Comprehensive Guide to Ford 8N Tractor Parts Diagram

The essence of traditional farming implements lies in their intricate design and robust functionality. To maximize their performance, it’s crucial to have a clear understanding of the various elements that make up these machines. Each component plays a pivotal role in ensuring efficiency and reliability in agricultural tasks.

Familiarity with the structure and arrangement of these essential features can significantly enhance maintenance practices. By exploring the connections and interactions between the various units, operators can ensure longevity and optimal operation. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions regarding repairs and upgrades.

In this guide, we delve into the specifics of a classic model that has left a lasting mark on farming communities. A visual representation will aid in grasping the layout of the critical sections, ultimately facilitating a deeper appreciation for the craftsmanship and engineering that contribute to its enduring legacy.

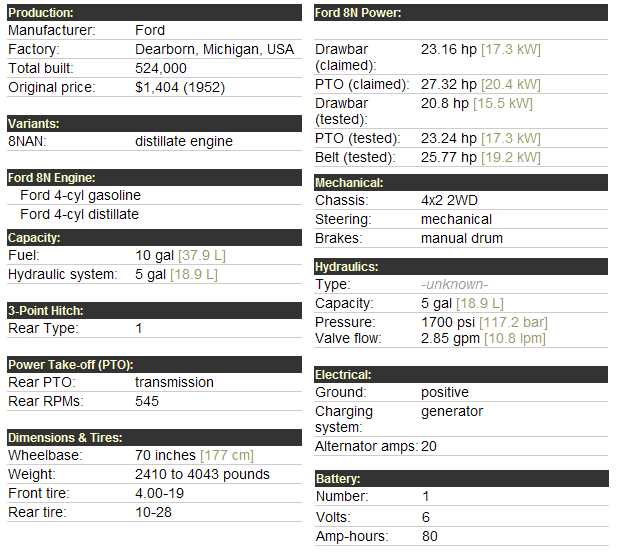

Understanding Ford 8N Tractor Basics

This section explores essential concepts related to a renowned agricultural machine, focusing on its functionality and historical significance. By examining key components and their roles, users can gain a better grasp of how this equipment operates and the importance of each element in its overall performance.

Key Features and Functions

The notable characteristics of this machine contribute to its efficiency in various farming tasks. It boasts a robust engine, a reliable transmission system, and various attachments that enhance its versatility. Understanding these features is crucial for anyone looking to maximize their experience with this agricultural tool.

Maintenance and Care

Proper upkeep is vital for sustaining performance over time. Regular inspections and timely replacements of critical components can prevent breakdowns and prolong the machine’s lifespan. Familiarizing oneself with maintenance practices ensures optimal operation and reliability.

History of the Ford 8N Tractor

The 8N model emerged during a transformative period in agricultural machinery, symbolizing innovation and efficiency. Its development marked a significant milestone in the evolution of farming equipment, showcasing advancements that catered to the needs of farmers in a rapidly changing agricultural landscape.

Introduction to the Model

Launched in the early 1950s, this vehicle was designed to enhance productivity and ease of use. It quickly gained popularity for its robust features and user-friendly design. Key aspects that contributed to its success include:

- Improved hydraulic systems

- Enhanced power capabilities

- Increased fuel efficiency

- Adaptability to various attachments

Impact on Agriculture

The introduction of this vehicle revolutionized farming practices, allowing for more efficient land management and crop production. Farmers embraced its versatility, leading to significant changes in agricultural techniques. Notable impacts include:

- Reduction in labor costs

- Increased crop yields

- Wider adoption of mechanized farming

- Greater accessibility for small-scale farmers

As a result, this machine not only transformed individual farms but also contributed to the overall modernization of the agricultural sector. Its legacy continues to influence contemporary machinery design and usage.

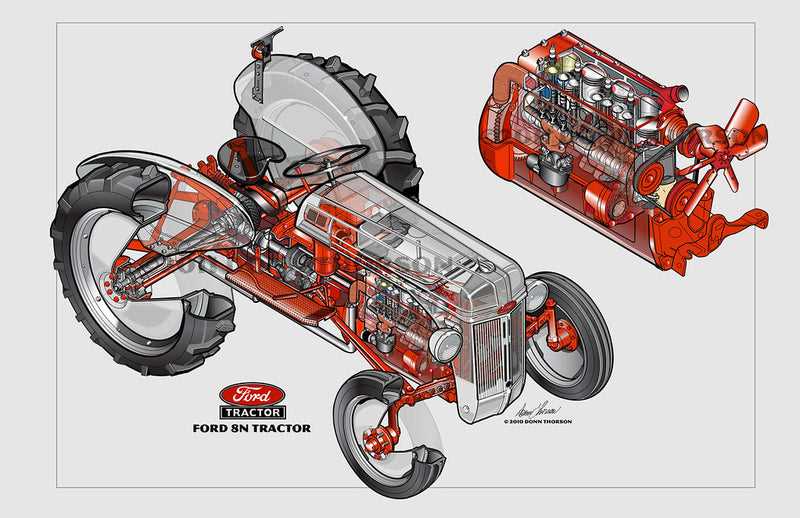

Key Components of the 8N Model

The 8N model showcases a variety of essential elements that contribute to its functionality and efficiency. Understanding these core components is vital for anyone looking to optimize their experience with this machinery. Each part plays a significant role in ensuring smooth operation and reliability.

