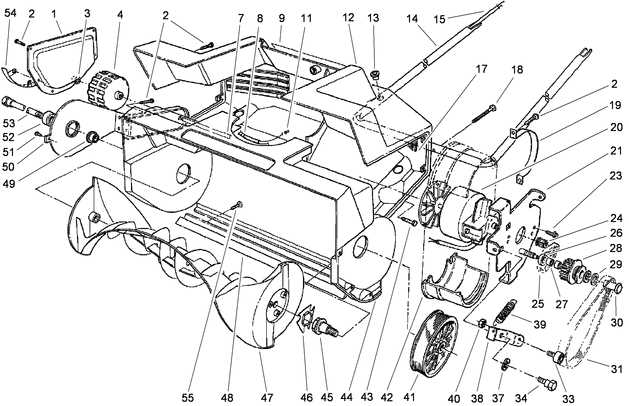

Toro 524 Parts Diagram Overview

When it comes to maintaining outdoor machinery, having a clear grasp of its individual elements is essential for optimal performance. Every piece plays a significant role in ensuring the overall functionality of your device, and recognizing these components can greatly enhance your repair and maintenance efforts.

In this section, we will explore a comprehensive overview of the various elements involved in your equipment. By dissecting these crucial parts, you can achieve a deeper understanding of their interactions and functionalities. This knowledge not only facilitates troubleshooting but also empowers you to make informed decisions during servicing.

Moreover, delving into the specific configurations and relationships between these components provides clarity on assembly and disassembly procedures. As you navigate through the intricate layout of your machinery, you will discover the ultimate advantages of being well-informed about its structure.

