Toro Parts Diagrams for Easy Identification and Repair

In order to maintain and repair machinery efficiently, it is crucial to have a clear overview of its individual elements and how they fit together. Whether for professional equipment or everyday tools, understanding how various components interact can significantly improve both maintenance and troubleshooting processes.

By analyzing the structure of the equipment, users can identify which elements are responsible for specific functions. This helps in recognizing potential issues early on and ensures that repairs or replacements are done swiftly and accurately. Such breakdowns also serve as a guide for regular upkeep, ensuring optimal performance over time.

With detailed overviews of mechanical elements, even complex systems can become easier to navigate. This resource will guide you through the most important aspects of mechanical structures, offering clarity and insight into their functionality.

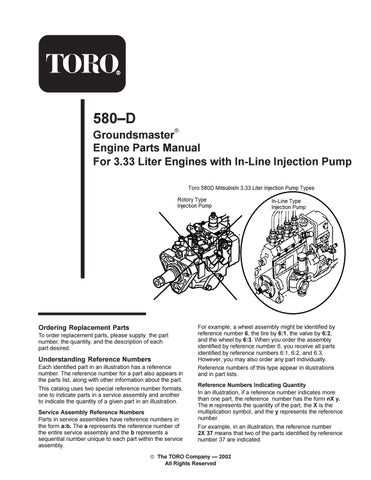

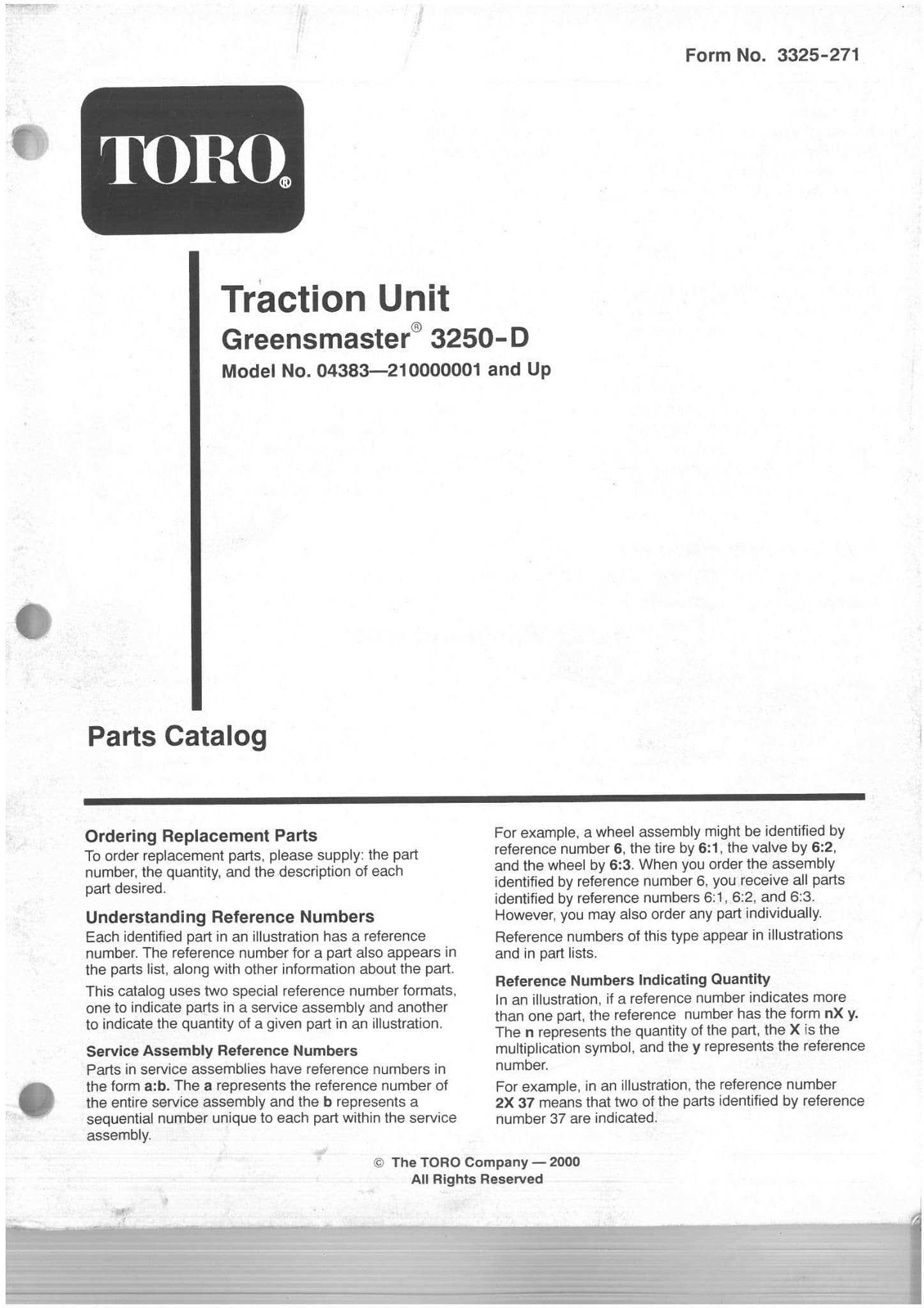

Toro Parts Diagrams: Overview and Importance

Understanding the structural layout and detailed components of machinery is crucial for maintenance and repair. Having a clear visual guide provides users with the necessary insights to identify various elements, ensuring smoother operation and longevity of the equipment. These schematics offer a comprehensive view, simplifying the process of ordering replacements and conducting repairs.

Here are some key reasons why these visual references are essential:

- They assist in the accurate identification of different components.

- Facilitate efficient troubleshooting and problem resolution.

- Support preventive maintenance by highlighting vulnerable areas.

- Streamline the process of sourcing replacement elements.

By relying on these visual layouts, users can avoid errors in reassembly and ensure that all components function

Understanding the Structure of Toro Equipment

Comprehending how outdoor machinery is organized is essential for efficient use and maintenance. The various components of any machine are interconnected to perform specific tasks, ensuring the whole system operates smoothly. By exploring the arrangement and purpose of these elements, one can gain a clearer picture of how each section supports the overall function of the equipment.

Key Components and Their Functions

Each mechanism includes several major elements, such as engines, blades, control systems, and drive mechanisms. These sections are designed to work together, with each playing a distinct role in achieving optimal performance. Understanding how these pieces fit into the larger structure helps in identifying potential improvements or troubleshooting any performance