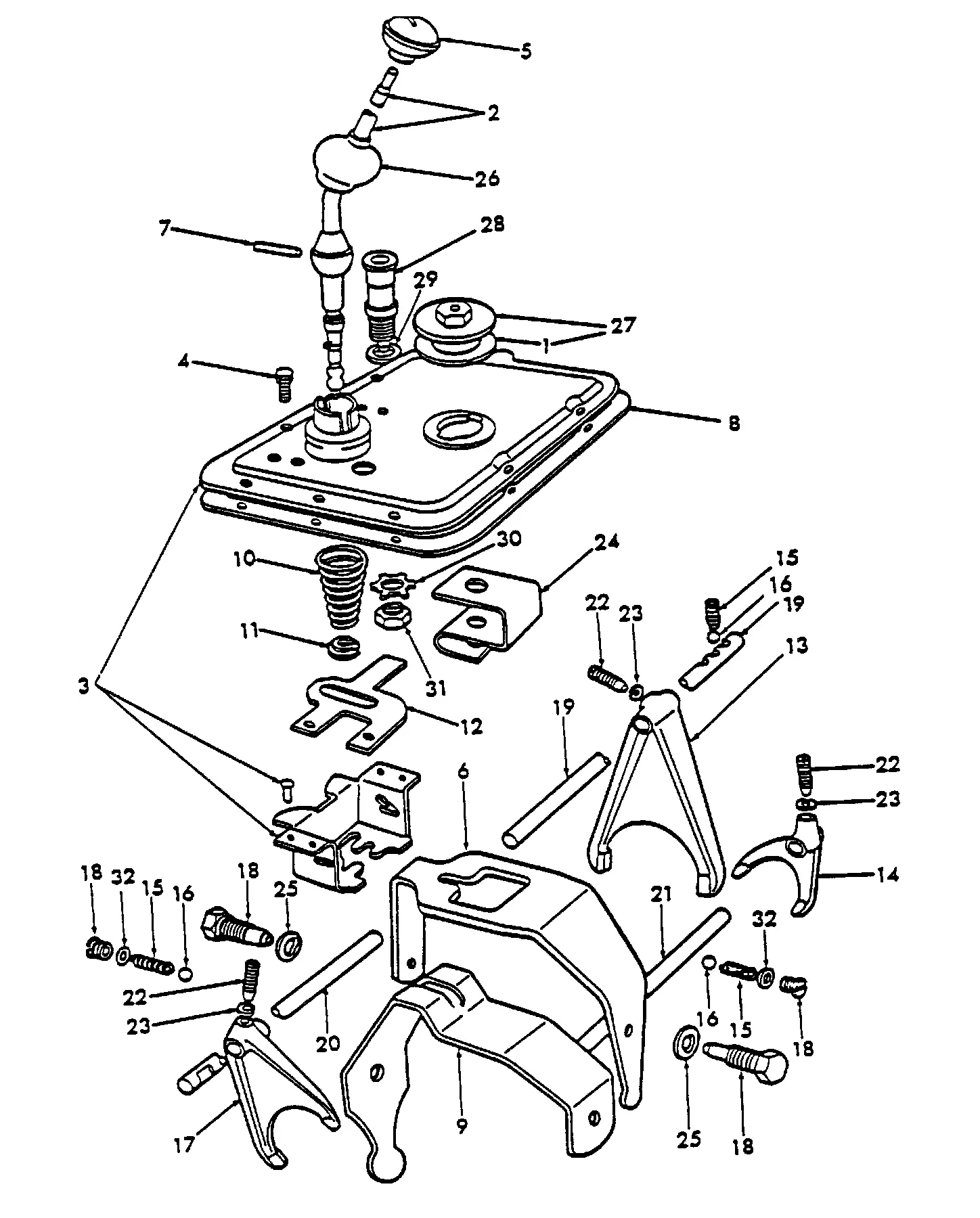

Engine and Transmission

The engine serves as the powerhouse, providing the necessary torque and horsepower for various tasks. Coupled with a robust transmission, it allows for seamless gear shifts and adaptability to different conditions, enhancing overall performance.

Hydraulic System

One of the most impressive features is the hydraulic system, which facilitates lifting and moving heavy loads. This system is designed for efficiency, allowing for precise control and smooth operation, making it indispensable for various agricultural tasks.

Common Issues with 8N Parts

Maintenance of classic machinery often reveals a variety of challenges that enthusiasts and operators must address. Understanding these common concerns can help in effectively managing and restoring functionality.

- Wear and Tear: Over time, components can become worn due to frequent use. This may lead to inefficiencies or complete failure.

- Corrosion: Exposure to moisture and elements can cause rust, particularly in metal parts, which compromises integrity.

- Fluid Leaks: Gaskets and seals may degrade, resulting in leaks that can affect performance and cause further damage.