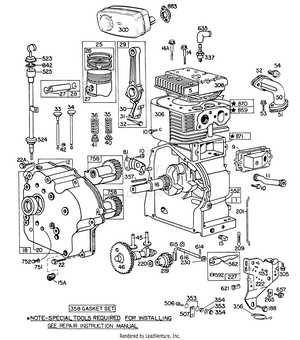

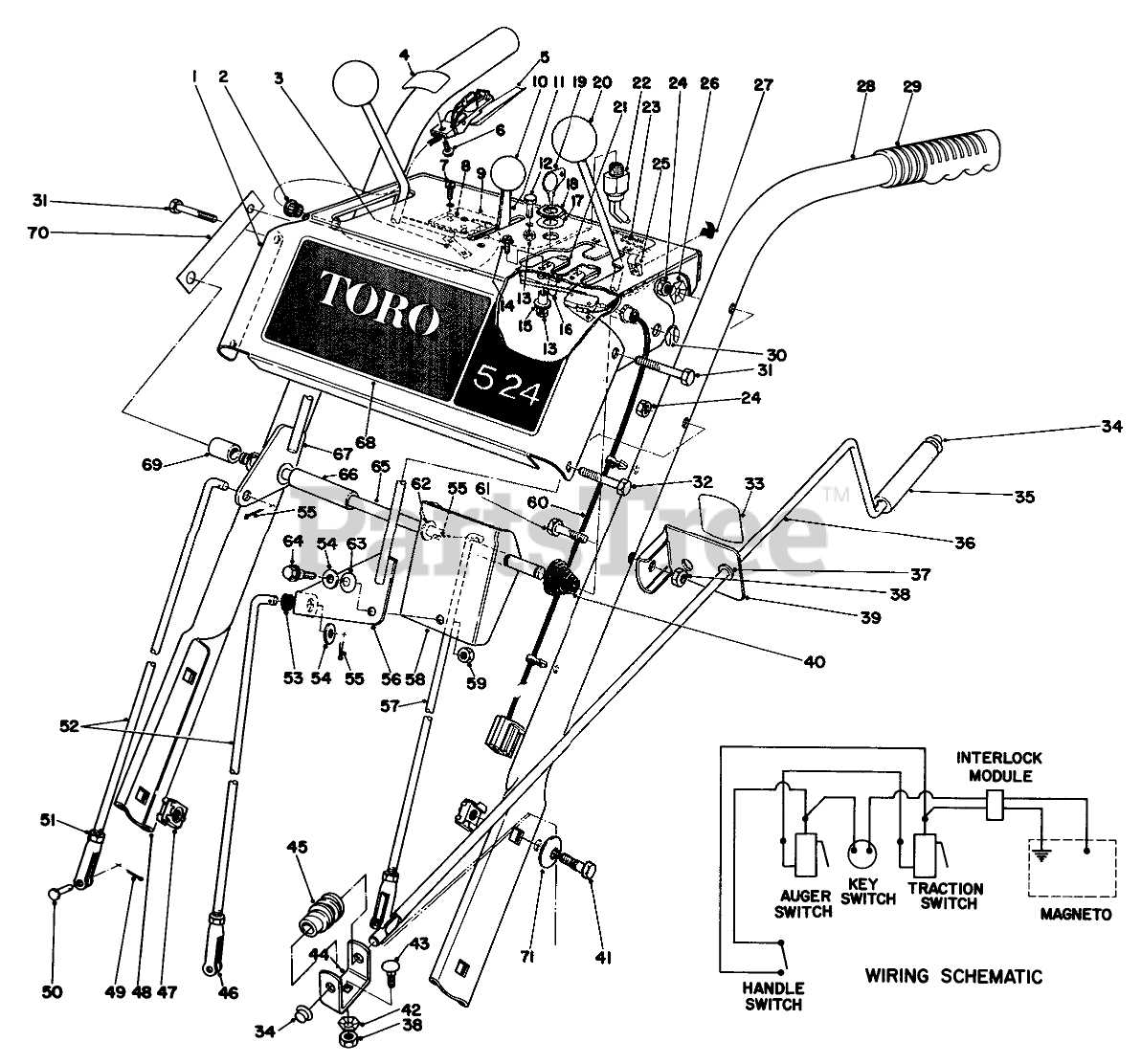

Understanding Toro 524 Parts Diagram

Familiarizing oneself with the components of any machinery is essential for effective maintenance and repair. A comprehensive visual representation aids users in identifying various elements and their functions within the equipment. This understanding not only enhances operational efficiency but also extends the lifespan of the machine.

Importance of Visual Guides

Visual guides serve as crucial tools for both novices and experienced operators. They provide a clear roadmap of each component’s location and its relationship to others, facilitating easier troubleshooting and assembly. By utilizing these illustrations, one can quickly pinpoint issues and execute repairs without unnecessary delays.

