Comprehensive Guide to Ford 3910 Tractor Parts Diagram

In the realm of agricultural equipment, comprehending the intricate elements that make up machinery is essential for optimal performance and maintenance. The effectiveness of these powerful machines largely depends on the precise functioning of their various components.

When exploring the construction of these machines, one can delve into detailed representations that illustrate each segment’s role and interconnections. Such insights not only enhance repair processes but also contribute to the ultimate longevity of the equipment.

For enthusiasts and operators alike, having access to visual guides becomes a valuable resource. These illustrations serve as a reference point, facilitating better understanding and fostering a deeper appreciation for the engineering behind these workhorses.

Understanding the Ford 3910 Tractor

This section delves into the characteristics and functionalities of a particular agricultural machine known for its reliability and efficiency. By exploring its design and engineering, we can appreciate the features that make it a valuable asset for various farming tasks.

Key Features

The machine is equipped with a robust engine that ensures consistent performance across diverse agricultural applications. Its intuitive controls and user-friendly interface make it accessible for both novice and experienced operators. Additionally, the model’s versatile attachments enhance its utility, enabling users to tackle a wide range of tasks with ease.

Maintenance and Care

Key Features of Ford 3910

This robust agricultural machine is designed to enhance productivity and efficiency on the field. Its innovative design combines power and versatility, making it an essential tool for various farming tasks. Below are some of the standout characteristics that contribute to its popularity among users.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a powerful engine that delivers exceptional torque and performance, suitable for demanding tasks. |

| Transmission | Features a user-friendly transmission system, allowing for smooth gear shifting and enhanced control. |

| Hydraulic System | Includes a reliable hydraulic system that supports various implements, increasing operational flexibility. |

| Durability | Constructed with high-quality materials, ensuring longevity and resistance to wear and tear in challenging conditions. |

| Compact Design | The compact size facilitates maneuverability in tight spaces, making it ideal for small to medium-sized farms. |

| Operator Comfort | Designed with ergonomics in mind, providing a comfortable seating arrangement and intuitive controls for ease of operation. |