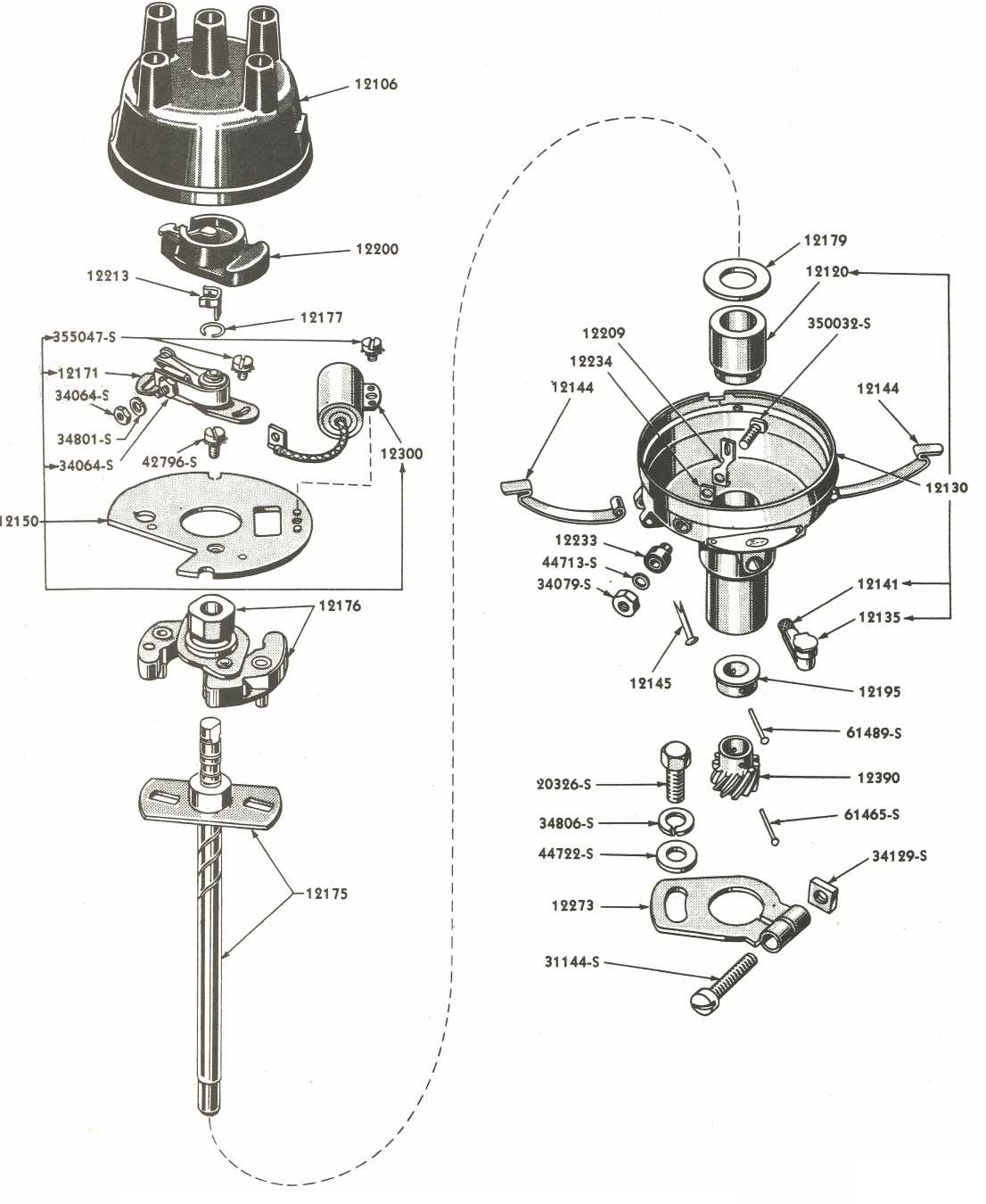

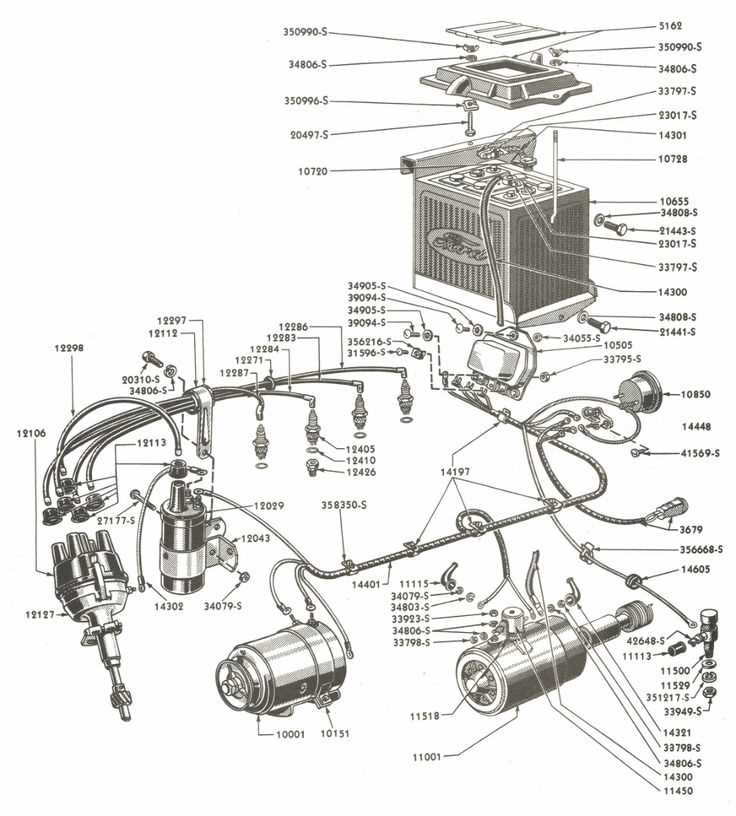

- Electrical Failures: Wiring and connections can deteriorate, leading to issues with starting or operational inconsistencies.

- Alignment Problems: Components may become misaligned, affecting performance and increasing the risk of damage to surrounding systems.

Regular inspection and proactive maintenance are essential to mitigate these issues and ensure the longevity of the equipment.

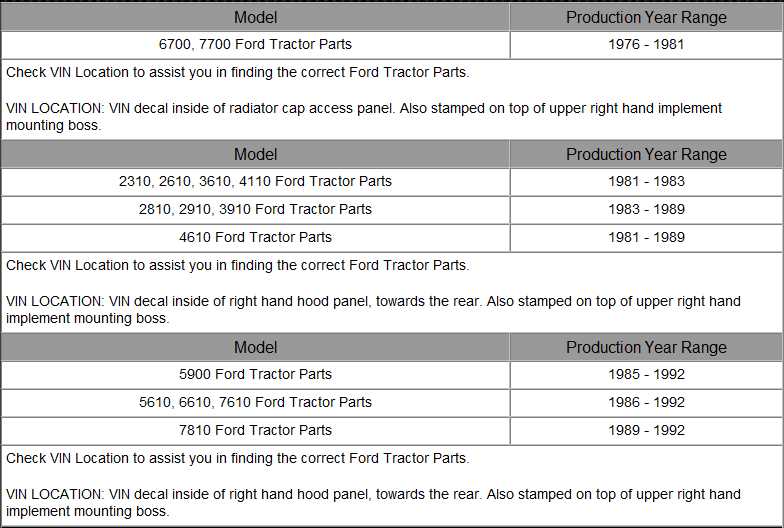

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process when you know where to look. Numerous resources are available to ensure you can restore functionality and maintain performance. From specialized online retailers to local suppliers, options abound for sourcing essential items.

Online marketplaces often provide a vast selection, allowing users to compare prices and find specific components with ease. Additionally, local shops may carry commonly needed items, offering the benefit of immediate availability. Forums and community groups can also serve as valuable resources, connecting enthusiasts who can share insights on where to obtain hard-to-find replacements.

For those seeking a more hands-on approach, salvage yards can be treasure troves of usable elements, often at a fraction of the cost. Networking with fellow enthusiasts or joining relevant organizations may lead to further recommendations and access to exclusive deals. Ultimately, whether online or offline, a little research can go a long way in ensuring you find exactly what you need.