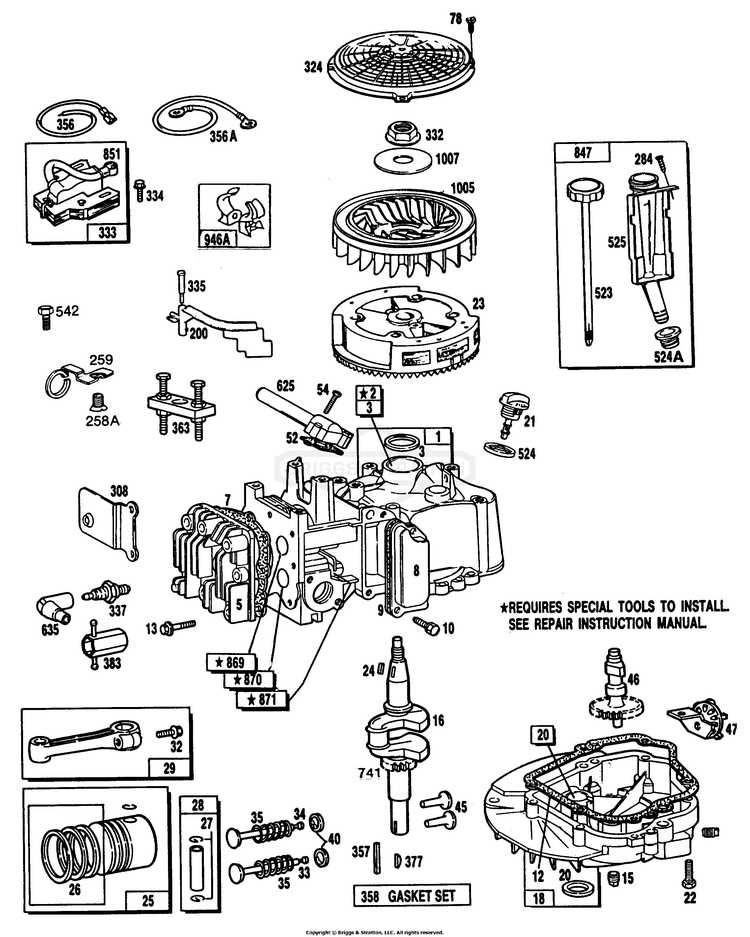

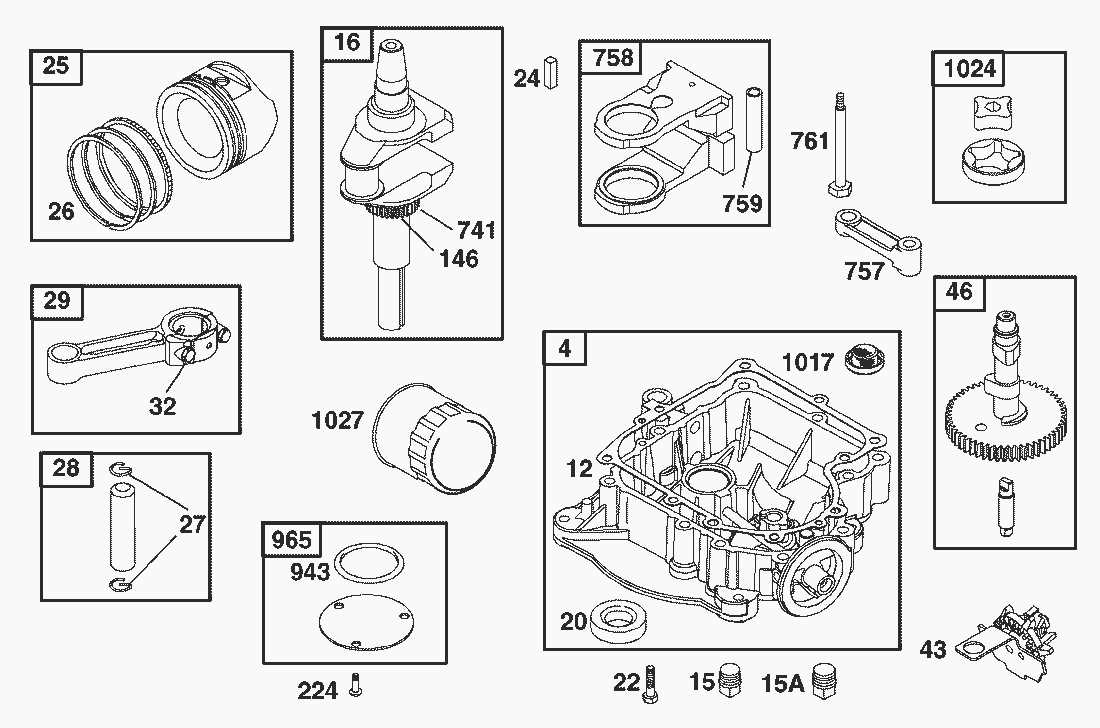

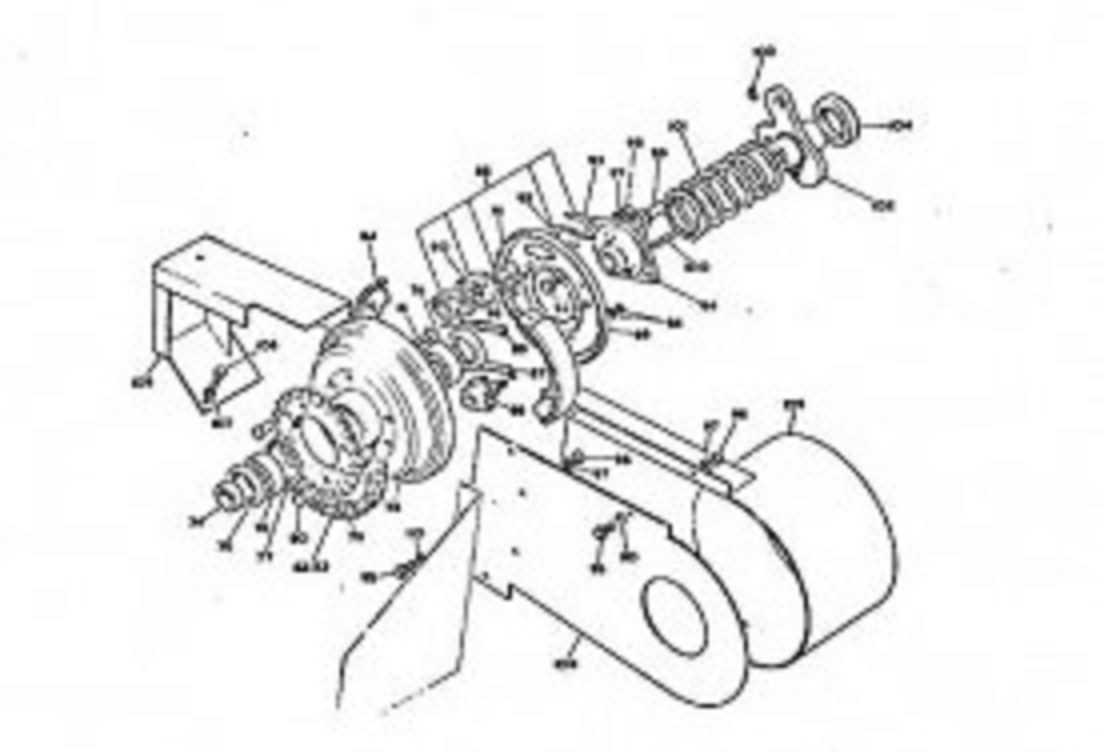

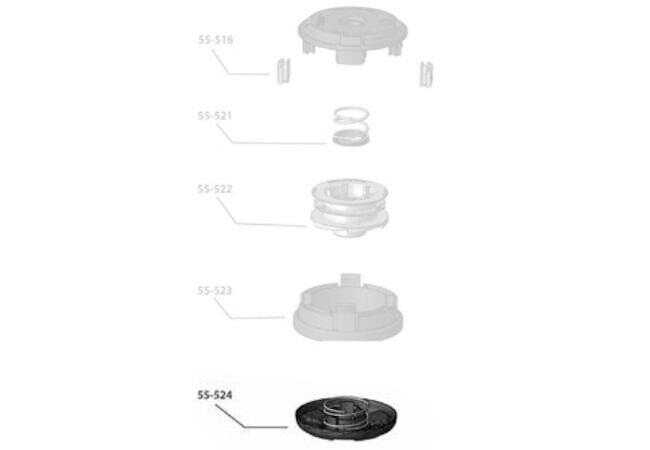

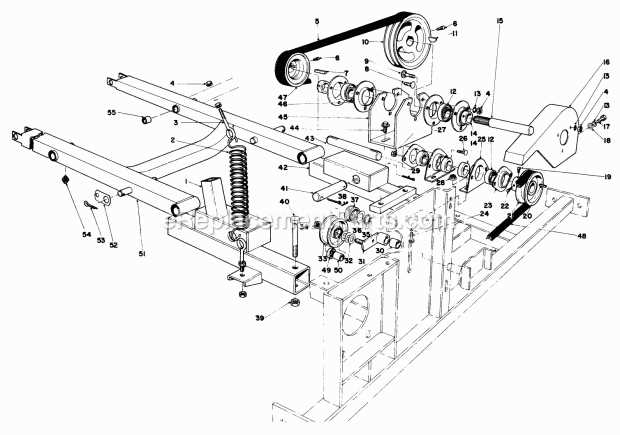

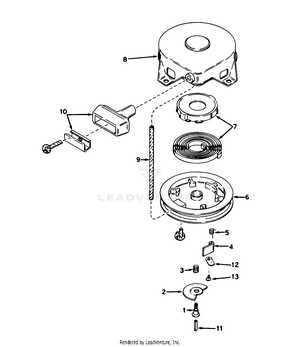

Key Components to Identify

When examining a schematic, it is vital to focus on the main sections, such as the engine assembly, drive system, and control mechanisms. Recognizing the function of each part can empower users to make informed decisions during maintenance tasks. Understanding the layout ensures that replacements are accurate and compatible, thereby preventing future complications.

