durability is one of the primary advantages of using original elements. These items are manufactured to meet stringent standards, providing reliability that inferior alternatives often lack. As a result, users can expect a longer lifespan and better resistance to wear and tear.

Another significant benefit is compatibility. Genuine components are crafted to work harmoniously with your machinery, ensuring smooth operation. This tailored fit reduces the likelihood of operational issues and promotes efficiency during use.

Additionally, choosing authentic items often leads to improved performance. When each element is designed to work together, it enhances the overall functionality of the equipment, allowing it to perform at its best.

Lastly, investing in original components can offer better warranty coverage. Many manufacturers provide guarantees for their authentic products, giving users peace of mind and protection against unforeseen issues.

Understanding Warranty Information

Warranty details are crucial for consumers, offering reassurance and clarity regarding the protection of their purchases. A warranty serves as a promise from the manufacturer, outlining the conditions under which repairs or replacements may be provided at no additional cost. Knowing how to navigate this information can help you make informed decisions and protect your investment.

Key components of warranty information typically include:

- Coverage Duration: This specifies the length of time the warranty remains valid.

- Scope of Coverage: It outlines what parts or issues are covered, and any exclusions that may apply.

- Claim Process: Details on how to initiate a warranty claim, including required documentation and contact information.

- Transferability: Information on whether the warranty can be transferred to a new owner if the product is sold.

Understanding these elements can enhance your overall experience and ensure that you utilize the benefits available to you. Always review the warranty terms thoroughly to avoid surprises and ensure you know your rights as a consumer.

Resources for Further Assistance

When seeking help with your equipment, numerous resources are available to ensure you have the information you need for maintenance and repairs. Whether you are a seasoned professional or a novice, these tools and platforms can guide you through troubleshooting and finding replacement components.

Online Forums are a fantastic place to connect with other users. Engaging in discussions can provide insights and solutions from those who have faced similar challenges. Many enthusiasts and experts share their experiences and can offer practical advice tailored to specific models.

Manufacturer Websites often host extensive libraries of documentation, including manuals and guides. These resources typically outline operational details, assembly instructions, and troubleshooting tips that are crucial for proper upkeep.

Local Dealerships can be invaluable when looking for specialized assistance. Their staff usually possess extensive knowledge about the products they sell, making them a reliable source for inquiries about functionality and replacement items.

Social Media Groups dedicated to specific equipment types allow users to share information and experiences. Joining these communities can keep you updated on the latest trends and modifications, along with practical tips that enhance your understanding.

By utilizing these resources, you can ensure that your equipment remains in optimal condition and that you are well-equipped to handle any issues that may arise.