Key Components in Toro Machines

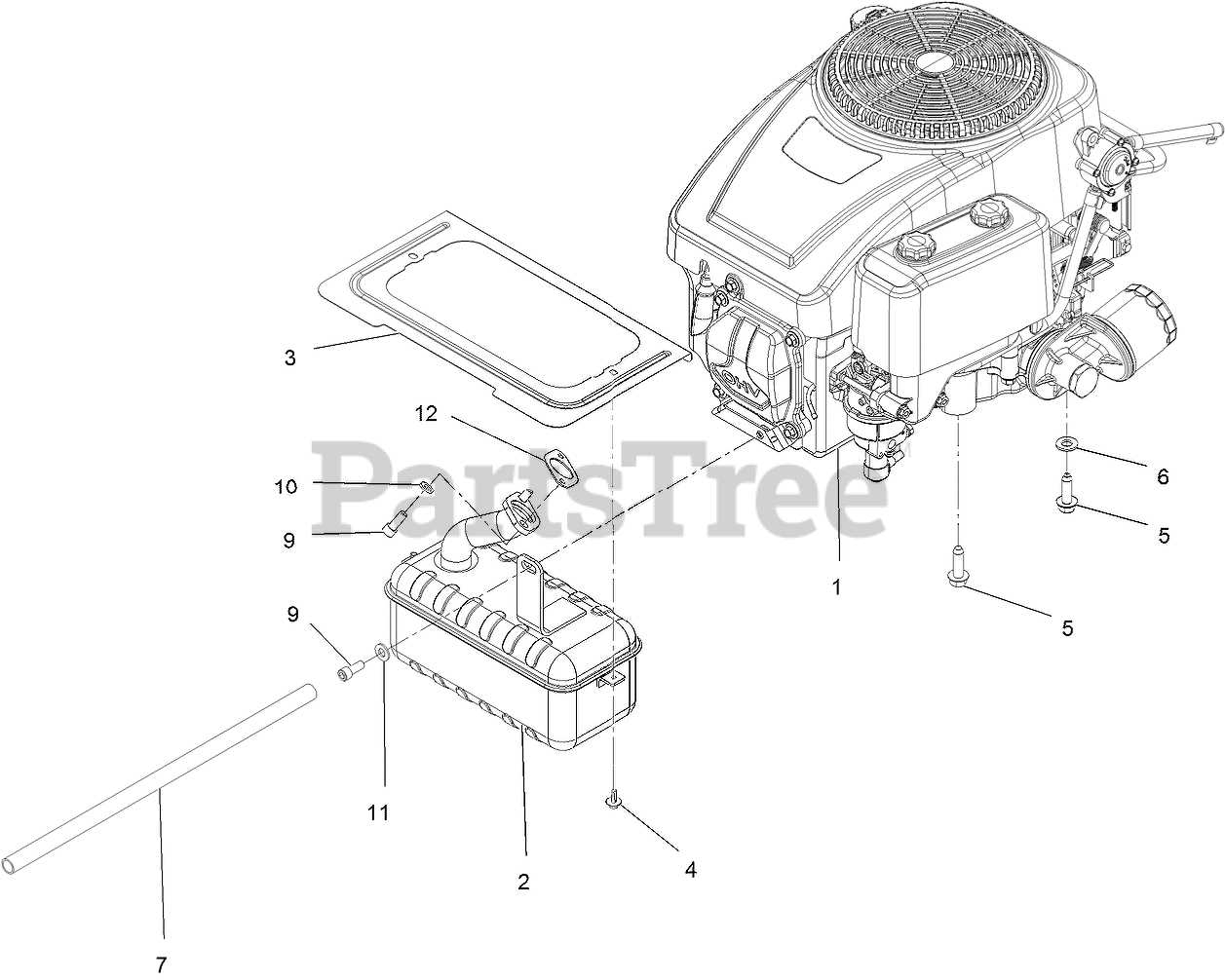

The functionality of equipment relies heavily on the seamless interaction of its essential elements. Understanding how these components work together is crucial for ensuring efficient operation and long-term durability. Each part plays a significant role in the overall performance and, when properly maintained, helps avoid unnecessary downtime and repairs.

Engine and Power System

The heart of any machine lies in its engine, which provides the necessary power to drive various functions. The engine must be robust, offering consistent energy to handle demanding tasks. Regular maintenance of the power system ensures reliable performance and extends the equipment’s lifespan.

Transmission and Drive Mechanism

The transmission system is responsible for transferring power from the engine to the wheels or tracks. It ensures smooth movement and optimal speed control. A well-functioning drive mechanism, paired with proper gear adjustments, allows the operator to navigate different terrains with ease

