Comprehensive Guide to Deutz Tractor Parts Diagram

The intricate world of heavy machinery is a fascinating realm where engineering excellence meets practical application. Each unit operates through a complex interplay of various elements, designed to ensure efficiency and reliability in demanding environments. This exploration delves into the essential components that make up these powerful machines, highlighting their roles and interconnections.

Recognizing the specific roles of each element is crucial for maintenance and troubleshooting. A detailed examination of these components provides insights into their functions, aiding users in optimizing performance and extending the lifespan of the equipment. Comprehensive knowledge empowers operators to make informed decisions regarding repairs and upgrades.

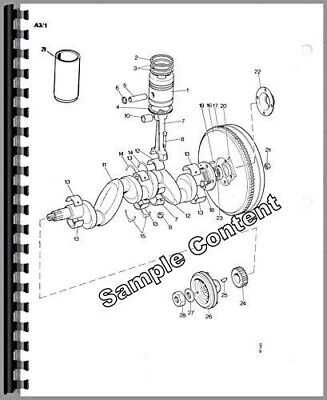

Additionally, visual representations can significantly enhance understanding, illustrating how different components fit together and interact. Such visual aids serve as valuable resources, simplifying complex information and enabling easier identification of parts during inspections. This systematic approach not only supports effective maintenance practices but also fosters a deeper appreciation for the engineering behind these robust machines.

Understanding Deutz Tractors

The world of agricultural machinery is vast, encompassing a range of vehicles designed to enhance productivity and efficiency in farming. Among these machines, a renowned manufacturer has built a reputation for quality and durability, ensuring that users have reliable equipment to support their operations. This section delves into the characteristics that define these robust machines, emphasizing their engineering excellence and versatility in various tasks.

Engine Performance is a crucial aspect of these machines, with powerful motors that offer both reliability and efficiency. These engines are designed to handle demanding workloads while minimizing fuel consumption, a key factor for any agricultural operation. The advanced technology integrated into these machines ensures optimal performance across different terrains and conditions.

Durability is another hallmark of this equipment, built to withstand the rigors of daily use in challenging environments. Manufacturers utilize high-quality materials and innovative designs to create machinery that can endure heavy loads and adverse weather, providing peace of mind to operators who rely on their equipment for success.

Furthermore, the ease of maintenance plays a significant role in the overall experience of using these machines. With thoughtfully designed components, users can access critical areas for servicing without extensive downtime. This focus on user-friendly maintenance helps ensure that equipment remains operational and efficient over the long term.

In summary, the legacy of these agricultural machines lies in their powerful performance, robust construction, and ease of upkeep, making them indispensable tools in modern farming practices. Understanding these elements allows operators to maximize their investment and ensure optimal productivity in their endeavors.

Importance of Tractor Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for users, providing clarity on how different elements interact within a system. They facilitate a better grasp of assembly, disassembly, and troubleshooting processes, ensuring that operators can work more efficiently and safely.

Enhanced Maintenance Efficiency

When individuals can easily identify specific components, they can perform routine checks and repairs with greater confidence. Visual aids streamline the process of locating parts, which minimizes downtime and maximizes productivity. This not only saves time but also reduces the likelihood of errors during maintenance tasks.

Facilitation of Learning and Training

For newcomers in the field, visual representations are invaluable educational tools. They help trainees understand complex machinery by breaking down intricate systems into comprehensible segments. As a result, individuals can acquire the knowledge needed to operate and maintain equipment effectively, fostering a culture of safety and competence.

Key Components of Deutz Tractors

Understanding the essential elements that comprise agricultural machinery is vital for efficient operation and maintenance. These crucial segments work together to ensure optimal performance in various farming tasks. Below are the primary components that play a significant role in the functionality of these robust machines.

- Engine: The powerhouse responsible for generating the necessary energy for operation.

- Transmission: This system transfers power from the engine to the wheels, enabling movement and speed regulation.

- Hydraulic System: A crucial element that facilitates lifting and lowering implements, providing necessary force for various tasks.

- Chassis: The framework that supports the entire structure and ensures stability during operation.

- Electrical System: Essential for powering lights, ignition, and other electronic components, ensuring efficient functionality.

Each of these segments is designed with precision and efficiency in mind, contributing to the overall productivity and reliability of the machinery in agricultural settings.

- Fuel System: Supplies the engine with the necessary fuel to maintain performance.

- Cooling System: Regulates engine temperature to prevent overheating and maintain efficiency.

- Suspension: Enhances ride comfort and stability, ensuring smoother operation over rough terrain.

- Cabin: Provides comfort and protection for the operator, often equipped with controls for easy management.

By recognizing the importance of each component, operators can make informed decisions regarding maintenance and upgrades, ultimately enhancing the longevity and effectiveness of their machinery.

How to Read a Parts Diagram

Understanding the layout of mechanical illustrations is essential for effective maintenance and repair. These visual guides provide a wealth of information, allowing users to identify components and their interrelationships. By familiarizing yourself with the symbols and notations used, you can navigate these resources with confidence.