Essential Components of Toro 524

Understanding the crucial elements of any snow-clearing machine is vital for optimal performance and maintenance. Each component plays a significant role in ensuring efficiency, durability, and ease of use, contributing to a smoother snow removal experience.

Main Features

Among the key features are the engine, which powers the entire unit, and the auger, designed for effective snow intake. The chassis provides structural integrity, allowing for stability during operation, while the drive system ensures reliable movement across various terrains.

Operational Elements

Additional components include the control panel, which allows the operator to adjust settings easily, and the snow chute, directing the cleared snow precisely where needed. Regular inspection and maintenance of these elements are essential for prolonging the lifespan and functionality of the equipment.

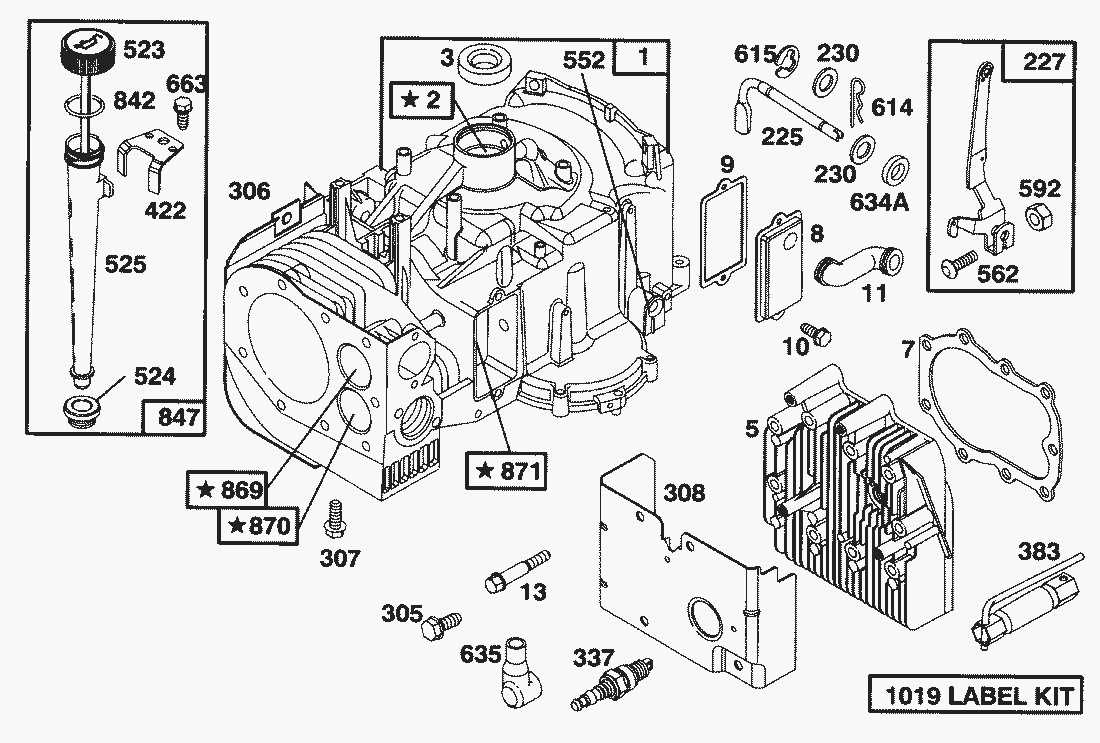

How to Read the Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repair. Such illustrations provide valuable insights into the assembly, making it easier to identify individual elements and their relationships within a system. By mastering the interpretation of these visuals, users can streamline their troubleshooting and replacement processes.

Identifying Components

Each symbol or number on the illustration corresponds to a specific item, often accompanied by a label for clarity. Familiarizing yourself with these notations will enable you to pinpoint the exact parts you need to address issues or perform upgrades. It is essential to consult the accompanying list to understand the specifications of each element depicted.

