Toro Zero Turn Parts Diagram Explained

The intricacies of lawn maintenance machinery can often seem overwhelming. Familiarity with the various components that contribute to the efficient functioning of these machines is essential for both enthusiasts and professionals alike. By exploring the layout and relationships between different elements, one can gain a clearer understanding of how to optimize performance and maintain longevity.

Knowledge of these intricate systems not only enhances operational skills but also empowers users to tackle common issues effectively. A comprehensive exploration of the various parts involved provides insights into the machinery’s overall design and functionality. This familiarity can lead to improved handling and troubleshooting capabilities.

Moreover, recognizing the significance of each component allows for informed decisions regarding upgrades or replacements. Ultimately, mastering the relationships between these elements can significantly elevate one’s proficiency in lawn care and equipment management.

Toro Zero Turn Parts Overview

This section provides a comprehensive look at the various components essential for the effective operation and maintenance of high-performance mowing machines. Understanding each element’s role contributes to optimal performance and longevity, ensuring that the equipment remains reliable and efficient in its tasks.

| Component | Description | Function |

|---|---|---|

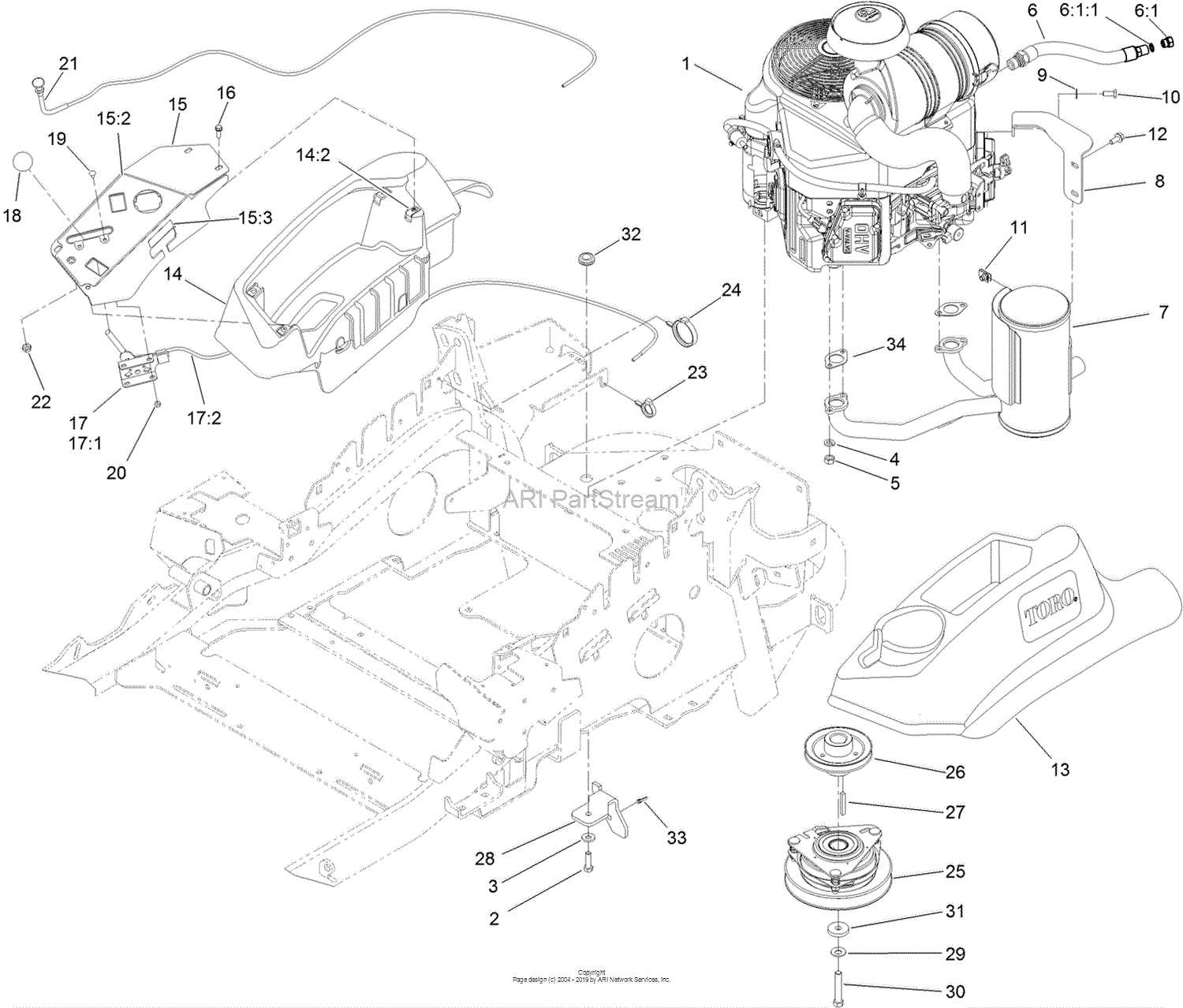

| Engine | The power source for the mower. | Drives the blades and provides mobility. |

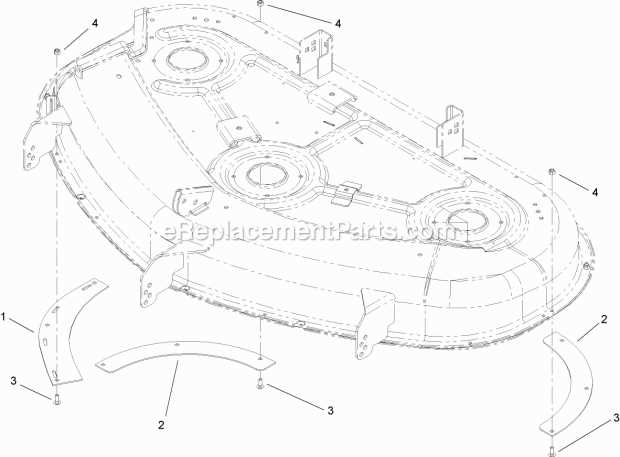

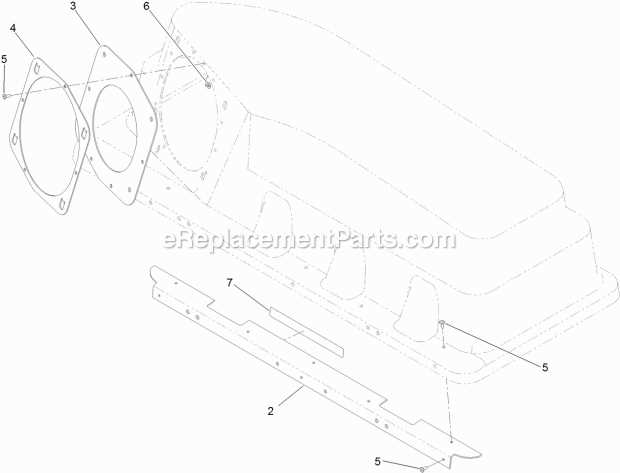

| Deck | The housing for the cutting blades. | Houses the blades for efficient grass cutting. |

| Blades | Sharp steel components that cut grass. | Perform the actual mowing of the lawn. |