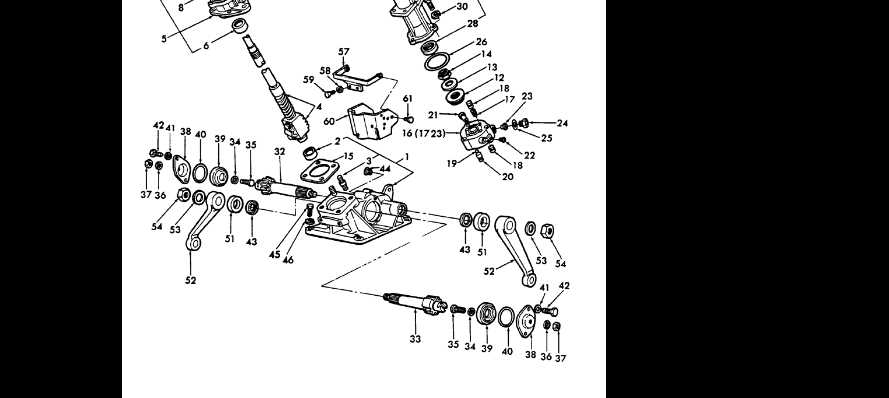

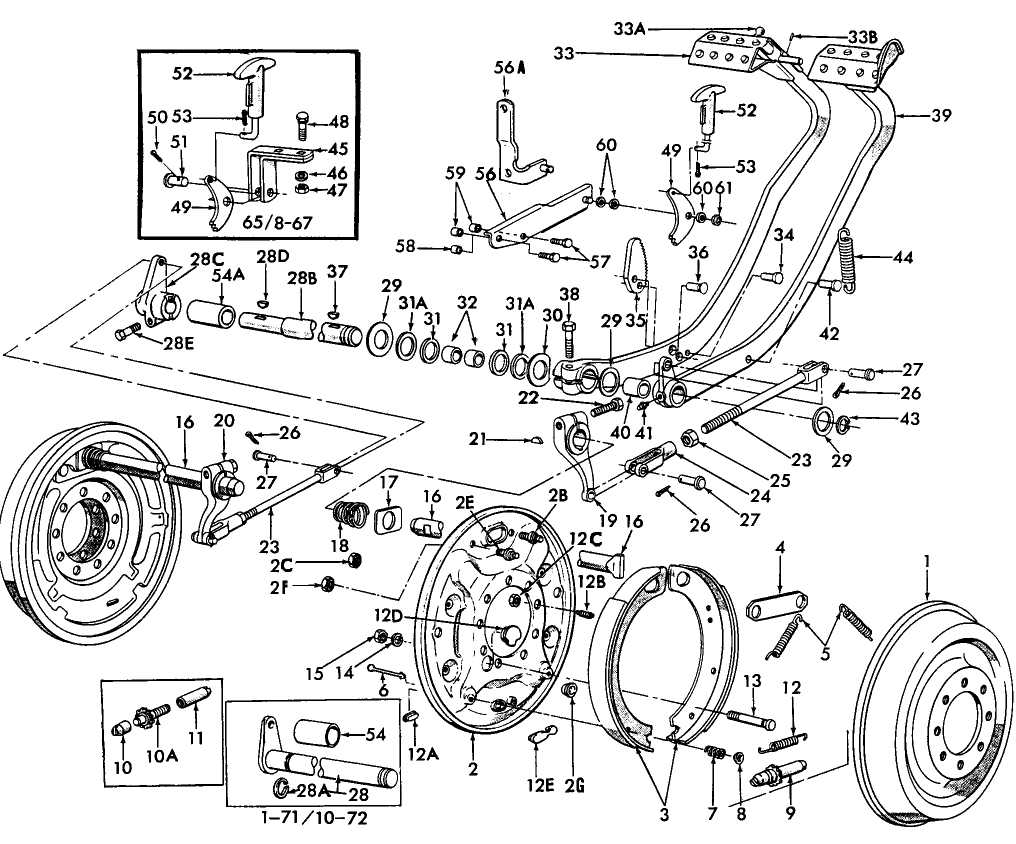

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining machinery. They serve as essential tools that enable users to identify various elements and comprehend their relationships within complex systems. These illustrations simplify troubleshooting, repairs, and replacements, making the maintenance process more efficient.

Enhancing Clarity

Detailed visual aids enhance clarity, allowing operators and technicians to quickly locate specific elements. This clarity reduces the likelihood of errors during repairs and ensures that every component is accounted for, ultimately improving the functionality of the equipment.

Streamlining Maintenance

Utilizing these visual tools streamlines the maintenance process. By providing an organized view of each element, they help in planning and executing tasks systematically. This organized approach not only saves time but also contributes to a longer lifespan for the machinery involved.

Common Issues with Ford 3910

Owners of this particular agricultural machine often encounter several recurring challenges that can impact performance and reliability. Understanding these common problems can help in timely maintenance and prevent more serious issues down the line.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Starting Problems | Difficulty in starting the engine can arise due to fuel system issues or electrical faults. | Check fuel lines and filters; inspect the battery and starter connections. |

| Hydraulic Leaks | Leaks in hydraulic systems can lead to decreased lifting capabilities and operational inefficiencies. | Inspect hoses and seals; replace any damaged components. |

| Overheating | Engines may overheat due to coolant system failures or debris buildup. | Ensure proper coolant levels; clean radiators and replace faulty thermostats. |

| Transmission Issues | Shifting problems can occur, affecting the ability to change gears smoothly. | Check fluid levels and quality; inspect for worn gears or linkage problems. |

| Electrical Failures | Malfunctions in the electrical system can disrupt starting and other functions. | Examine wiring and connections; replace faulty fuses and relays. |

Identifying Essential Components

Understanding the fundamental elements of any agricultural machine is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring smooth operation, and recognizing these parts can aid in troubleshooting and repairs. A thorough grasp of the structure enhances the efficiency of farming tasks and extends the lifespan of the equipment.

Key Functional Elements

Among the primary components, the engine stands out as the powerhouse, providing the necessary energy for operation. Additionally, the transmission system facilitates movement, allowing for seamless navigation across various terrains. The hydraulic system, another vital element, enables lifting and controlling attachments, enhancing versatility in tasks.

Maintenance Considerations

Regular inspection of these critical components is essential for preventing breakdowns. Keeping an eye on fluid levels, belts, and filters can significantly impact overall functionality. Awareness of these essential parts not only aids in identifying issues early but also ensures that the machine remains a reliable partner in agricultural endeavors.

Where to Find Parts Diagrams

Locating visual references for machinery components is essential for effective maintenance and repair. These illustrations not only simplify the identification of individual elements but also facilitate the understanding of assembly and disassembly processes. Whether you are a seasoned technician or a DIY enthusiast, knowing where to find these resources can enhance your repair experience.

Online Resources

The internet offers a plethora of platforms dedicated to machinery and equipment. Websites specializing in agricultural machinery often host a wide array of visual guides. Manufacturer websites may also provide downloadable resources that include detailed views and descriptions. Additionally, forums and community groups can be invaluable for obtaining shared insights and links to useful visuals.