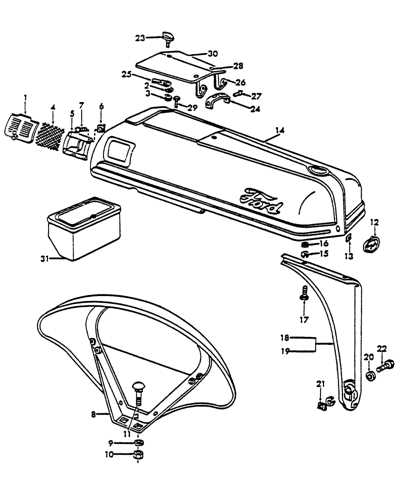

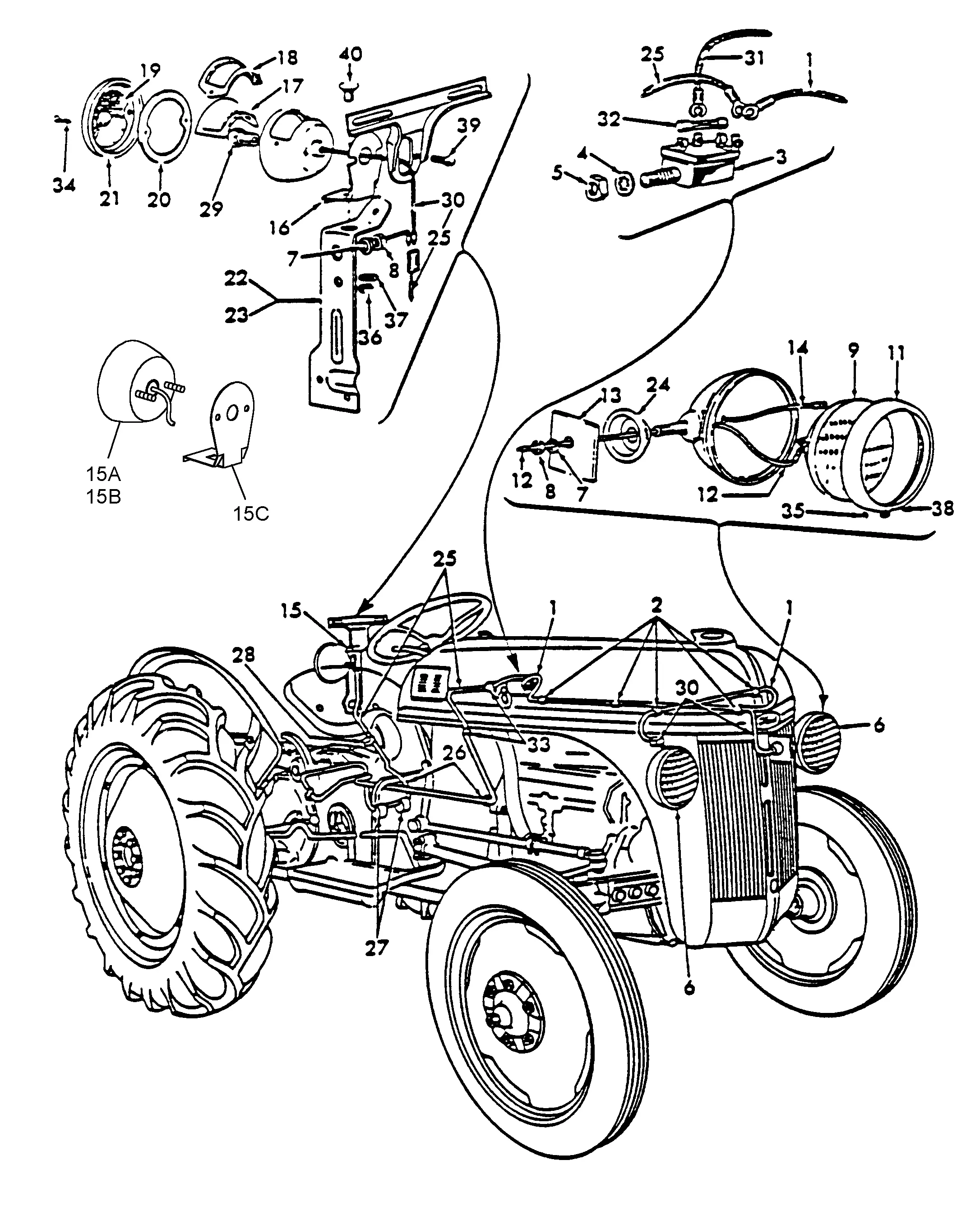

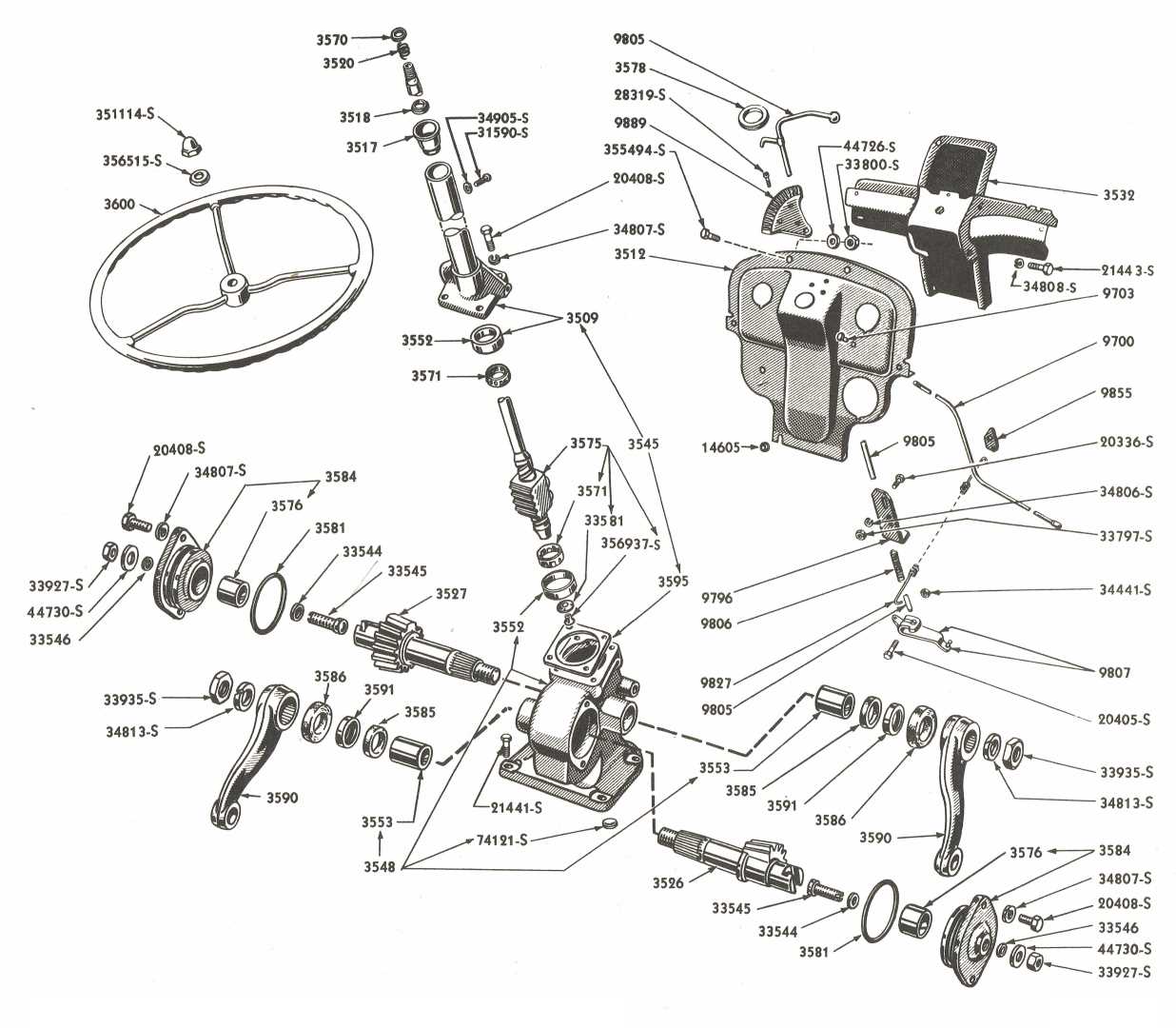

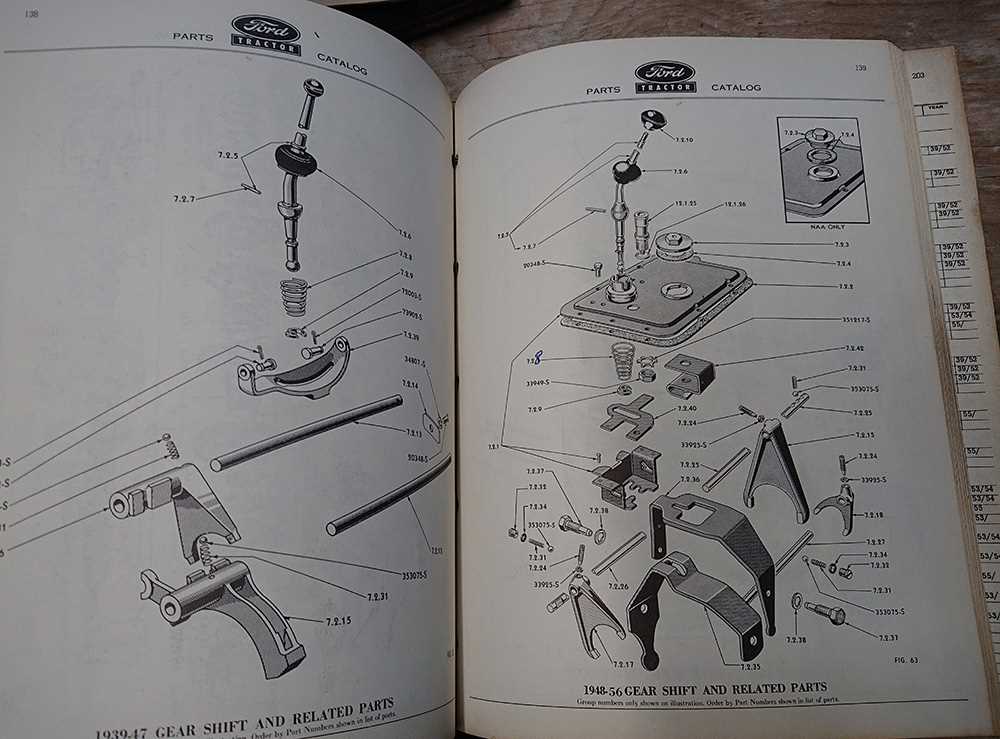

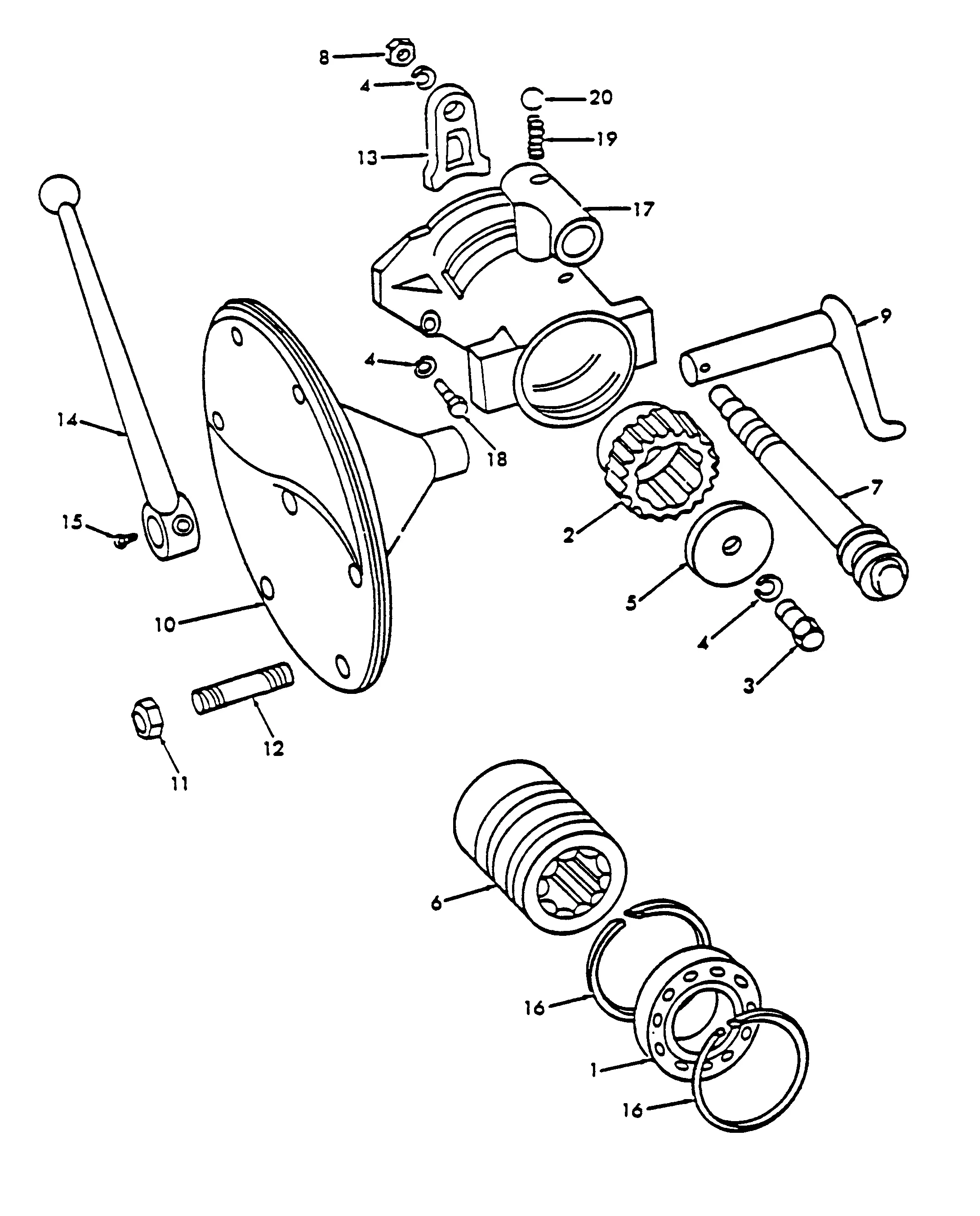

Importance of Accurate Diagrams

Precise illustrations serve as essential tools in the maintenance and repair of machinery. They provide users with a clear visual reference, enabling them to identify components and understand their interconnections. Such clarity is vital for ensuring that repairs are executed correctly, minimizing the risk of errors that could lead to further complications.

Facilitating Efficient Repairs

Detailed schematics streamline the repair process by allowing individuals to locate parts quickly. This efficiency reduces downtime, making it easier to restore functionality to equipment. With an accurate visual guide, technicians can follow step-by-step procedures, enhancing their confidence in tackling even the most complex tasks.

Enhancing Safety