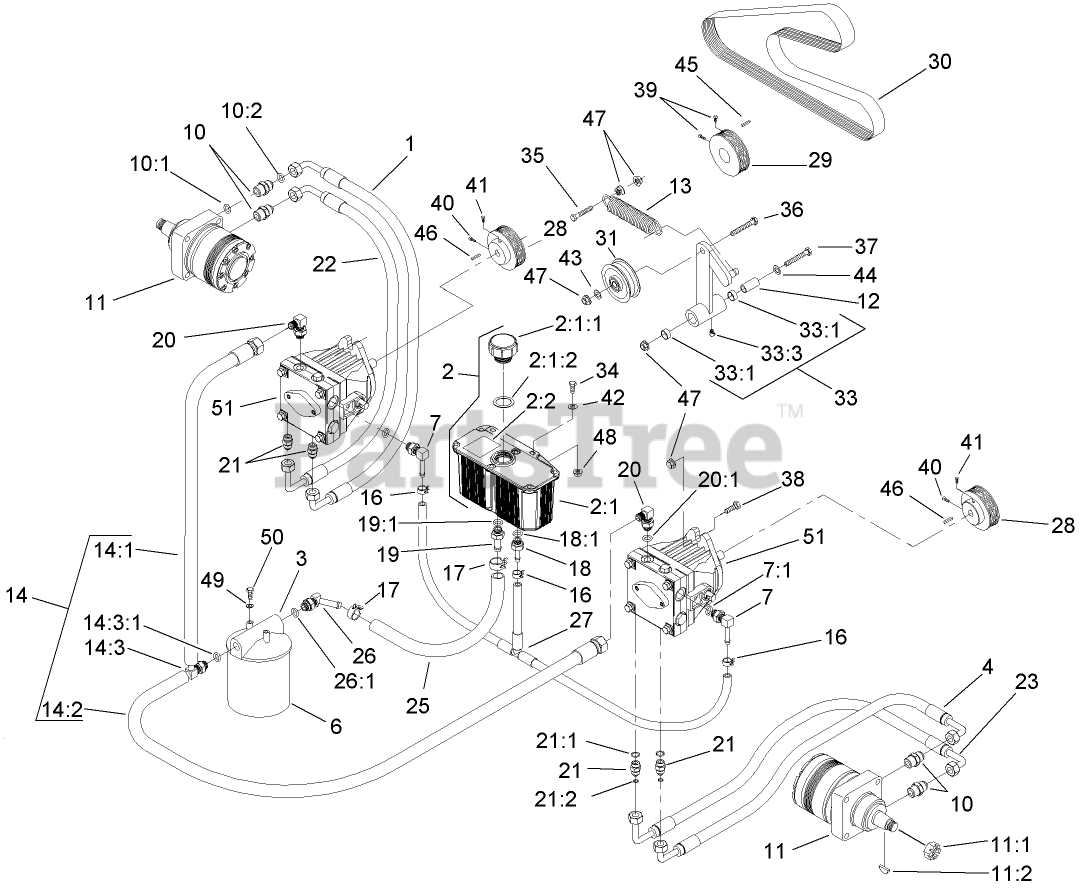

| Transmission | The system that transfers power to the wheels. | Enables smooth movement and steering. |

| Wheels | Circular components that provide mobility. | Allow movement across different terrains. |

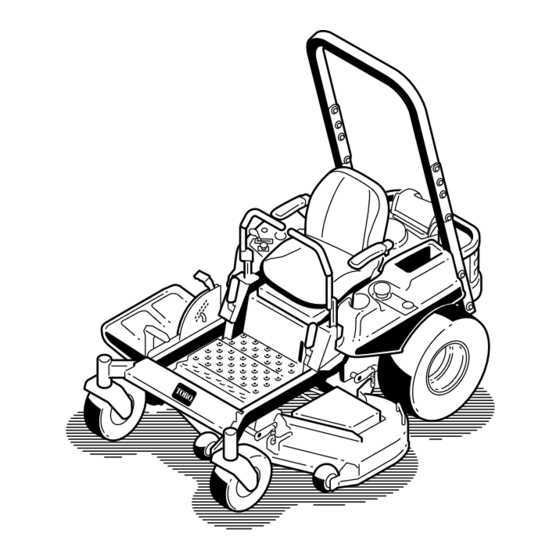

| Seat | The operator’s seating area. | Provides comfort and control during operation. |

| Fuel Tank | Container for storing fuel. | Supplies fuel to the engine for operation. |

Understanding Zero Turn Technology

This innovative mowing system transforms the way landscaping is approached, offering enhanced maneuverability and efficiency. By allowing operators to navigate obstacles with precision, it streamlines the process of lawn maintenance.

