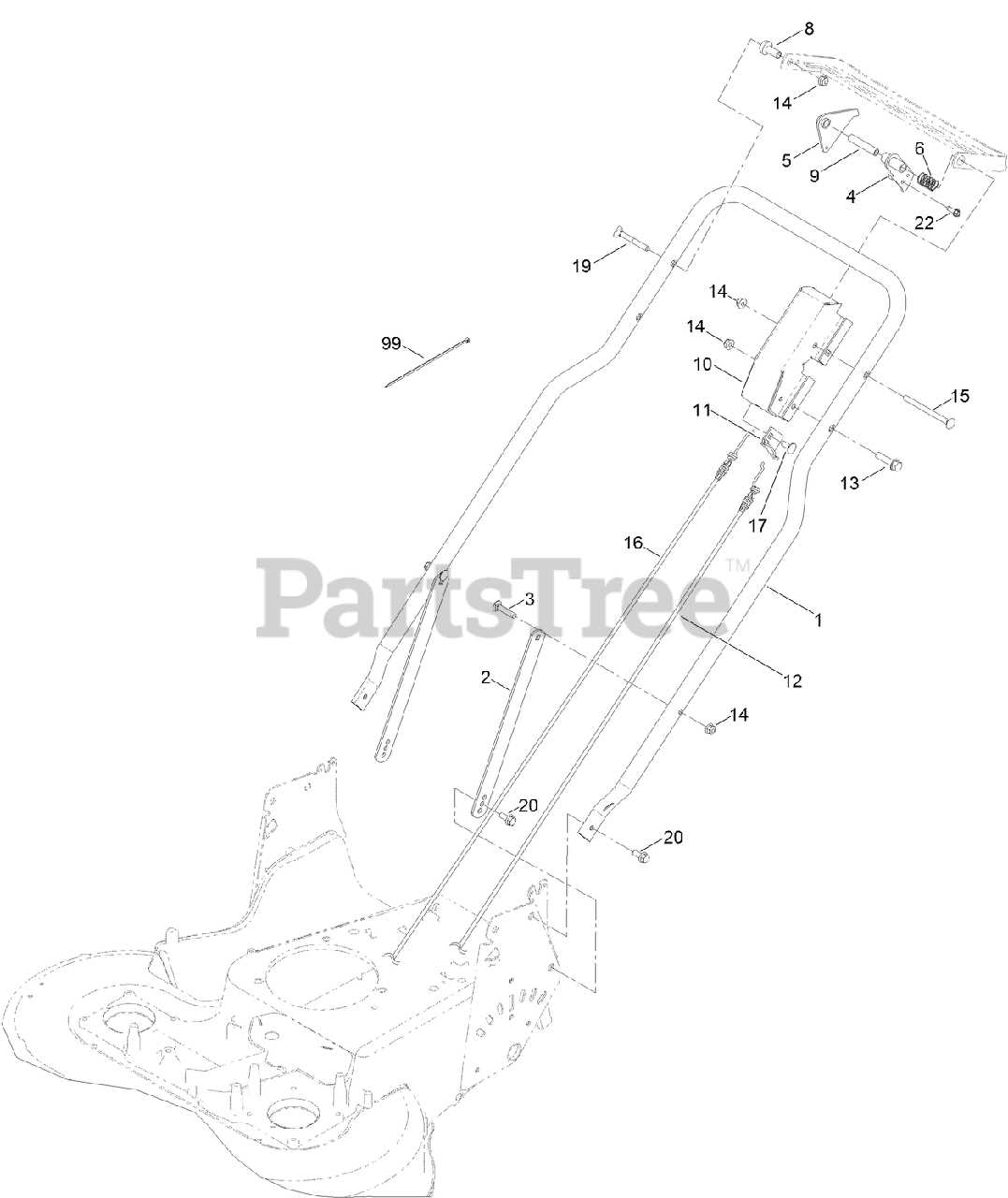

Toro 30 Inch TurfMaster Parts Diagram Overview

Understanding the internal structure and essential components of your lawn maintenance tool is crucial for its proper use and upkeep. By familiarizing yourself with the detailed layout of the key elements, you can ensure efficient functionality and quickly address any issues that may arise during operation. This guide provides an insightful breakdown of the necessary components and their respective roles within the system.