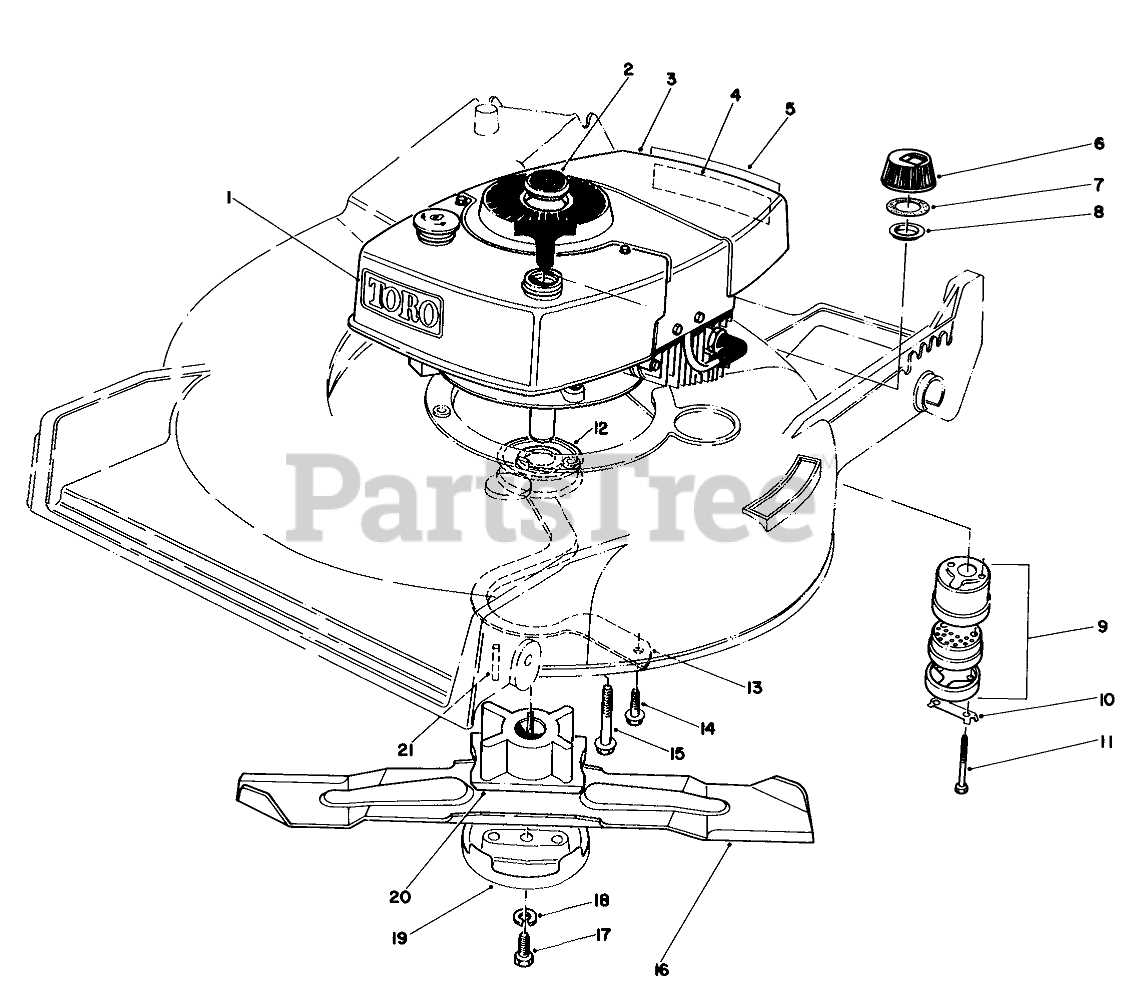

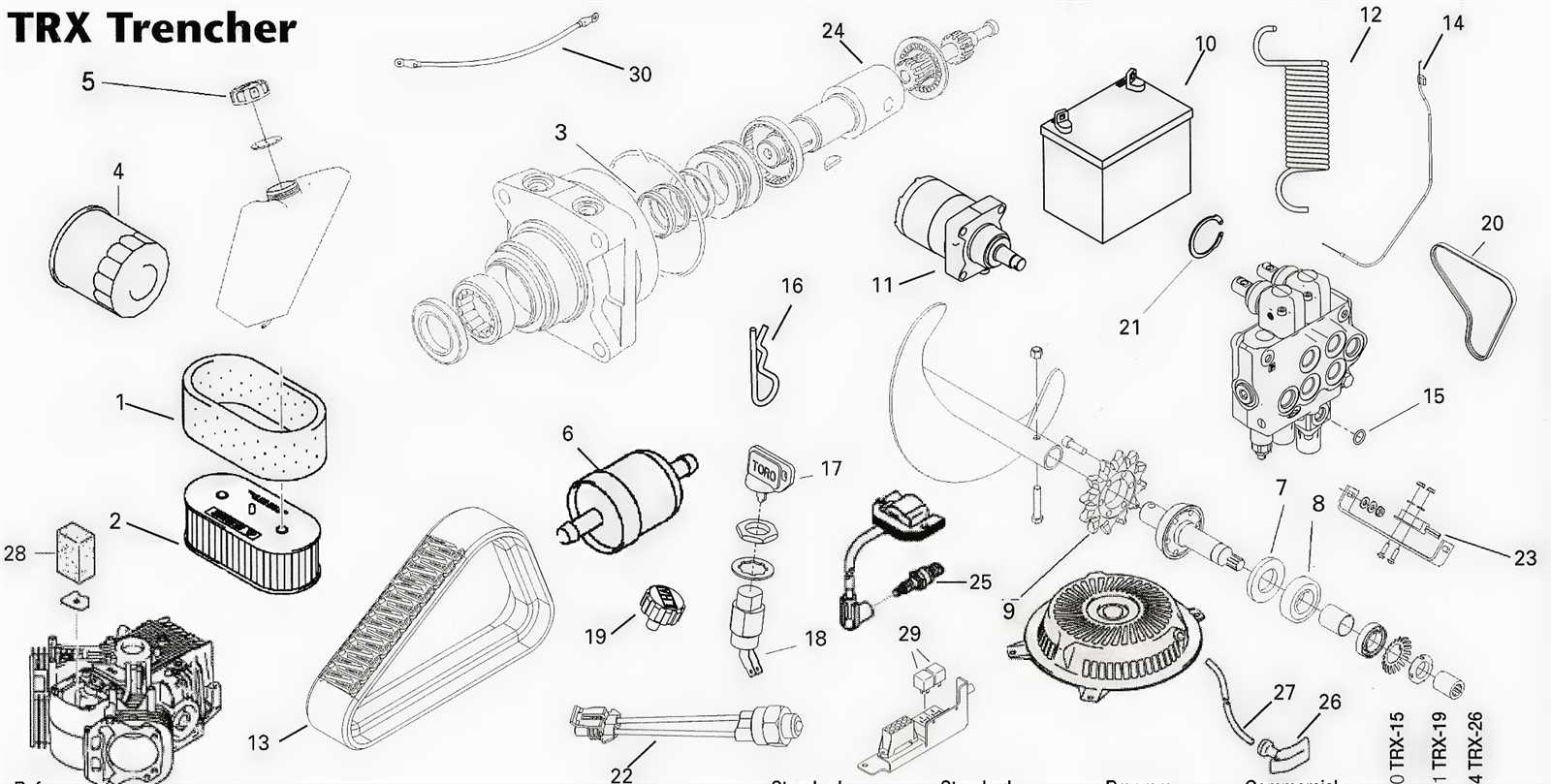

How to Interpret Toro Diagrams

Understanding equipment schematics is essential for effective maintenance and repair. These illustrations provide a visual guide to the assembly and components of complex machinery, helping users to identify each element and its function within the whole system.

Key symbols and their meanings can be crucial when examining such illustrations. Various lines, arrows, and labels are used to indicate connections, movements, and placements of parts. Familiarizing yourself with these symbols ensures accuracy when identifying or replacing specific elements.

Another important aspect is the layout and structure of the illustration. Components are typically displayed in a logical sequence, reflecting their real-world positioning or assembly process. This helps users easily follow each step in the installation or repair process.

Lastly, always pay attention to notations and reference numbers included in these diagrams. These indicators provide important details, often linking to further

Finding the Right Part Using Diagrams

Identifying the correct component for repair or replacement can be simplified by utilizing detailed visual guides. These resources break down complex machinery into individual elements, making it easier to pinpoint exactly what needs attention. By referencing such guides, users can avoid unnecessary guesswork and ensure they obtain the proper replacement for efficient repairs.

Understanding Visual Guides

Visual breakdowns of mechanical systems help users see how different components fit together. These guides provide a clear layout of each section, allowing for precise identification of individual pieces. Whether you’re maintaining equipment or replacing a specific element, these visuals are invaluable for ensuring accuracy.