Key features of this technology include:

- Independent wheel control for agile movements.

- Compact design for easy navigation in tight spaces.

- Reduced mowing time due to improved operational speed.

Understanding the mechanics behind this system can elevate user experience and maximize results. Here are some important components:

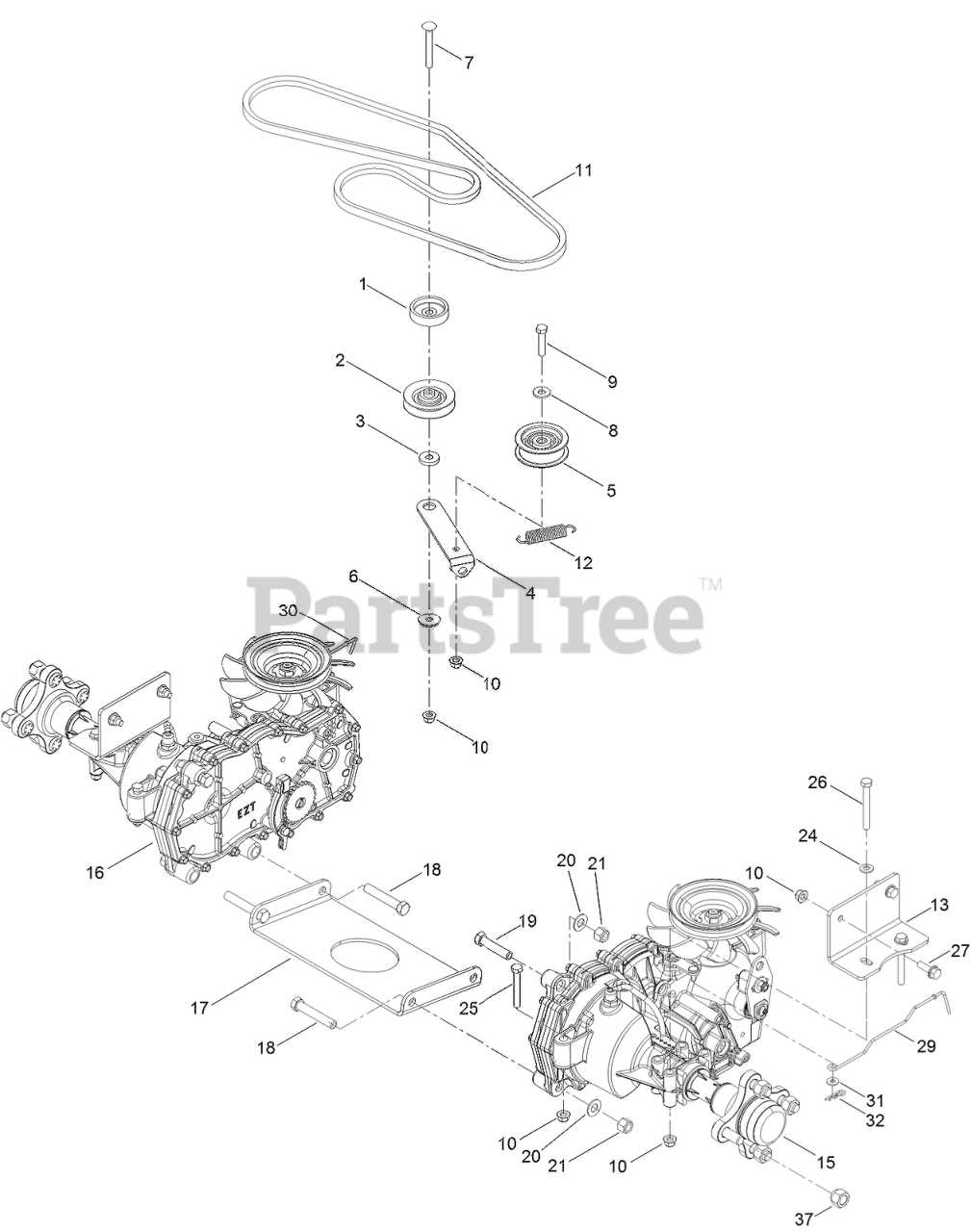

- Transmission system for power distribution.