Familiarize Yourself with Symbols

Most illustrations use standardized icons to represent various elements. Studying these symbols can significantly enhance your comprehension. Pay attention to color coding, which often indicates functionality or priority, and note any accompanying labels that provide context.

Identify Key Components

Once you understand the symbols, focus on the primary elements depicted in the illustration. Take your time to trace connections between parts and observe how they interact. This will not only help you locate specific items but also give insight into the overall structure and operation of the system.

Common Issues with Tractor Parts

In the world of agricultural machinery, several challenges can arise with various components, impacting overall functionality and performance. Understanding these issues is essential for maintenance and efficient operation, ensuring longevity and reliability of the equipment.

Wear and Tear

Over time, continuous use can lead to degradation of crucial components. Factors such as exposure to harsh conditions, heavy loads, and inadequate lubrication can accelerate this process. Regular inspection and timely replacement of worn-out elements can prevent more severe malfunctions.

Compatibility Problems

Another common challenge is the incompatibility of certain components. When replacing or upgrading parts, it’s vital to ensure they are suitable for the specific model. Mismatched elements can lead to inefficiency and may even cause damage, highlighting the importance of referencing accurate specifications.

Finding Replacement Parts for Deutz

Locating suitable components for your machinery can be a daunting task, but it is essential for maintaining optimal performance. Understanding where to source these items is crucial for ensuring that your equipment runs smoothly and efficiently. This section provides guidance on how to effectively find the necessary replacements, ensuring longevity and reliability.

Utilizing Online Resources

The internet is a valuable tool for discovering appropriate replacements. Numerous websites offer catalogs and listings tailored to specific machinery. Online marketplaces often provide user reviews, which can help in assessing the quality and compatibility of various components. Additionally, manufacturer websites frequently feature sections dedicated to replacement items, complete with specifications and installation guides.

Local Dealers and Distributors

Another excellent option is to visit local dealers or distributors who specialize in machinery supplies. They usually possess extensive knowledge about the equipment and can recommend suitable replacements. Building a relationship with these suppliers can also lead to better support and potential discounts. It’s advisable to inquire about warranties and return policies to ensure peace of mind with your purchase.

Maintenance Tips for Deutz Equipment

Proper upkeep of agricultural machinery is essential for ensuring longevity and optimal performance. Regular maintenance not only prevents costly repairs but also enhances efficiency during operation. Here are some practical guidelines to keep your machinery in top condition.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Check Fluid Levels | Weekly | Inspect oil, coolant, and fuel levels regularly. Top off as needed. |

| Inspect Belts and Hoses | Monthly | Look for signs of wear or cracks. Replace any damaged components immediately. |

| Clean Air Filters | Every 100 hours | Replace or clean filters to ensure proper airflow and engine performance. |

| Grease Moving Parts | Every 50 hours | Apply lubricant to joints and pivot points to reduce friction and wear. |

| Inspect Tires | Monthly | Check for proper inflation and tread wear. Adjust pressure as necessary. |

| Conduct Safety Checks | Before each use | Ensure all safety features are functional and that emergency equipment is available. |

Following these maintenance tips will help ensure your machinery operates smoothly and efficiently, minimizing downtime and enhancing productivity.

Comparing Models: What to Know

When evaluating various agricultural machinery, it’s essential to understand the key differences and features that can influence performance and suitability for specific tasks. This comparison not only aids in making informed decisions but also ensures that you select the most appropriate model for your needs.

Here are some critical factors to consider when comparing different machines:

- Engine Power: Assess the horsepower and torque, which determine the capacity for heavy-duty tasks.

- Weight and Stability: Heavier models often provide better stability, particularly in uneven terrain.

- Transmission Types: Look into manual vs. automatic transmissions, as they affect ease of use and control.

- Fuel Efficiency: Evaluate how much fuel each model consumes under various working conditions.

- Maintenance Requirements: Consider the ease of servicing and availability of components for upkeep.

- Technology and Features: Investigate advanced technologies like GPS, telematics, and user-friendly interfaces.

By systematically examining these aspects, you can better determine which machine aligns with your operational needs and budgetary constraints. Additionally, understanding the long-term value and resale potential of each option can guide your investment decision.

Supplier Options for Parts Acquisition

When it comes to sourcing components for machinery, understanding the various avenues available for procurement is essential. Choosing the right supplier can significantly impact both the quality of the items and the efficiency of your operations. There are several options to consider, each with its own advantages and potential drawbacks.

Types of Suppliers

- OEM Suppliers: These manufacturers provide original equipment, ensuring compatibility and reliability. Often more expensive, they offer the benefit of superior quality and warranty support.

- Aftermarket Suppliers: Offering a range of alternatives, these vendors can provide cost-effective solutions. However, quality may vary, so thorough research is necessary.

- Local Distributors: Proximity can reduce shipping costs and delivery times. These suppliers often have a solid understanding of regional needs and preferences.

- Online Retailers: E-commerce platforms offer convenience and competitive pricing. It’s important to read reviews and check ratings to ensure credibility.