From blades to mechanical connections, each part of your outdoor tool plays a vital role in ensuring smooth and effective performance. By gaining a deeper understanding of these elements, you can maintain and enhance the longevity of your equipment, helping you achieve optimal results with minimal disruption.

Whether you’re performing routine maintenance or troubleshooting specific issues, having a clear view of how the individual parts fit together will allow for more accurate repairs and adjustments. This detailed examination will help you make informed decisions about replacements and upgrades, ensuring your tool remains in top condition.

Component Breakdown for a 30-Inch Lawn Maintenance Machine

The detailed examination of the key elements of this large-scale lawn mower is essential for understanding its functionality and ensuring proper upkeep. By breaking down the primary systems, operators can efficiently maintain each section and replace necessary elements when needed. This guide will focus on the major mechanical and functional areas of the device.

- Cutting System: The cutting mechanism includes multiple blades that ensure a wide, consistent cut, crucial for large areas. Regular sharpening and balancing are recommended.

- Drive Assembly: The propulsion system comprises belts and pulleys that work together to move the mower forward, allowing for smooth operation across varying terrains.

- Deck Structure: The framework that supports the cutting system and shields internal components is designed for durability and stability. Periodic inspection is advised to avoid any issues from debris buildup.

- Control Panel: The user interface allows for easy adjustments of speed, cutting height, and other operational parameters, ensuring customizable performance for different conditions.

- Wheel System: Large, durable wheels provide the necessary traction and mobility for handling uneven or rough ground while protecting the grass underneath.

Understanding the Structure of the Mower

Grasping the overall layout of a lawnmower is essential for effective maintenance and operation. Each component is carefully designed to fulfill a specific role in ensuring smooth performance. From the cutting deck to the engine, every part works together to create a reliable system for cutting grass efficiently. This section provides a clear overview of how the machine’s structure is organized, focusing on key areas that contribute to its functionality.

| Component | Description |

|---|---|

| Engine | The powerhouse of the machine, responsible for driving the blades and propulsion system. |

| Cutting Deck | The area where the blades rotate to trim the grass, varying in size to suit different needs. |

| Wheels | Provide stability and mobility, ensuring easy maneuverability across different terrains. |

| Handlebars | Allow the operator to steer and control the machine with ease, ensuring smooth operation. |

| Fuel Tank | Stores the fuel required to power the engine, offering a range of operation based on capacity. |

Key Elements of the Cutting System

The cutting system is central to ensuring a smooth and efficient trimming process. It relies on several interrelated components that work in harmony to deliver precise and clean results. Understanding the essential parts of this mechanism is key to maintaining optimal performance.

Blade Configuration

At the core of the cutting mechanism is the blade setup, designed for sharpness and durability. The blades are arranged to optimize grass cutting and promote healthy lawn growth. Regular inspection and maintenance of these cutting edges are vital to avoid uneven trims or dull performance.

- High-strength steel for durability

- Sharp edges for precise cutting

- Balanced design for smooth operation

Deck Design

The structure surrounding the cutting system plays a pivotal role in directing clippings and ensuring efficient performance. A well-designed deck minimizes the risk of clogs and enhances airflow, contributing to cleaner cuts and better dispersal of grass clippings.

- Optimized airflow for efficient grass collection

- Robust construction to withstand wear

- Adjustable height settings for versatile trimming

Exploring the Drive Mechanism

The drive system is a crucial component that ensures the machine operates smoothly and efficiently. It connects various elements to enable motion, contributing to both the speed and maneuverability of the equipment. By examining how this mechanism functions, one can better understand its role in delivering optimal performance.

Key Components of the Drive System

At the heart of the system are several interconnected parts, each designed to fulfill specific tasks. These include transmission elements, pulleys, and belts that work in tandem to transfer power. The coordination between these components is essential for maintaining steady and reliable operation.

Maintenance and Troubleshooting

Regular inspection of the drive system is necessary to avoid wear and tear. Lubricating the moving parts and checking for misalignments can prevent breakdowns. Identifying issues early allows for prompt adjustments, ensuring long-term durability and functionality of the machine.