- Steering mechanisms for directional control.

- Cutting decks designed for versatility and performance.

Ultimately, mastering this technology can lead to superior lawn care and maintenance outcomes.

Key Components of Toro Mowers

Understanding the essential elements of lawn care machines enhances their efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance and longevity.

- Engine: Powers the machine, providing necessary torque and speed.

- Deck: Houses the cutting blades and determines the mowing width.

- Transmission: Facilitates movement and speed control across different terrains.

- Wheels: Support mobility and stability while maneuvering.

- Blades: Cut grass efficiently, contributing to a neat finish.

Familiarity with these fundamental components allows users to delve into troubleshooting and enhancing their mowing experience.

Common Parts for Toro Models

Understanding the essential components of various lawn care machines can enhance maintenance and repair efficiency. This section outlines frequently encountered elements that are critical for the performance of these outdoor power tools. Familiarity with these components aids in troubleshooting and ensures optimal operation.

Key Components

- Blades: Vital for achieving a clean cut, these are designed for different grass types and conditions.

- Belts: Used to transfer power from the engine to the cutting mechanism, ensuring smooth operation.

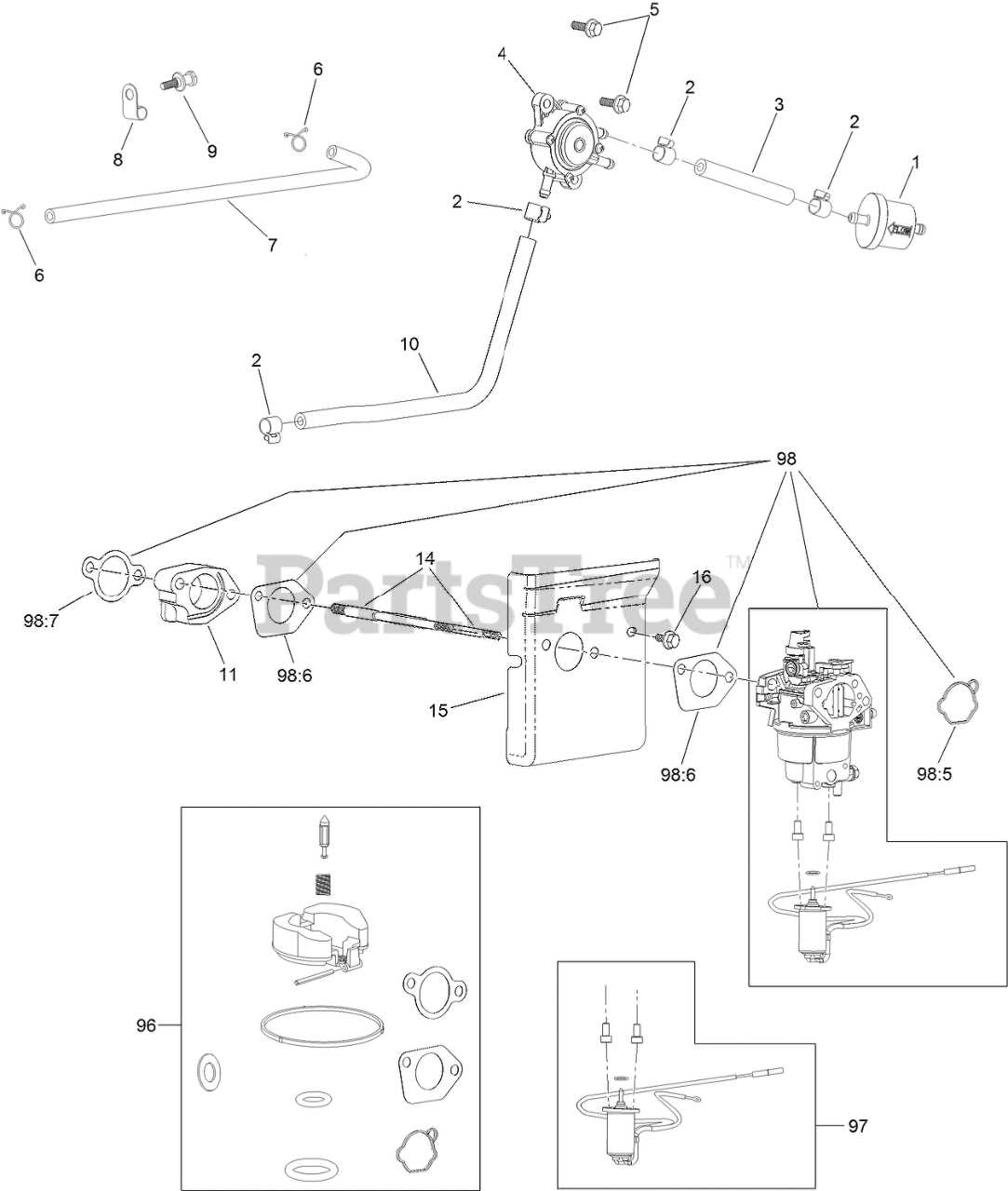

- Filters: Air and fuel filters maintain engine efficiency by keeping contaminants out.

- Wheels: Provide mobility, with various sizes and tread patterns suited for different terrains.