Understanding Connections

The lines and arrows in the representation indicate how components interact with each other. These connections can reveal the assembly order and help you comprehend how various parts work together. Recognizing these relationships is key to ensuring that reassembly is done correctly after maintenance or replacement.

Common Issues with Toro 524 Parts

When maintaining outdoor power equipment, users often encounter several frequent problems that can impact performance and longevity. Understanding these common challenges can help in troubleshooting and ensuring proper functioning of the machinery.

Worn Components

One of the primary concerns is the wear and tear of various elements, which can lead to decreased efficiency. Regular inspections are essential to identify signs of damage or deterioration early.

Misalignment Problems

Misalignment can cause significant operational issues, including uneven wear and unexpected breakdowns. Ensuring proper alignment during assembly and maintenance can prevent these complications.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Worn belts | Squeaking noises, slippage | Replace belts regularly |

| Clogged filters | Reduced power, overheating | Clean or replace filters |

| Loose fasteners | Vibration, instability | Tighten all bolts and screws |

Finding Replacement Parts Easily

Locating components for outdoor equipment can often be a daunting task, but with the right approach, it can be straightforward and efficient. Understanding where to look and what resources to utilize can save time and ensure that you find the right items without hassle.

Utilizing Online Resources

The internet is a treasure trove of information when it comes to sourcing components. Here are some tips to make the most of online resources:

- Visit official manufacturer websites for accurate product listings.

- Explore dedicated online retailers that specialize in outdoor machinery.

- Check forums and community groups where enthusiasts share advice and recommendations.

Local Shops and Distributors

In addition to online options, local retailers can be invaluable. Consider these strategies:

- Contact nearby hardware stores or specialized shops to inquire about availability.

- Build relationships with local distributors who may offer personalized assistance.

- Attend trade shows or local events to connect with vendors and gather information.

By leveraging both online platforms and local resources, finding the right components becomes a manageable task, ensuring your equipment remains in top condition.

Maintenance Tips for Toro 524

Proper upkeep of your outdoor equipment is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns, allowing you to tackle tasks without interruption. Here are some essential tips to keep your machinery running smoothly throughout the seasons.

| Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 50 hours | Use high-quality oil to lubricate internal components and prevent wear. |

| Air Filter Cleaning | Every 25 hours | Remove debris and dirt to ensure proper airflow and engine efficiency. |

| Spark Plug Inspection | Every season | Check for wear and replace if necessary to ensure easy starting. |

| Fuel System Maintenance | Every season | Clean the fuel system to prevent clogging and ensure smooth operation. |

| Blade Sharpening | Every 25 hours | Keep blades sharp for clean cuts and to reduce strain on the engine. |

Following these guidelines will help maintain the efficiency and performance of your machine. Regular checks and timely actions can significantly extend the lifespan of your equipment, making your outdoor tasks more enjoyable and efficient.

Where to Buy Toro Parts Online

Finding components for your equipment online can be a straightforward process if you know where to look. Numerous retailers offer a wide selection of items, ensuring you can find what you need for maintenance and repair. Whether you’re searching for original equipment or aftermarket options, the right sources can save you time and money.

Here are some recommended places to explore for your equipment needs:

| Retailer | Website | Notes |

|---|---|---|

| Manufacturer’s Official Store | www.example.com | Offers authentic items and the latest models. |

| Specialty Parts Retailer | www.example2.com | Wide variety of components at competitive prices. |

| Marketplace | www.example3.com | Connects buyers with various sellers; great for second-hand items. |

| Local Dealers | www.example4.com | Support local businesses; often have knowledgeable staff. |

When purchasing online, ensure to check the return policy and customer reviews to make an informed decision. Taking these steps will help you find the right components efficiently and effectively.

DIY Repairs Using the Diagram

Engaging in self-repair can be both rewarding and cost-effective. Understanding how various components fit together is crucial for anyone looking to fix their equipment. By utilizing an illustrative guide, you can effectively identify and address issues that may arise, ensuring your device runs smoothly.