Clear and correct visuals also contribute significantly to safety. By clearly depicting how components fit together, they help prevent improper assembly that could lead to hazardous situations. Understanding the layout of machinery not only aids in repairs but also promotes a safer working environment, as users are less likely to make mistakes that could result in accidents.

Guide to Maintenance and Repair

Regular upkeep and restoration are essential for ensuring the longevity and efficiency of your equipment. By understanding the basic components and their functions, you can tackle common issues and perform preventive measures effectively.

Essential Maintenance Tips

- Inspect fluids regularly to maintain optimal performance.

- Clean and replace filters to ensure air and fuel flow.

- Check tires for proper inflation and tread wear.

- Lubricate moving parts to reduce friction and wear.

Common Repair Procedures

- Diagnose issues by observing performance changes.

- Replace worn components promptly to avoid further damage.

- Follow manufacturer guidelines for repairs to maintain warranty.

- Consult expert resources for complex repairs and troubleshooting.

Upgrading Ford 8N Parts

Enhancing the functionality and performance of vintage machinery can significantly improve efficiency and longevity. This section explores various options for modernizing components, ensuring that these classic machines can meet contemporary demands while retaining their charm.

One of the primary areas for enhancement involves the powertrain, where upgraded transmission elements can provide smoother operation and better responsiveness. Additionally, improving the braking system can enhance safety and control, making operation more reliable in various conditions.

Another key focus is the electrical system. Replacing outdated wiring and integrating modern lighting solutions can lead to increased visibility and improved safety during nighttime use. Upgrading the ignition system can also contribute to better fuel efficiency and easier starting, especially in colder climates.

Moreover, enhancing the hydraulic system with newer components can significantly boost lifting capacity and responsiveness, allowing for more efficient operation of attachments and implements. These upgrades can transform performance, making the equipment more versatile for different tasks.