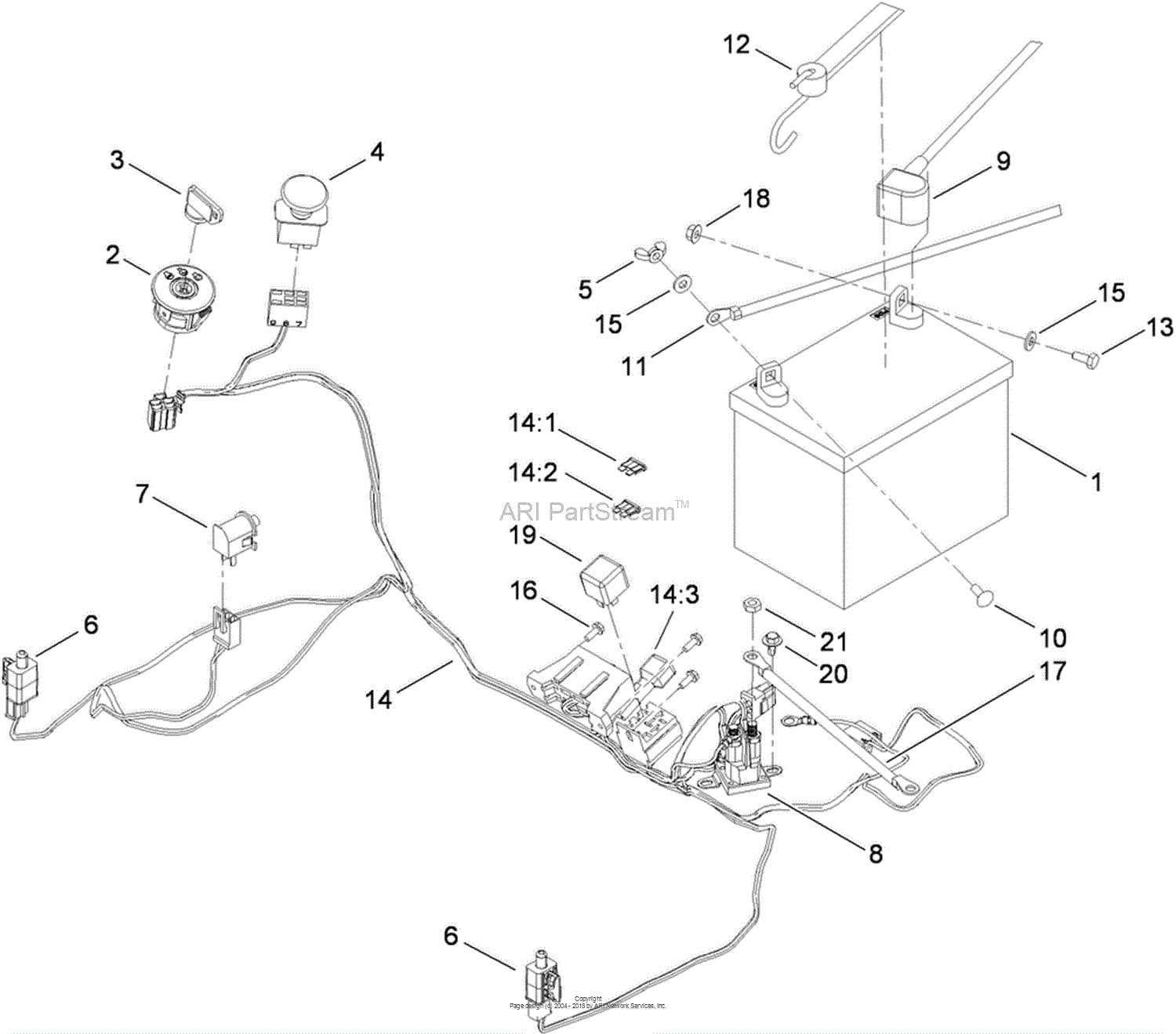

- Battery: Powers electric starters and other electrical components essential for functionality.

Maintenance Essentials

- Regularly check and replace blades for optimal cutting performance.

- Inspect belts for wear and tension to prevent slippage.

- Clean or change filters to maintain airflow and fuel efficiency.

- Examine wheels for damage and ensure proper inflation.

- Monitor batteries for charge levels and replace as necessary.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visuals provide a clear representation of various components, helping users identify and locate each piece. Familiarity with these schematics enables efficient troubleshooting and facilitates the ordering of the correct items when replacements are needed.

Key Components of Illustrations

Each technical illustration typically includes a variety of symbols and numbers that correspond to specific elements. Recognizing these features is crucial for proper interpretation. Below are some common aspects found in these representations:

| Element | Description |

|---|---|

| Numbers | Often indicate the part’s reference number for ordering. |

| Lines | Show connections between different components, illustrating how they interact. |

| Labels | Provide names or descriptions of parts for easy identification. |

Interpreting Symbols and Codes

Most technical illustrations also employ symbols that represent specific functions or features. Being aware of common symbols helps in understanding the design and assembly process. Always refer to the accompanying legend or key that explains these symbols for clarity.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of your outdoor machinery. By following a consistent maintenance routine, you can ensure optimal performance and reduce the likelihood of costly repairs. Here are key practices to keep your equipment running smoothly.

Regular Inspections

Conduct routine checks on various components, including belts, blades, and fluids. Early detection of wear and tear can prevent more significant issues later. Replace any worn parts promptly to maintain efficiency.

Cleaning and Storage

After each use, clean the machine to remove debris and dirt that can cause damage over time. Store your equipment in a sheltered location to protect it from harsh weather conditions, which can accelerate deterioration.

Identifying Worn Parts Easily

Recognizing components that have seen better days is crucial for maintaining optimal performance in any machinery. Timely identification of wear can prevent further damage and costly repairs. By being vigilant and informed, operators can ensure their equipment remains in top condition.

One effective method is to regularly inspect key elements for signs of wear such as fraying, cracking, or discoloration. Establishing a routine check schedule allows for the early detection of issues before they escalate. Pay close attention to areas that experience high stress or frequent movement, as these are more prone to deterioration.

Utilizing a visual guide can also aid in understanding what to look for. Diagrams and illustrations highlighting common signs of wear help to simplify the inspection process. Additionally, maintaining a record of previous findings can assist in tracking the lifespan of various components, making it easier to identify when replacements are necessary.