Considerations for Selection

- Quality Assurance: Evaluate the supplier’s reputation and product quality through reviews and recommendations.

- Cost: Compare prices across different suppliers to find a balance between cost and quality.

- Availability: Ensure the supplier can meet your demand in a timely manner to avoid delays.

- Customer Support: Reliable customer service is crucial for resolving issues and getting assistance when needed.

Benefits of Using Original Parts

Opting for authentic components in machinery maintenance ensures optimal performance and longevity. These specially designed elements are crafted to meet exact specifications, providing a perfect fit and reliable functionality. Choosing original options not only enhances efficiency but also protects your investment over time.

Quality Assurance

Genuine components undergo rigorous testing and quality control, ensuring that they meet the highest standards. This commitment to excellence minimizes the risk of malfunction, leading to fewer repairs and downtime. When you invest in authentic solutions, you can trust that your equipment will operate smoothly and effectively.

Long-Term Cost Savings

While the initial expense of authentic components may be higher, the long-term benefits often outweigh the costs. Using high-quality materials reduces the likelihood of premature wear and failure, resulting in significant savings on repairs and replacements. By prioritizing original solutions, you are ultimately making a wise financial decision for the future of your machinery.

DIY Repairs: A Practical Guide

Embarking on do-it-yourself repairs can be both empowering and cost-effective. Whether it’s maintaining machinery or addressing common malfunctions, understanding the essential components and their functions is crucial for successful interventions. This guide aims to provide you with the foundational knowledge to tackle repairs confidently.

Assessing the Issue

Before diving into any repair project, it’s vital to accurately identify the problem. Conduct a thorough inspection, looking for signs of wear, leaks, or unusual noises. Taking notes on your observations can help you track what needs attention and facilitate the repair process.

Gathering the Right Tools

Having the appropriate tools at your disposal is essential for any DIY endeavor. Equip yourself with basic hand tools such as wrenches, screwdrivers, and pliers. Additionally, consider investing in specialized tools that may be necessary for specific tasks, ensuring that you’re prepared for any challenges that arise.

Understanding Components

Familiarize yourself with the various elements involved in your machinery. Knowledge of how each part functions and interacts with others can significantly streamline your repair efforts. Use manuals and online resources to gain insight into the assembly and disassembly processes.

Executing Repairs

Once you’ve diagnosed the problem and gathered your tools, it’s time to proceed with the repairs. Follow a systematic approach: disassemble components carefully, replace any damaged items, and reassemble everything in the correct order. Always prioritize safety by wearing appropriate gear and following recommended practices.

Testing and Final Checks

After completing the repairs, conduct thorough tests to ensure everything operates as expected. Check for leaks, listen for any abnormal sounds, and observe performance under normal operating conditions. This final step is crucial for verifying the success of your DIY project.

By equipping yourself with knowledge and skills, you can take control of your repairs, save money, and prolong the lifespan of your equipment.

When to Consult a Professional

Understanding the intricacies of machinery maintenance can sometimes be challenging. While many tasks can be tackled independently, there are instances when enlisting the help of an expert is essential to ensure safety and optimal performance. Recognizing these situations can save time, prevent further complications, and enhance the longevity of your equipment.

Signs You Need Expert Assistance

There are several indicators that suggest it’s time to seek professional guidance. These signs may include persistent issues that do not resolve despite your efforts, unfamiliar sounds or behaviors from the machinery, or the need for specialized tools and knowledge to address specific problems.

| Signs | Description |

|---|---|

| Persistent Problems | Issues that reoccur or worsen despite attempted fixes. |

| Unusual Noises | Sounds that are not typical during normal operation. |

| Lack of Knowledge | Unfamiliarity with the components or repair procedures required. |

Benefits of Professional Help

Engaging a professional not only brings expertise but also access to the right tools and resources. Professionals are equipped to diagnose problems accurately and provide solutions that you may not have considered. This approach can ultimately lead to more efficient repairs and maintenance practices.

Online Resources for Tractor Owners

In today’s digital age, enthusiasts and operators of agricultural machinery have access to a wealth of information online. Various platforms provide valuable resources that can enhance knowledge, support maintenance, and facilitate the acquisition of necessary equipment.

Key Types of Resources

- Forums and Community Groups: Online forums offer a space for owners to share experiences, troubleshoot issues, and exchange advice.

- Tutorials and How-To Guides: Many websites host step-by-step guides covering everything from routine maintenance to complex repairs.

- Manufacturer Websites: These often include official documentation, specifications, and contact information for customer support.

- Video Platforms: Visual learners can benefit from numerous channels dedicated to machinery operation and upkeep demonstrations.

- Marketplaces: Online marketplaces can connect users with suppliers of essential tools and accessories, making it easier to find specific items.

Finding Reliable Information

When seeking information, it’s crucial to evaluate the reliability of sources. Look for platforms with positive user reviews, expert contributions, and a strong community presence. Engaging with reputable sites not only ensures accurate information but also helps build connections with fellow enthusiasts.