Local Dealers and Repair Shops

Your local dealers and repair facilities can serve as excellent sources of information. Many have access to proprietary resources and can provide printed materials or direct you to online tools. Engaging with experienced technicians can also yield tips on the best places to find comprehensive illustrations for your specific model.

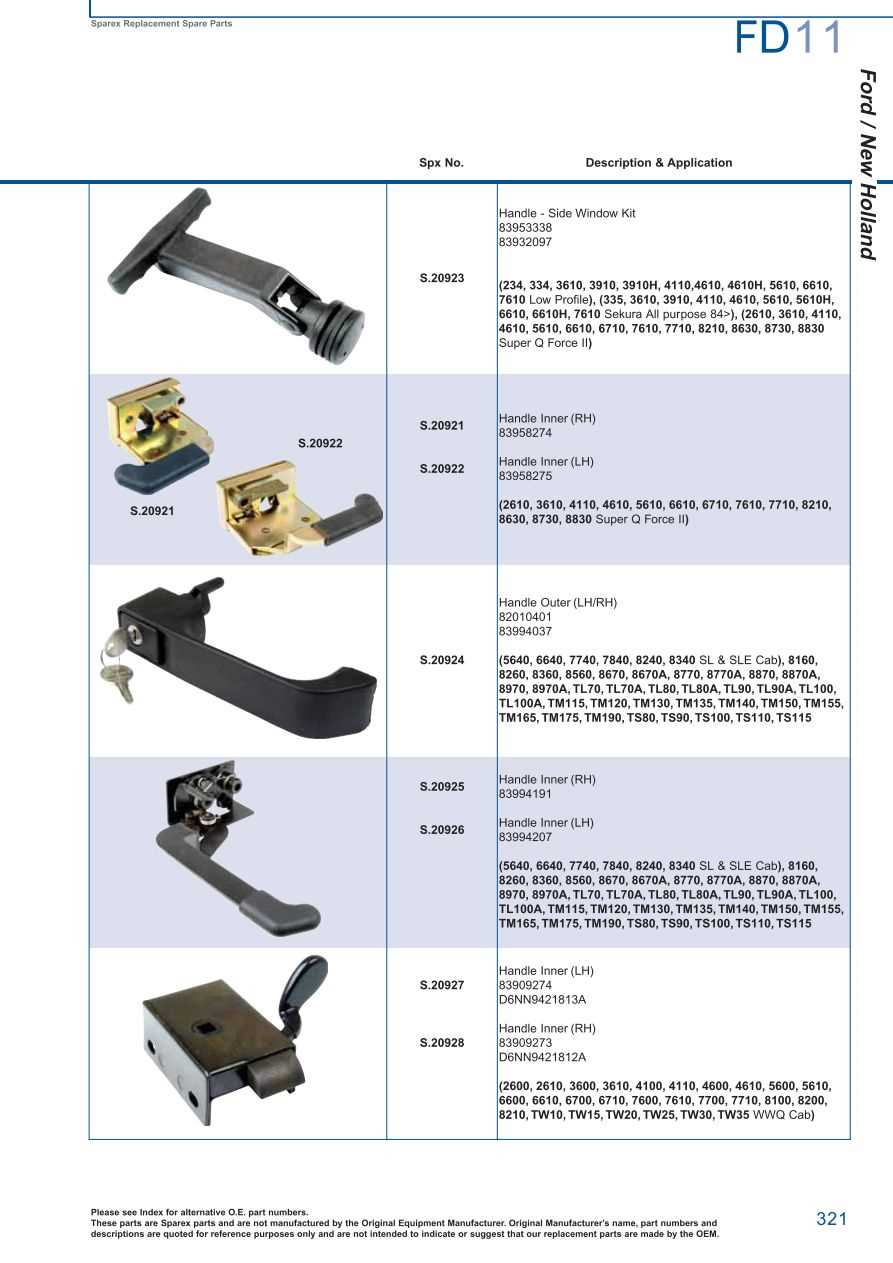

Buying Genuine vs. Aftermarket Parts

When it comes to maintaining machinery, the choice between authentic components and alternatives can significantly impact performance and longevity. Understanding the differences in quality, cost, and availability is essential for making informed decisions that will benefit both your equipment and your budget.

Quality and Reliability

Genuine components are designed and manufactured to meet specific standards set by the original maker, ensuring optimal performance and compatibility. In contrast, aftermarket options may vary in quality, with some brands offering excellent alternatives while others may fall short. Choosing reliable suppliers and researching reviews can help mitigate risks associated with non-original items.

Cost Considerations

Price is often a deciding factor in the purchase process. Authentic components typically come with a higher price tag due to their guaranteed quality and warranty protections. However, aftermarket options can provide cost savings, but it’s crucial to weigh these savings against potential risks such as reduced lifespan or increased maintenance needs.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended life of your machinery. By following a consistent maintenance routine, you can enhance performance and reduce the risk of unexpected breakdowns.