Parts Essential for Optimal Operation

Maintaining efficiency and smooth functionality of your equipment relies on key components working together seamlessly. Each element has a specific role in ensuring the machine performs its tasks effectively, preventing downtime and maximizing productivity. Understanding the significance of these components helps ensure long-term durability and reliable operation.

Vital Mechanical Components

At the heart of the system, essential mechanical elements drive the performance. These include the core power unit, which provides the energy needed to operate efficiently, and the cutting mechanism, designed for precision and durability. Regular inspection and upkeep of these elements can prevent wear and tear, enhancing overall longevity.

Supporting Systems for Smooth Performance

In addition to the primary mechanical components, secondary systems play a crucial role in maintaining steady performance. The drive system ensures controlled movement, while the adjustment controls allow for fine-tuning operations. These support systems are vital for achieving consistent results, making maintenance of these areas equally important.

How the Blade Assembly Functions

The blade system plays a crucial role in ensuring the smooth cutting of grass, delivering a precise and clean result. This mechanism operates through the coordinated movement of its components, which work together to create an efficient mowing process. The blades, positioned strategically, are designed to rotate at high speeds, allowing them to slice through grass with minimal effort. Understanding the functionality of this system helps improve overall machine performance.

At the heart of the assembly, the blades are mounted securely to ensure stability during operation. As they rotate, the cutting edges come into contact with the grass, trimming it to the desired length. The angle and sharpness of the blades are crucial for achieving a smooth cut without damaging the lawn. The design allows for a balance between power and precision, optimizing both performance and the longevity of the blades themselves.

The blade system is engineered for durability and ease of maintenance. Regular sharpening and proper adjustment are key to maintaining its effectiveness. Ensuring that the blades are clean and free from debris is also essential, as this prevents obstructions and maintains optimal cutting efficiency. A well-maintained blade assembly ensures consistent results, making the mowing process more effective and reducing wear on the machine.

Analyzing the Fuel System Components

The fuel system plays a crucial role in ensuring the smooth operation of any engine. By properly regulating fuel delivery, it helps maintain performance and efficiency. In this section, we will explore the essential elements of this system, focusing on their function and importance.

Fuel Tank: The starting point of the fuel system, the tank stores the fuel that powers the engine. It is designed to hold an adequate amount of fuel and prevent contamination from external elements. Ensuring the fuel tank is clean and free from leaks is vital for smooth engine operation.

Fuel Pump: The pump is responsible for transferring fuel from the tank to the engine. It maintains the necessary pressure for proper combustion. Over time, wear or clogging can affect its efficiency, leading to fuel delivery issues.

Fuel Filter: This component removes impurities and debris from the fuel before it reaches the engine. A clean filter ensures that the engine receives only pure fuel, preventing damage to sensitive parts like injectors and combustion chambers.

Fuel Injector: The injector controls the amount of fuel that enters the combustion chamber. Proper functioning is essential to achieving the right fuel-to-air ratio for optimal engine performance. Any malfunction can result in poor fuel efficiency or engine misfires.

Fuel Lines: These pipes or hoses transport fuel from the tank to the engine and between other components. They must be checked regularly for signs of wear, cracks, or leaks that could lead to fuel loss or dangerous situations.

Regular maintenance and timely replacement of any worn or damaged components are essential for keeping the fuel system in peak condition. Understanding these elements helps ensure the longevity and reliability of the engine.

Detailed View of the Engine Layout

This section provides an in-depth exploration of the key components that make up the engine’s structure and operation. Understanding the arrangement of these elements is essential for maintaining optimal performance and troubleshooting potential issues. By breaking down the engine into its essential parts, we can ensure that each piece functions in harmony with the others.

Main Components

- Power Unit: This is the central powerhouse that drives the machine, converting fuel into mechanical energy.

- Fuel System: A crucial network responsible for storing and supplying the fuel to the engine, ensuring continuous operation.

- Cooling System: Designed to prevent overheating, this system maintains the engine’s temperature within safe operating limits.