Steps for Locating Components

To find the right part, start by consulting

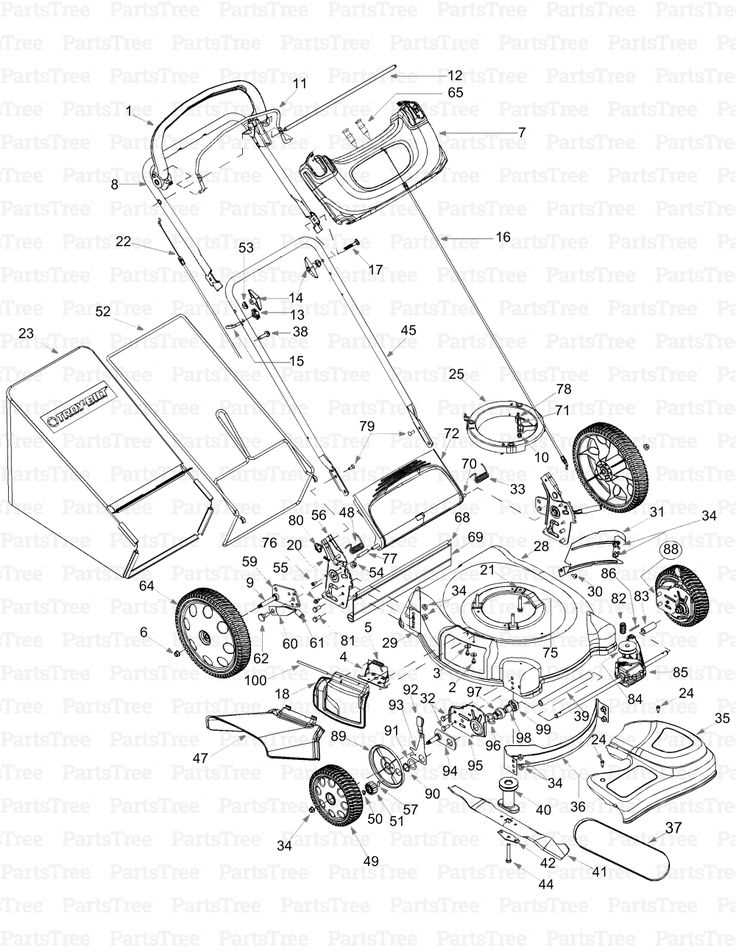

Visual Breakdown of Toro Lawn Mowers

This section provides a comprehensive overview of the various components that make up lawn mowing equipment. Understanding these elements is crucial for both effective operation and maintenance. By examining the structure and functionality of these machines, users can enhance their gardening experience and ensure optimal performance.

Key Components Overview

The following table highlights the essential parts commonly found in lawn mowing machines, detailing their functions and significance in the overall operation.

| Component | Function |

|---|---|

| Engine | Provides the necessary power to operate the mower and drive the cutting blades. |

| Blade Assembly | Responsible for cutting grass at varying lengths, ensuring a clean finish. |

| Deck | Encloses the cutting mechanism, providing stability and housing the blades. |

| Wheels | Facilitate movement across various terrains, allowing for maneuverability. |

| Handle | Provides control and guidance during operation, ensuring user comfort and safety. |

Understanding Functionality

Grasping how these components interact enhances the user’s ability to maintain the equipment effectively. Regular inspection and servicing of each part contribute to prolonged lifespan and performance efficiency.

Snow Blower Diagrams for Maintenance

Effective upkeep of snow-clearing machinery is essential for optimal performance and longevity. Visual references play a crucial role in understanding the assembly and operation of these machines, enabling users to identify components and their functions easily. Proper knowledge of the layout facilitates efficient troubleshooting and ensures that maintenance tasks are performed correctly.

Understanding the Layout

Visual schematics provide insight into the arrangement of various elements within the snow-removal equipment. Each segment serves a specific purpose, contributing to the overall functionality. Familiarizing oneself with these illustrations allows for a better grasp of how to care for and repair the machinery, leading to enhanced reliability during winter conditions.

Importance of Regular Inspection

Routine examinations based on the provided visual guides help in detecting wear and tear before they escalate into significant issues. Maintaining awareness of potential problem areas through these resources can prevent costly repairs and ensure the machine operates at its best. Keeping an eye on critical components, as indicated in the visuals, will contribute to a smoother and more effective snow removal experience.

Toro Sprinkler System Parts Explained

Understanding the components of an irrigation system is essential for efficient maintenance and operation. Each element plays a crucial role in ensuring optimal water distribution, which ultimately contributes to a healthy landscape. This section will provide insights into the various components of a sprinkler setup, helping users make informed decisions about their irrigation needs.

- Controllers: These devices manage the watering schedule and duration, allowing for customized irrigation based on environmental conditions.

- Valves: Essential for regulating water flow, these components open and close to direct water to specific areas of the landscape.

- Sprinklers: The main delivery units that disperse water onto the lawn and garden, available in various types such as fixed, oscillating, or rotating models.

- Hoses: Flexible tubes that transport water from the source to the distribution points, available in different diameters and lengths.

- Backflow Preventers: Safety devices that prevent contaminated water from flowing back into the main supply, ensuring the quality of the water system.

- Filters: Components designed to remove debris and contaminants from the water supply, protecting the system’s internal parts from damage.

- Emitters: Devices that provide localized irrigation, ideal for gardens and flower beds, delivering water directly to the root zone.

Each of these elements is vital for the effective functioning of an irrigation system, and understanding their roles can enhance both performance and longevity. Regular maintenance and timely replacements of any worn-out components will ensure that the system operates smoothly, delivering water efficiently and effectively.

Troubleshooting Equipment with Diagrams

Identifying and resolving issues in machinery can often be a complex task. Visual aids play a crucial role in simplifying the process, allowing users to pinpoint problems quickly and effectively. By leveraging detailed illustrations and schematics, operators can navigate through common malfunctions and enhance their understanding of the equipment’s functionality.