Engaging with fellow users or consulting with experts can provide valuable insights into common failure points and maintenance tips. Sharing experiences can lead to improved techniques for spotting worn elements and enhancing overall machinery longevity.

Where to Buy Toro Parts

Finding the right components for your outdoor equipment is essential for maintaining its performance and longevity. Whether you’re a professional landscaper or a weekend gardener, knowing where to source quality elements can make all the difference in ensuring your machinery runs smoothly.

Online Retailers

One of the most convenient ways to acquire necessary items is through online retailers. Numerous websites specialize in garden machinery, offering a vast selection of items. You can often find competitive prices and detailed specifications, making it easier to identify what you need.

Local Dealers and Service Centers

Another option is to visit local dealers and authorized service centers. These establishments typically stock genuine components and can provide expert advice. In addition, purchasing from them may come with the benefit of professional installation services, ensuring that your equipment remains in peak condition.

In summary, whether you choose to shop online or visit local providers, the key is to ensure you’re sourcing reliable components to keep your outdoor machinery functioning optimally. Don’t hesitate to compare prices and ask for recommendations to find the best solutions for your needs.

Installation Guide for Toro Components

This section provides a comprehensive approach to assembling various components for lawn maintenance equipment. Proper installation is essential for optimal performance and longevity, ensuring that each part functions harmoniously within the whole system.

Step 1: Preparation

Before beginning, gather all necessary tools and components. Ensure your workspace is clean and organized to facilitate a smooth assembly process.

Step 2: Referencing the Manual

Consult the specific manual for your equipment model. It contains crucial information about the correct placement and orientation of each element, which is vital for successful integration.

Step 3: Assembly Process

Start with the base components and gradually work your way up. Pay attention to any alignment markers and secure each piece using the appropriate fasteners. Double-check connections to avoid future issues.

Step 4: Final Inspection

Once assembled, conduct a thorough inspection. Ensure all components are firmly attached and free from any obstructions. This step is crucial for safety and efficiency during operation.

Step 5: Testing

Finally, perform a test run of the equipment to confirm everything operates as intended. Monitor for unusual sounds or vibrations, which may indicate improper installation.

Troubleshooting Common Issues

Addressing frequent complications with lawn care equipment can enhance performance and extend lifespan. Understanding the root causes of these problems is essential for efficient resolution.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine won’t start | Faulty spark plug, empty fuel tank, or clogged air filter | Check spark plug condition, refill fuel, clean or replace air filter |

| Ineffective cutting | Dull blades, uneven deck height, or debris buildup | Sharpen or replace blades, adjust deck height, clean undercarriage |

| Excessive vibration | Worn bearings, unbalanced blades, or loose components | Inspect and replace bearings, balance blades, tighten all fasteners |

Safety Precautions When Repairing

When undertaking maintenance on machinery, adhering to safety guidelines is crucial to prevent accidents and ensure a successful repair. Awareness and preparation can make a significant difference in the repair process.

- Always wear appropriate personal protective equipment, including gloves and safety goggles.

- Disconnect power sources before starting any maintenance tasks.

- Ensure the working area is clean and free of obstructions.

- Use the correct tools for the job to avoid injuries.

- Read the manufacturer’s manual for specific safety instructions related to the equipment.

By following these precautions, you can create a safer environment for yourself and others while working on mechanical systems.

Upgrading Your Toro Equipment

Enhancing your gardening machinery can significantly boost its performance and lifespan. By selecting the right components and accessories, you can transform your equipment into a more efficient and reliable tool for your landscaping tasks.

Benefits of Upgrading

- Improved Efficiency: Enhanced parts lead to better fuel consumption and operational speed.

- Increased Durability: New components can extend the lifespan of your machinery.

- Enhanced Comfort: Upgraded features can improve user experience during operation.

Key Areas to Focus On

- Engine: Consider a performance upgrade for more power and efficiency.

- Blades: Sharper or specialized blades can enhance cutting performance.

- Transmission: Upgrading the transmission system can improve maneuverability.

- Accessories: Adding attachments can expand the functionality of your machine.