Finally, investing in ergonomic improvements can greatly enhance the user experience. Comfortable seating and controls can reduce fatigue during long hours of operation, making the machinery not only more effective but also more enjoyable to use.

Identifying Genuine Parts vs. Imitations

Understanding the distinction between authentic components and counterfeit alternatives is crucial for maintaining optimal performance and longevity. Genuine items are engineered to meet specific standards, ensuring reliability and compatibility, while imitations often compromise quality, leading to potential failures and costly repairs.

One effective way to identify authenticity is by examining packaging and labeling. Authentic items typically feature clear branding and quality assurance marks, while counterfeit products may lack these identifiers or display inconsistencies. Additionally, purchasing from reputable dealers or authorized distributors can significantly reduce the risk of acquiring substandard alternatives.

Price can also serve as an indicator; if an offer seems too good to be true, it often is. Authentic components usually come with a price reflective of their quality, whereas imitations might be significantly cheaper. Conducting thorough research on trusted manufacturers and their specifications can further aid in making informed decisions.

Lastly, seeking feedback from experienced users can provide valuable insights. Communities dedicated to enthusiasts often share experiences regarding various options, highlighting the pros and cons of each. This knowledge can ultimately empower individuals to choose wisely, ensuring the durability and efficiency of their machinery.

Essential Tools for 8N Repairs

Having the right equipment is crucial for effective maintenance and restoration tasks. A well-equipped workspace ensures that every job can be tackled efficiently, leading to better results and longevity of the machine.

Basic Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flat and Phillips)

- Pliers (needle-nose and regular)

- Socket set

Specialized Equipment

- Torque wrench for precise fastening

- Oil filter wrench for easy changes

- Fuel line disconnect tool

- Multimeter for electrical diagnostics

Comparing 8N to Other Ford Models

The 8N model holds a significant place in the lineage of heavy-duty machinery, showcasing a blend of innovation and practicality. When examining this model alongside its counterparts, various factors such as design, functionality, and technological advancements come into play, revealing both unique characteristics and shared traits.

| Feature | 8N Model | 9N Model | 2N Model |

|---|---|---|---|

| Production Years | 1947-1952 | 1939-1942 | 1942-1947 |

| Engine Type | 4-Cylinder | 4-Cylinder | 4-Cylinder |

| Horsepower | 23 | 22 | 24 |

| Transmission | 4-Speed | 3-Speed | 3-Speed |

| Hydraulic System | Position Control | Draft Control | Draft Control |

Each model brings its own advantages and nuances, contributing to the overall heritage and functionality of the lineup. While the 8N is noted for its advanced hydraulic system, earlier iterations like the 9N and 2N laid the groundwork for many of the innovations that followed, reflecting the evolution of machinery design and user needs.

Resources for Ford 8N Enthusiasts

For those passionate about classic machinery, a wealth of information and tools exists to enhance the ownership experience. These resources provide guidance on maintenance, restoration, and community engagement, ensuring enthusiasts can keep their beloved machines in top condition.

Online Communities

Joining online forums and social media groups can be invaluable. Members share tips, troubleshooting advice, and personal experiences, creating a supportive network. Engaging in discussions can also lead to lifelong friendships with fellow enthusiasts.

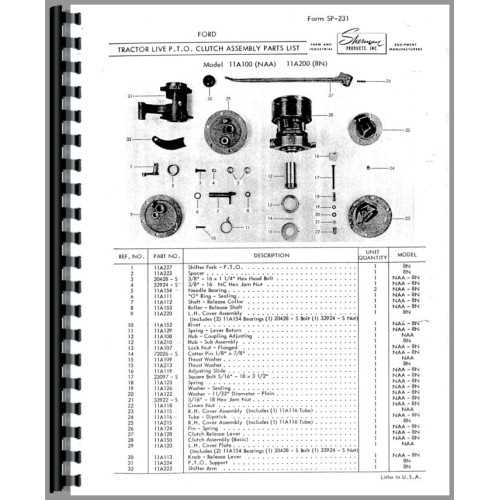

Repair Manuals and Guides

Accessing comprehensive repair manuals is essential for understanding intricate mechanisms. These guides often contain detailed instructions, illustrations, and troubleshooting steps, making repairs more manageable. Investing in a good manual can ultimately save time and effort.

Impact of Parts on Performance

The components of any machinery significantly influence its efficiency and effectiveness. Understanding how each element contributes to overall functionality is essential for optimizing operations and ensuring longevity.

Key factors that demonstrate the relationship between components and performance include:

- Durability: High-quality materials enhance the lifespan and reduce the frequency of maintenance.

- Compatibility: Ensuring that elements work well together minimizes friction and wear, leading to smoother operation.

- Design Efficiency: Well-engineered components improve airflow, fuel consumption, and power output.

- Maintenance Accessibility: Easily replaceable elements facilitate regular upkeep, preventing breakdowns and improving reliability.

In summary, the interrelation between components and overall performance cannot be overstated. Careful selection and understanding of each piece’s role are vital for achieving optimal results in any machinery operation.