Benefits of Using an Illustrative Guide

- Enhances understanding of internal structures

- Helps locate specific components easily

- Facilitates organized repair processes

- Encourages confidence in troubleshooting

Steps for Effective Repairs

- Begin by studying the reference carefully to familiarize yourself with the layout.

- Gather necessary tools and replacement parts that may be needed.

- Follow the guide step-by-step, ensuring each component is correctly addressed.

- After completing repairs, test the equipment to confirm functionality.

- Document any changes made for future reference.

Tools Needed for Toro 524 Maintenance

Proper upkeep of your equipment requires a selection of essential instruments to ensure optimal performance and longevity. Having the right tools on hand not only simplifies the maintenance process but also enhances safety and efficiency during repairs and inspections.

Basic hand tools are crucial, including wrenches, screwdrivers, and pliers, which allow for easy adjustments and part replacements. Additionally, a set of socket tools can facilitate work on various components, providing the leverage needed to tackle stubborn fasteners. A torque wrench is important for ensuring that all connections are tightened to the manufacturer’s specifications.

To maintain clean and efficient operation, you’ll also need cleaning supplies such as brushes and rags, along with appropriate lubricants to reduce friction and wear. A diagnostic tool may be beneficial for identifying issues and ensuring that all systems are functioning correctly.

Finally, safety equipment such as gloves and goggles should always be utilized to protect yourself during maintenance tasks. Having the right gear will not only make the job easier but will also promote a safe working environment.

Identifying Worn Out Components

Recognizing when elements of your equipment have reached the end of their service life is crucial for maintaining optimal performance. Over time, various parts can experience wear and tear, leading to decreased efficiency and potential malfunction. Understanding the signs of deterioration will help in timely replacements, ensuring smooth operation and longevity of the machine.

Common Indicators of Wear

Several factors can signal that a component is no longer functioning effectively. Look out for physical signs as well as performance changes that may indicate the need for replacement.

| Indicator | Description |

|---|---|

| Cracks or Fractures | Visible damage on the surface that compromises structural integrity. |

| Excessive Play | Unusual movement or looseness in parts that should fit snugly. |

| Unusual Noises | Grinding, squeaking, or rattling sounds during operation. |

| Leaking Fluids | Signs of fluid escaping from seals or joints. |

| Overheating | Components that run hotter than normal, indicating inefficiency. |

Importance of Regular Inspection

Regular checks can prevent minor issues from escalating into major problems. Keeping a close eye on your equipment helps to identify worn elements early, allowing for proactive measures that save time and resources. Establishing a routine maintenance schedule ensures that all components remain in good condition, ultimately enhancing the reliability and efficiency of your machinery.

Customer Reviews of Toro 524 Parts

This section provides insights into user experiences with components related to snow removal equipment. Feedback from customers can guide potential buyers in making informed decisions regarding their purchases. Reviews often highlight quality, durability, and performance, reflecting the reliability of these essential elements.

| Customer | Rating | Review Summary |

|---|---|---|

| John D. | 5/5 | Excellent quality and easy to install. Highly recommend! |

| Sarah M. | 4/5 | Good performance, but took a bit longer to arrive than expected. |

| Mike R. | 3/5 | Decent parts, but not as durable as I had hoped. |

| Linda T. | 5/5 | Perfect fit! My machine runs like new again. |

| James L. | 4/5 | Great value for the price, satisfied with my purchase. |

Upgrades and Modifications Available

Enhancing the performance and functionality of your outdoor equipment can lead to significant improvements in efficiency and usability. Various upgrades and modifications are available, allowing users to tailor their machines to better suit specific tasks and preferences.

| Modification Type | Description | Benefits |

|---|---|---|

| Engine Upgrade | Install a more powerful engine to boost performance. | Increased power and efficiency for demanding tasks. |

| Attachment Options | Add specialized attachments for enhanced versatility. | Ability to perform a wider range of tasks. |

| Handlebar Adjustments | Modify the handlebar height and angle for comfort. | Improved ergonomics and reduced fatigue during operation. |

| Tire Upgrades | Switch to all-terrain or specialty tires. | Better traction and stability on various surfaces. |

| Fuel Efficiency Modifications | Incorporate fuel-saving technologies or parts. | Reduced operating costs and environmental impact. |