When approaching troubleshooting, consider the following steps:

- Examine the issue: Gather information about the symptoms, including any unusual sounds or performance issues.

- Refer to visual aids: Utilize schematics to identify relevant components and systems related to the problem.

- Conduct a systematic inspection: Follow a logical sequence to assess each part, looking for signs of wear, damage, or disconnection.

- Compare with standard procedures: Use illustrations to match your findings against manufacturer specifications or guidelines.

- Document findings: Keep a record of your observations and any corrective actions taken for future reference.

In addition, here are some common issues and their potential solutions:

- Engine won’t start:

- Check the fuel level and quality.

- Inspect the ignition system for faults.

- Ensure that all safety switches are engaged.

- Uneven cutting performance:

- Verify blade sharpness and alignment.

- Examine the height adjustment settings.

- Look for obstructions in the cutting path.

- Excessive vibration:

- Check for loose components and fasteners.

- Inspect for worn or damaged parts.

- Ensure proper assembly of all units.

Utilizing visual references not only streamlines the troubleshooting process but also empowers users to maintain their equipment effectively. By following a structured approach and leveraging illustrations, operators can enhance their diagnostic skills and ensure optimal performance of their machinery.

Benefits of Using Official Diagrams

Utilizing authorized visual representations for equipment components offers numerous advantages for users and technicians alike. These illustrations serve as reliable resources for understanding the layout and functionality of machinery, ensuring accurate repairs and maintenance. By adhering to official guidelines, individuals can enhance their efficiency and confidence when handling tasks related to their equipment.

Enhanced Understanding

Official visuals provide clear and detailed information about the construction and assembly of machinery. This clarity aids users in grasping complex systems, allowing for improved troubleshooting and problem resolution. The precise representation of components ensures that individuals can identify and address issues promptly, ultimately extending the lifespan of their equipment.

Time and Cost Efficiency

By relying on authorized illustrations, users can minimize the risk of errors during repairs. This accuracy not only saves time but also reduces costs associated with unnecessary parts replacement or incorrect assembly. When maintenance is conducted correctly the first time, users benefit from both financial savings and enhanced operational performance.

| Benefits | Description |

|---|---|

| Improved Clarity | Detailed visuals assist in understanding complex machinery layouts. |

| Reduced Errors | Accurate representations minimize mistakes during repairs. |

| Cost Savings | Efficient repairs lower the likelihood of unnecessary part replacements. |

Comparing Parts Across Toro Models

Understanding the variations in components among different models can significantly enhance maintenance and repair efficiency. By analyzing the similarities and differences in construction elements, users can make informed decisions about compatibility, upgrades, and replacements. This examination aids in optimizing performance and prolonging the lifespan of equipment.

Identifying Common Components

Many models share similar construction elements, which can simplify repairs. Recognizing these commonalities allows for easier sourcing of replacements and ensures that users can effectively troubleshoot issues. Additionally, understanding which features are consistent across various designs can help in making informed choices when purchasing new equipment.

Evaluating Unique Features

While many components are standardized, some designs incorporate unique features tailored to specific tasks. Evaluating these distinctive aspects can provide insights into the intended use of each model. This knowledge empowers users to select the right equipment for their particular needs, ensuring optimal functionality and efficiency in operation.

Online Resources for Toro Parts Diagrams

Accessing detailed visual references for equipment components can significantly enhance the repair and maintenance process. Numerous online platforms offer comprehensive resources that facilitate the identification and ordering of essential components. These platforms often feature interactive elements, making it easier for users to navigate through various sections and locate specific items.

Recommended Websites

Here are some reliable sources to find useful visual guides and related information:

| Website | Description |

|---|---|

| www.mowerparts.com | An extensive collection of schematics and images for various types of lawn care machinery. |

| www.equipmentparts.com | A user-friendly platform offering breakdowns and part lists for multiple models of gardening equipment. |

| www.partslookup.com | A comprehensive database with detailed schematics and ordering options for a wide range of outdoor tools. |

Benefits of Using Online Resources

Utilizing these online platforms not only saves time but also ensures accuracy in identifying the right components needed for repairs. The availability of high-resolution images allows for better visual confirmation, while interactive features enable users to zoom in and explore specific areas in detail. Additionally, these resources often include customer reviews and support options, further aiding in the decision-making process.