- Ignition Mechanism: The ignition system is responsible for starting the engine, triggering the combustion process that powers the machine.

Supporting Systems

- Lubrication System: Keeps all moving parts well-oiled, reducing friction and wear during operation.

- Exhaust System: Responsible for directing harmful gases away from the engine and out of the machine.

- Air Intake: Ensures a continuous flow of air for the combustion process, enhancing engine efficiency.

Maintaining the Wheels and Axles

Proper upkeep of the wheels and axles is essential to ensure smooth operation and longevity of your equipment. These components are crucial for mobility and performance, so regular maintenance can prevent unnecessary wear and costly repairs.

Follow these steps to keep the wheels and axles in optimal condition:

- Inspection: Regularly check the wheels for any signs of damage or excessive wear. Look for cracks, flat spots, or punctures that could compromise their performance.

- Lubrication: Apply a suitable lubricant to the axle shafts and bearings. This helps reduce friction and ensures smooth rotation.

- Alignment: Make sure the wheels are properly aligned with the frame. Misalignment can cause uneven wear and lead to handling issues.

- Tightening: Periodically check that all wheel fasteners and axle bolts are securely tightened to prevent loosening during operation.

- Cleaning: Clean the wheels and axles regularly to remove dirt, debris, or grass buildup that can impair movement and cause damage over time.

By following these simple steps, you can extend the life of your equipment, improve its efficiency, and avoid unexpected malfunctions.

Overview of the Control System

The control system of a lawn care machine plays a crucial role in ensuring optimal operation and user-friendly functionality. It integrates various components to provide precise management of speed, direction, and power, all of which contribute to a smooth and efficient performance. Understanding the layout and connection of these elements is essential for operators looking to maintain and troubleshoot the system effectively.

Key Components

The control system consists of several key elements that interact with one another to regulate the machine’s overall functioning. These typically include throttle controls, steering mechanisms, and braking systems. Each part is designed to provide intuitive and responsive handling, enabling the operator to navigate diverse terrains with ease.

Maintenance Considerations

Proper maintenance of the control system ensures longevity and reliability. Regular checks of the throttle linkages, cables, and steering components help prevent wear and tear. Additionally, keeping the control elements clean and lubricated can reduce the risk of malfunctions and improve overall performance. Attention to detail during these maintenance routines can significantly enhance the system’s responsiveness and accuracy.

Safety Features and Protective Parts

Ensuring safety during operation is crucial for any machinery designed for outdoor tasks. This section focuses on the integral safety mechanisms and components that help minimize risks to the user. Properly maintained and well-constructed safety features play a key role in preventing accidents and enhancing the overall performance of the equipment.

Protective Guards and Shields

Many machines include various guards and shields designed to protect the operator from flying debris, moving parts, or any unexpected mechanical failures. These shields cover exposed areas and are made from durable materials that resist impact, ensuring the safety of the user during operation.

Safety Cutoff Mechanisms

Automatic shutdown systems are essential for preventing potential hazards when certain safety conditions are not met. These mechanisms immediately stop the machinery if an unsafe situation is detected, such as improper use or malfunctioning parts, effectively minimizing the risk of injury.

Electrical System and Wiring Diagram

The electrical configuration of the machine is crucial for ensuring its functionality and safety. Proper wiring ensures seamless communication between various components, such as the power source, ignition system, and operational controls. Understanding the layout helps in diagnosing issues, performing routine maintenance, and replacing any faulty parts efficiently.

Wiring Connections play a key role in maintaining the electrical integrity of the system. Each connection is designed to link specific components in a way that prevents short circuits and electrical failures. The process of tracing the connections and identifying potential weaknesses is essential for troubleshooting.

Power Supply and Controls are central to the electrical framework. The distribution of current throughout the system must be carefully managed to avoid overloads and ensure consistent performance. Identifying the flow of power from the source to the various sections of the equipment provides insight into how different systems work together to ensure smooth operation.

Maintenance of the electrical setup involves regular inspection of wires, connectors, and components for signs of wear, damage, or corrosion. Proper maintenance can extend the life of the system and prevent unexpected malfunctions that could disrupt the equipment’s operation.