Check Fluid Levels: Regularly monitor and refill oil, coolant, and hydraulic fluids to keep components functioning smoothly.

Inspect Belts and Hoses: Frequent examination of belts and hoses for wear and tear can prevent serious failures and costly repairs.

Clean Air Filters: Keeping air filters clean ensures optimal engine performance and efficiency, reducing fuel consumption.

Grease Moving Parts: Lubricating moving components reduces friction and wear, prolonging the lifespan of the machine.

Follow the Manufacturer’s Guidelines: Adhering to recommended maintenance schedules and practices is crucial for longevity and reliability.

Step-by-Step Repair Guide

This section provides a comprehensive approach to conducting repairs effectively and efficiently. Following a structured method will ensure that every aspect of the maintenance process is addressed.

-

Preparation:

- Gather necessary tools and equipment.

- Review the service manual for specifications.

-

Assessment:

- Inspect the machine for visible damage.

- Identify any malfunctioning components.

-

Dismantling:

- Carefully remove any parts that need repair.

- Organize components to avoid misplacement.

-

Repair:

- Fix or replace damaged parts as needed.

- Ensure all replacements meet quality standards.

-

Reassembly:

- Put all components back in their original positions.

- Double-check connections for security.

-

Testing:

- Run the equipment to ensure proper functionality.

- Monitor for any unusual sounds or performance issues.

Following these steps will facilitate a successful repair, maximizing the longevity and efficiency of the machinery.

Upgrading Your Ford 3910

Enhancing the performance and efficiency of your machine can significantly improve productivity and longevity. This section explores various modifications and enhancements that can elevate your equipment’s capabilities, making it more adaptable to a variety of tasks.

Performance Enhancements

Investing in upgrades such as a more efficient engine, improved transmission, and enhanced hydraulic systems can lead to better overall performance. These enhancements can provide increased power and responsiveness, making your work easier and faster.

Comfort and Usability Improvements

Upgrading the operator’s environment can also yield great benefits. Consider investing in ergonomic seating, improved controls, and better visibility. These modifications not only enhance comfort but also contribute to greater operational efficiency.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Engine Upgrade | More powerful engine for improved performance | Increased efficiency and speed |

| Hydraulic System | Enhanced hydraulic capabilities | Better lifting and maneuvering |

| Seating | Ergonomic seat design | Increased comfort during long hours |

Safety Precautions During Repairs

Ensuring a secure environment during maintenance activities is crucial for preventing accidents and injuries. Awareness of potential hazards and adherence to safety protocols can significantly enhance protection for individuals involved in mechanical tasks.

Essential Safety Gear

- Wear protective goggles to shield your eyes from debris.

- Use gloves to prevent cuts and abrasions.

- Ensure steel-toed boots are worn to protect feet from heavy objects.

Work Area Considerations

- Keep the workspace clean and organized to avoid tripping hazards.

- Ensure proper lighting to enhance visibility of all tasks.

- Have a first aid kit accessible for emergencies.

Popular Modifications and Enhancements

Upgrading agricultural machinery can significantly enhance performance, efficiency, and overall usability. Enthusiasts often seek to improve various aspects, from power output to comfort, ensuring their equipment meets specific operational demands. Here, we explore some common enhancements that users frequently consider.

| Modification | Description |

|---|---|

| Engine Tuning | Adjusting fuel and air mixtures to boost horsepower and torque. |

| Suspension Upgrades | Installing advanced shock absorbers for improved stability and ride quality. |

| Cab Enhancements | Adding ergonomic seating and climate control for greater comfort during operation. |

| Lighting Systems | Upgrading to LED lights for better visibility and lower energy consumption. |

| Implement Attachments | Incorporating specialized tools to expand functionality and versatility. |

Resources for Ford 3910 Owners

For individuals managing their agricultural machinery, accessing reliable information and components is essential for effective maintenance and operation. A variety of resources are available to ensure owners can keep their equipment running smoothly and efficiently.

Online forums and communities provide valuable insights and advice from fellow enthusiasts and experts. Websites dedicated to machinery offer detailed guides, troubleshooting tips, and user experiences that can help address common issues. Additionally, local dealerships and specialty shops often stock essential components, ensuring quick replacements when needed.

Numerous manuals and handbooks are available for download, covering everything from basic operation to advanced repairs. These resources empower owners with the knowledge necessary to perform routine maintenance and understand their machinery better.

Finally, consider subscribing to agricultural magazines or newsletters that feature articles, product reviews, and innovations in the field, keeping you informed about the latest trends and solutions for your machinery needs.